-

Posts

2,871 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

Thank you Håkan If that minor chipping was a problem for me I actually would have thrown out the whole model a long time ago. There are many mistakes made and corrected along the way that only I or a close up with a camera can see. These are all my honourary awards for not having given up. I actually put a dab of white glue in those chip spots and rubbed some sawdust into it, let it dry a bit and passed sand paper over it lightly to hid it a bit. If a plank is placed over it it would never be seen again.

-

Managed a couple hours in the shop this afternoon. First was cutting out the sheave block holes through the hull. I managed only two of three that pass through the starboard side of the hull. I cut out between the holes using an small X-acto saw blade as it would fit in the hole. Then I opened the rectangular hole with small files, checking for fit regularly. There was some chipping. Once the block fit I ran a pencil mark around the block next to the hull then I sanded the inboard and outboard end of the block to be 1/16" proud of the mark. The pencil mark was slightly clear of the frame so the "extensions" out and inside of the frame was slightly more than 1/16" which is 4" at scale. I then clamped the block in my table vise. Drew a straight set of pencil lines above and below the sheave holes at the hole extreme diameter as a guide. Using a scalpel I scored along the lines in an effort to avoid chipping the surface of the wood when chiselling. Then I micro chiselled out the sheave opening between the holes, shaped the sheave and chiselled the rope groove into the sheave. Then turned it around and did the other side. All pencil marks on the block and hull were erased, followed by light sanding. The blocks were then glued into the frame holes permanently. I have the two fixed blocks on the port side to do next and then there is one last set that passes through the frames forward of these. They are ever so slightly larger at 13" (0.20") versus 10" (0.16"). Not necessarily very noticeable at this scale but I'll do my best.

-

I just read an extremely well written article about shop wood dust and its effects by Seri Robinson, an associate professor of wood anatomy at Oregon State University, and just had to share it. https://www.oneida-air.com/blog/dust-collection-in-a-shared-shop-a-wood-scientists-perspective My father-in-law work with wood all his life, started in the back woods logging camps of New Brunswick chopping and sawing trees, dragging them down to the rivers edge with horse drawn sleds, then dancing on the logs as the drifted down the river to the mill, to ending his career in the local lumber yard making roof trusses and cutting pressure treated lumber for customers. In all that time he never wore any filtered mask... they weren't a consideration for his job until the year after he retired, the year he health declined and he became dependant on supplementary oxygen 24/7. Dust in his lungs. I've been wearing a proper shop filtered dust mask for years, added dedicated dust collection system to my workstations, and added a micro dust filter unit in my shop.... and there is still dust accumulating down there. Please read the article and consider your health.

-

I may be coming to you for "how to" suggestions! Welcome aboard!

