-

Posts

2,866 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

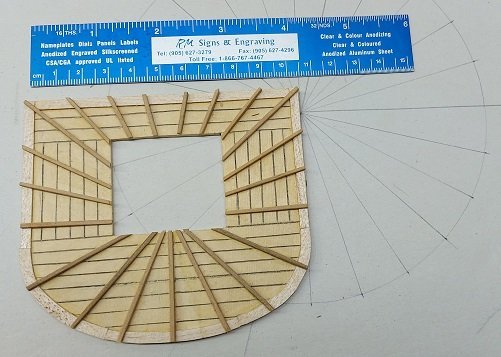

Took the TREES apart to shape them then reassembled. Removed the BIBS, remade and refitted them. TREES installed and battens installed. Made the TOP (platform) that sits on the trees. Three layers of 1/32" glued cross grain. Planks laid out and scored with a knife, highlighted the joint with a pencil, then sanded. Underside scored to show the different overlap. More work to be done to the TOP before it is fitted permanently.

-

I understand what you are saying about the hoops. It was an effort to try to keep them straight and level and evenly spaced... I am not saying I was successful. I thought if it should look like kaka I paint the space between the hoops (under the rope) as camouflage. Worst case... off it comes. I guess I should wrap some twine between a couple and see the "damage" before I get further ahead of myself! Tapers... yes. Angle... very slight. Thank you.

-

Been busy putting things on, taking them off, putting them back on... normal stuff. Removed the bibs, added the wooden hoops for the woodling ropes, added the metal hoops above the stops, made the cross/trestle tree assembly, put the bibs back on. I sanded the wooden hoops so they are presentable. Made my bolsters but have not added them to the tree assembly as yet. Need to add other metal hoops, battens, and build the tree platform.

-

Looking darned good. If it were any of the sea cadets I knew the sweeps would be all wonkey! Still waiting to see how the rudder yoke connects to the tiller. I know how it worked on the whalers but they had a mizzen mast to pivot on.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Air gap and mesh! What else us there to learn?

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

I wonder if an auction would be frowned upon.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

The sweeps on the whalers and cutters I am familiar with were exactly that and very light, made of ash.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Had you considered mounting her suspended from davits? 😇

