-

Posts

113 -

Joined

-

Last visited

Profile Information

-

Location

Huntington, WV

Recent Profile Visitors

-

wool132 reacted to a post in a topic:

Armed Virginia Sloop by CiscoH - Model Shipways - 1:48

wool132 reacted to a post in a topic:

Armed Virginia Sloop by CiscoH - Model Shipways - 1:48

-

wool132 reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

wool132 reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

wool132 reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

wool132 reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

wool132 reacted to a post in a topic:

Rattlesnake by Ed Ku20 - Model Shipways - 1:64

wool132 reacted to a post in a topic:

Rattlesnake by Ed Ku20 - Model Shipways - 1:64

-

wool132 reacted to a post in a topic:

HMS Winchelsea by James G (Jim) - 1:48

wool132 reacted to a post in a topic:

HMS Winchelsea by James G (Jim) - 1:48

-

wool132 reacted to a post in a topic:

Lowell Grand Banks Dory by MisterSteele - FINISHED - Model Shipways - 1:24

wool132 reacted to a post in a topic:

Lowell Grand Banks Dory by MisterSteele - FINISHED - Model Shipways - 1:24

-

Very nice job - congratulations!! Jonathan

- 25 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

wool132 reacted to a post in a topic:

HMS Speedy by Theodosius - Vanguard Models - 1:64

wool132 reacted to a post in a topic:

HMS Speedy by Theodosius - Vanguard Models - 1:64

-

Kevin reacted to a post in a topic:

Lady Eleanor by Kevin - FINISHED - Vanguard Models - 1/64 - Fifie fishing boat - built Dec 22, 2022 to Jan 23, 2023

Kevin reacted to a post in a topic:

Lady Eleanor by Kevin - FINISHED - Vanguard Models - 1/64 - Fifie fishing boat - built Dec 22, 2022 to Jan 23, 2023

-

Wow! Took you less time to complete a fine Lady Eleanor model than it took me to unwrap the box and examine the contents! Great job! Jonathan

- 38 replies

-

- Lady Eleanor

- Vanguard Models

-

(and 1 more)

Tagged with:

-

wool132 reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

wool132 reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

wool132 reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

wool132 reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

Obormotov reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

wool132 reacted to a post in a topic:

Glad Tidings by Paul Le Wol - FINISHED - Model Shipways - 1/24 - pinky schooner

wool132 reacted to a post in a topic:

Glad Tidings by Paul Le Wol - FINISHED - Model Shipways - 1/24 - pinky schooner

-

Dave_E reacted to a post in a topic:

Rattlesnake by Ed Ku20 - Model Shipways - 1:64

Dave_E reacted to a post in a topic:

Rattlesnake by Ed Ku20 - Model Shipways - 1:64

-

Keith Black reacted to a post in a topic:

Rattlesnake by Ed Ku20 - Model Shipways - 1:64

Keith Black reacted to a post in a topic:

Rattlesnake by Ed Ku20 - Model Shipways - 1:64

-

I found a video from five years ago by a guy who had no luck trying to tune his Buck. The good news is that there were a couple of comments from folks who were able to get it to work well: Beavis Christ: "Try flipping the blade so that the bevel is facing down. I set mine up that way, and it works wonderfully. When setting it up, I put it on a piece of glass, or any totally flat surface, and put a piece of paper just under the front of the block, let the blade drop down and sit flat against the glass, and tighten the screw." Robbie Vigil: "(Put) Sand paper between the blade and holder and put the bevel down and it's good to go." Another suggested trying a replacement blade (about $10 bucks) from Lee Valley. I use this miniature block plane ($45) from Lee Valley to taper my planks. No tuning required. Highly recommended. Jonathan

-

Ryland Craze reacted to a post in a topic:

Lowell Grand Banks Dory by DonBMichigan - FINISHED - Model Shipways - 1:24 scale

Ryland Craze reacted to a post in a topic:

Lowell Grand Banks Dory by DonBMichigan - FINISHED - Model Shipways - 1:24 scale

-

DonBMichigan reacted to a post in a topic:

Lowell Grand Banks Dory by DonBMichigan - FINISHED - Model Shipways - 1:24 scale

DonBMichigan reacted to a post in a topic:

Lowell Grand Banks Dory by DonBMichigan - FINISHED - Model Shipways - 1:24 scale

-

You're off to a great start! Jonathan

- 40 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

CommodoreErie reacted to a post in a topic:

Grand Banks Dory by CommodoreErie - FINISHED - Model Shipways - 1:24

CommodoreErie reacted to a post in a topic:

Grand Banks Dory by CommodoreErie - FINISHED - Model Shipways - 1:24

-

Congratulations on finishing your build and it looks mighty fine! Jonathan

- 34 replies

-

- Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

DB789 reacted to a post in a topic:

Saucy Jack by Glenn-UK - FINISHED - Vanguard Models - 1:64 - A Barking Well Smack

DB789 reacted to a post in a topic:

Saucy Jack by Glenn-UK - FINISHED - Vanguard Models - 1:64 - A Barking Well Smack

-

I recently bought some Gorilla Gel super glue to use instead of wood glue when I start my Zulu planking. Hmm... Jonathan

- 62 replies

-

- Saucy Jack

- vanguard models

-

(and 3 more)

Tagged with:

-

GrandpaPhil reacted to a post in a topic:

Lady Eleanor by wool132 - FINISHED - Vanguard Models - 1:64 - Fifie

GrandpaPhil reacted to a post in a topic:

Lady Eleanor by wool132 - FINISHED - Vanguard Models - 1:64 - Fifie

-

It's been a while since I finished my two builds of this dory but as I recall the ModelExpo Hull Yellow Ochre was noticeably tacky for a fairly long time. It eventually dried out, so forge on! I just finished my Fifie build and used hand-brushed ModelExpo Warm White, Bright Red Trim, and Bulwarks Dark Green. The Dark Green was kind of tacky (not as bad as the Ochre) but I was able to sand down the Warm White on the hull with only a day or so of drying time. On that model I also sprayed on Badger acrylic paints for the primer, the red oxide lower hull, and the black upper hull with the brushed warm white in between those two. Jonathan

- 34 replies

-

- Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you! I've started the Zulu kit so I've been referring to your build log rather frequently as I get started. You did a nice job on your build! 🙂 Jonathan

- 15 replies

-

- Lady Eleanor

- Vanguard Models

-

(and 1 more)

Tagged with:

-

HM Cutter Cheerful 1806 by JPR62 - 1:48 scale

wool132 replied to JpR62's topic in - Build logs for subjects built 1801 - 1850

Full recoveries are good! Now, your next challenge is to stay recovered! 🙂 Apt name for the model, too. Jonathan -

That brings up an interesting point. I remember reading somewhere that the writer Guy de Maupassant ate lunch every day in the Eiffel Tower restaurant. A waiter said that he must really like the tower and the de Maupassant said "No, It's the only place I can eat lunch and not see the damn thing!". If you're inside the suit, you're just running along as usual (maybe a little warmer) and you can't see it but to those outside it is a memorable event. 🙂 I'll stop going off topic now. Jonathan

- 62 replies

-

- Saucy Jack

- vanguard models

-

(and 3 more)

Tagged with:

-

I used to store blog references using browser bookmarks. I wound up with a long list of bookmarks and had no idea what they were for without clicking on them to find out. Quite tedious. Putting a link in the spreadsheet next to the build step(s) provides a context for the bookmark and I can add clarifying text in the link's verbiage if I want. If you wish to link to a specific reply rather than the whole page of entries, right click on the "Posted at ..." in the black bar at the top of the targeted entry and choose Copy Link and paste that into the sheet. As for most of the pictures, I use the iOS Screenshot utility to capture an image from the screen to the clipboard. I paste that into a blank spreadsheet cell, adjust the row height so the image is visible, and add a link if desired. Jonathan

- 5 replies

-

- Vanguard Models

- Lady Isabella

-

(and 1 more)

Tagged with:

-

I'm thinking that the first planking surface is a great testing ground for surfacing since it will be covered up by the second planking. As for Penguins, I've nabbed the wrong Glenn - sorry! ("Glenn Shelton followed in a penguin costume..." in an article on the Dalby Parkrun in The Scarborough News, circa 2017) Jonathan

- 62 replies

-

- Saucy Jack

- vanguard models

-

(and 3 more)

Tagged with:

-

Thanks for your informative post before being off with your grandsons! I'll be sure to give this a go when I get there on the Zulu. Neither my Fifie nor my Nisha planking was as smooth as what you've got. By the way, you wouldn't happen to know anything about a penguin suit, would you? Have a good time! Jonathan

- 62 replies

-

- Saucy Jack

- vanguard models

-

(and 3 more)

Tagged with:

-

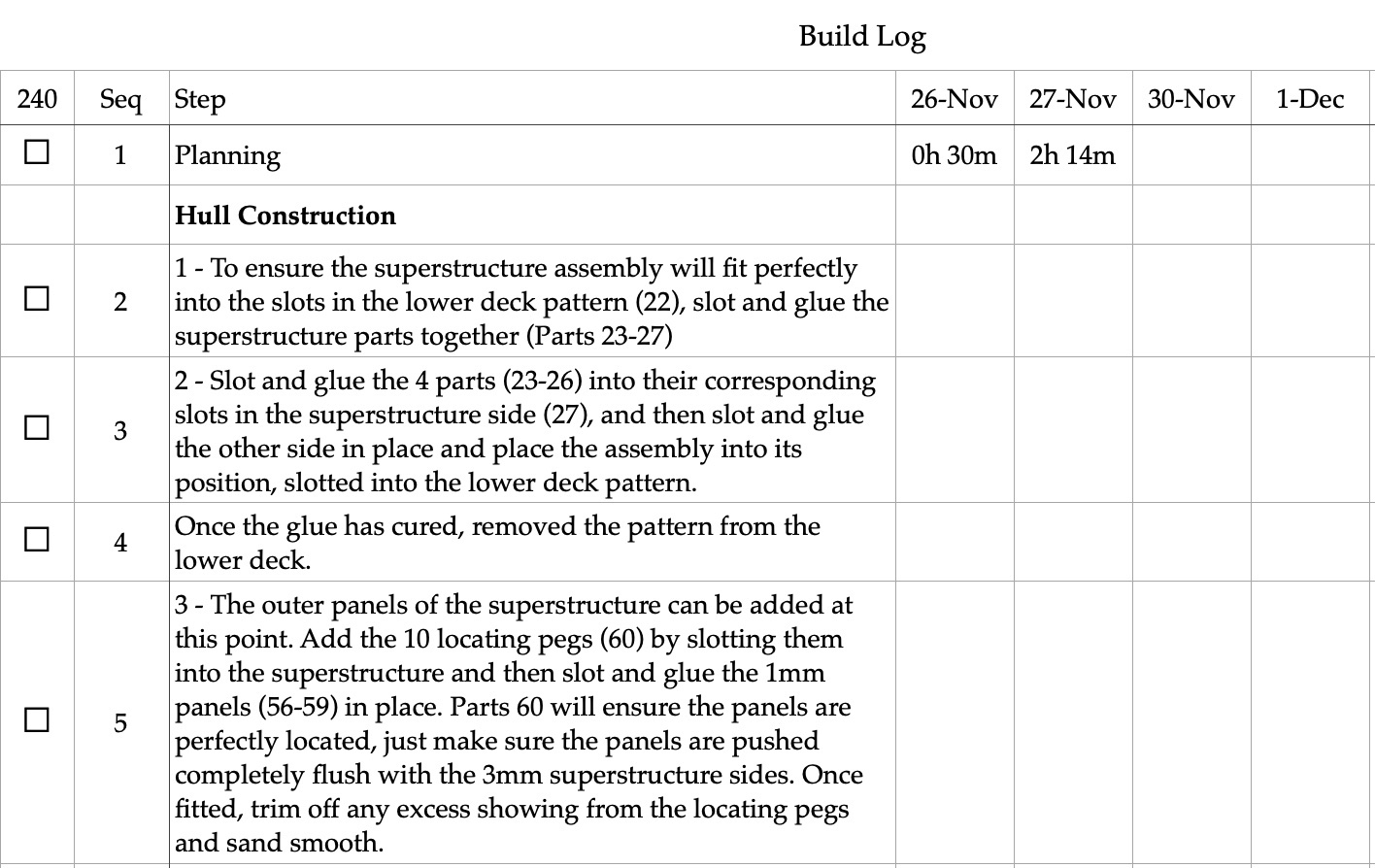

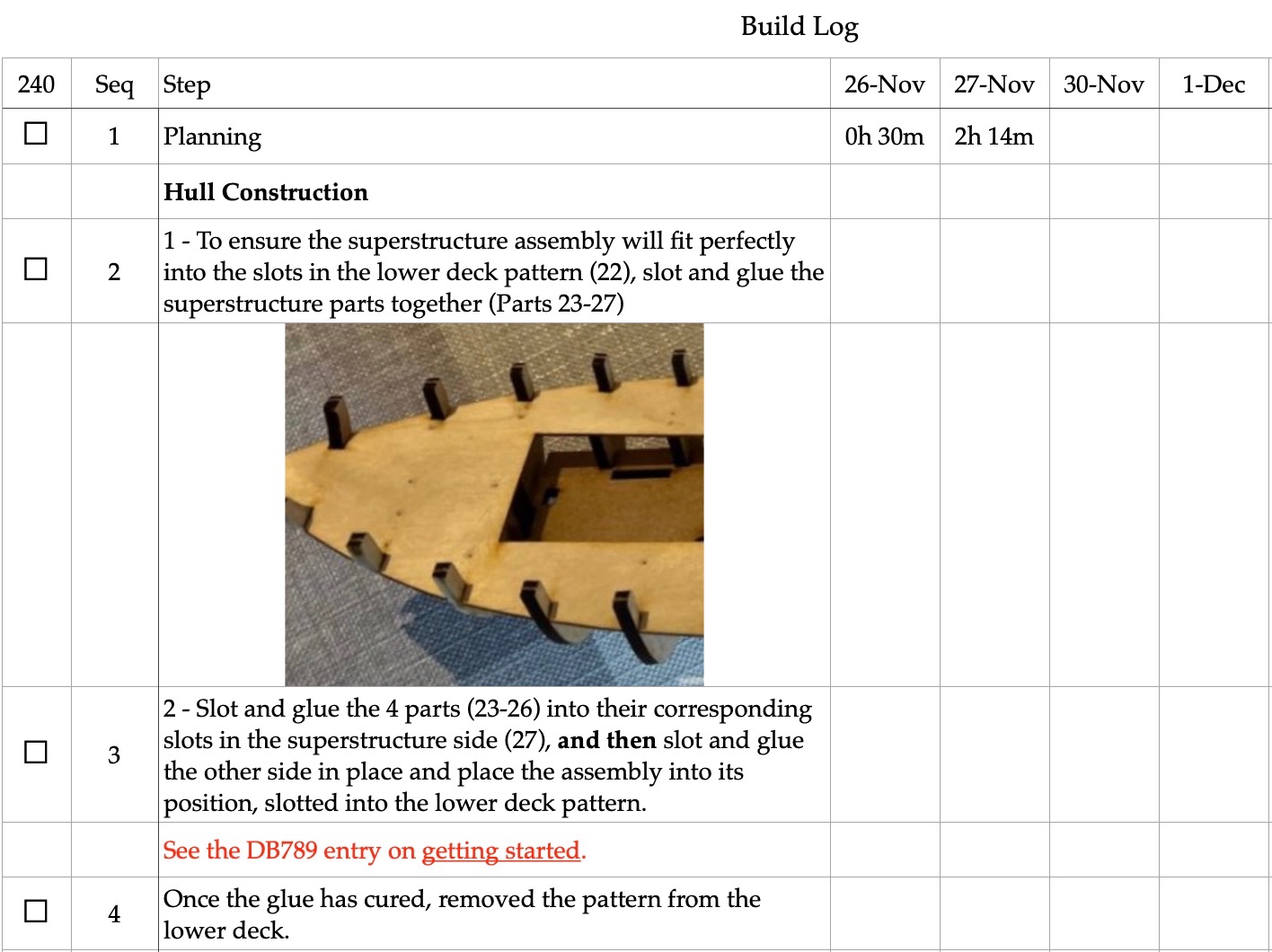

A word about preparation. In order to better keep track of where I am during a model build, I create a spreadsheet with all the build steps from the manual. I imagine that for a lot of you this is all ho-hum, nothing new but I include it here in case you're new to the hobby or you haven't thought much about some of the advantages of using a spreadsheet in a build. To do this, I select everything from the first step to the last in the PDF instruction file (pictures and all) and paste the clipboard contents into a blank spreadsheet. I use iOS Numbers and just the text gets put into the sheet. (Windows and Excel may do the same thing.) I then add two columns in front of the one for the steps. One is a checkbox that toggles between not done and done. The other is a sequence number for the rows with actual content and not headings (in this case Hull Construction). Columns are added after the steps to record the time spend on each step for the days when I work on the model. I inserted a formula in the top left cell to count the number of unchecked checkboxes in the first column. In this case, there are 240 steps left to complete the model. With any luck, that number will go down as I slave away at the workbench. 🙂 The rows with headings are inserted at various points in the file to give a general idea of what's being worked on. These are usually provided in the Vanguard instructions, though sometimes I add them if I feel they're missing. Once the sheet has been created, I can reorder the steps if I wish, highlight key steps, insert links to other builder's blog entries or insert pictures of their work or techniques, add comments (like what NOT to do or things to avoid), add rows to create sub-tasks for a complex step, etc, etc. A sample is shown below: Jonathan

- 5 replies

-

- Vanguard Models

- Lady Isabella

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.d84ec4dad1d7791e855dca06210ab6f3.thumb.jpg.f45209242e851d4409eca1a09293165b.jpg)