-

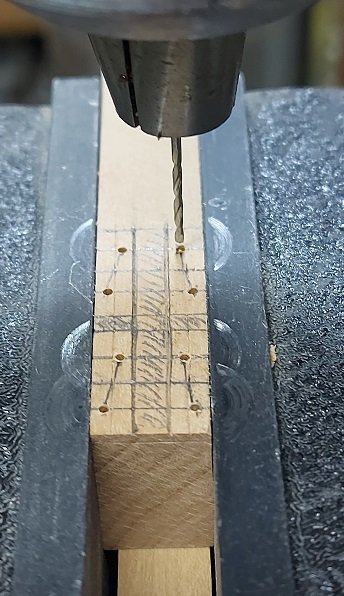

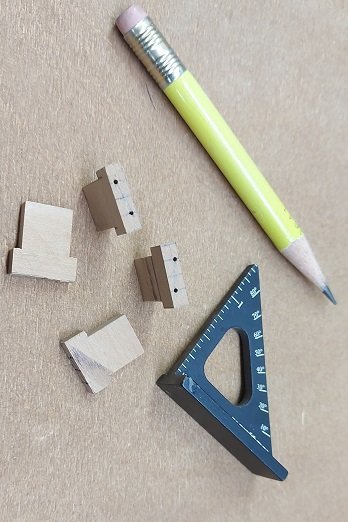

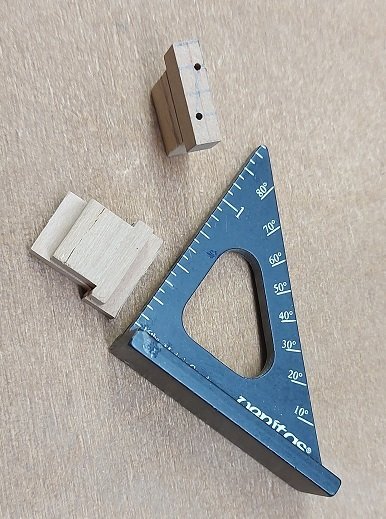

I managed to spend about 90 minutes in the shop today and likely won't get back until Monday afternoon. I prepared some larger stock material and laid out four fixed blocks for drilling and cutting leaving extra material on the inboard and outboard hull frame sides as mentioned was necessary in an earlier post. This was mounted in my vise and magnetic clamped to my drill press table. Using a #60 drill bit (about 2-1/2" diameter at scale) I drilled the holes through for the sheave pockets. I then cut the notches for the ears and cut the four blocks free of the stock. You can clearly see the size difference with the one photo where I placed the trainer block on top of these. Then came the very scary part. I had laid out the fixed block locations on the hull a few days ago, double checked them yesterday, triple checked them today. Using a drill bit about 2/3rds the diameter of the pocket width I carefully drilled a dimple and slowly drilled the hole, then repeated two times for three holes in each of the four pockets. I had discovered that when using my cordless drill and resting the edge of the battery at its foot against the table top the bit was perfectly level with the table top. I needed to only watch that the bit was parallel to the frame. Next I will hollow out the pockets and size them to fit snugly with the fixed blocks. While the blocks are inserted I will mark them proud of 4" inboard and outboard of the timber (1/16" at scale). The blocks will be sanded back to that shape and then the sheaves will be carved into them. I have a plan.... wish me luck!

-

Question on Sanding Sealer

AON replied to acaron41120's topic in Painting, finishing and weathering products and techniques

Re: your first posting As per the second posting - Yes you are correct. -

Captian Eddy by petehay

AON replied to petehay's topic in - Build logs for subjects built 1901 - Present Day

Typo, January Issue 15 Sorry -

Yes, I've seen photos in TFFM. I do not have a mill or a first class X-Y adjustment means... but I seem to manage. I was thinking of giving your sandwich build a go but I need to allow for the tilt in the slot... maybe a wooden sheave shaped on the mini lathe? I'll be making fresh sawdust later this afternoon. PS: I just reviewed Kevin's video and it did not show the various steps he took to make the parts but he did show I'm in good company with the number of scrap pieces accumulating. Practise make perfect barely acceptable!

-

Four of five breasthooks installed The fifth is above the deck so I'll wait until the deck beams are installed before I do it. I took a stab at making a fixed block. This one is scrap but I learned something from it. The block ears are located inboard when installed but I need to make them thicker to allow finish shaping them to the profile of the timbers while keeping them the thickness of the inner planks. I also need to make the block thicker to protrude far enough outboard to allow shaping them to the outside profile thickness of the plank on the frame. David shows this quite clearly in TFFM Vol 1 pg 166 The sheave is tilted 6 to 10° in the block. I marked it at 10° and stayed a bit inside the mark. Using micro chisels I tried shaping the sheave inside on one side. Might be time to go revisit Kevin Kenny's build videos and see how he did his.

-

Captian Eddy by petehay

AON replied to petehay's topic in - Build logs for subjects built 1901 - Present Day

Pete If you go to the Model Shipwrights of Niagara club website (link below) and scroll down to this months newsletter, January 2024 Issue 15 and scroll to pages 9 and 10 https://modelshipwrightsofniagara.weebly.com/monthly-newsletters We had a presentation on making a ships wheel that you might be able to adapt -

found myself coming back to this multiple times well done

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

I've never seen seizing in action or wire rope being splice. What a treat! In the end the spliced steel wire grips the tail or core like a Chinese finger trap. What a talented bunch of people

