-

Posts

1,028 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

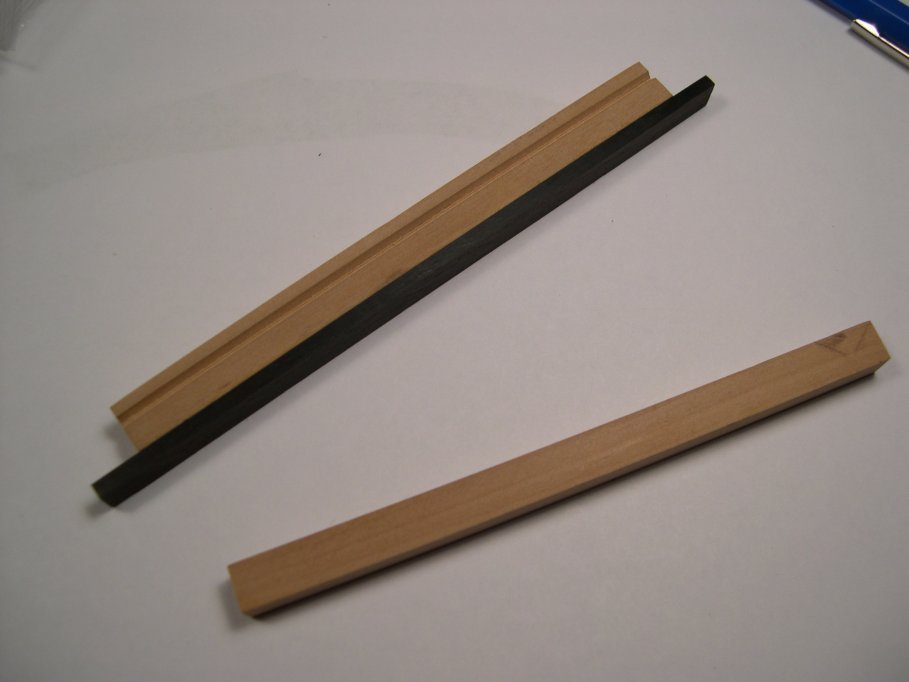

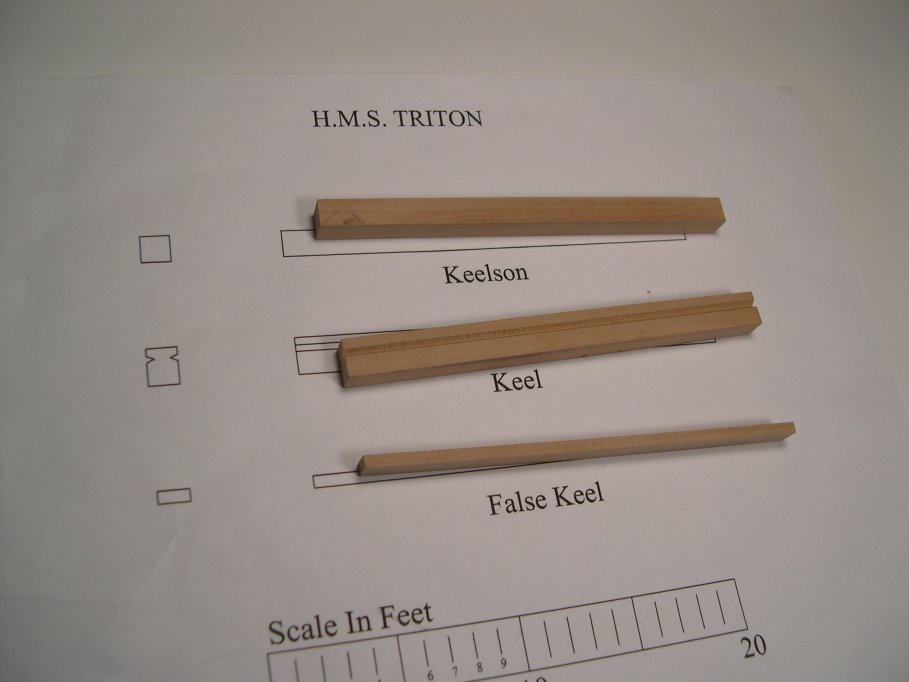

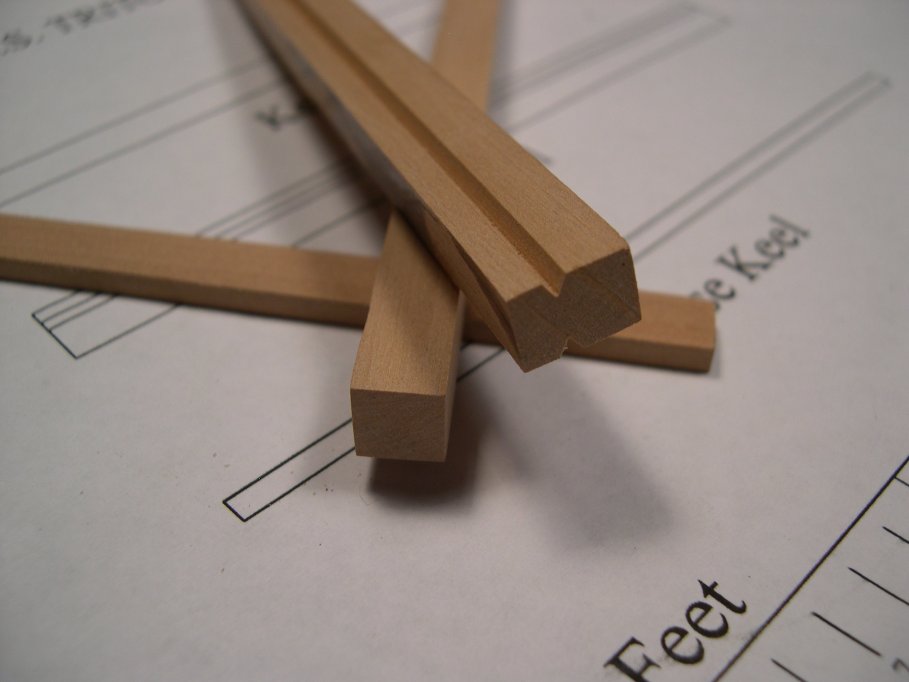

Per request to keep the pictures coming here we go. I decided to make the False Keel from ebony as shown on the material list. I think it gives a nice contrast. It's my first and only glue joint on this project so far. There is also a shot of my frame parts and a dry fit frame part on the keel. The keel is made from Boxwood and the frame timbers are Swiss Pear. I can't wait to get a frame glued up. Maybe in the next few days.

-

Jaager, Thank you for the great information. Let me give you an idea of my situation. I have been a modeler all my life, mostly plastic. I have also always loved maritime history and wooden ships and in the last couple of years have built a couple of kits. I have been buying hand and power tools in preparing for retirement and bigger wood ship kits and scratch building. I will be retiring in just over 3 weeks from now. I have a 9" band saw still sealed in the box, a spindle sander in the box, a Sherline mill and lathe and 3 weeks ago got my Byrnes Table saw. I have also ordered the Byrnes Thickness Sander and Disk Sander. I think of them as an investment for my years of retirement. I plan to build a couple of more kits and do some simple scratch building until I have more confidence in my skills to do a big scratch project like the frigate HMS Naiad or a Swan Class sloop. I probably have too many tools already but I have worked a long to be able to do what I want when I retire and this has turned into a passion for me. It's a skill that I really want to develop into an art like so many on this forum have. I may never get there but sure want to try.

-

Jaager, I will be doing some scratch building so frames and such. Whatever will be required for a scratch project. I will probably use a hand jewelers saw for really small intricate work. I got pretty handy with it cutting the details on coins. I will see what the local DIY stores have. One thing I would like is dust collection. It sure helps keep thing cleaner.

-

It looks like my friend is getting a new scroll saw and I will be shopping for a new one. I appreciate all the input. Any thoughts on the commercially available saws? I can't go overboard on the price. I need to keep it fairly reasonable.

