-

Posts

6,133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

Kit review 1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

James H replied to James H's topic in REVIEWS: Model kits

I imagine that's very likely. If in doubt, just drop Pavel an email and verify. It really looks a very sweet kit. -

Kit review 1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

James H replied to James H's topic in REVIEWS: Model kits

It was apparently for the first few, but not sure how many that means. All new purchases will be fine. If in doubt, mail them with your serial number and see if yours is affected. -

Kit review 1:25 Drakkar ‘Oseberg’ - Ships of Pavel Nikitin

James H posted a topic in REVIEWS: Model kits

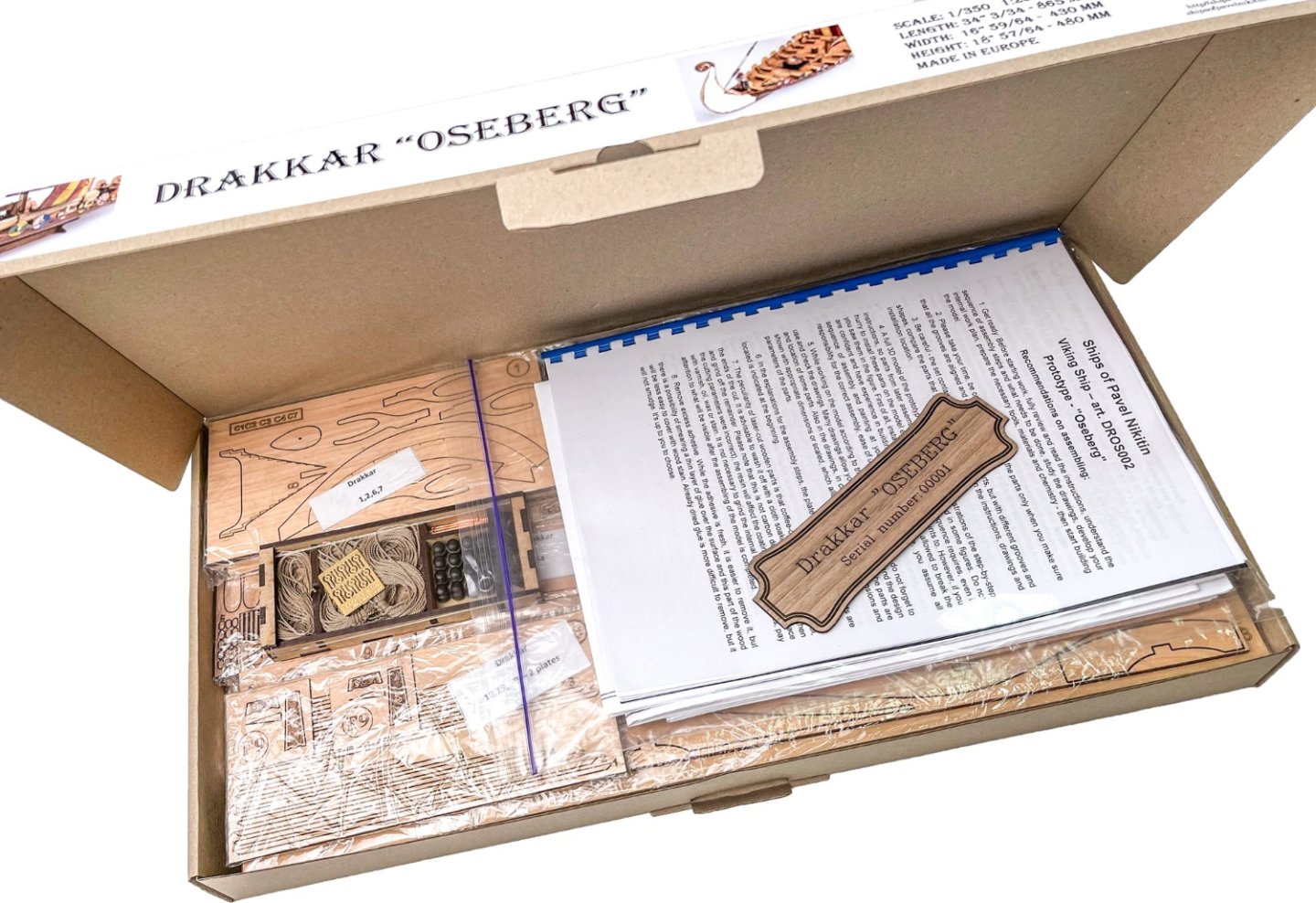

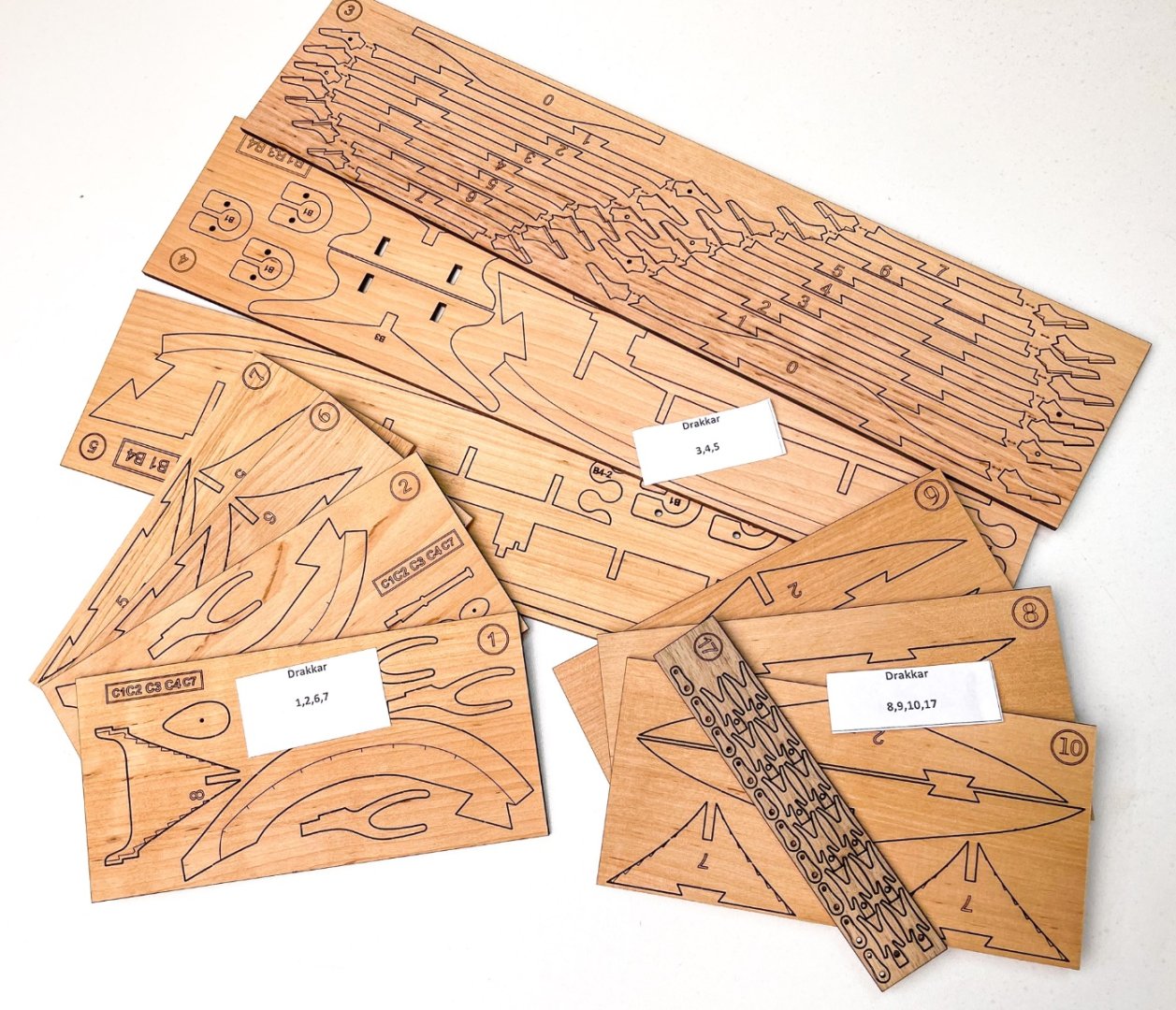

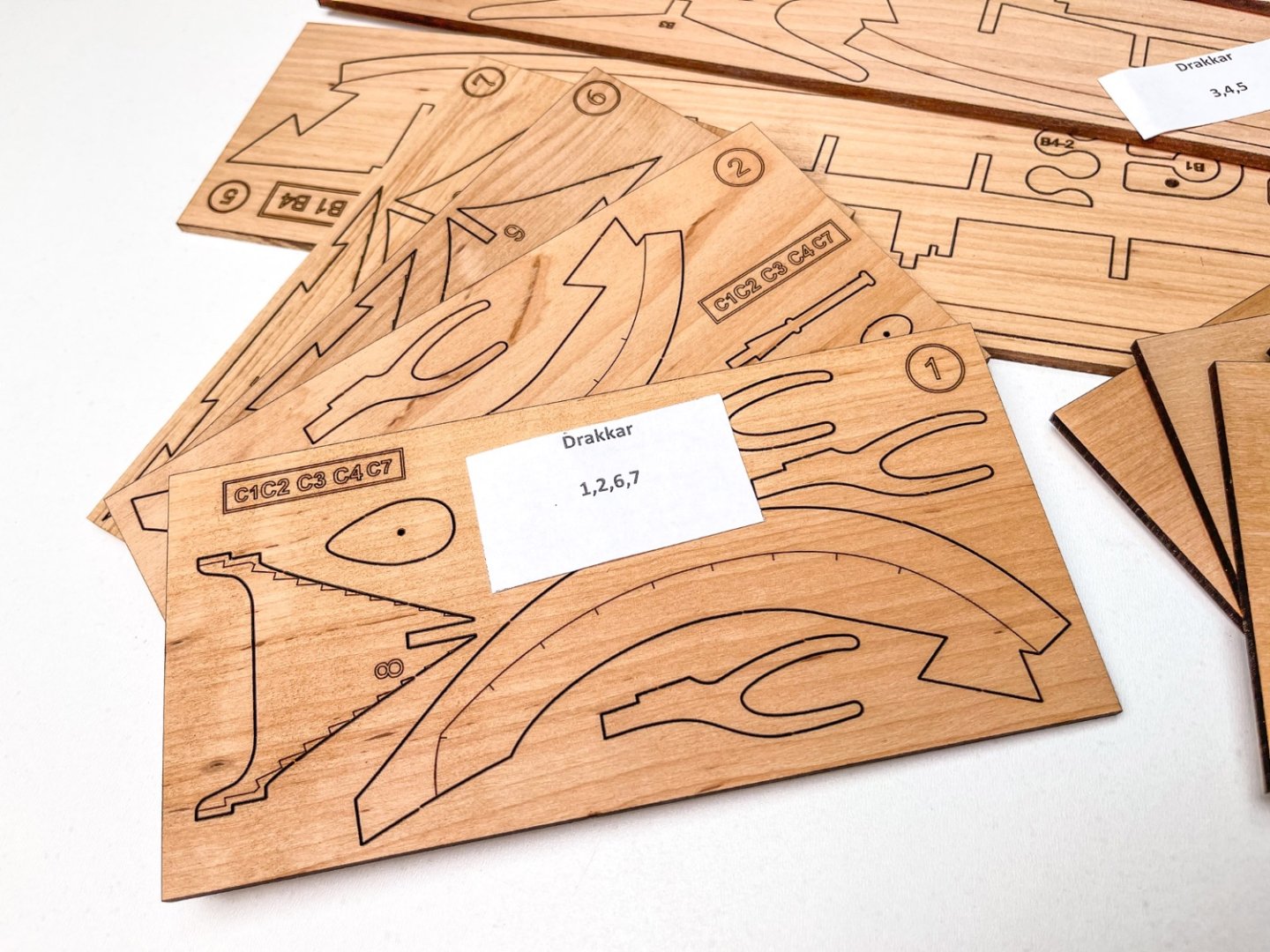

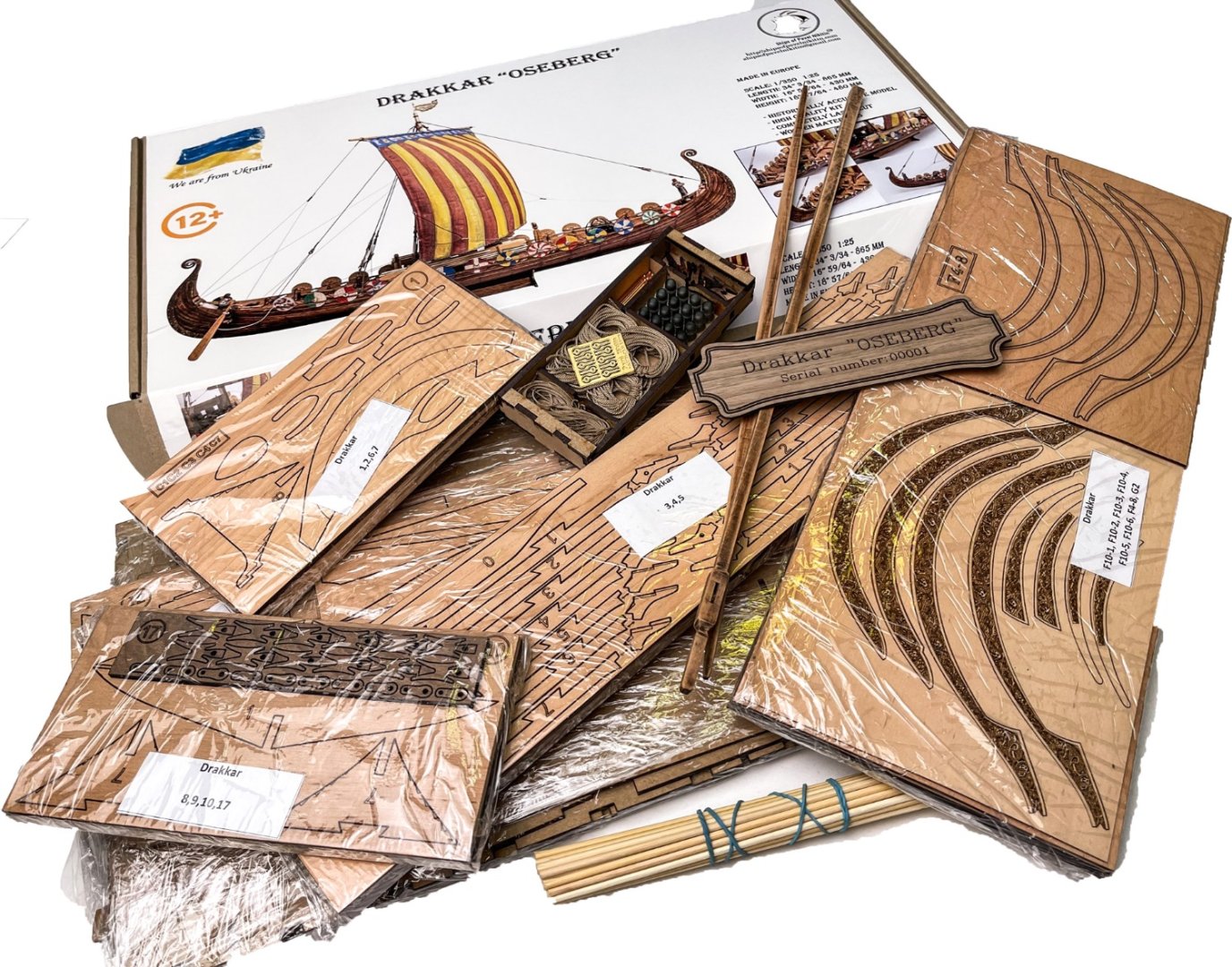

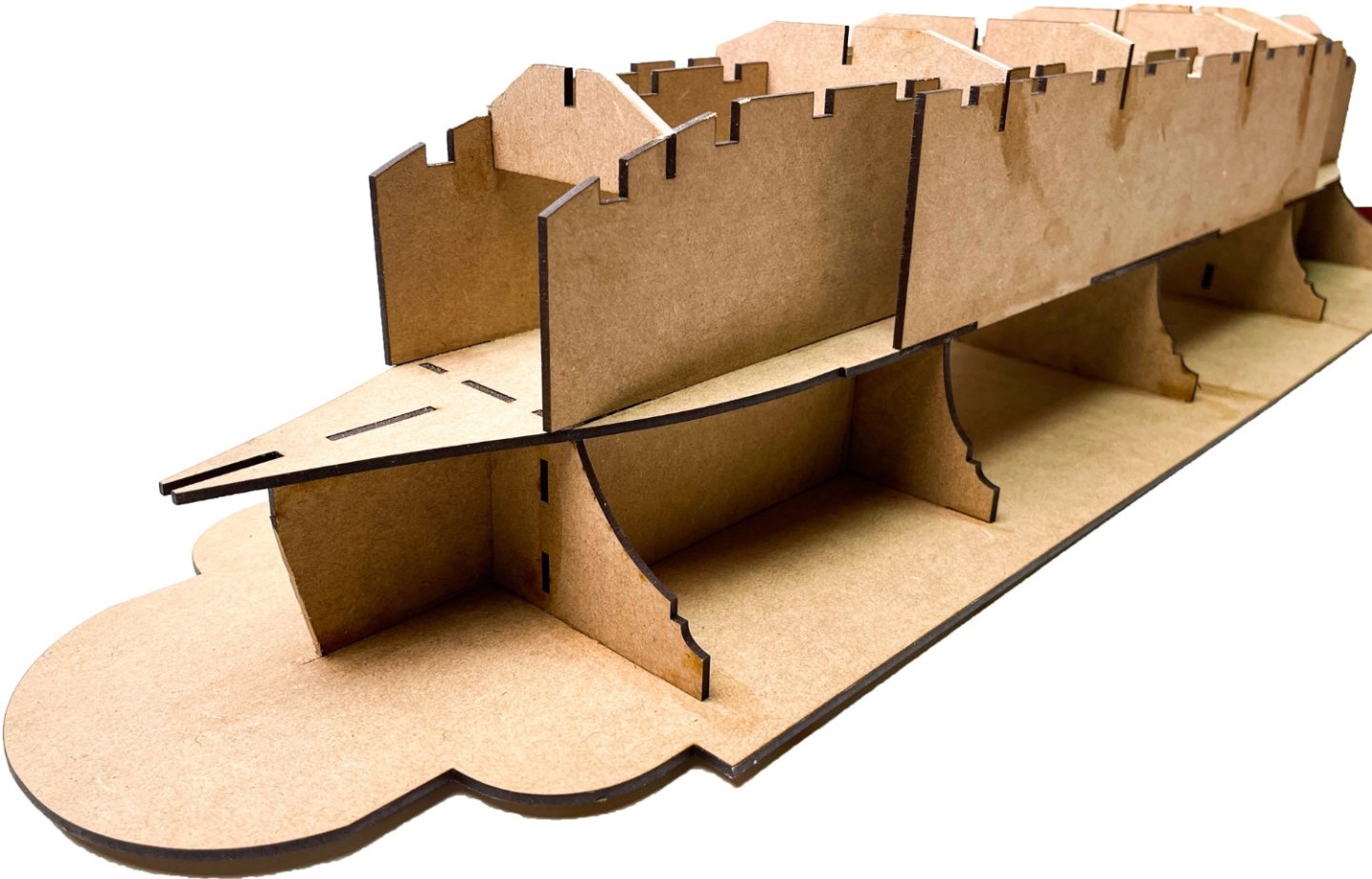

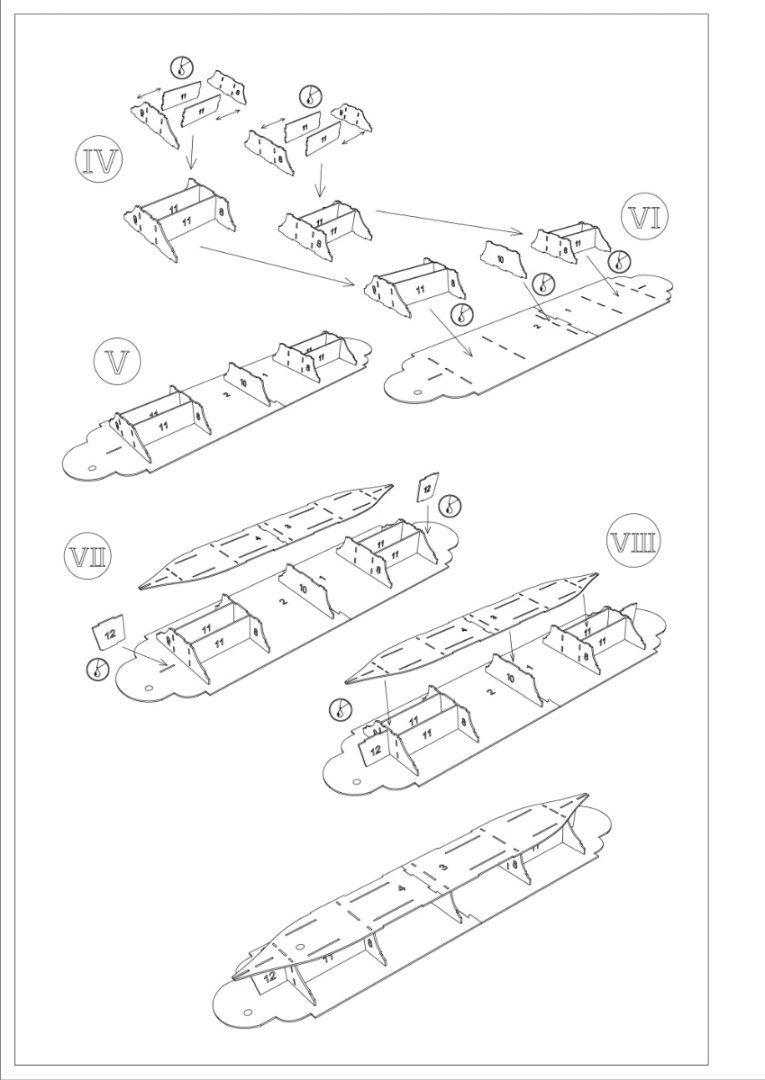

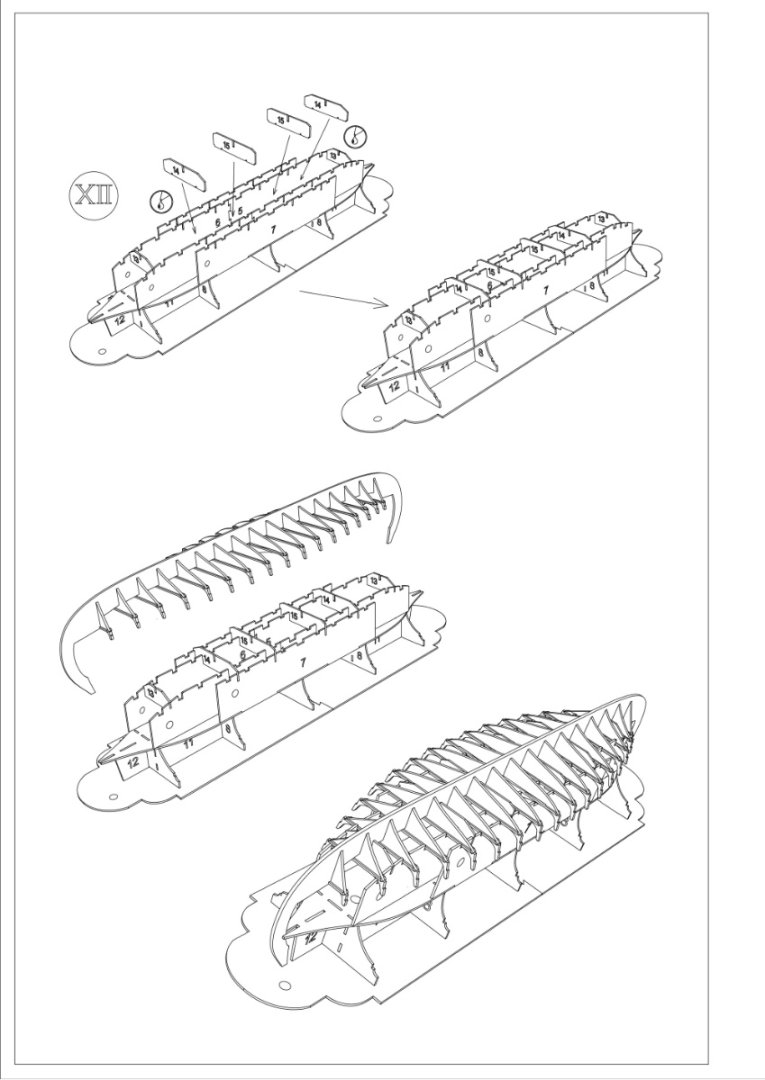

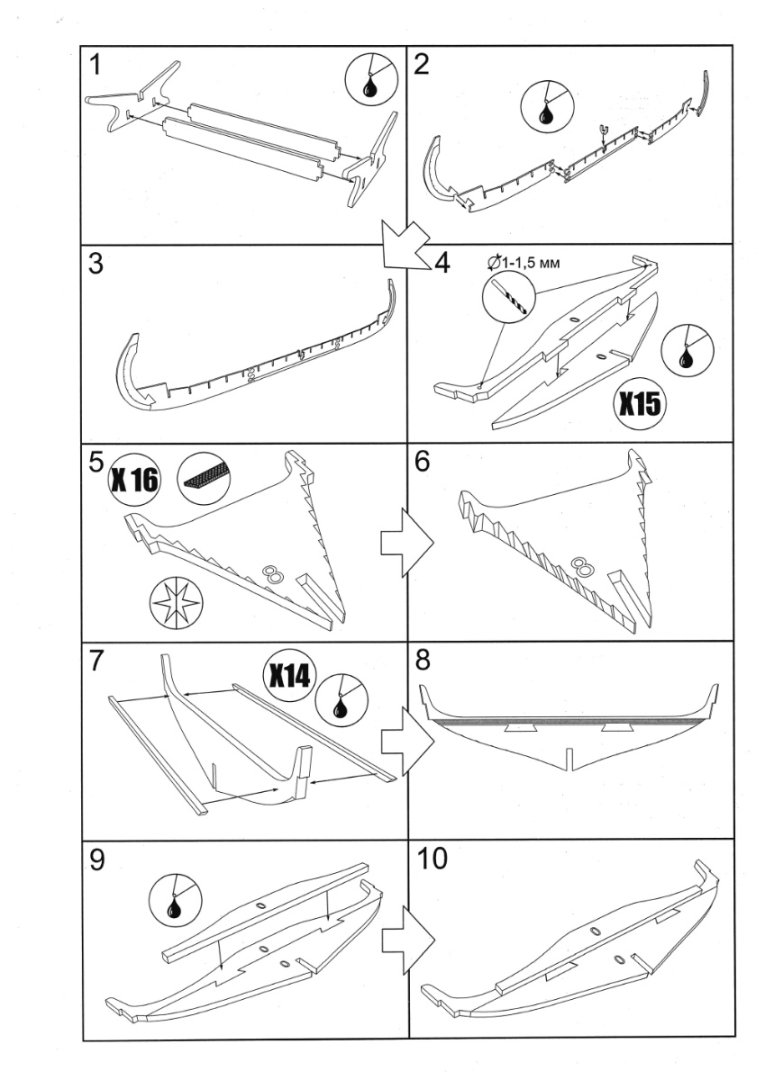

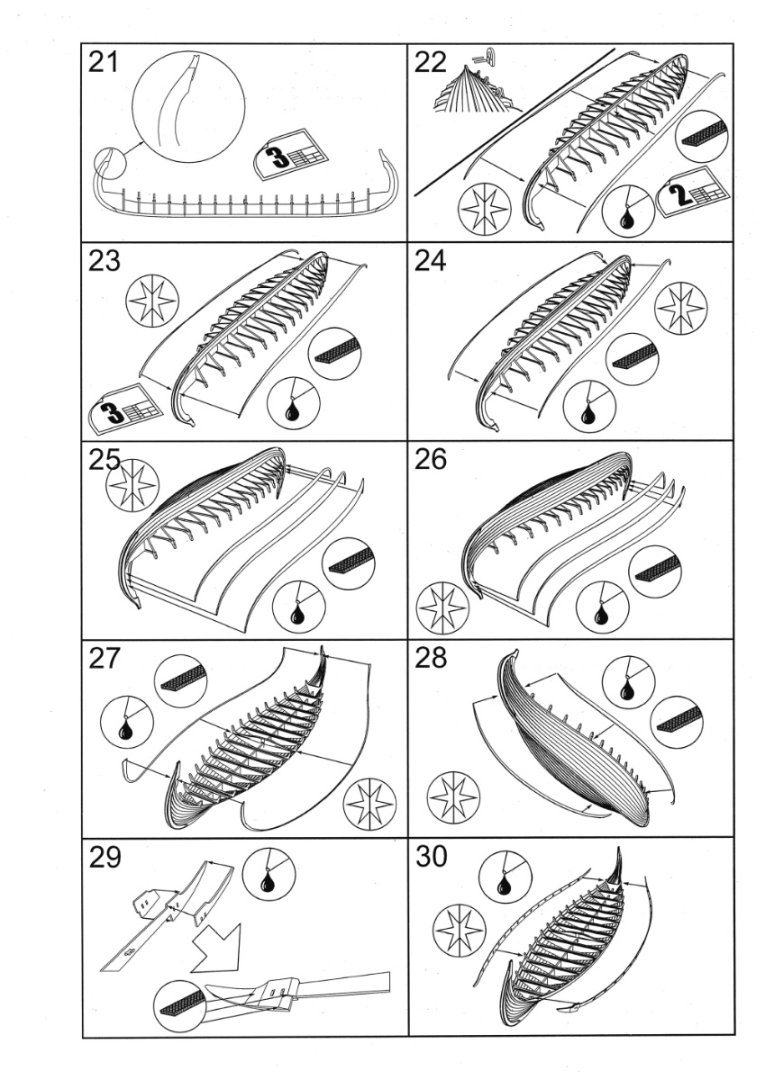

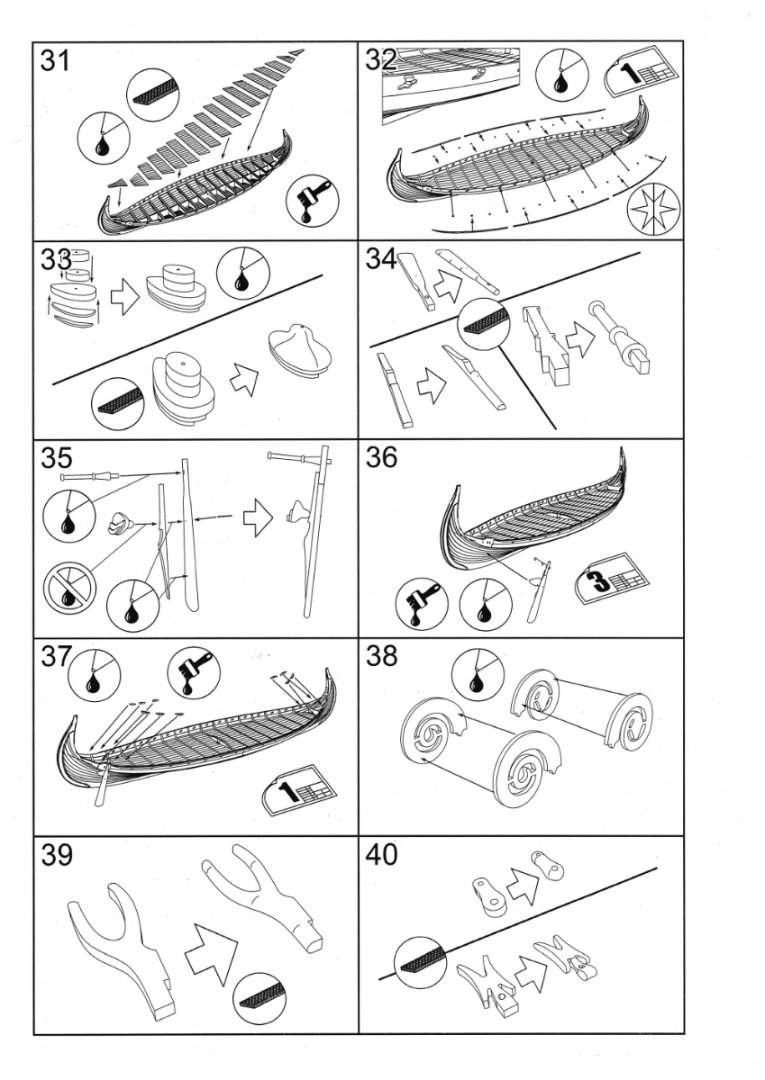

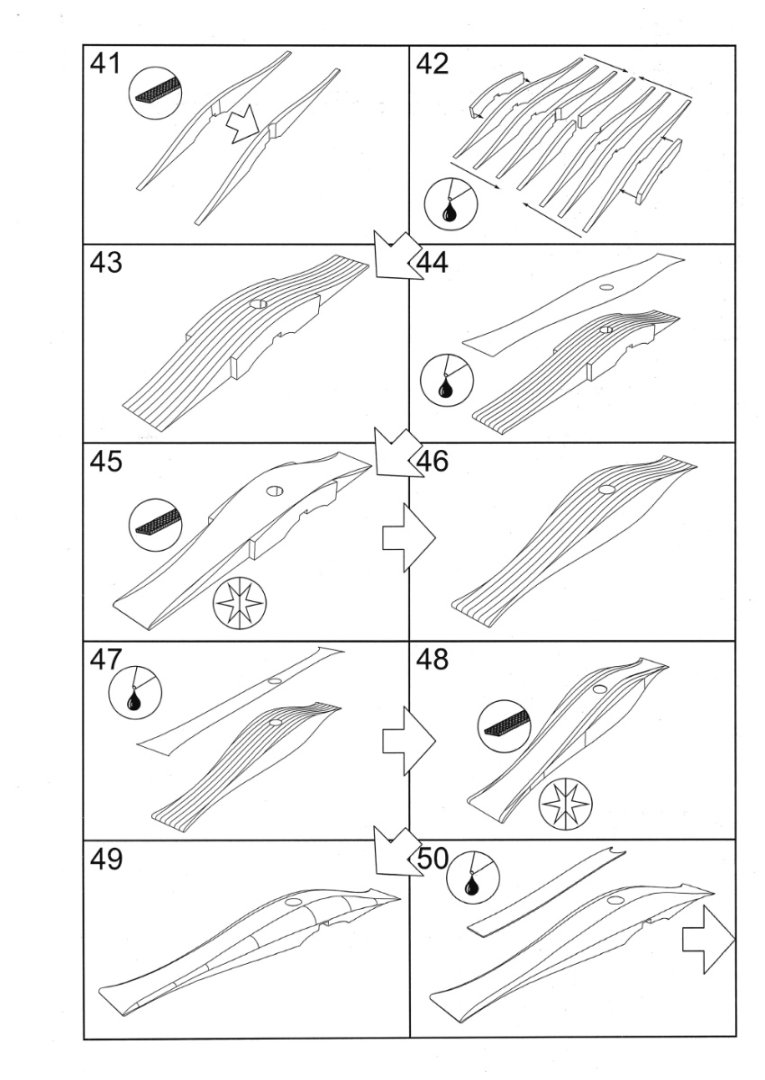

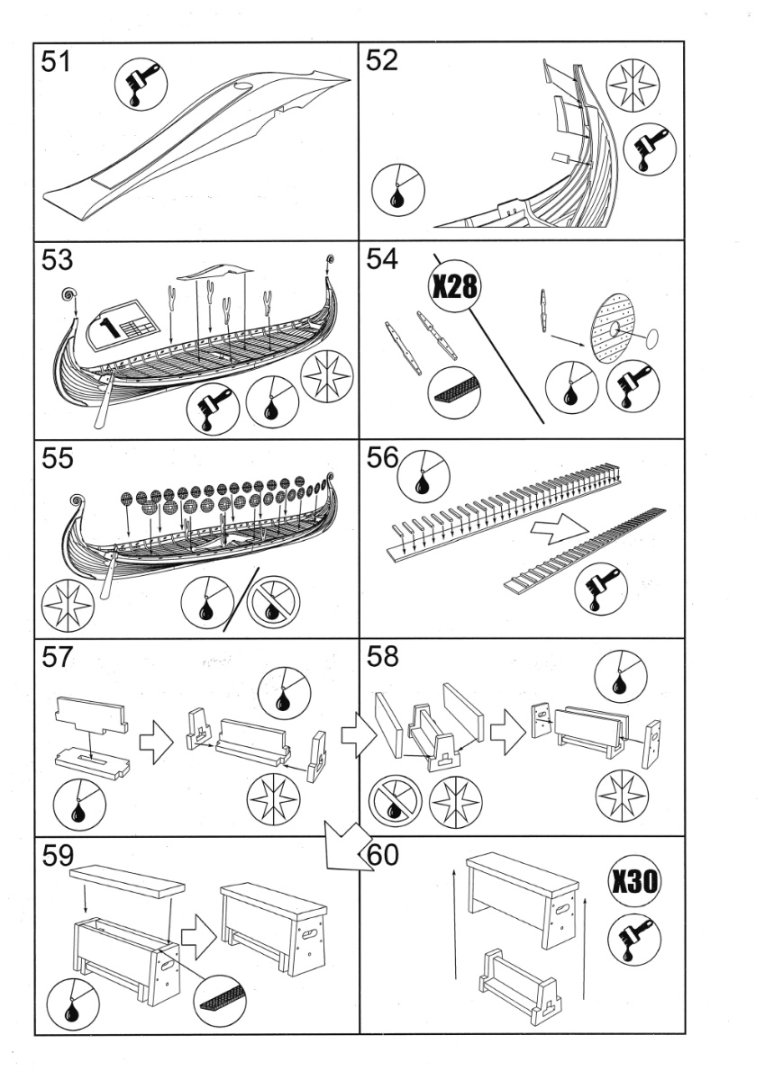

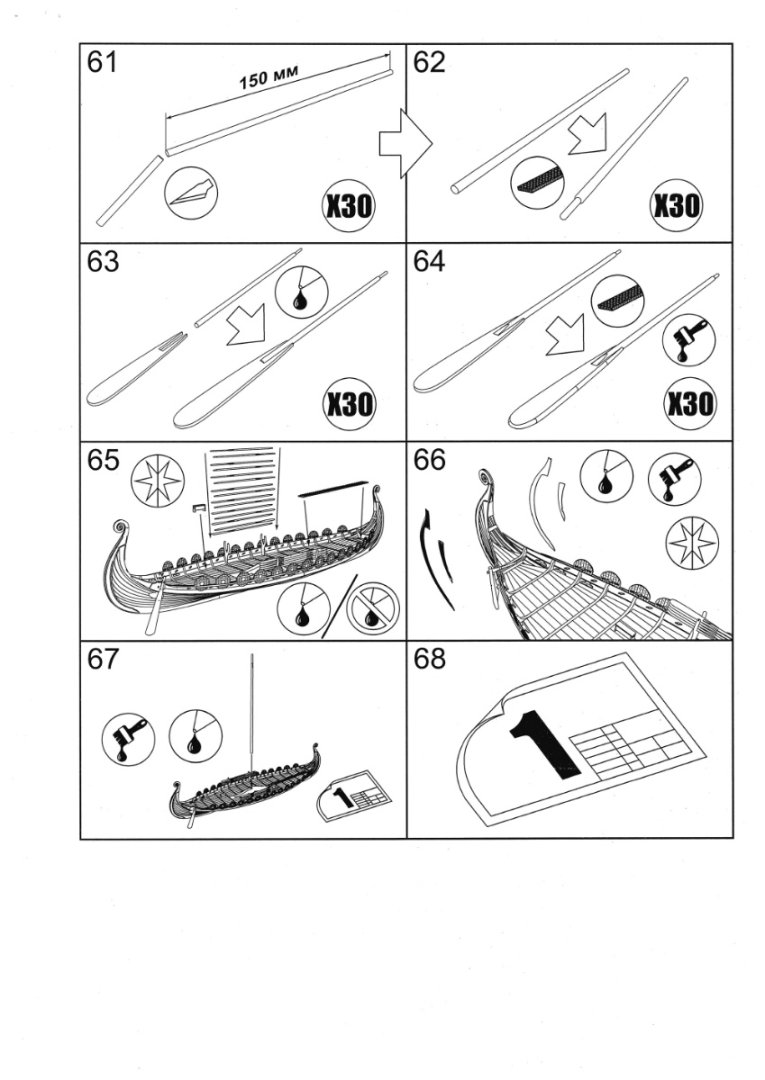

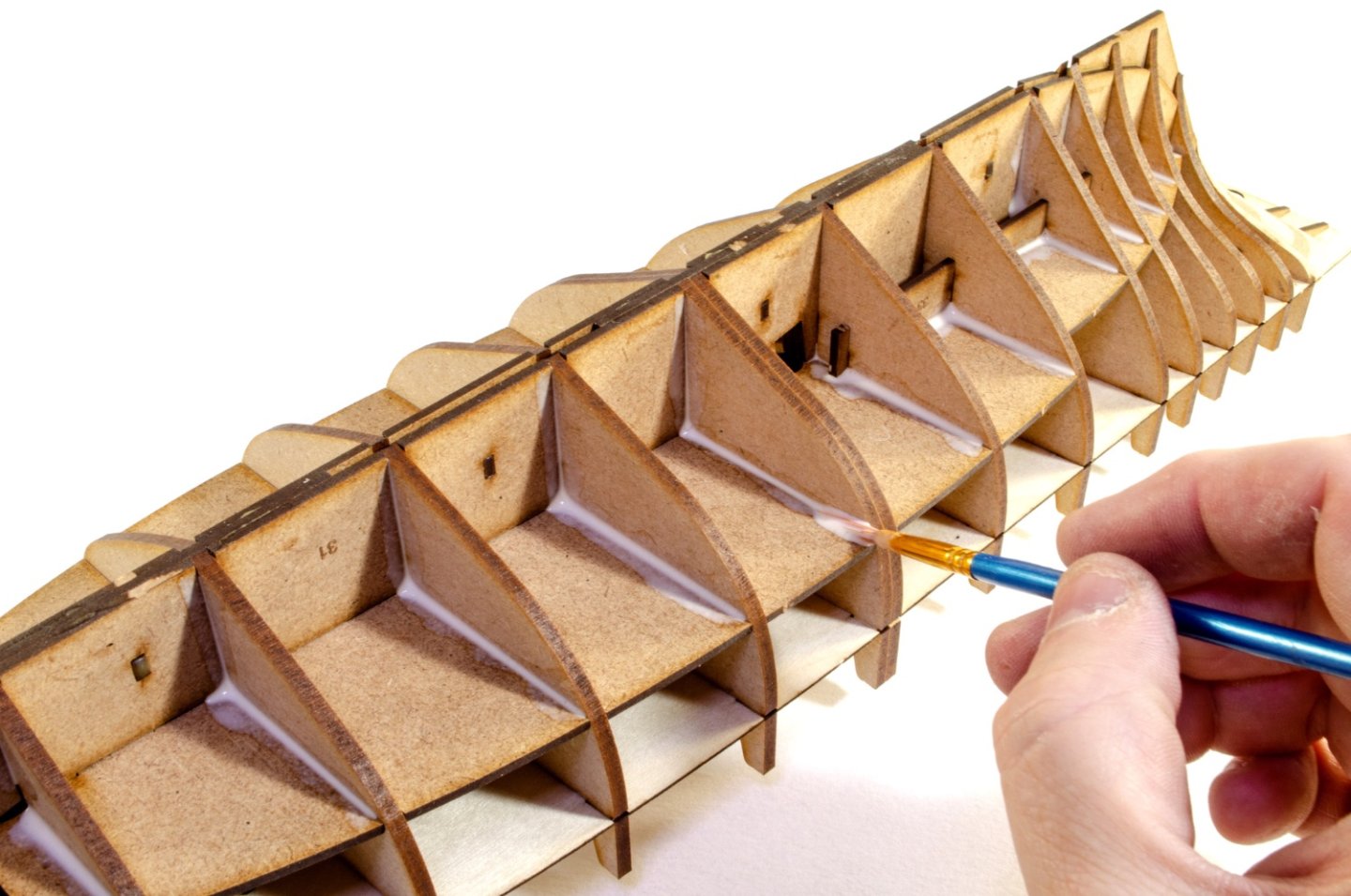

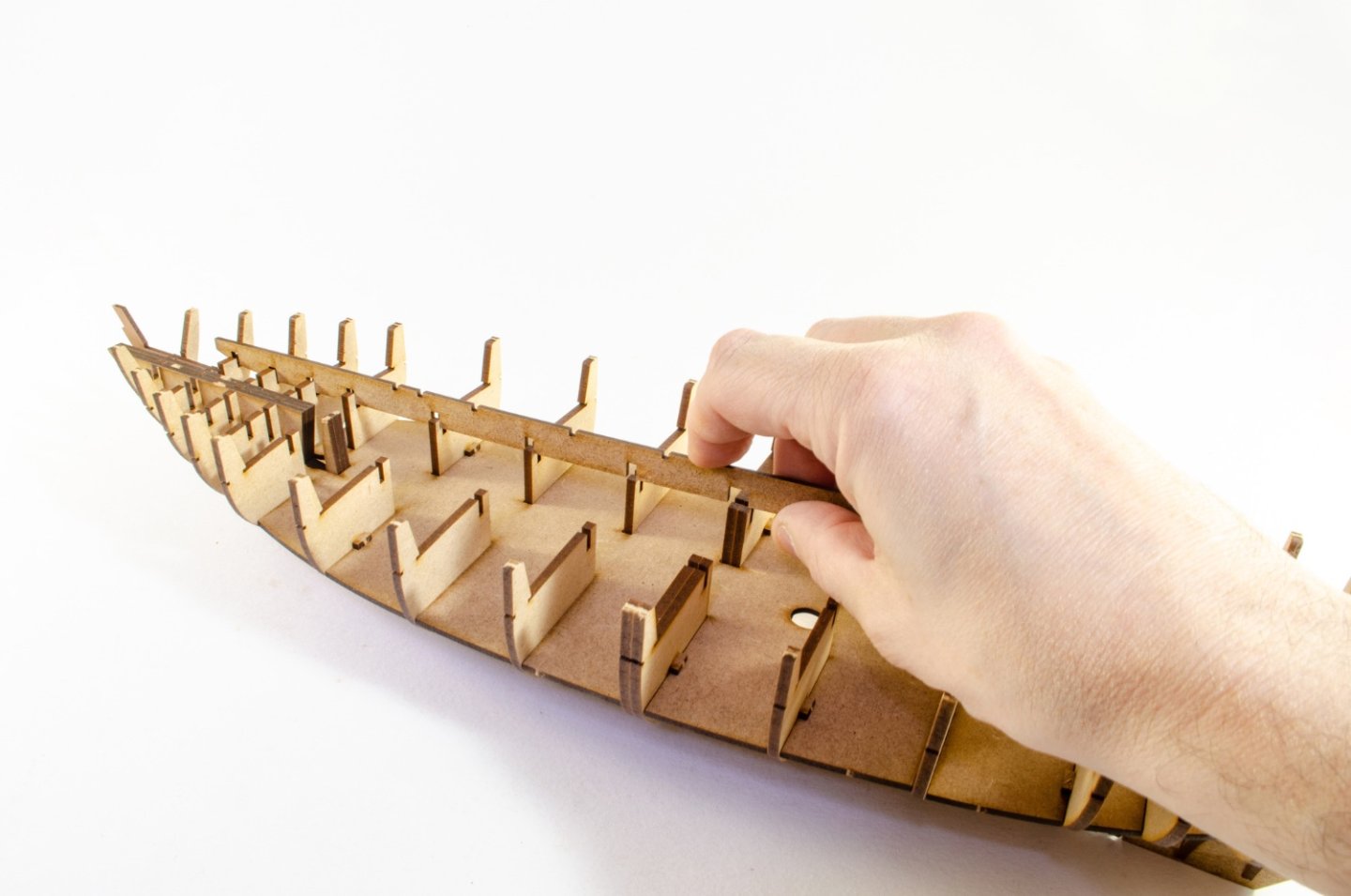

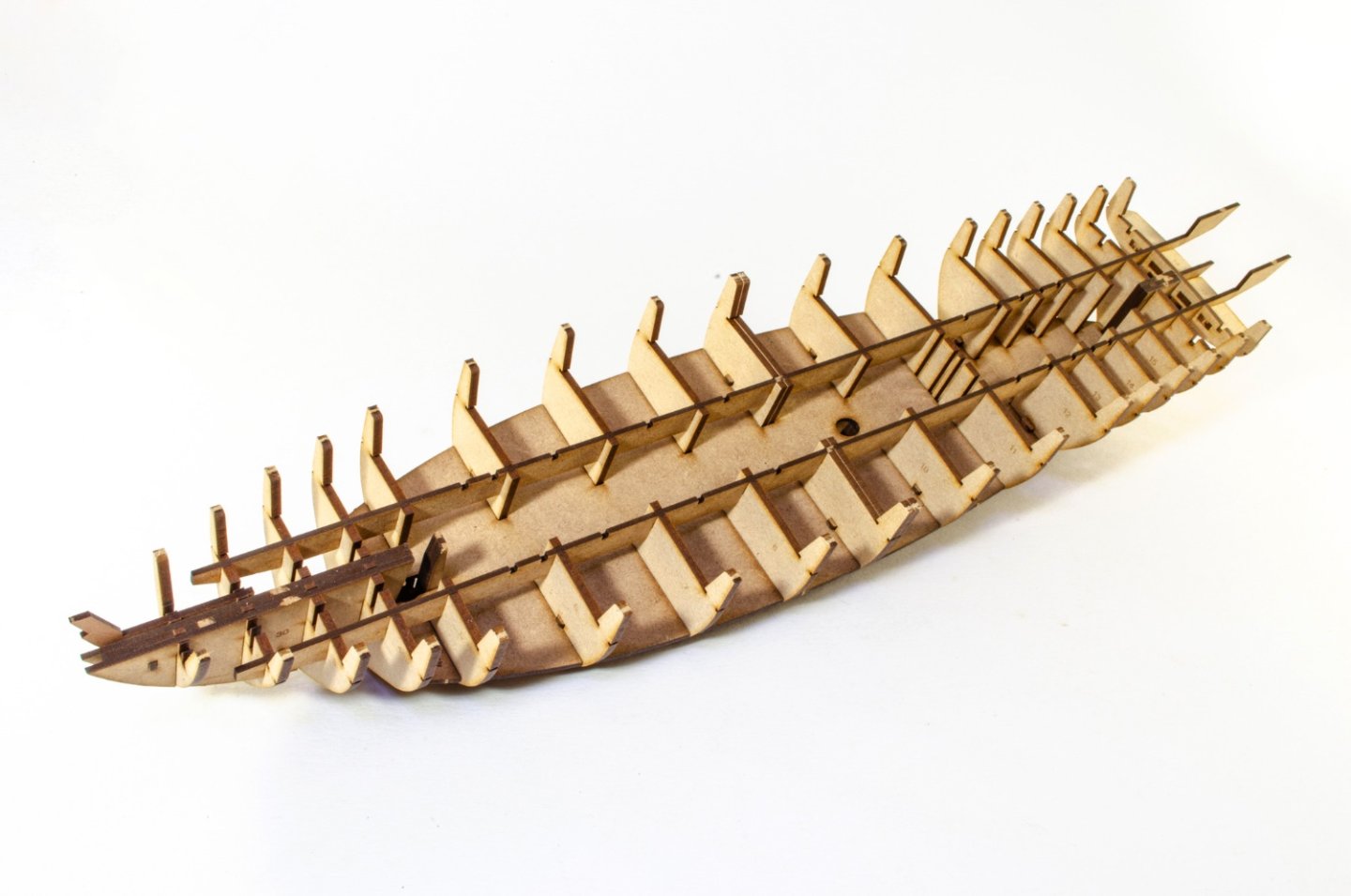

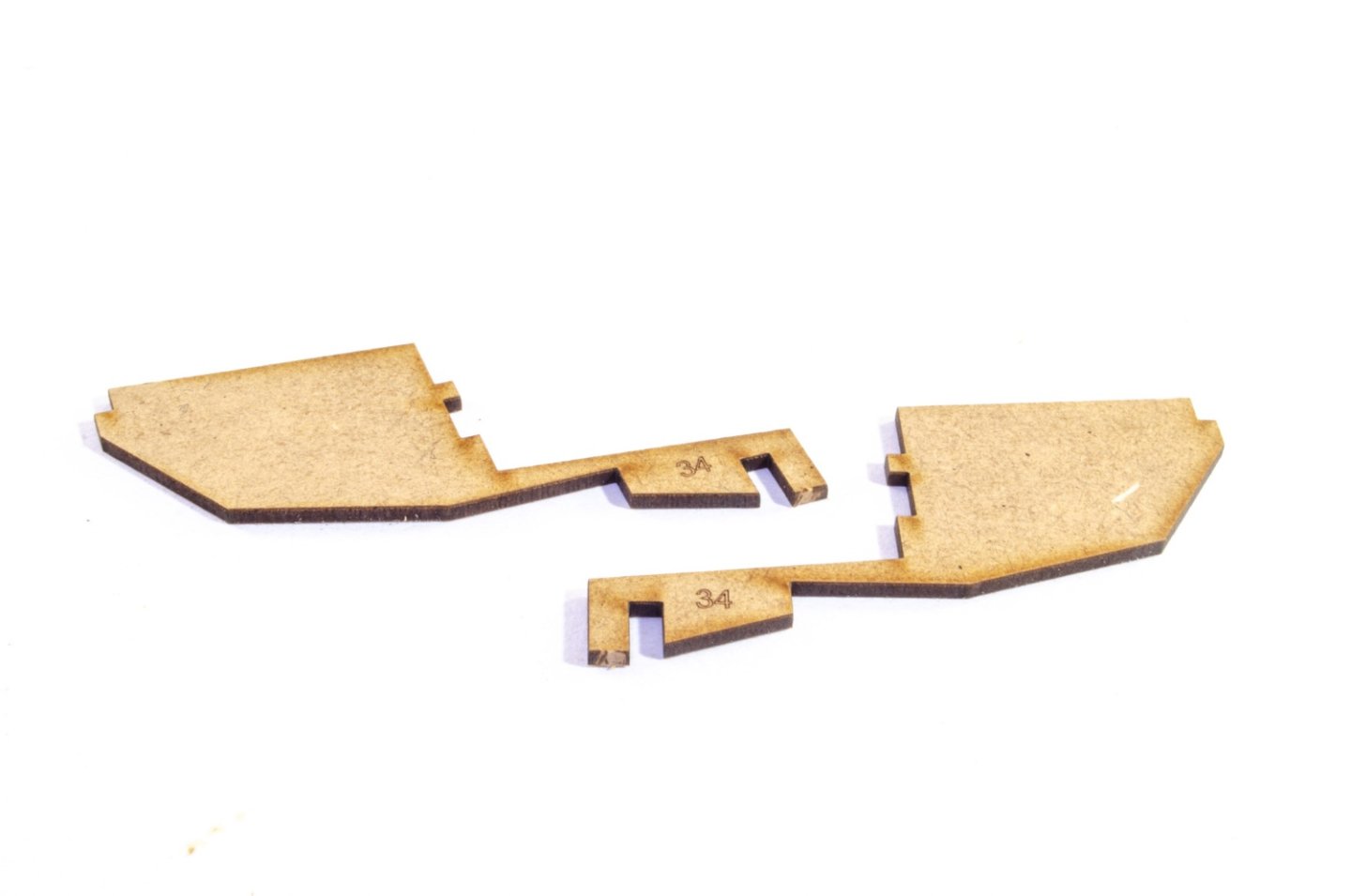

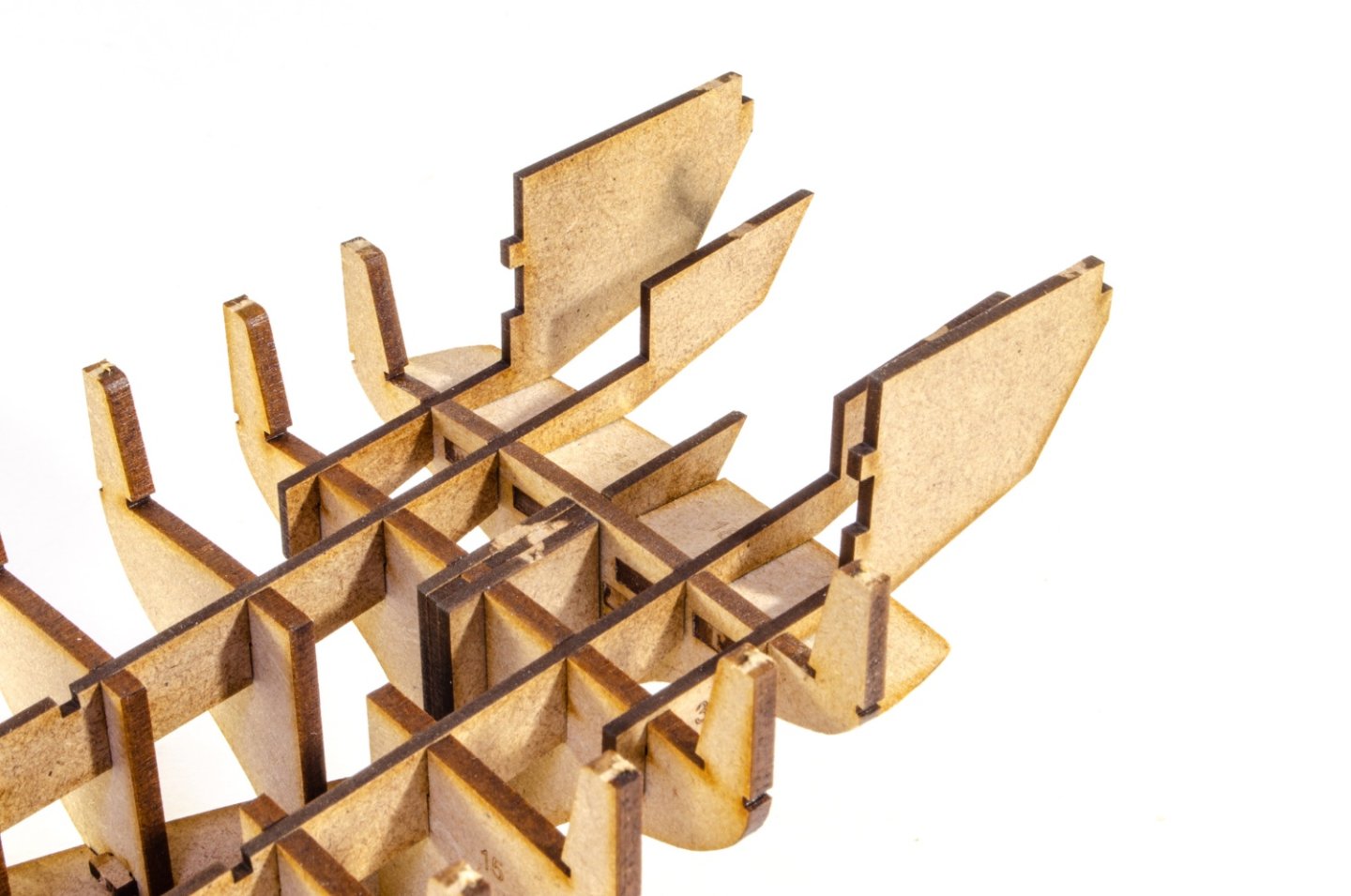

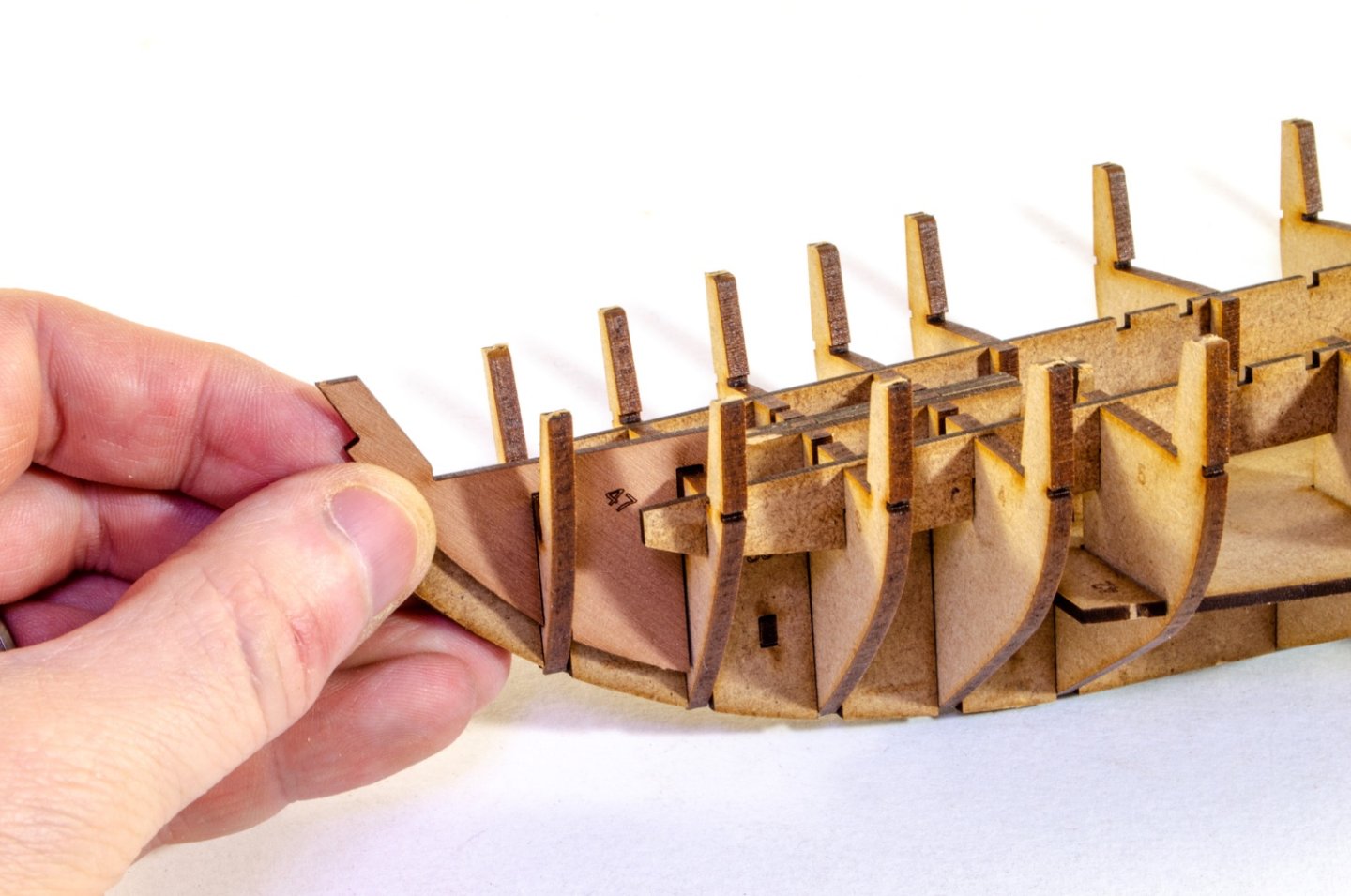

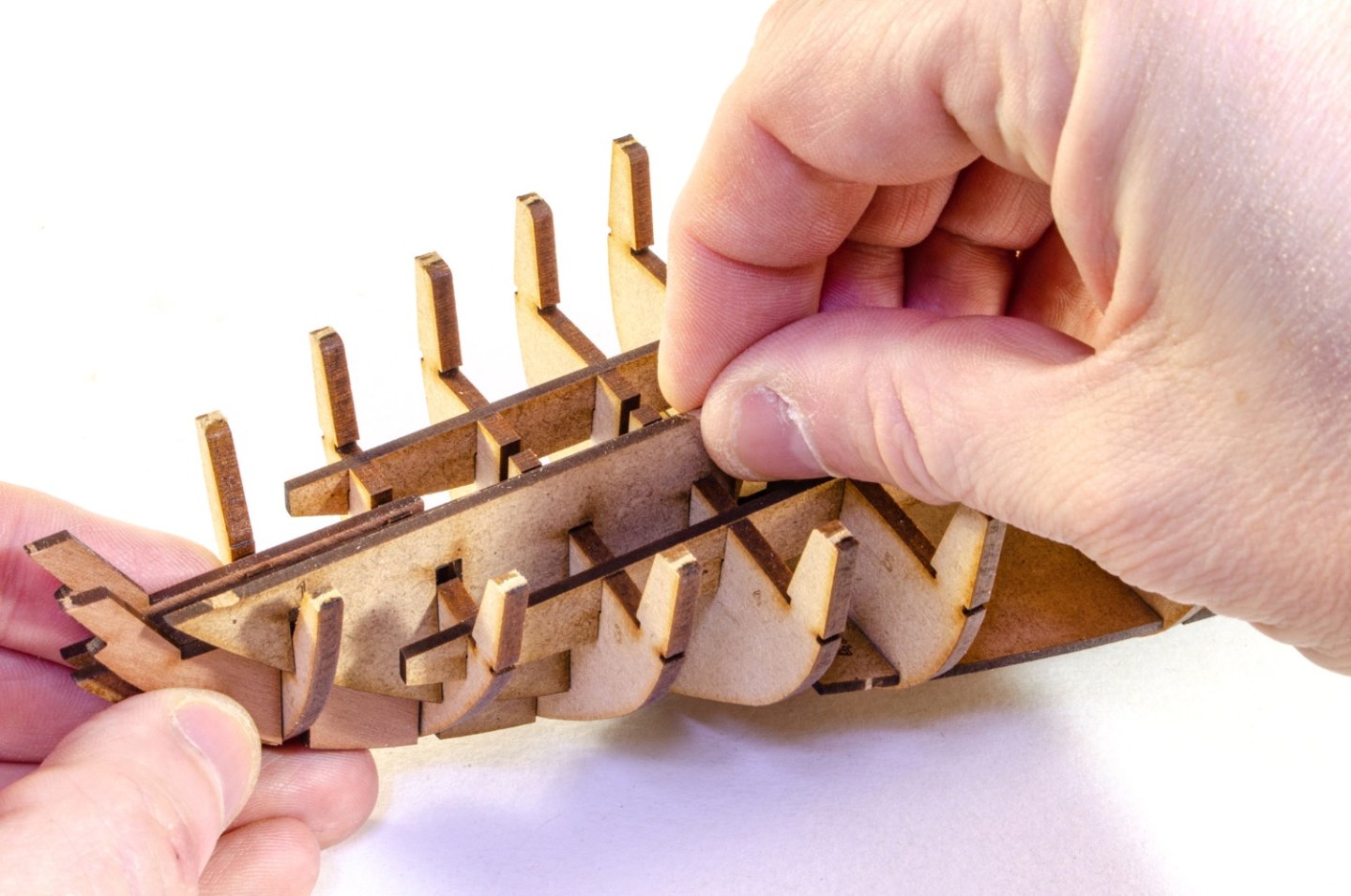

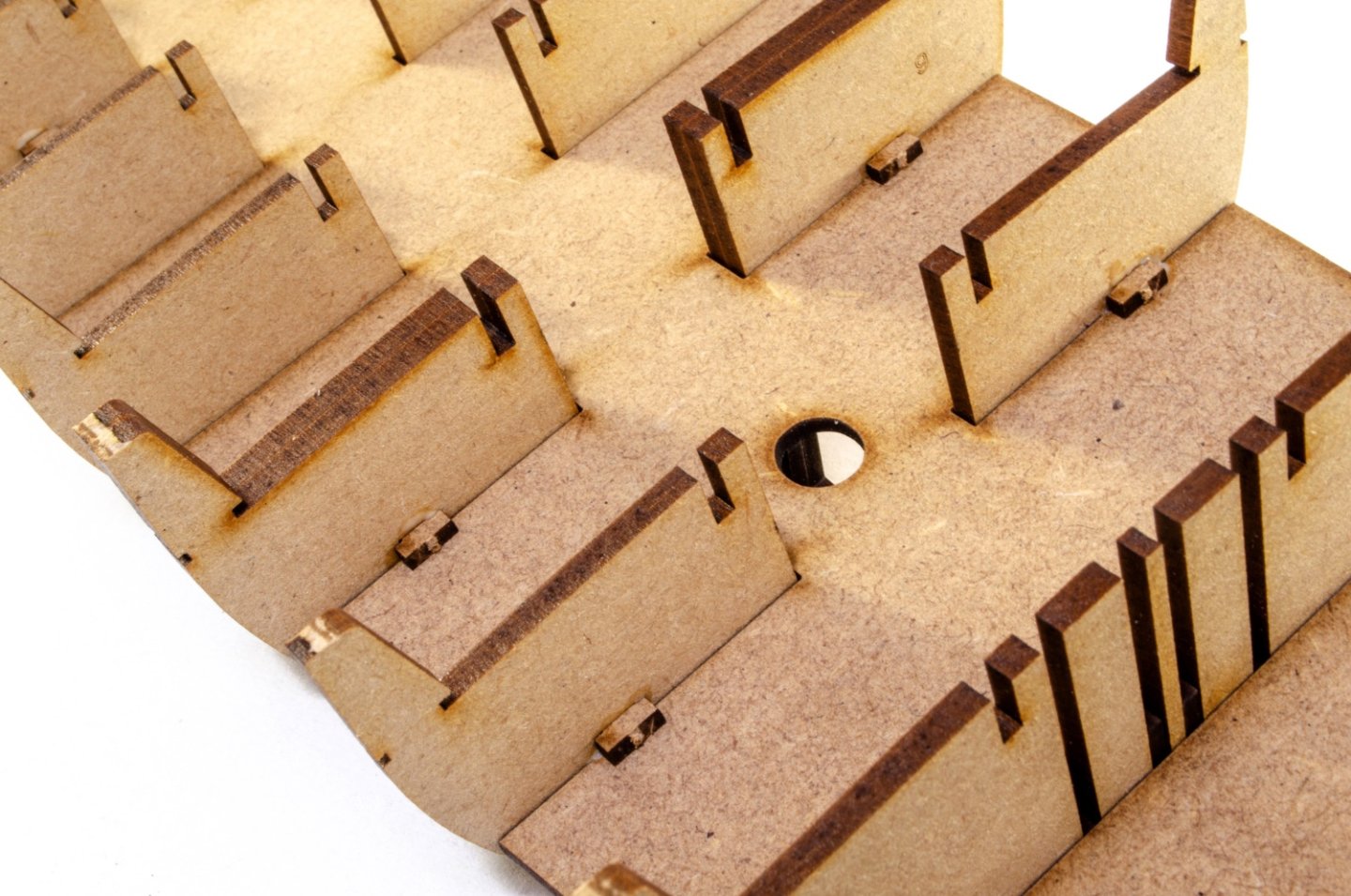

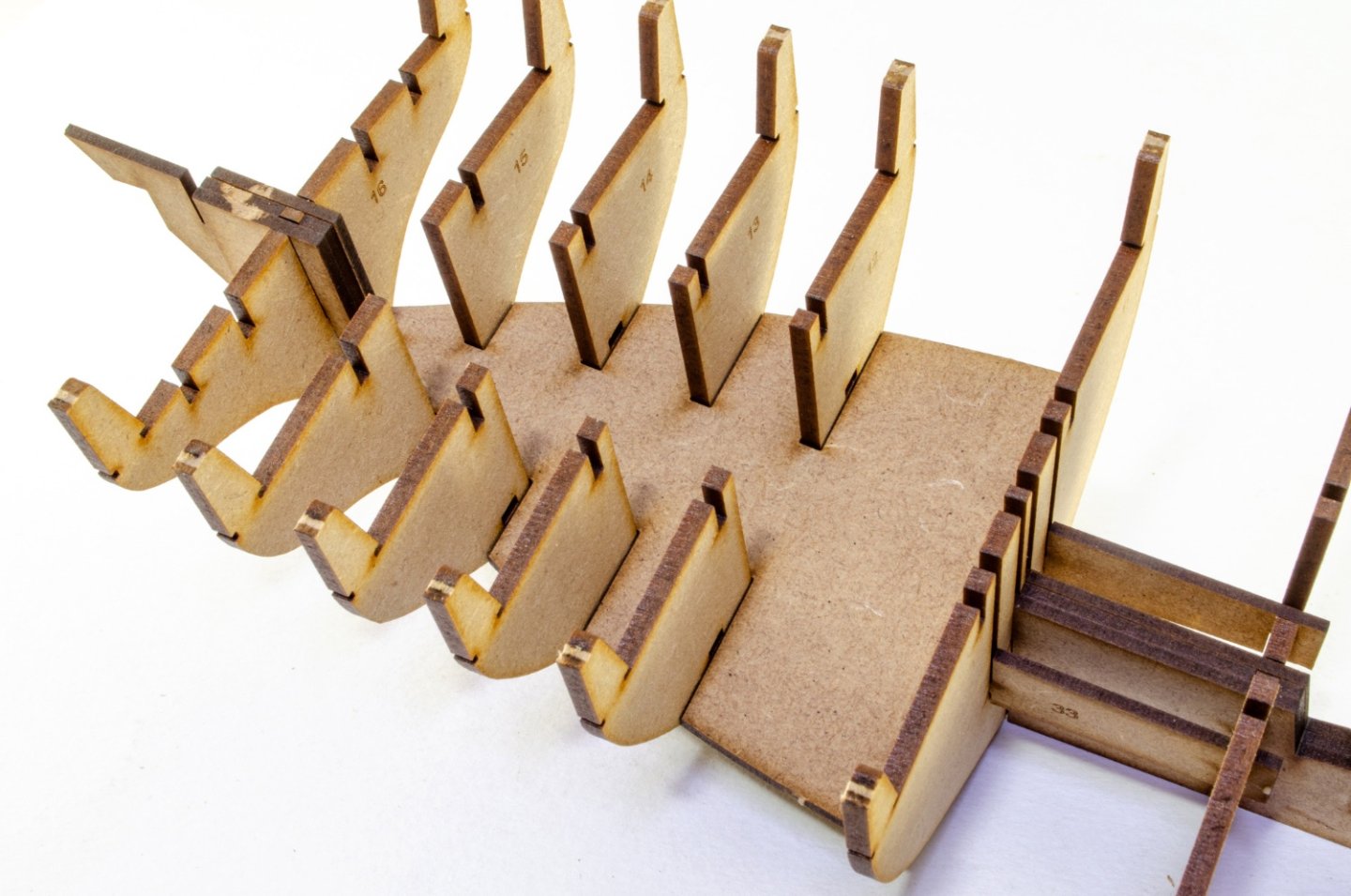

