-

Posts

2,871 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

Thank you for another excellent video. Regarding interpreting 2D drawings. Having worked in the industry for many years I found the introduction of 3D models and views to be invaluable in getting my message across to shop people who had trouble reading more complicated 2D prints. Having said that, I too have the TFFM volume you are using, and have the 3D images package. I find they are an excellent reference to use with the books, and have cleared up some confusion for this old 2D draughtsman! Regarding the 3" shift of your frames. It was before you made the stem and stern supports stationary! I had the same problem, except I cannot blame termites.... it was damn shop gremlins (?).

- 1,132 replies

-

Did you have to take it outside so I would have to listen to the tropical birds then imagine the gentle warm breeze coming in off the beach just before I have to go outside to shovel snow! 🤔

- 1,132 replies

-

Just did a google search and Iroko does seem to have tiny white streaks in it.... and I did develop a couple small rashes after working with it. At first I thought it might be Teak by which it is aka African Teak although it is not teak. The attached google photo is somewhat darker than my piece but I am going to assume this is what it is until something more convincing comes along. Thanks again!

-

Thank you all. I will look up Iroko as I've never heard of it before. The small piece of this mystery wood (Adhmad Rúndiamhair) that I was given seems to have been reclaimed from a piece of furniture (my guess). I have heard back from the two wood suppliers I deal with ( Exotic Woods in Burlington, Ontario and McQueen Custom Cuts which is nearer to me and supplies to local business and wood carvers), and neither have a clue as to what this might be. I certainly hope it is not a fungus. It doesn't seem to be. As for protection from wood dust, I always wear my dust mask (with HEPA Filters) and eye protection. I am constantly concerned for my eyes now ( Cataracts for which I recently had surgery, and Branch Retinal Vein Occlusion caused by Macular Edema for which I've been getting injections in my left eye for the last 4 years), and my Father-in-law worked at a lumber yard for 30 years which gifted him with COPD in his retirement years.

-

from google search: Unbleached Titanium White is a warm beige tinted white. This oil paint can be used to lighten colors with a different effect than regular whites.

-

I have been given a very small quantity of wood (one piece 1" x 4" x 12" or 25.4 x 101 x 305mm) and I haven't a clue what it is. Can anyone help me identify it. it is a more dark than light shade of brown, with short streaks of white in it. The surface was stained and the end has something like a glue on it so I cannot see the end grain. I cut a few strips as I thought I'd use it but then I saw the actual colour pattern and now it's got me wondering. There is no specific scent and no appreciable weight to it.

-

Sorry about that each image was uploaded with the source in it's name... eg: Truss Parrel pg105-5 (-5 means 5th image from the page) The Masting + (and) Rigging of ESOW (English Ships of War 1625-1860 by James Lee) If you copy them out you will have the info I thought for some reason it would display if you hovered your mouse over them

-

there are a couple more but I fear I may be pushing things a bit with my photos from Index - The Masting and Rigging of English Ships of War 1625-1860 by James Lee:

-

-

here is some more info from The Masting and Rigging of English Ships of War 1625-1860 by James Lee, pgs 66 and 67

-

does this help? Top Gallant Yard from The Masting and Rigging of English Ships of War 1625-1860 by James Lee, pg 95

-

Now that you're re-organized you'll never be able to find anything. 🤣

- 1,132 replies

-

Thanks for the info Mike It looked like the glue was in the hole first and seemed awkward.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Mike Do you put a dab of glue in the drilled hole and then inset the treenail, or do you chamfer the lead corner of the treenail as a leader to help initial insertion and apply a dab of glue to the end of the treenail then insert it?

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Regarding the name I almost passed on looking at your build but then thought I was being stupid... after all, some ships were renamed two or three times. I had no idea what your ship might be. I am glad I took a peek. Alan O'Neill (From the Irish County Cork O'Neills)

