-

Posts

6,133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

Nice solution to cutting those sections evenly.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

tool review Perma-Grit tools

James H replied to James H's topic in REVIEWS: Model Shipwrighting Tools, Parts and fittings

I use the broad, flat stick for pairing down dowel to make mast lower sections. Been doing that tonight.- 17 replies

-

- permagrit

- perma-grit

-

(and 3 more)

Tagged with:

-

Strap you to a plank for a week and be spoon-fed your meals. You'll be right in no time! Hope it's fixed up soon.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I don't doubt there's probably a few more anomalies on my rigging, but don't tell anyone if you see them 😆 I figured Chris didn't need me hassling him any more than I normally do during a prototype build, so I go into 'get it done' mode more often than not.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

More likely me not knowing anything about rigging and just wanting to get the job done. Do it the way Chris explains. This is also a reason I hate doing rig for instructions as I am clueless with it.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Some work has started on making mast parts. At the moment, it's anything but tapering! I've just set up my lathe to make a start on the various dowel sections. In the meantime...

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I'll be starting my bowsprit sometime this week. I can see from yours that the rake will make it extremley imposing.

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

This one was an issue at the datacenter and not any issue with MSW itself. There was a problem with the power which supplied many server cabinets at the datacenter and the outage took probably many 1000s if not 100,000's sites offline what depended on that datacenter. We were simply a casualty of that. The engineers there upgraded the power supplies and now we are back.

-

Just for note, Pt.2 of my Indy article is now out in the Model Boats mag. Here's the intro pages. My workroom has also had a serious deep clean too. It really needed it. I've reinstated my beck storage station, and stripped down the photo area where you can now see the Indy hull. New cutting mat and this weekend I'll have a new chair so I can work more comfortably. Ignore the Spitfire kit. That will be started after Indy is complete and I go on a small hiatus from wood.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I just love how this is turning out. You're at one of my favourite points in this build. 🍿

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The manual for this shows a couple of clear photos. All I did was run a single strip of tape along the keel, up against hull. From there I just added the plates in a brick fashion. That single run of tape can then later be scribed to fit the brick pattern. Add the tape plates above the waterline and then add a feint waterline over the copper. Use a fresh blade and cut along the line before removing the excess from above the waterline.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

One last small update as I'm heading off to watch TV with my better half. Grecian now has her flag. This is sprayed in a mild starch solution, weighted with croc clips until dry, and then small spots of PVA used to tack into final position.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

To be bluntly honest, I don't really think most kit builders would really care about stuff like this. Maybe as 'some' modellers progress down a more serious route, would they contemplate details such as tapering of those areas. I would think that most kit modellers wouldn't want to progress down that route and are happy to build very respectable finished projects without the sort of things that only a purist would look at.

-

Here's a pic I took of the optional flag. This is perfectly screen printed on both sides and has zero bleed. I'll fit this to Grecian this week.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

I hope you'll try your hand at this one.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

There will also be an optional American flag. I'll post another picture next week showing the flag mounted to the model.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