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

People confusing him with his older brother. 😇

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

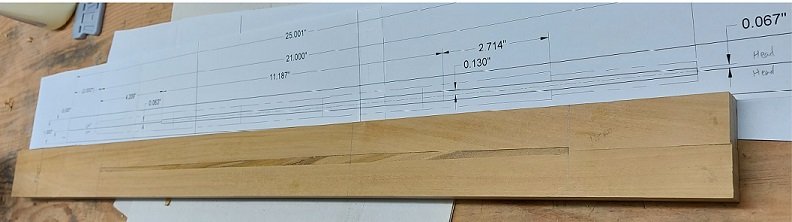

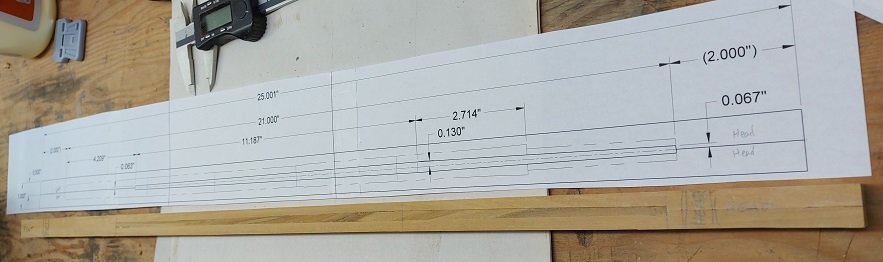

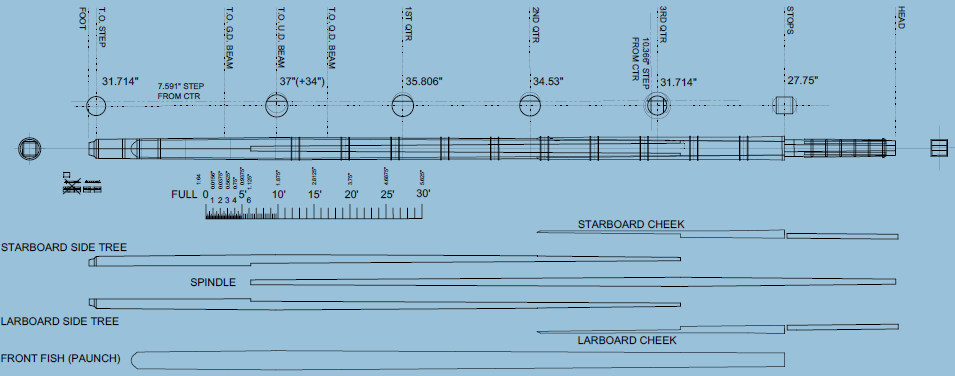

Made my transfer batten from a piece of plaster wall lath (hemlock strip). Marked off each quarter location and step where the diameter dimensions were indicated. I was concerned my three pieced glued mast might pull apart on the lathe during turning so I marked off where the hoops and woolding bands are located and drilled #31 hole on centre at each location through the port/starboard sides and pinned through each hole with a 1/8" dowel. I lightly crimp notched the surface of the dowel with the grooves on my pliers, applied wood glue, then tapped it through the hole and cut it flush. Belts and braces. This might not have been necessary but I'd rather not find out. Once the woolding ropes are wound on the lower pins will be hidden. The upper pins will be under the cheeks so they won't be visible either. Now we let that dry and cure. Turning hopefully tomorrow.

-

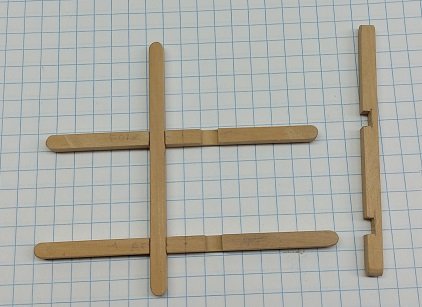

Sanded the spindle to shape. Glued up the three pieces (side trees and spindle) and left them clamped overnight. Trimmed the excess off the sides of the tree blanks and put these pieces aside to be used for the aft fish and cheeks. Now being square I can shave off the four corners a bit and it will be ready to turn down to size.... maybe tomorrow or Wednesday. I've prepared another sheet with location and diameter info that will be transferred to a batten which can be held against the part on the lathe to help relocate these critical spots once the pencil marks have be cut away. I will leave the square ends untouched to help me relocate the four sides to create the flats for the fore and aft fish and side cheeks. Hopefully I've thought this through adequately.

-

For me the 27ft Whalers were single banked while the 32ft Cutters were double banked.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Extremely short frames progress report: I am presently working on square frames 13Aft to 11Aft having made up a batch of new blanks. As the nice weather is upon us I will find myself drawn outside to soak up some vitamin D from the glorious sun. I will be making another attempt at my figure head while out there. Third time is the charm??? Always eager to attempt something new, I spent a considerable amount of time studying the construction of "made masts". My ship would have had them for all the lower masts. The problem with these are that all the pieces that make up a "made mast" are hidden from view so the question that begs to be answered is "why bother?". My answer seems to be "for the challenge of it". I'll try one to start. My bowsprit is already done so it was spared the trial. I've drawn up a simplified version of the Main Mast and will attempt it first. I've ripped and planed two blank pieces for the side trees and one for the spindle (and one spare). I've completed the notching of the side trees to accept the spindle by double side taping the two pieces together with the centre of each facing upwards. I rubber cemented my cutout pattern to the outsides of each and double side taped two hacksaw blades to the pattern with the non-tooth edge lined up to the edge of the cutout on the pattern to act as a stop guide when removing the waste. I removed the waste from the spindle notch with a wood rasp and files. Presently the spindle blank ready to be shaped. I rubber cemented my template to one side and will use my 90° setup block as a backer to hold it dead parallel to the bench disk sander on the rest plate. This will take some patience to assure the fit is proper... even though no one will see 80% of it as it will be inside the mast! The lower portion will be hidden by the front and rear fish pieces. Wish me luck.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.