-

Thanks for the warning, I almost did.

-

I have a Delta single speed scroll saw that I have never had out of the box in over 3 years that I have owned it. Now that I am getting deeper into building I will be needing a scroll saw but am not sure if this is the best one for me. Would I be better off with a variable speed saw? Are there advantages to it? I have a friend that wants my NIB old one and I am happy to give it to him if it's worth replacing.

-

Mick, As I am cutting out the frame parts for my Triton cross section I am looking over your Washington Galley build again. Maybe I missed it due to lake of sleep but I am wondering what your primary tool is for shaping and sanding the frames after they are cut out. Do you use a spindle sander for the inside curves? I have 3 sets of frame parts left to cut out and then I will start putting them together. I do wish I left more wood on the outside of the lines for fairing like you did but will live with what I have unless it becomes a problem. Thanks for any information.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Richard, I didn't take any pictures but I just used the Sherline vise with a strip of wood under the keel section to get the keel edge above the top of the vise and level. Then it was just a matter of getting the point of the bit lined up with the center of the rabbit and cranked down to the correct depth. Then I just ran the mill as fast as it would go and ran it down the length of the keel section. I then just flipped it over using the same settings and ran the length on the other side. It came out perfect on the first try. I used a 2 flute pointed mill bit. I don't know the angle of the flutes but I had it and it looked right. This is the first time I used the mill to make a real part so I am far from an expert.

-

Opinions on Sherline DRO for Lathe

alde replied to rtropp's topic in Modeling tools and Workshop Equipment

I have turned brass, aluminium and mild steel on mine with absolutely no trouble. It has all the power you need. The DRO is the way to go. I have one box and the kits for my mill and lathe and love it. Very easy to use and accurate. -

Pete, When are we going to see more? I have been rubber cementing frame patterns to wood and hope to start cutting them out tomorrow. I will update my log soon. I am really excited about this project and hope I don't neglect my schooner too much. A question though. How much meat should I leave on the frame parts for fairing? I am working at 1/48th scale. I don't want to leave too much to sand but want enough to fair them well.

-

Mill Column for Sherline Lathe

alde replied to mikiek's topic in Modeling tools and Workshop Equipment

Mike, I see a brand new mill on ebay right now for $660. That's only $260 more than the attachment plus it has its own motor assembly. You would have to buy th DRO and other stuff separately anyway. The mill takes up 12" x 15" of shelf space and is 19" tall. -

Mill Column for Sherline Lathe

alde replied to mikiek's topic in Modeling tools and Workshop Equipment

Mike, I'm with the others on this one. I would get the separate tool if space is the main concern. The mill attachment will take up almost as much space as the mill. I have both and they are fantastic tools. As far as cost goes the attachment is almost $400. How much more is the whole mill? They would both be ready to go when you need them without converting them and worried about alignment and set-up every time. -

Bob, You must be retired and have the time to dedicate to modeling. You are moving at lightning speed and still do precision work. I will have more time on my hands for modeling soon. I retire in about 5 weeks.

-

I feel like I am jumping in the deep end with this one but since I got the new Byrnes saw I wanted a special project to learn how to use it and my Sherline mill. I used the mill to cut the rabbit and it came out pretty good if I must say so myself. It will be slow going for a while because I am still working the schooner and don't want to set it aside completely. I will have plenty of questions and welcome any help offered.

-

Mick, One thing that I love about this forum is the support offered and the fact that nobody is judgmental and when mistakes are pointed out it is done in a very constructive way. My experience is that it is like that to a person, from the new modelers to the most experienced artists. I have never been given so may words of encouragement and assistance as I have on this forum. People take time away from the little time they have to pursue the hobby to help others. That really is a special thing that this forum offers. It's very much appreciated.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Mick, you are far and above me in skill and work quality. I am getting closer to being able to take on a project like yours but small steps for me. I am taking your suggestion and starting the Triton Cross Section. It will be very slow going though because I still have the schooner to finish.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.