1:25 Drakkar ‘Oseberg’ Ships of Pavel Nikitin Catalogue # DROS002 Available direct for approximately £160 (7400 ₴) at time of writing History It is believed that the word “drakkar” originates from the Old Norse words “dreki” and “kar,” which mean “dragon” and “ship,” respectively. The warship acquired this name because the head of a dragon or another mythical creature (like Jormungandr) usually adorned the ship’s bow. The shape of the ship was also long and narrow, resembling a sea serpent. The Vikings constructed drakkars out of pine, oak, or ash wood. They used a special technique for splitting trees along the grain. They then watered the planks and held them above a fire to make them more flexible. The shipbuilders put the parts of the ship together with iron rivets and nails and bound them with cords and ropes. After that, they tarred the whole structure and caulked it by plugging holes and gaps and making the seams watertight. The sail was rectangular or square. It was made of sheep’s wool and covered with grease so that it didn’t get drenched. If there wasn’t a fair wind, the Vikings used oars – 20 to 35 pairs of them. In the Viking age, few ships could compete with a drakkar in terms of sheer speed, but drakkars were also very nimble. Thanks to the drakkar’s shallow draft, the Northmen could easily sail along rivers and fjords. They could land in places that were very difficult to access and attack their enemies unexpectedly. These warships were also barely visible between the waves because of their low sides. This helped the Vikings catch their enemies unawares, even in the open sea. Drakkars were created for more than just war, however. They were solid and capacious, so the Vikings sometimes used them for trade and to transport goods, but more often these ships were used for sailing long distances. How far did the Vikings travel? They reached the shores of Iceland, Greenland, and North America, to name but a few destinations. (Abridged from Vikings: War of Clans) The kit We’ve not exactly been awash with good kits of what we would call a typical Viking drakkar, or ‘longship’ as it’s more commonly known, despite the actual ancient translation. The Amati and Dusek are the kits which most come to mind. Pavel Nikitin’s new kit is also the largest in scale of this iconic vessel, weighing in at a whopping 1:25 scale! That equates to the following sizes: Length: 865mm Width: 430mm Height: 480mm Like the San Bartolome kit I recently looked at, the Drakkar is a second reworking, bringing a number of improvements over the original release, such as laser engraved ‘carved’ details on the bow and stern, including the ‘curls’ at each of those points. On other kits, this is where you would normally see such things as a dragon’s head, but this ship does not carry them, as per the actual recovered ship. I think in some respects, this was perhaps not as per a normal drakkar, but I could be wrong. The kit itself is packed into a slender but heavy corrugated box with a flap-opening lid depicting the finished model in all her glory, fitted with striped sail and 28 shields of varying décor. Inside the box, the various sheets are grouped into packages that are wrapped in cellophane, or ‘clingfilm’ as we know it in the UK. This keeps the sheets very tightly together. There are around 40 sheets of materials to build the drakkar. But that’s not all. Included with the ship is a very sturdy MDF jig which will most certainly aid those tasks that would otherwise be difficult, such as adding those clinker planks. As with other Pavel kits, this one also includes a homemade MDF and acrylic parts box, with the part numbers clearly engraved on the sliding lid. This box includes different sizes of high-quality rope in differing sizes (no fuzz!), 3d-printed boss heads for the many shields, cleats etc. The first task for the builder is to assemble the jig before then embarking on building the bulkheads. The bulkheads consist of a lower half into which a dovetailed