-

Posts

1,028 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

Chuck, If you decide to replace the whole light fixture you might look at LED shop lights. They sure are nice and don't have exposed bulbs that could break.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

At least the story had a happy ending. It's funny how we do things like that on pure instinct without even thinking ahead on what will happen.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutter Cheerful by iosto - 1/4" scale

alde replied to iosto's topic in - Build logs for subjects built 1801 - 1850

Outstanding work. She looks fantastic. -

Jesse, I think they look pretty darn good. The paint is a bit rough. Once you come up with a good way to smooth them out you will find that thinner paint will go on much better. Don't get frustrated. You have a knack for working things out.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Sounds pretty cool. It would make for a nice display and would teach you different techniques.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Nice to see you make some progress. Looks great.

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Congratulations on your upcoming retirement. My last day after 36 years 4 months is July 1st. Judging by your Morgan build you should have no trouble jumping right in on the Confederacy.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

That's a very clever way of cutting the rabbit on the long stock. As simple as it is I would never have thought of it. Do you run the mill at very high speed when working with wood? I was very pleased with how clean the rabbit was for my Triton Cross Section using the mill. I just ran it as fast as it would go.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Yea, I'm really looking forward to getting to more detail work. I have also been looking at photos of schooners and see a few with the colors I am thinking about. I like the look. I don't know why this is not a more popular kit. The hull goes together pretty easy and I think she's a good looking boat. It's really a perfect kits for a beginner.

-

Mick, I have Goodwins Construction and Fitting book. I guess I better get to reading. So much to learn but that is one of the things I love about this hobby.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

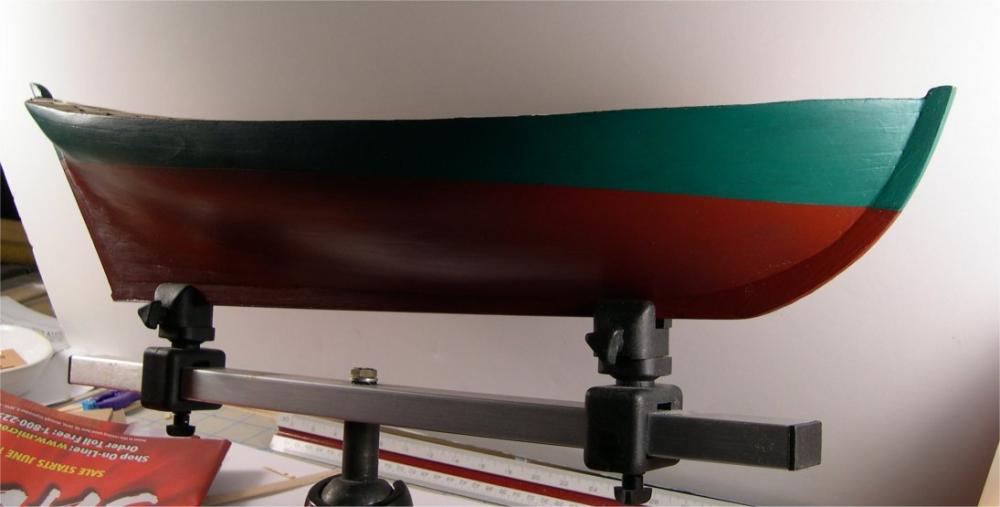

I have been a little preoccupied with the Triton Cross Section but have not forgotten the Glad Tidings. I have put some paint to the hull and wanted some opinions of the green color. Would this be an appropriate color for a 19th Century fishing boat? I think I like it but am not really 100% sure about it. I am thinking of going with the yellow as it was built by Chapelle but wanted something different. I may go that way after all. What do you all think? For some reason the picture shows up with the bow cut off but if you click on it you can see the full hull.

-

Mick, A question. Do the historical building references tell us why they only bolted every other frame to the keel? Are the bolts only to hold the keelson down while it holds the frames to the keel? Not that it matters. I just would have thought they would want to add as much strength to the structure as possible.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Kurt, It was Micks log that inspired me to order the Washington Galley plan set and also start a Triton Cross Section build. He is a true credit to the hobby.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Thanks for looking in Mick. I just have 3 sets of frame timbers to cut out and then they will start to go together. I was planning on stopping at a glass shop to order a couple of pieces of tempered glass. It really does sound like a great way to keep everything flat and even pressure for the glue joints.

-

Those look great Jesse. A big improvement over the kit parts for sure.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.