-

Posts

1,027 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

Mark, ANCRE has a book called “French Frigates” The frigates in the French Navy 1650-1850 (available in English). l have not seen the book so don’t know if it would be of any help to you. Maybe ANCRE could help point you in the right direction for you carving details anyway.

-

Seeing the frames in relation to the exacto knife really brings home the size of the boat. I can’t wait to give it a go with a group build. It will make for a great learning experience with several different levels of modeler skill.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Requesting feedback for future MSW Group Projects

alde replied to Chuck's topic in Group Projects on Model Ship World

I am not an engineer but do come from an engineering field. I was a draftsman and mechanical engineering technician for the US Navy for many years. I do tend to get caught up on details but my modeling skills have not reached the point where I can put most of it into a model. I confess to sometimes just buying ship drawings because I enjoy looking at them with no intention of building the ship. My point is that I don't mean to nit pick the finer details. However you do it is fine with me. I just appreciate the fact that you are doing it. -

Requesting feedback for future MSW Group Projects

alde replied to Chuck's topic in Group Projects on Model Ship World

Wouldn't it be better to correct errors on the contemporary models instead of carrying them on into the future? -

Thanks for doing this Chuck. It's much appreciated.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I spent 15 years of my professional life as a draftsman and more than 25 additional years heavily involved with drawings and ship design for the US Navy. That said these stern frames have been a real challenge for me to figure out. I kept referring to Bob's (rafine) build and the Hahn plans and think I came up with something that will work. Like Bob I had to make some parts including the stern frames because as Bob found out the legs are too short on the kit parts. It's all part of building and part of the fun for me is figuring this stuff out. I will take some pictures later. I still need to cut out a couple of frames and get it all together. The Hahn book has no good photos of the stern framing for the Halifax. It does for the Hannah but it's quite a bit different.

-

Thanks for stopping by and giving me some encouragement. What ship did you build with this method. Im about done with the fairing and will work on improving the rabbit a bit then it's time to lay in the wale strakes. I'm still leaning toward using the ebony for them. I bought a nice dark guitar fingerboard blank and it's almost too nice to cut up. I'll have it all pre-bent and shaped before o commit glue to it.

-

Ian, your workmanship is beautiful. I have this kit but don't want to start it until I can do it justice like you have. She has such great lines.

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

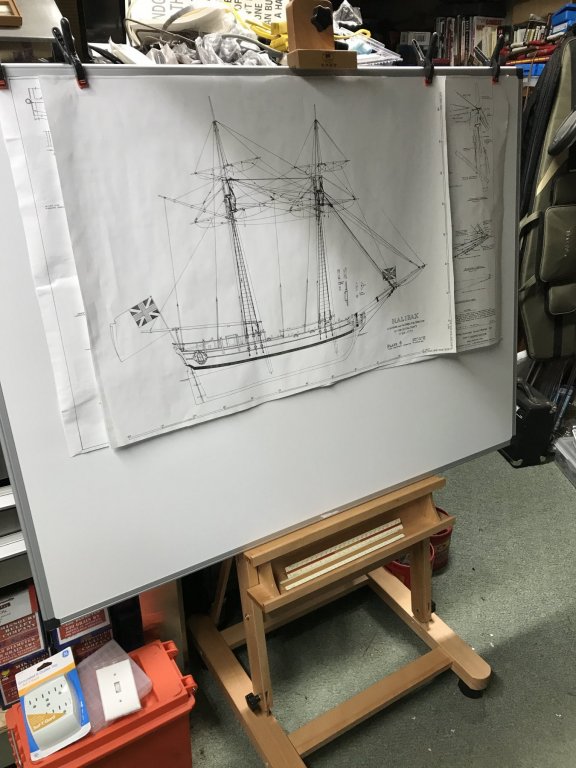

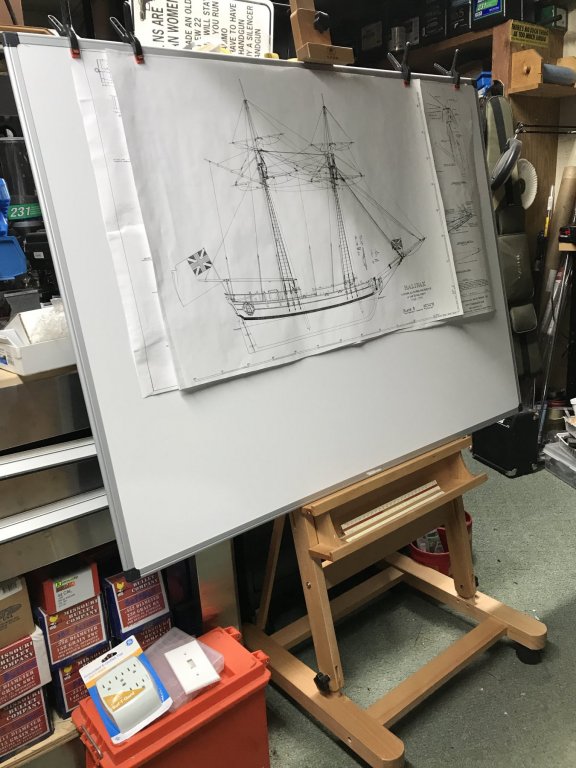

Laying out plans in a smaller workshop

alde replied to alde's topic in Modeling tools and Workshop Equipment

You guys sure have some good solutions. I opted for a painters easel on wheels with a white board on it. My only mistake was not getting a magnetic white board. I may end up replacing it with one. -

Requesting feedback for future MSW Group Projects

alde replied to Chuck's topic in Group Projects on Model Ship World

Count me in Chuck. I would love to learn sailmaking. Maybe it can include furled and unfurled sails. -

Thanks Lou, it finally feels like something is coming together and looking like a hull. Maybe by the end of next week I'll try fitting the shear strake. I have some nice dark ebony strips and I was thinking of using that for the shear but I understand it's not easy to work with. I may try cutting and bending it anyway. If I can fit it OK I'll use it. If not there is always paint for the black planks. I used ebony for my guitar fingerboard and it cut and glued just fine but I didn't have to bend it.

-

It's been slow going but it is going. I managed to get all the framing done and treenailed the half frames to the keel assembly. This is the first time I have made treenails and it took a bit of practice before I could get them down to a scale 1 inch without too much trouble. I also did some fairing and it seems to be going ok. It's going to be a slow job to fair the inside. It's going to take some thought and custom sanding pads to get it done. So far so good.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.