upper half is fitted. The most outboard parts of each bulkhead are also separate parts. On the sheet, these are shown adjacent to their position on the uppers, with arrows depicting the location. This will add a little strength to the outer bulkheads, plus that change in grain direction at that point, will also help. There are also engravings on the completed bulkheads which denote where you need to pre-bevel the bulkheads prior to installation on the keel. The keel itself is a multipart assembly, with dovetail connection points. The bulkheads will be installed to the keel, inverted upon the building jig, and here is where the hull will sit until fully planked. A drakkar has a single mast and spar. These are provided as laser-cut/tapered parts that you will need to round off. Looking at the shape of these parts, then this is a welcome touch. Strips of dowel are also provided for the numerous oars. The paddles for these are pre-cut. For display purposes, a stand is also included, as is an engraved plate with a serial number. The kit is 00009. I am informed that the timber for this kit is a combination of walnut, cherry, alder, and beech. The instruction book is 28-page spiralbound A4 production with a protective plastic cover. The first part of the manual is text which relates to the numerous stages. Those stages are presented in drawing form in the second half of the manual. The drawings do appear to be nice and clear, and construction takes place over 68 stages. Inside the sleeve of the manual is a piece of laser-cut paper which contains three profiles which are designed to lay against the laminates that form the ‘fish’ or mast base. These are laid on at various stages and shaped to them. One plastic sleeve contains three nicely printed plan sheets which show the drakkar in various profiles, and in rig etc. The second wallet contains a single printed