-

Posts

1,028 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

Maybe a stain to give them a little contrast with the deck?

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

They look really good in a natural finish. Black looks good too but red would be too much IMO. Maybe nature trucks with red axles? I ordered the Cheerful starter kit today. I am really excited but need to be patient and finish a couple more kits before I start it.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Elijah, Kurt's cherry veneer should be perfect for your planking. You will learn so much and have great rewards for it. You really seem to be willing to take on a challenge and working through things.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Nigel, Thanks for putting a second set of eyes on it. it looks like if i use the plank patterns on the plans they will note close to fitting at least at the bow. they are way too wide. I am using my tick strip at each bulkhead and dividing it by the number of planks in the belt. I know this may seem elementary to some of you seasoned plankers but it's still voodoo science to me. It will be slow going but it looks like it will lay out according to the plans.

-

Well, I got all my deck beams in and that was easy enough but now it's time to plank the hull. I have read and re-read the instructions, read the Jim Roberts planking book and some on line information as well as some build logs. I'm still not sure I have a firm understanding of it. I have sectioned off the 3 belts per the instructions and ran my battens. It looks to have a good flow and seems to match the plans pretty well. The plans have plank patterns and I may see how those fit but I want try spiling my own planks too. I have a proportional divider so I thought I could use it and tick strips. Am I going in the right direction? It seems that some of you guys pick this stuff right up and do a great job. I seem to be really planking challenged. Of course if I just did it and quite worrying about it I would be better off.

-

That's so cool. I love the snub-nose cannon. Did you use a needle fine to cut the belaying pin/quoin?

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The fairing is going pretty well. The bulkheads are pretty thick which is really nice. It makes it much easier to see the hull shape up. I don't want to take much more off so I am checking it often with a piece of planking. Please excuse the messy bench. Maybe I will get it straightened out before I go much further.

-

Sal, Your masts and rigging look great so far. I can't wait to see the yard arms come together and be shipped. Will you start from the top and work down? I have seen people completely build out a mast before they install it and also do like you are where you build it up on the ship. I can see advantages to both methods. I love the detail of the rigging.

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Elijah, You are doing great. You are thinking things through and taking your time with your build. The rewards will be worth it. Keep it up.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

I got the hull halves together. The fit was pretty good and it went well. I have started fairing and that is going slow but pretty good so far. I really like the lines of this little ship. After the fairing the supports for the cabin and cockpit. Some of my bulkhead supports might be in the way but they should be easy to shim. I am a real wood butcher compaired to some of you guys but it's getting better.

-

Chuck, I am pretty new to ship modeling and have started my second build and am about half way through reading this build log. It's seeing beautiful builds like this that got me interested in the hobby. When the plan and bulkhead set is available again I will be ordering it to put aside for when I feel I can do it justice. As you suggested in your log, I need to learn to slow down and take my time. It's not a race to see how many ships we can build. Al

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I have been using a 6" wooden block for fairing my bulkheads on my new build. I have tried the flexible sanding boards and they work well but are hard to hold on to and curve around the bulheads. What do most people use for this? It's going OK with the solid block but thought a flexible sander might be more precise.

-

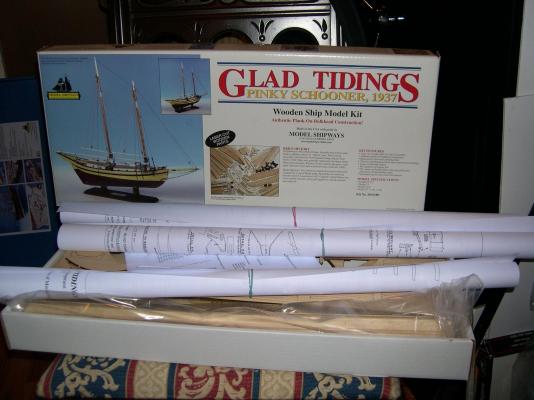

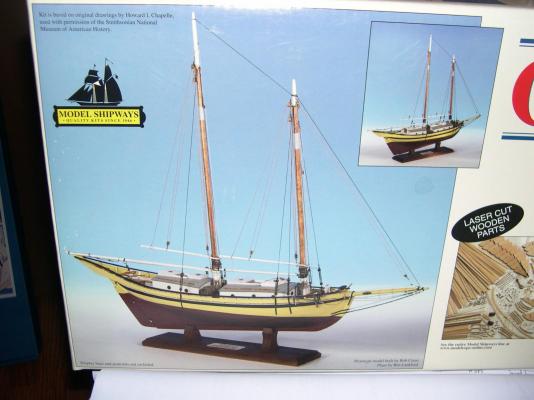

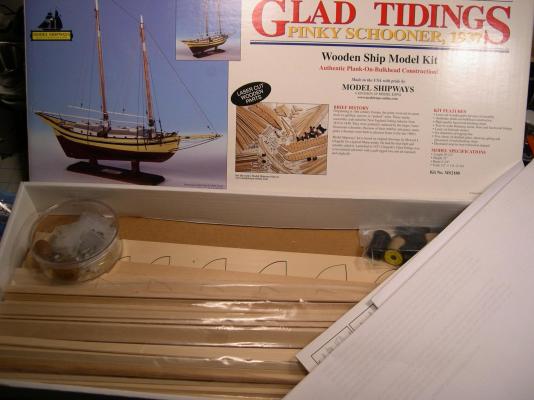

Here we go with ship number 2. I am almost done with the Bounty Launch but wanted to set it aside for now to start something new. I had the Glad Tidings and the Armed Virginia Sloop on the shelf and decided to go with this one. I love the lines of this little schooner. I got it started with no trouble so far. Cutting the rabbit went pretty well. All the bulkheads are in place and the supports are going in. I should have the 2 halves together very soon and will start to plan the planking. I hope to learn as much from this build as I did the Bounty Launch. I will do my best to keep the log updated and take as many pictures as possible. Sometimes I get carried away and forget. I'm sure I will have plenty of questions. I sure wish I had the skill and nerve to jump into a bigger project but I want to take it slow and build my skills. I also need to learn to slow down and take my time. Thanks for stopping by. Please don't hesitate to point out anything that looks out of place or to ask questions about the kit or what I am doing. Al

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.