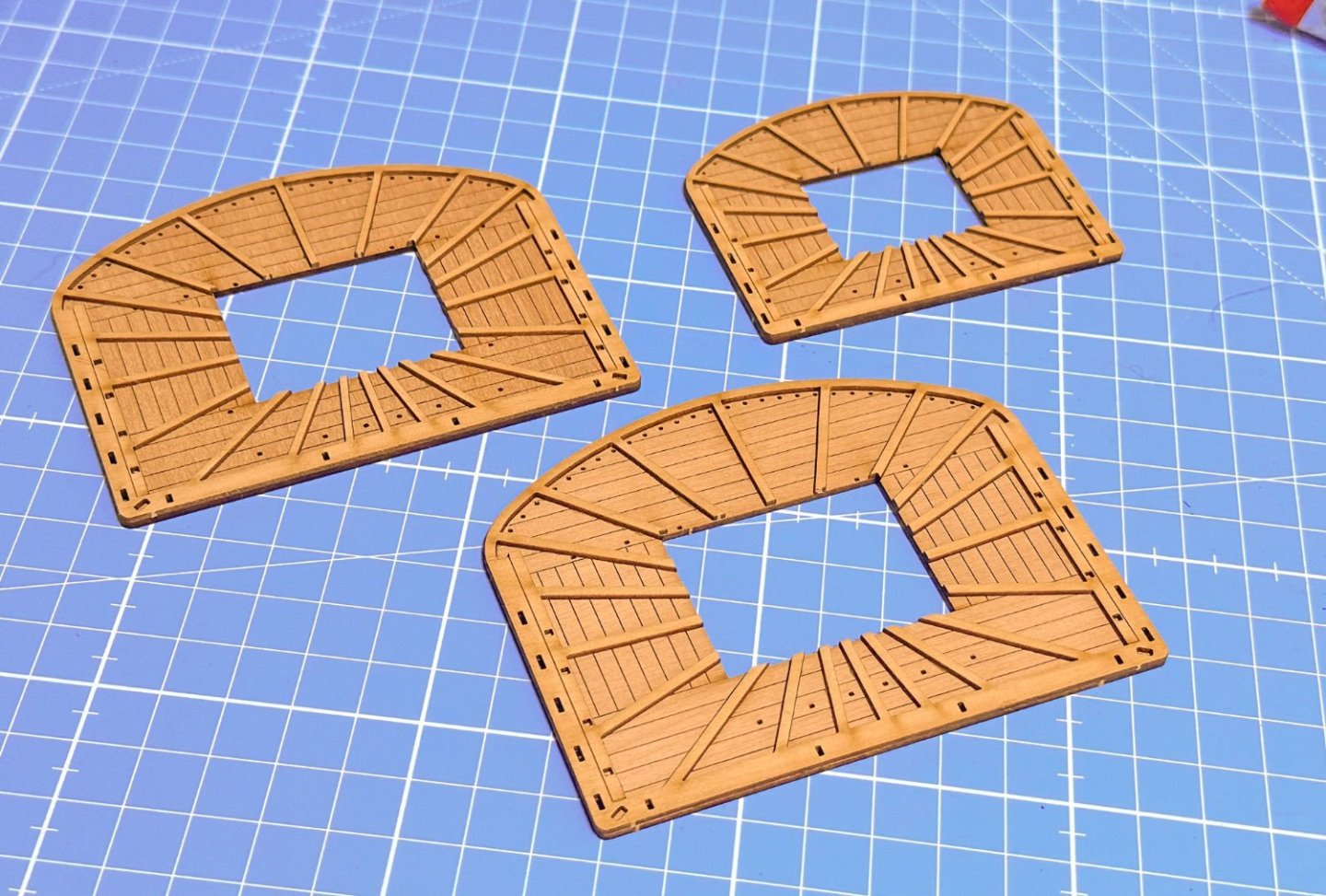

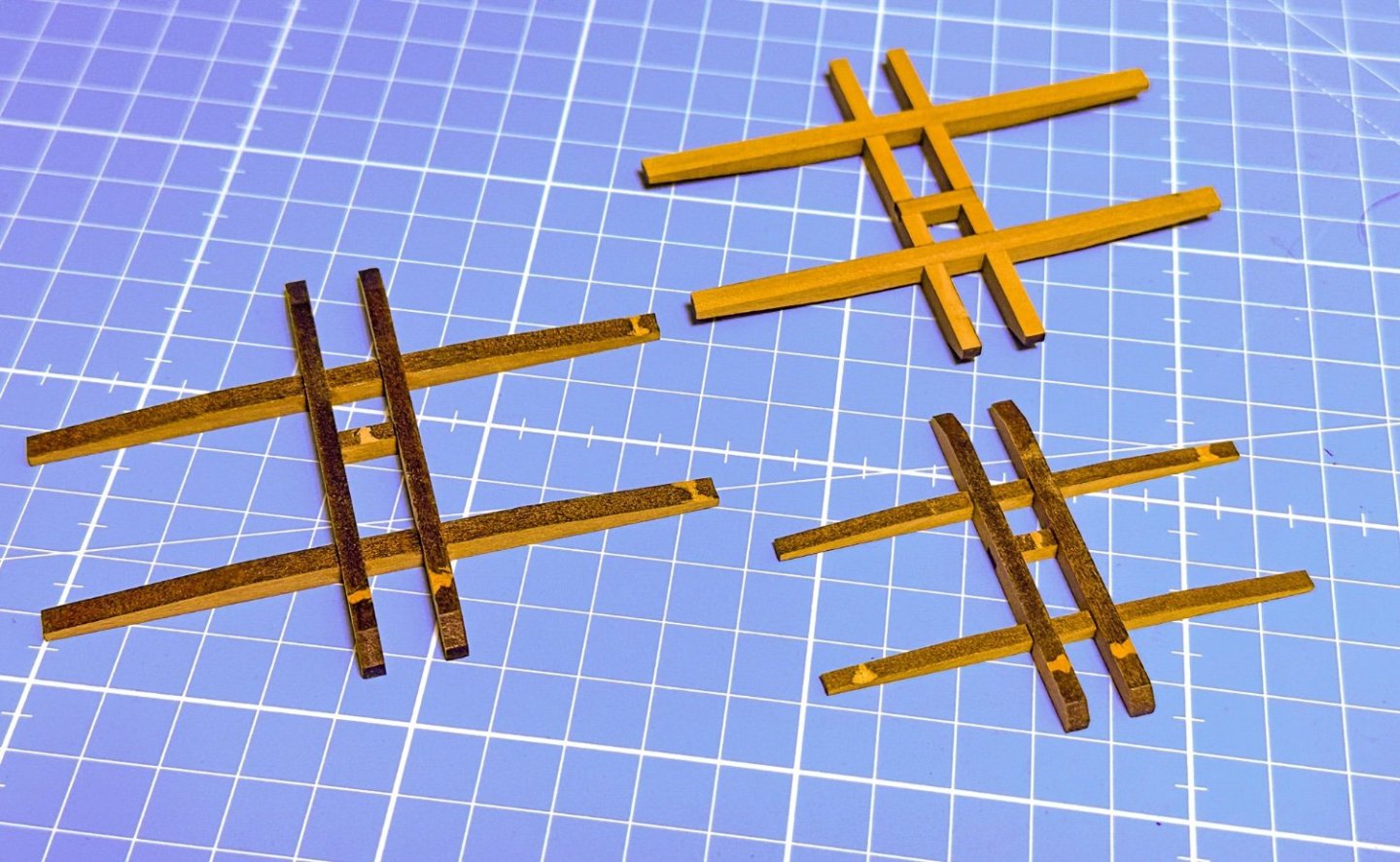

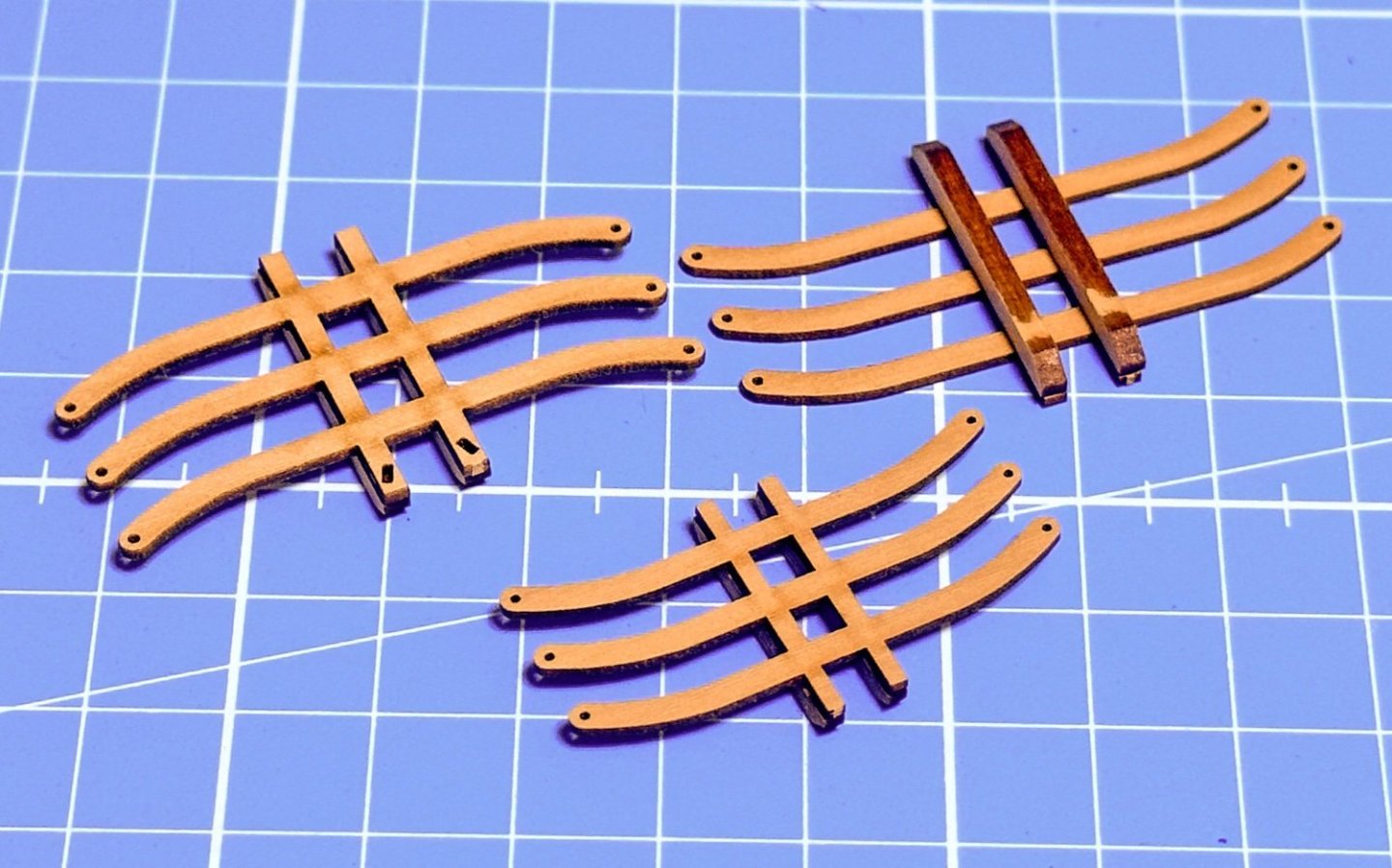

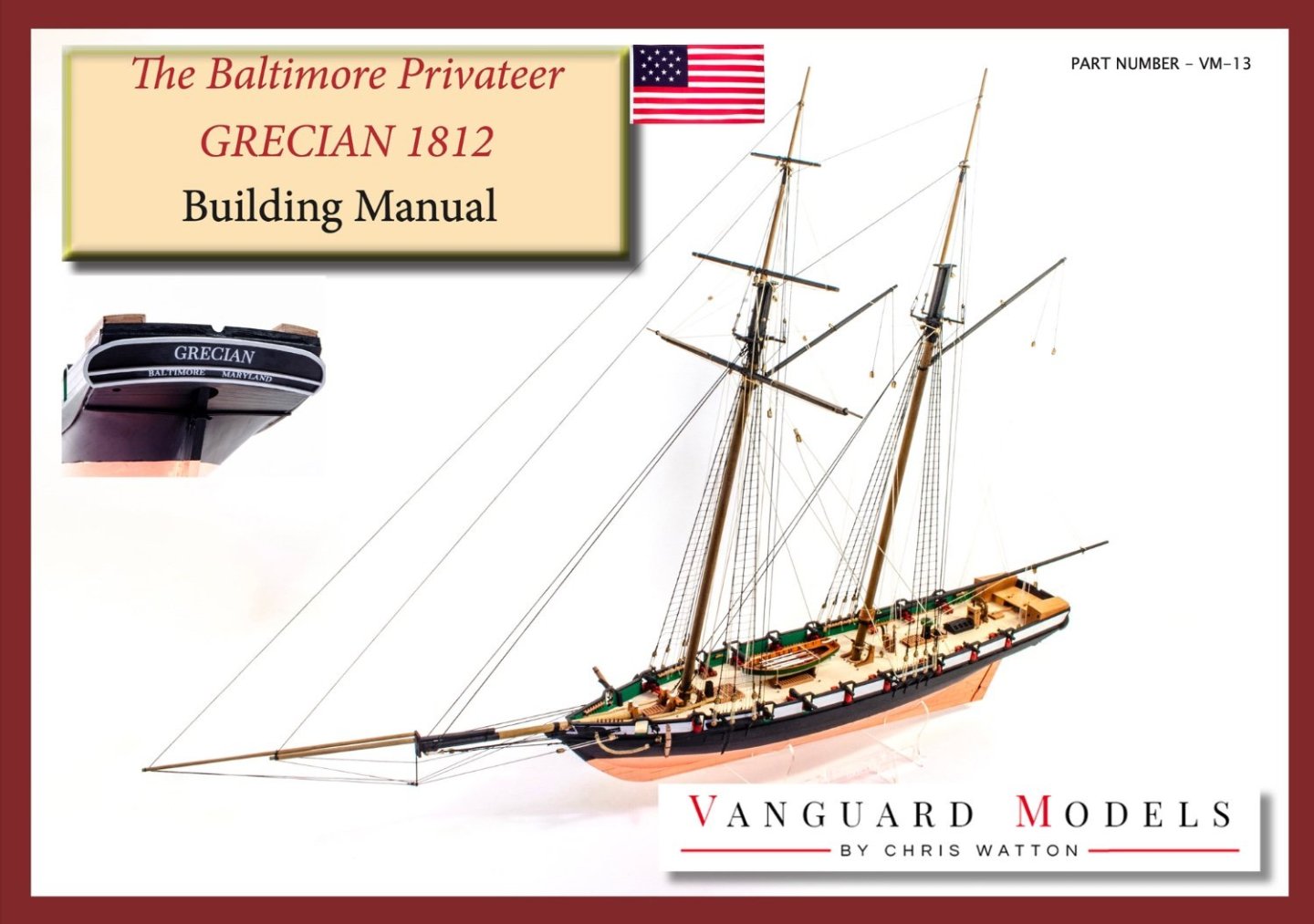

Here's the front page of the manual. There will be a pre-order open early next week too At that point, you'll also be able to download and look at the manual. Options will be available for a period-correct flag and also a limited number of PE copper plate sets instead of the standard copper tape that's supplied.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.