piece of material for the sail. You will obviously need to cut and stitch this yourself. The photos show this brightly painted, but I’d read that these were usually quite dark as protected with tar due to the expense of the sails back in days of yore. I do admit that the painted sail looks beautiful, and I’d probably go with that. The size of the sail is really quite an indicator at the size of this model in a large 1:25. Conclusion From both appearance and materials, this kit stands head and shoulders above other contemporary kits of Viking drakkar, by a very wide margin. Being based on the Oseberg remains, she also appears to be the most accurate of all of them too. The timbers used in the kit are stated as imitating those of the real vessel, which may have been the case, but the ships themselves were coated in tar and would’ve been quite dark. I suppose the final choice would be for the modeller. I would probably go for the tarred look. In all, I’m seriously impressed with this kit and Pavel’s determination to improve what already looked like the best kit available for this subject. All the small touches like the 3D shield bosses and the highly detailed laser carvings instead of the usual white metal fayre, really sets this apart. If you’ve ever had a thing about Viking ships or just want to build something a little different, then I really recommend this new release. *It was found that the kit had planks which were slightly too narrow to overlap properly. Pavel is now sending over replacement plank sets so I can eventually have a shot at building this lovely model kit. My sincere thanks to Pavel Nikitin for sending this kit out for review on MSW. To buy directly, click the link at the top of this article. -

The barrels are inserted at the very end and are easy to sit on the carts. I used CA gel.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