- 1,132 replies

-

My official last post for 2023! The last pieces to make were the sliding foot assemblies that allow the tiller rope to pass through the deck on both sides of the rope barrel while keeping water from passing through to the deck below. I envisioned making these two assemblies in pieces but after completing a scaled drawing I realised it would be much too small for my limited talent. I made a base plate to represent the quarter round trim work, and carved a single block to make the lower housing and the sliding shoe pieces. As these pieces on my model are fixed my rudder will not turn. I used a #66 drill to make the 2" diameter rope hole through it and dabbed some metallic copper paint around the holes to represent the copper trim work. Both assemblies are identical. When mounted, one is rotated 180°. As the ship's real wheel was rotated the drop of the seven wraps of rope around the hub or barrel would shift forward and aft. The real Tee shaped shoe would slide in the fixed housing Tee slots to accommodate the shift as the rope passes through a slotted hole the deck. Next I decided it was also time to consider adding the five sets of fixed blocks to the frames and I needed to research and draw these at my build scale. First I needed to understand what ropes passed through them so I would know their sizes and be able to determine the sheave diameters and other dimensions associated with them. They were identified as: 1. The main yard braces (4-1/2" circumference). This is a double sheave at the stern quarter on the poop deck level, just above the planksheer. The forward end of these sheaves tilts upwards between 6° and 10°. I split the difference and drew mine at 8°. This seems to be a filler block of wood between timbers and behind a face plate or plank. I will not be installing this one so soon as there is no cutting into the framing timbers required and they are located quite high in the build. 2. The main sheets (7-1/2" circumference).This is a single sheave at station 22 across from the mizzen mast at the upper deck level. The forward end of this sheave tilts upwards 8°. This is a filler block fit into a rectangular opening from the inboard side of the ship. The inside face of the block has ears or tabs at both sides that rest against and are bolted to the timbers. David Antscherl had an excellent sketch in both his book series: The Fully Framed Model and also in the NRJ Spring 2012 issue 57-1, Shop Notes (pg 45). 3. The foresail sheets (7" circumference). This is a single sheave at station (1) forward of the main mast mast at the upper deck level. The forward end of this sheave tilts upwards 8°. This block is similar to item 2 above. 4. The mainsail tacks (9-1/2" circumference). This is a single sheave at station G-forward, across from the belfry but on the upper deck level. The aft end of this sheave tilts upwards 8°. This block is similar to both items 2 and 3 above. 5. The cat fall snatch blocks (5-1/2" circumference). This is a single sheave located between the planksheer and fife rail, above the cat tail at the forecastle deck level at station Y. This sheave is level to the planksheer and deck. I will likely not be installing this one so soon for the same reasons listed for not doing the main yard brace fixed blocks (item 1 above). I used Steels' rigging tables found in Volume 1 of The Elements and Practice of Rigging and Seamanship to determine the line sizes and both Rees' and Steels' block sizing calculations to determine the sheave diameters and thickness. I listed these earlier in my build. So, my list of items to do next grows.

-

I've spent the last two days researching what lines went through the chesstrees on the ship's hull. Your last group of photos showed me. Thank you!

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

...and the pedestals are done. I left a wee bit extra material at the foot and more again at the head so it can be adjusted to fit the space when the time comes. All is stored away at the moment. As I might not post again until the new year I would like to thank all those that have been following, visiting occasionally, and offering encouragement. Wishing all a very Merry Christmas and a most enjoyable New Years!

-

Chucked out my second set of ship's wheels. Due to my reduced scale of 1:64 the thickness would be 0.06". After my first attempt I decided this was a bit too thin for my talents. I increased it to 0.09". My spokes are 0.03" diameter. I tried to turn and shape these chucked into my Dremel and using files but it is just too tiny for me. I decided to follow the KISS principal and used bamboo sized through a draw plate. I built a rotary device so I could drill the holes to slide the spokes through the outer ring and into the inner/central hub. The tiny drill bit went a wee bit askew and the spokes did not pass through to the hub evenly spaced on the inside. Looked great on the outside. I had made my spokes a little longer than required. I mounted my rotary device on my sander and sanded the spokes down to the correct extension length outboard of the outer ring... spinning it from spoke to spoke. I was gluing the rope barrel to the second wheel when the outer ring glued joint broke at one spot. Tried to fix this and dropped it. Broke into a few more parts. I decided this was a sign to toss it and do it again. Sanded a new bunch of wedges to 0.08" instead of 0.09. A tiny change but a wee bit closer to 0.06". Lets see if the third time is the charm with everything else I learnt.

-

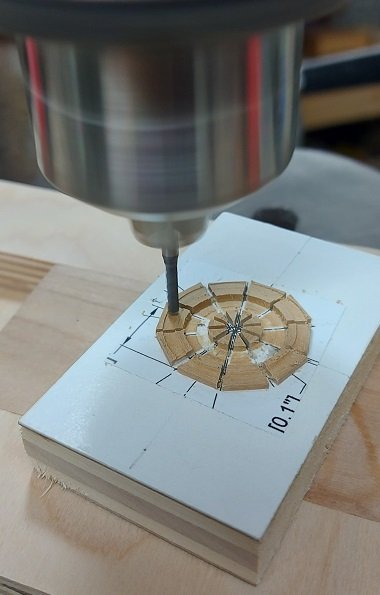

All three lower masts are assembled less their woolding ropes. I don't know why but the mizzen was a beast to complete. They are presently stored in their stand in a box safely out of my shop. I decided to try to make a ship's wheel. Three attempts so far. All failed, but I learnt quite a bit. Refined my setup. I have a sliding top in a fixed base. My template is rubber cement glued to a thicker card that is rubber cemented to a rotating table (block of wood on a metal pin). I bevelled all the under edges of the rotating top and waxed the moving bits. The wood was PVA glued to the template. The rotating top was centred under the cutter and all was clamped in position. The sliding top was moved so the cutter was located properly, then lowered to touch, the top was rotated slowly and the cutter was lowered to remove a thin slice, then repeated. This worked well the last time. It was the wheel spokes the did me in this time. I didn't like them at all. I am rethinking that step.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.