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

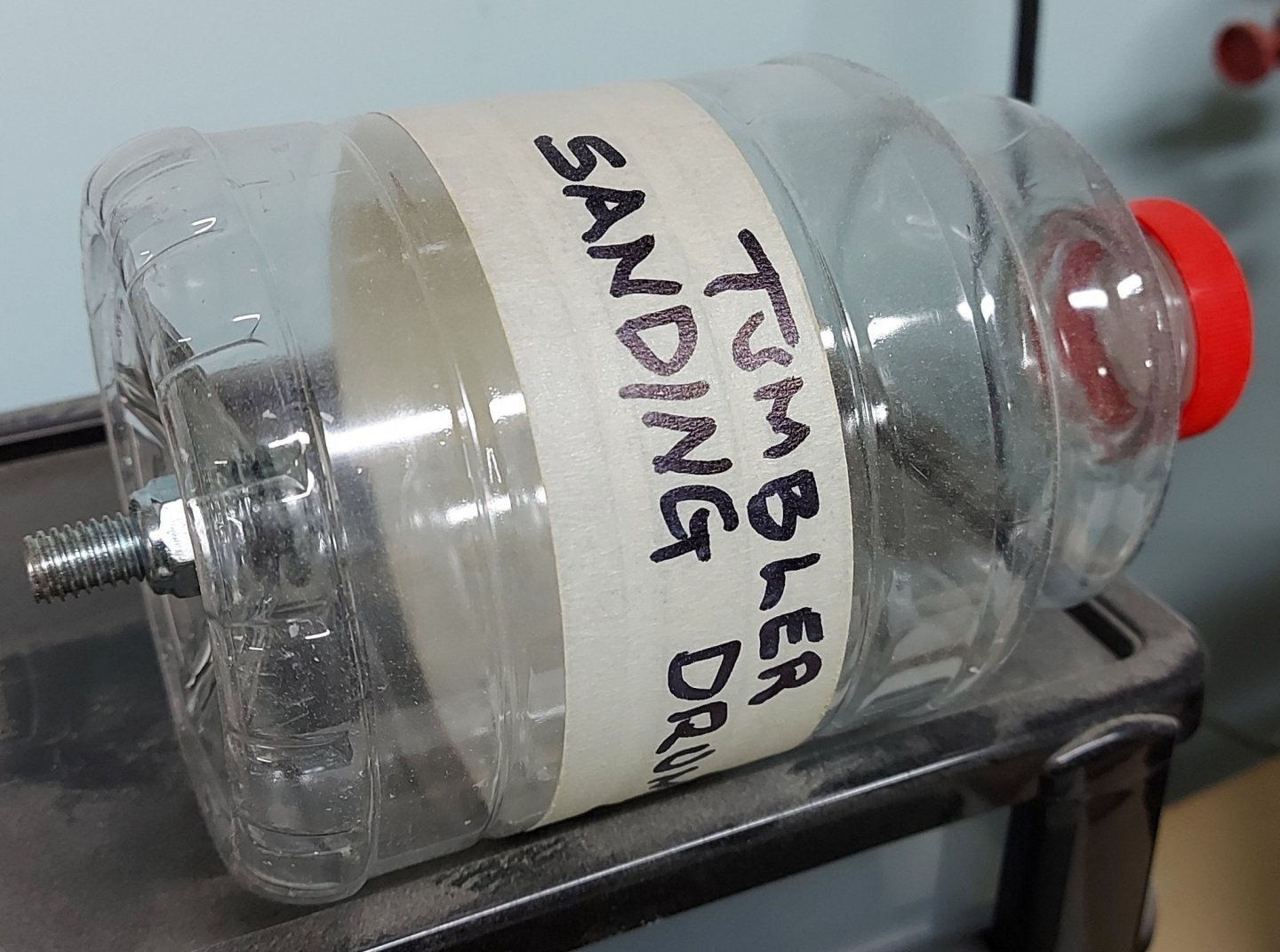

I had the idea weeks ago to make a sand tumbler. I saved a Orville Redenbacher Popcorn plastic bottle and screw top, and drilled a hole in the base for a bolt. I slipped a flat washer and O-ring over the bolt to seal it to the bottle base to keep the sand in. I intend to get a small bucket of clean beach sand to use in the "tumbler", but haven't made it out to the shore of Lake Erie just yet (a 30 minute drive). I'd fill the container about quarter full to start and slip the bolt into my wood lathe set to it's slowest speed. Toss in some scrap bits with holes drilled through for a test run. To empty it I'd dump the contents back into the bucket with a screen/sieve to catch the parts. I got the idea from fluidized bed furnaces and hopper screw augers used to remove debinded casting sand from Solution Furnaces. The former had sand flow like a fluid through every crack and crevice to heat treat gears, bolts, golf clubs, etc.. The latter seemed to be self cleaning via sand rubbing against the hopper and chute. So I imagine the sharp edges of the tiny sand grains would wear away and soften the edges of blocks, grooves and holes. All I need now is the darned sand.

-

FYI The official response from DREMEL regarding their right angle drill attachment and their flex-shaft: "Unfortunately, the right angle and the flex shaft are both attachments for our rotary tools, but are not compatible with each other." Seems like a missed opportunity and short sightedness on the part of their engineering and marketing group... and so I suggested they might want to get their design group working on it. Of course I expect no action, but will be pleasantly surprised if a year and a half from now it is offered.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.