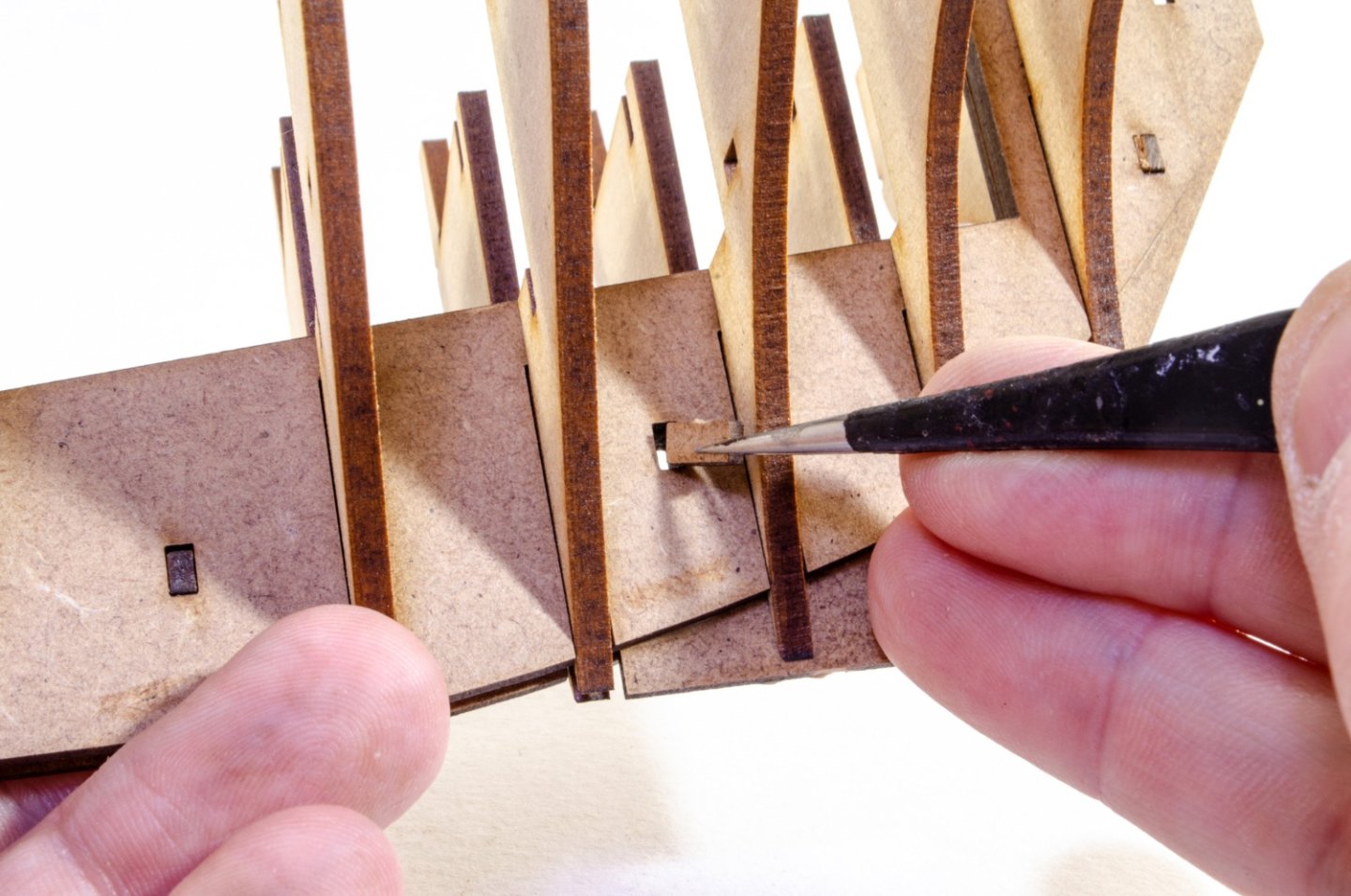

I know it looks odd before fairing, with all those port parts stuck out, but all looks correct to me.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

It’s only a case of removing a majority of the material and not in sanding to final shape. With a hull this size, that really pays off!

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

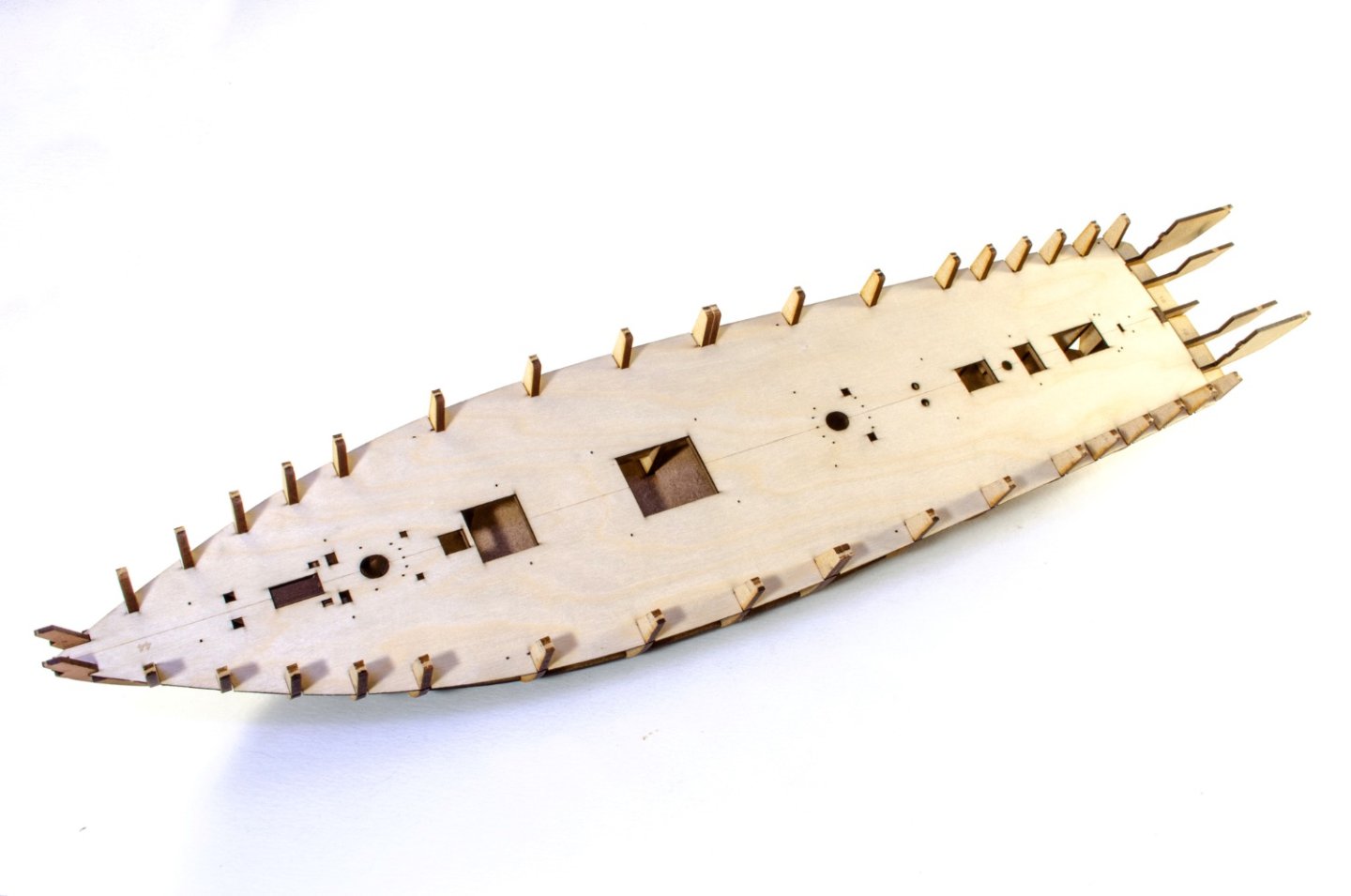

That’s just the ply deck. The engravings are to help with placing the planking strips.

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

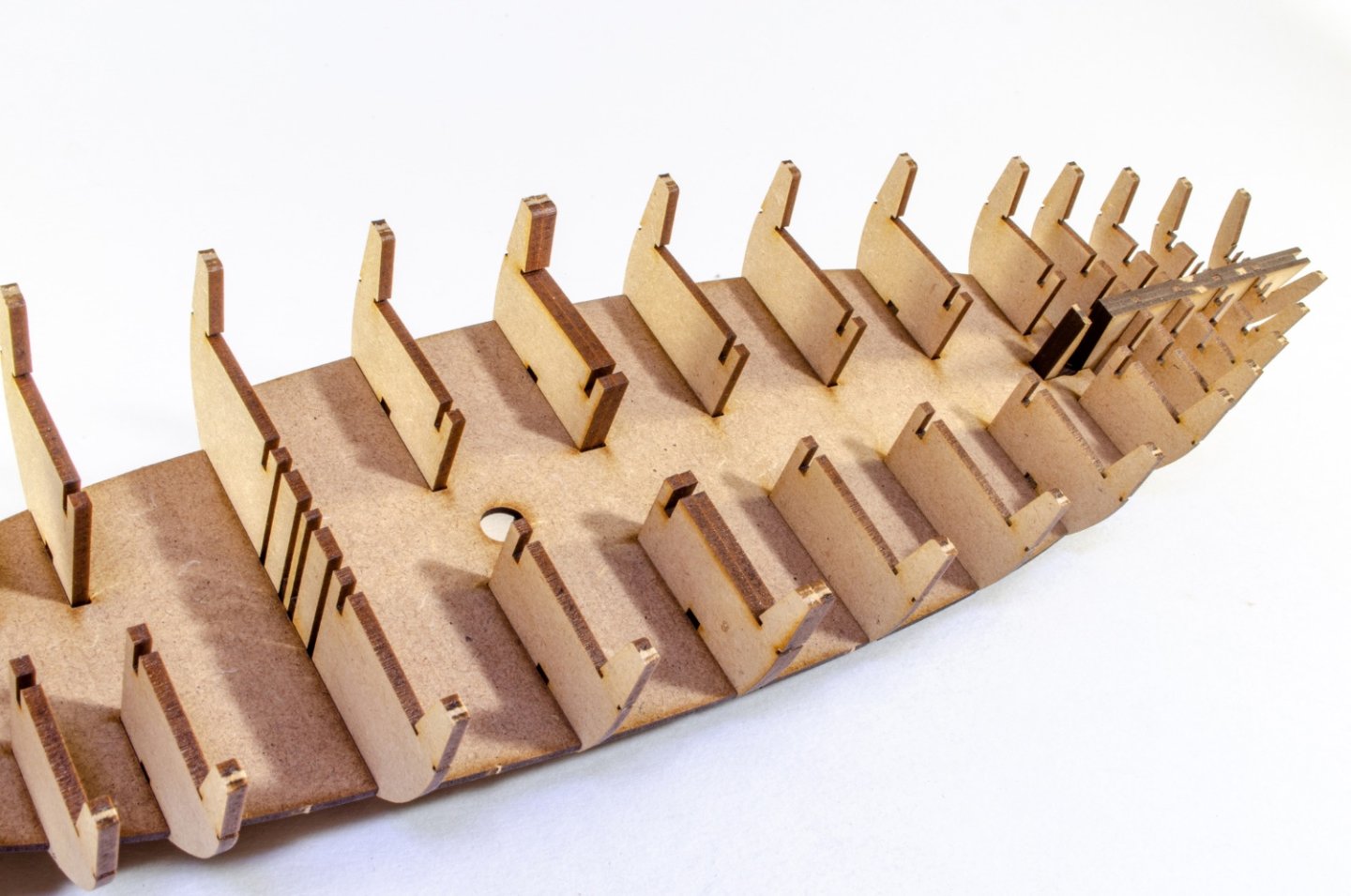

Yes, those beams will just be discarded later. They do a nice job of keeping the bulwarks at the correct width during planking.

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

You'd need an endoscope to see anything down there 😆

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

She really is just beautiful. Skills I could only dream of emulating.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

What a great final product to have for the build! You really should consider doing an Indy in that format. Maybe at port anchor and being loaded with provisions etc? I only suggest it as I know it'd look great and I wouldn't be able to pull it off myself 🤣

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

That build looks real sweet! I hope you can share more with us, perhaps in a build log too?

-

Looking real nice. You'll notice how things will become much more solid with the frames now.

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

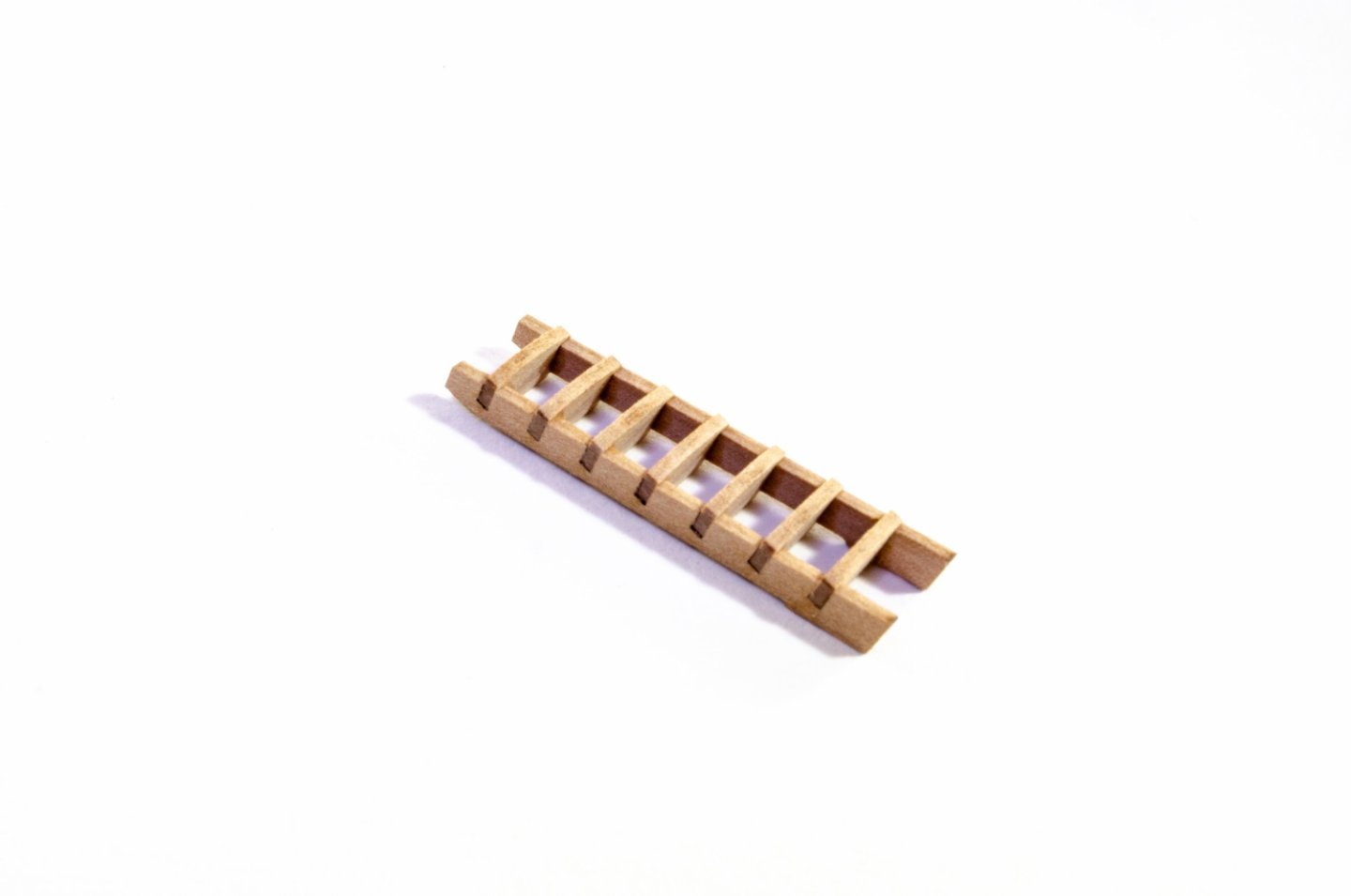

....more. As I've done quite a lot, I've very much abridged the number of photos for each stage. Binnacle. This is smaller than those I've built for British vessels but identical in construction. The chimney is turned brass as per Indy, Sphinx etc. A single ladder is now built for the deck hatch opening. Grecian will come with more armament than you'll actually need. This means that you will be able to choose the gun combination that you prefer, and we will supply options for you. These photos show the carronades and two sizes of cannon. All this before I actually plank the hull! Until next time.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

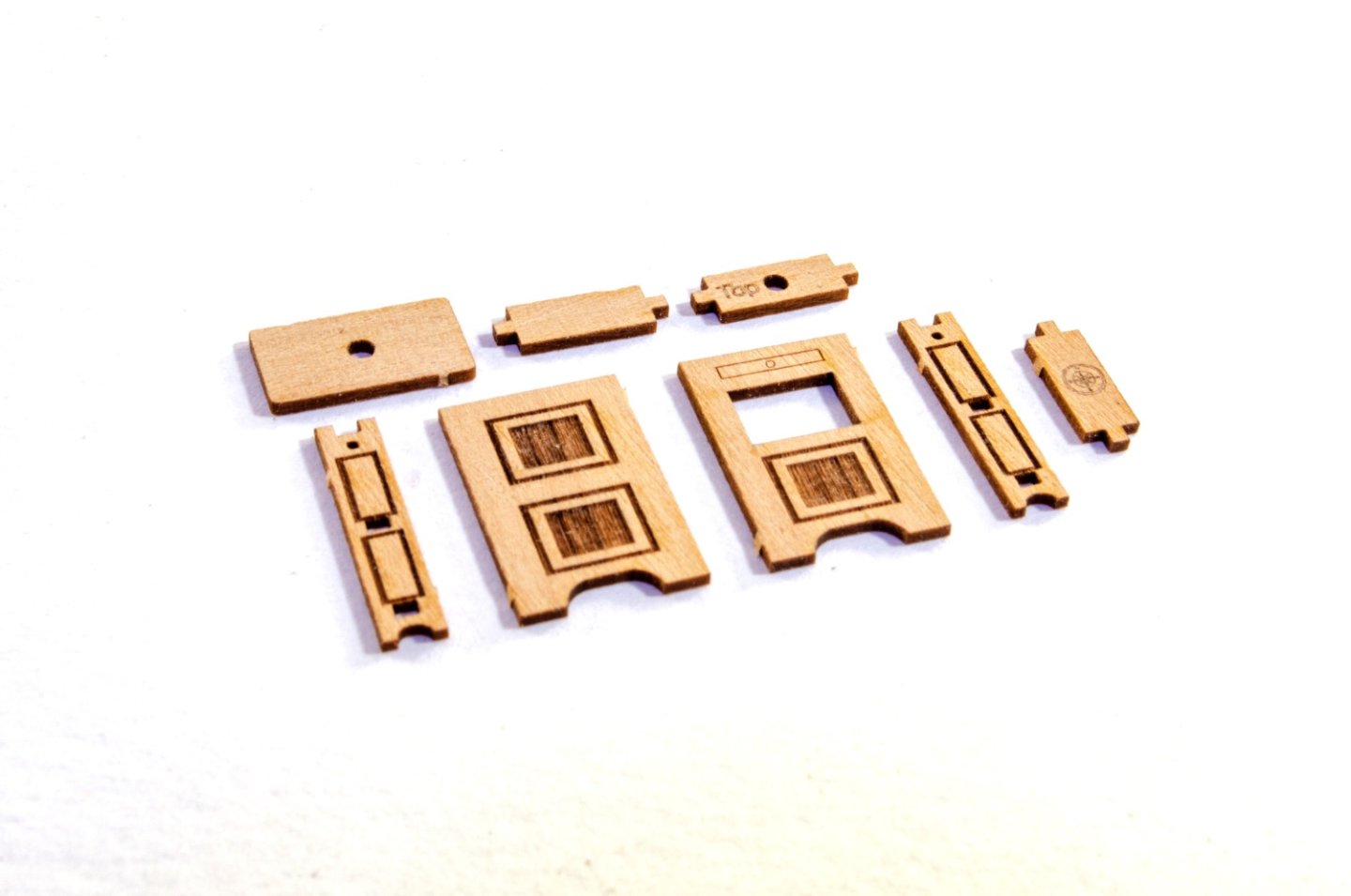

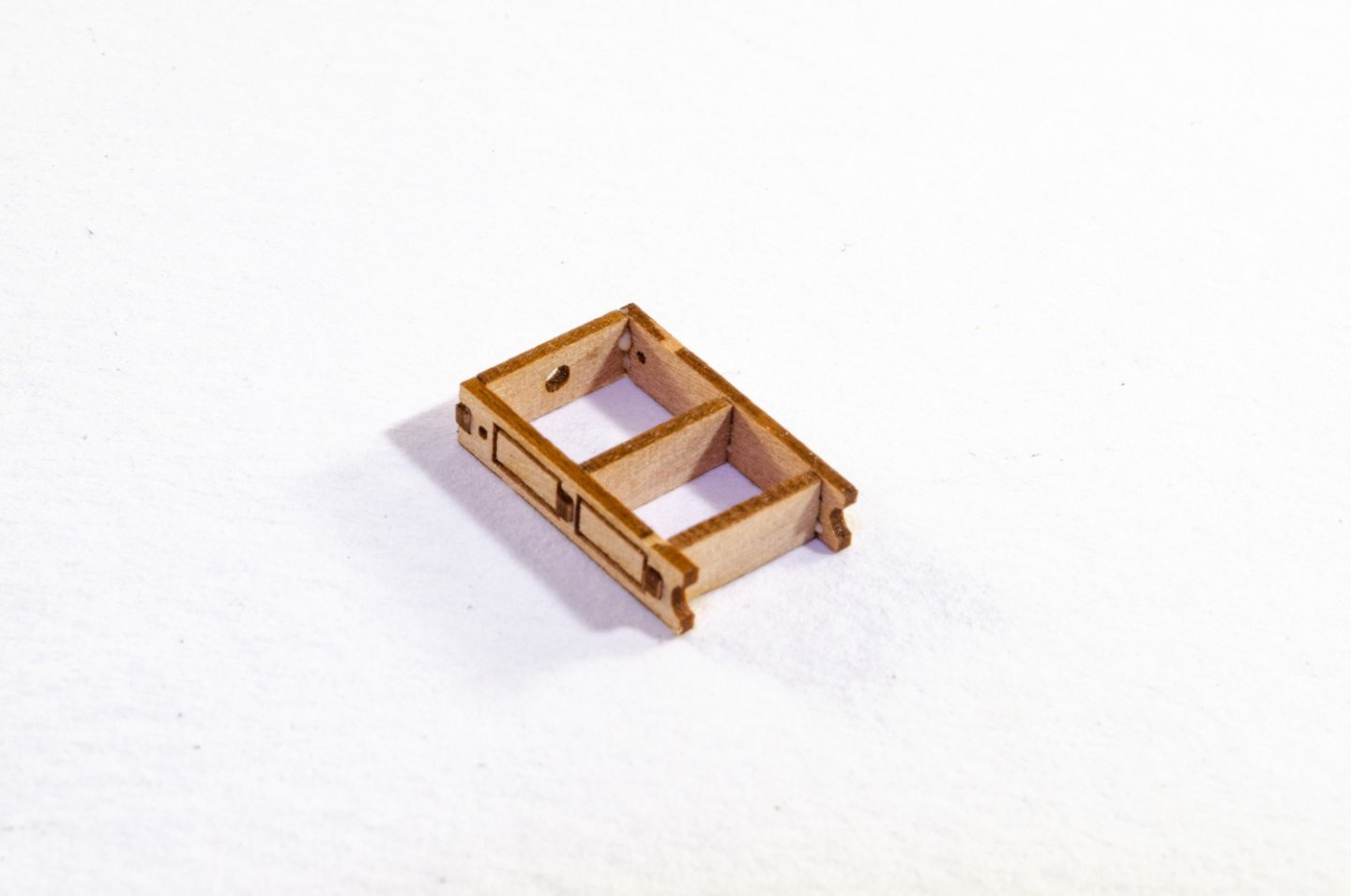

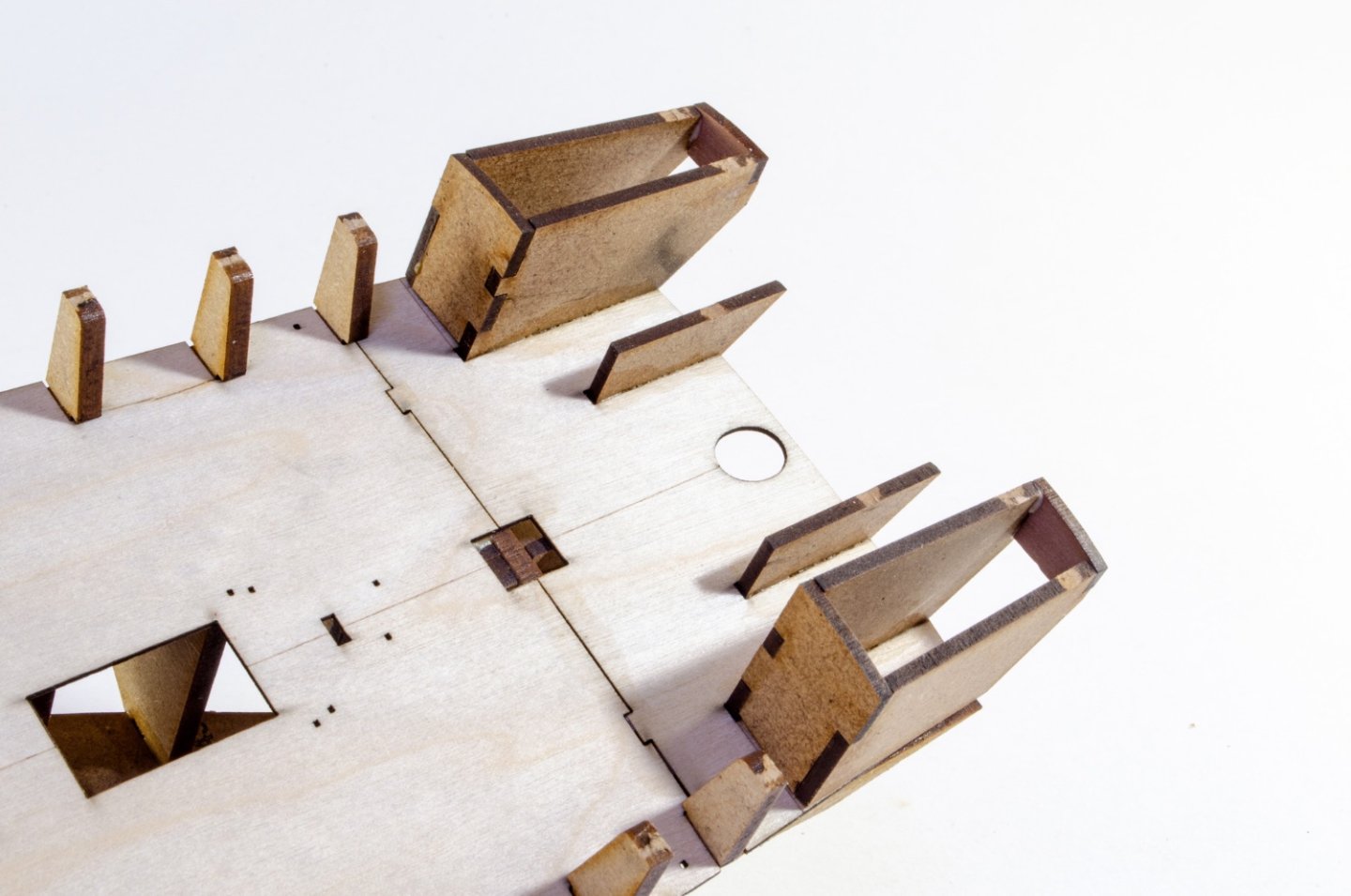

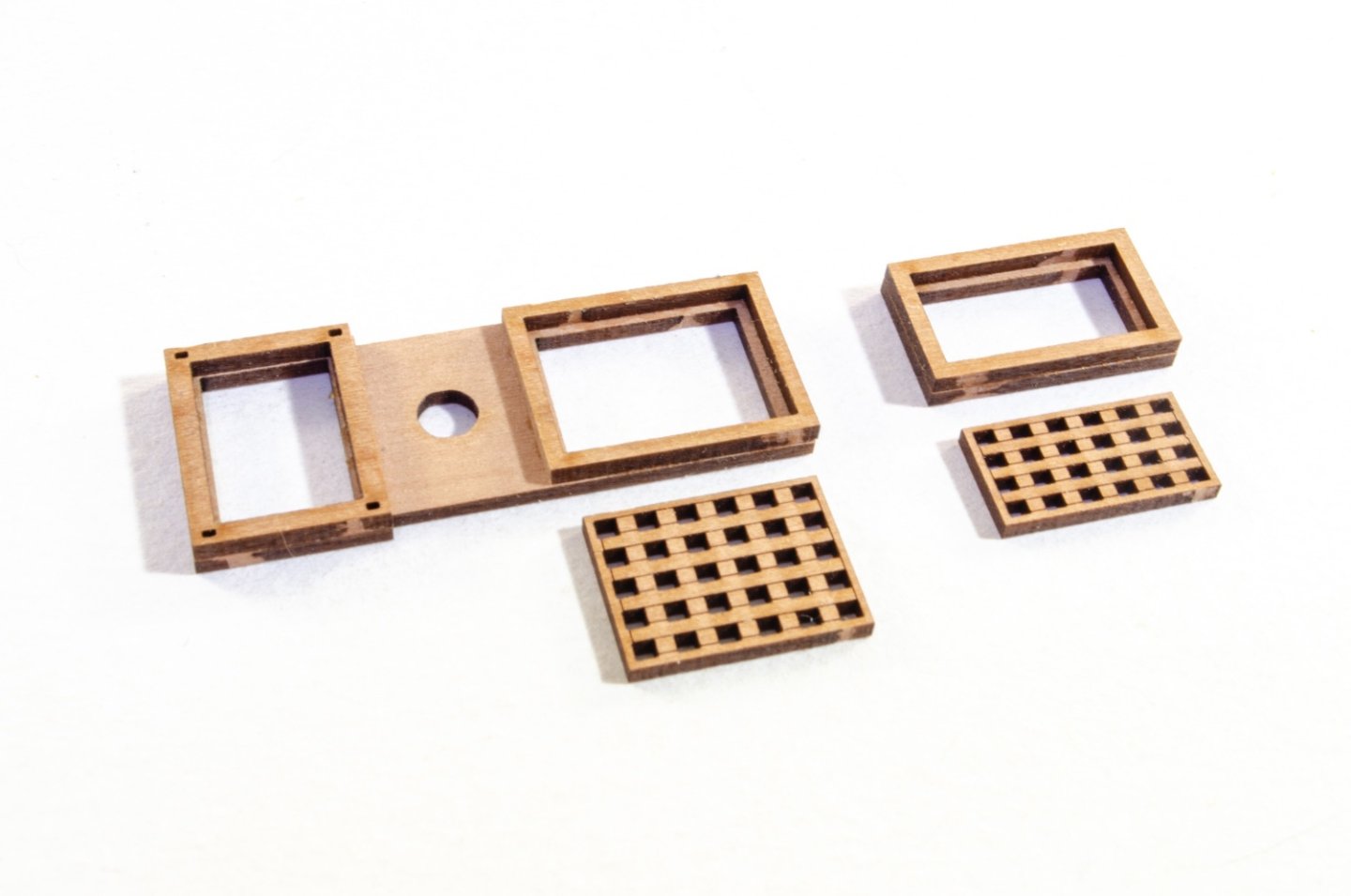

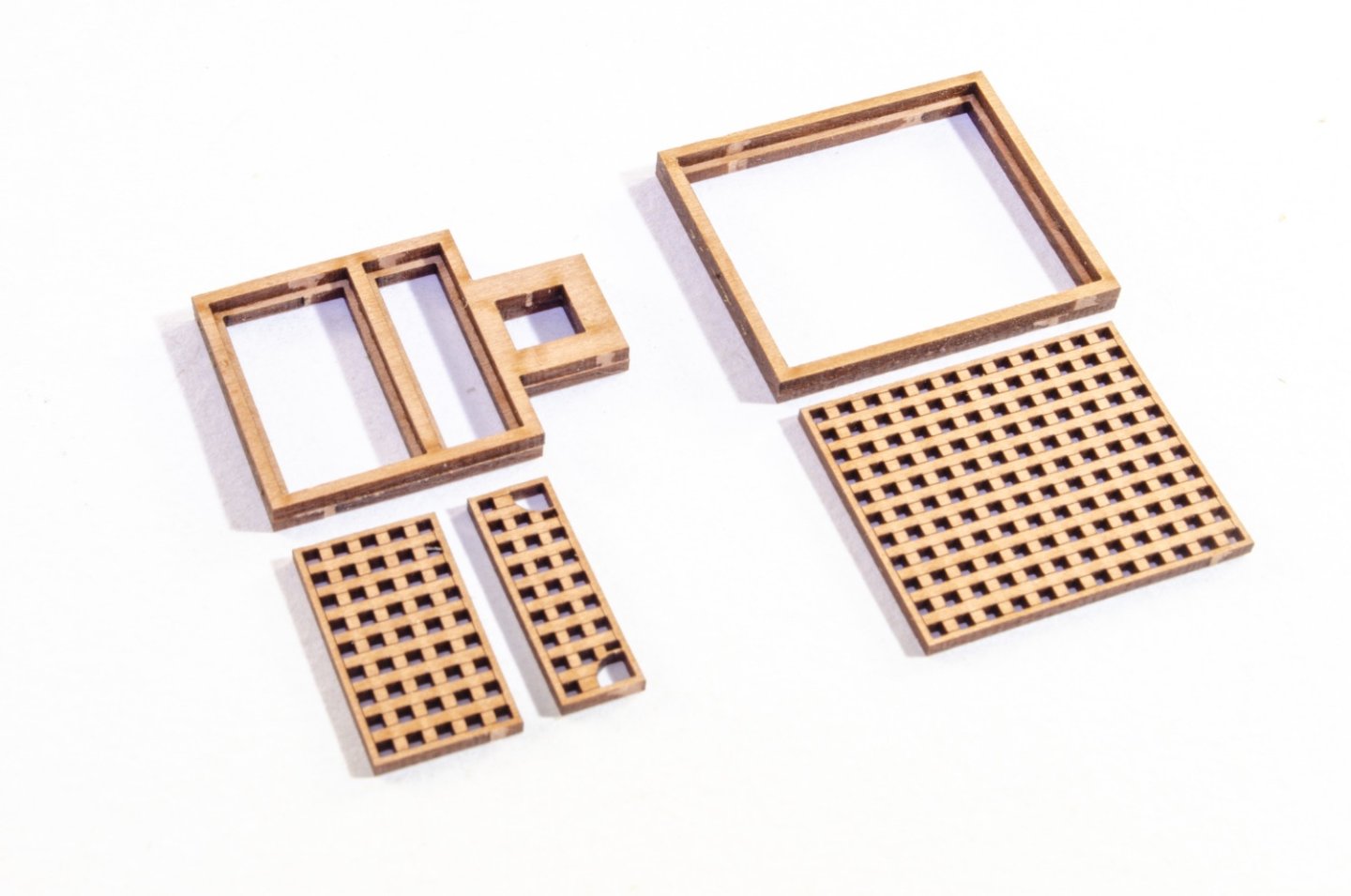

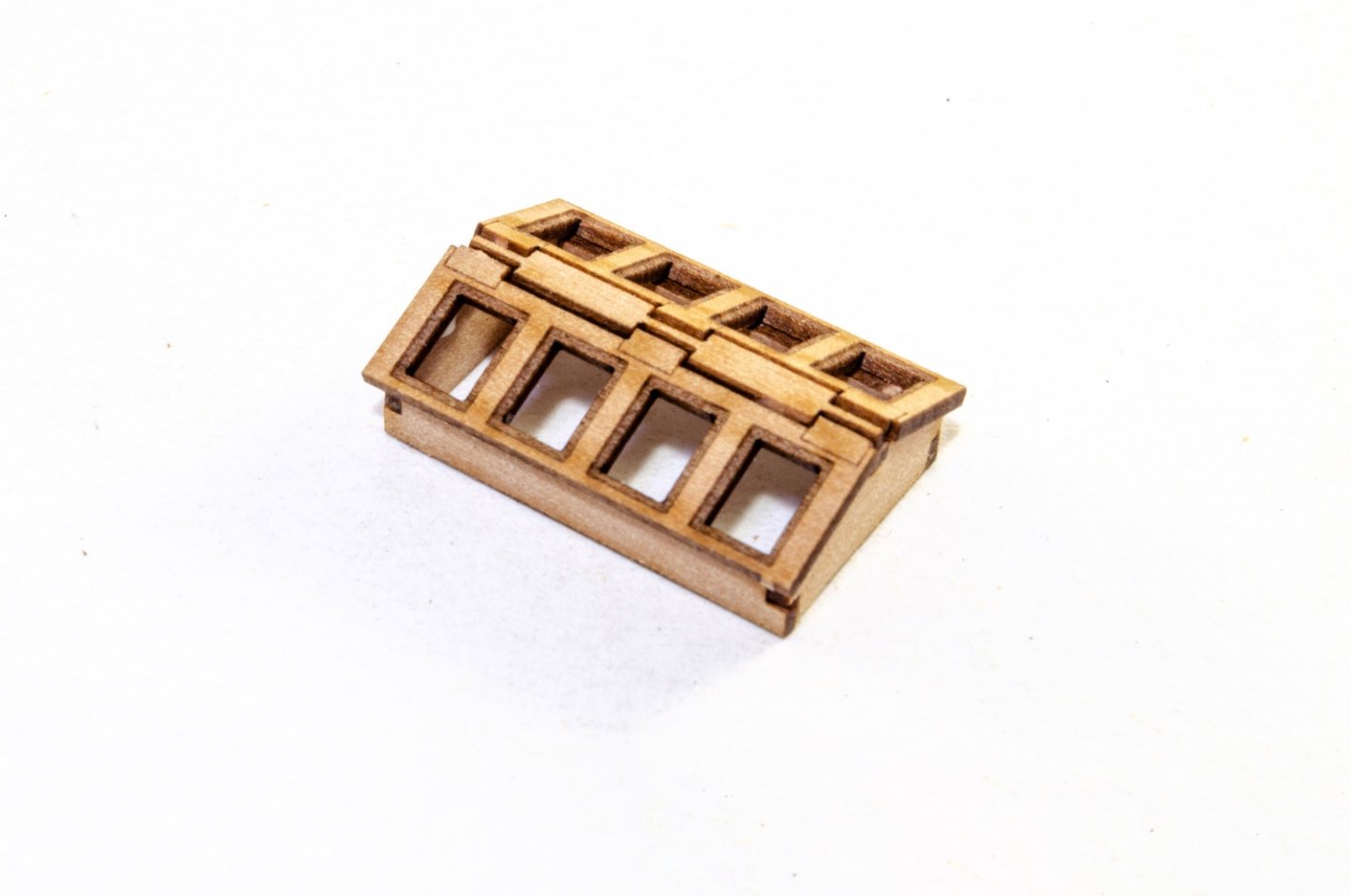

....continued. Like Indy, the hull can now be safely turned over as all parts are locked in place with the pegs, and also with the deck, in this case. Dilute glue is now painted into all the various joints and seams. Filler parts are added to both bow and stern so the planking as something to adhere to. Here you see the stern superstructures now being built up. One of these will be the WC and the other is presumably sone sort of locker. On with the coamings. These are nice and easy to build up. Once glued, the lasered edges are removed and the sides evened up. The grates are left out until the coamings are fitted to the deck. This simply aids correct positioning on the deck. Capstan. This is identical in construction to those on just about every other VM kit. They are so easy to build up and the fittings precise. Skylight. Although different in size to the one Iast added to Indy, the appearance is very similar, and the construction also nice and simple. PE parts are included for the hinges and window frames. The modeller can use a bit of acetate, if they wish, to glaze the panes from the underside.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

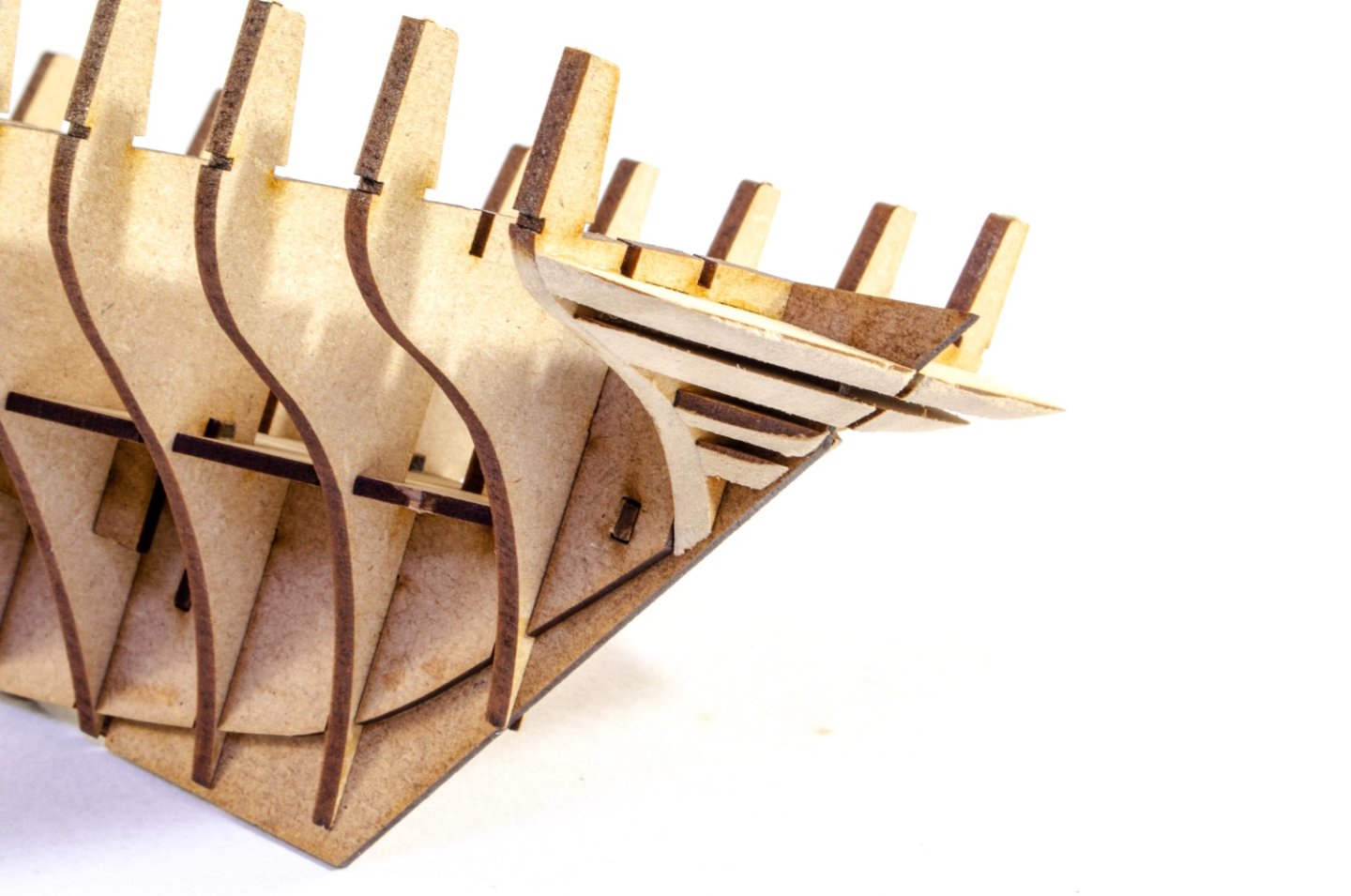

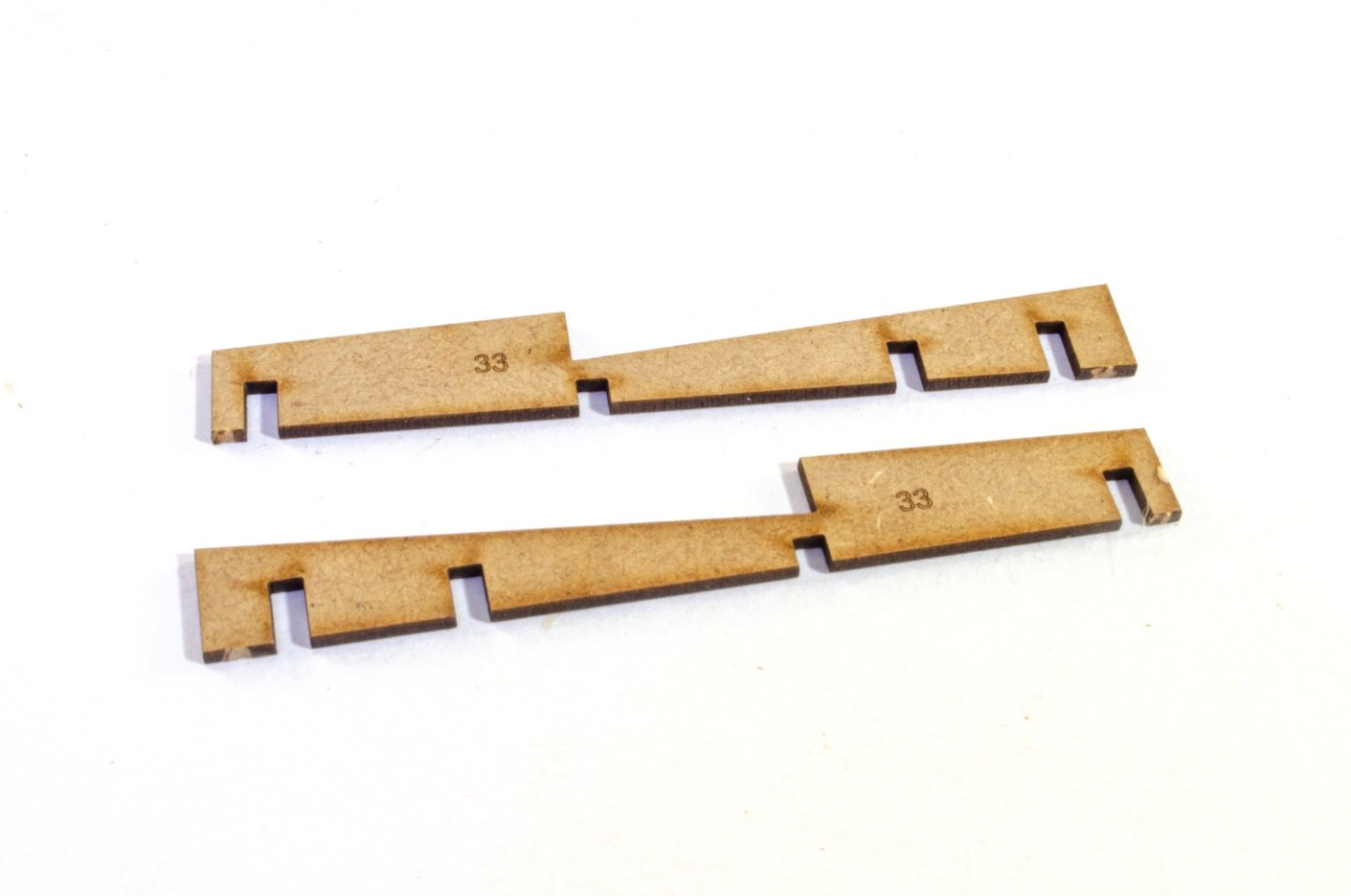

Update No.2. This will be in 3 parts as it's almost 40 photos. The hull is currently in a state of being faired, so I'll show the hull up to just before then, plus all the other things I've built up. Pre-bevelling was done on the stern section that I built in the last update, and this was then dry slotted into the bulkhead slot on keel. This can be finalised when the hull is being faired. Longitudinal bracing parts are now slotted across all of the bulkheads, except for #1. Again, this is dry fitted. No glue needed yet. These parts will further solidify the bulkhead positions. The previous parts incorporated a section of the poop superstructures, and the next two parts will add further elements of this. All will become clearer. At the bow, we have more parts that slot into bulkheads, creating the sides of the bowsprit entry point, and also to add fairing and planking. Beams are now fitted across the open bulkheads. There are three different types of beam, relating to the position and camber. A 0.8mm ply deck is now fitted. This is thin enough to be slightly bent and pushed into position into the slots at the bottom of each bulkhead ear. This usually gives a nice, satisfying click when finally located.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

She builds up fairly quick at this stage and seems to get more imposing by the hour.

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Just remember to taper those planks as you fit them. Take a few of them and soak them, then add a gentle curl into them also. That will help get those first ones installed a little easier if you're not used to working on them.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

...continued Those doublers are now pinned into place with a series of plugs. These are glued into position. Before the sub decks can be fitted, the need bolstering a little from below towards the stern. These two parts are now fitted which create a firm base for the sub decks. Those sub decks are now DRY FITTED into place. Now, we have a lot of unglued joints that could come apart, so this is stopped by gluing a series of plugs through the holes in the bulkheads, holding the sub decks firmly in position, and all the other parts in a perfect position. And the last in this update shows the final bulkhead, with the various forms glued into place prior to being shaped and secured to hull. ....until next time.

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.