-

Posts

6,139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

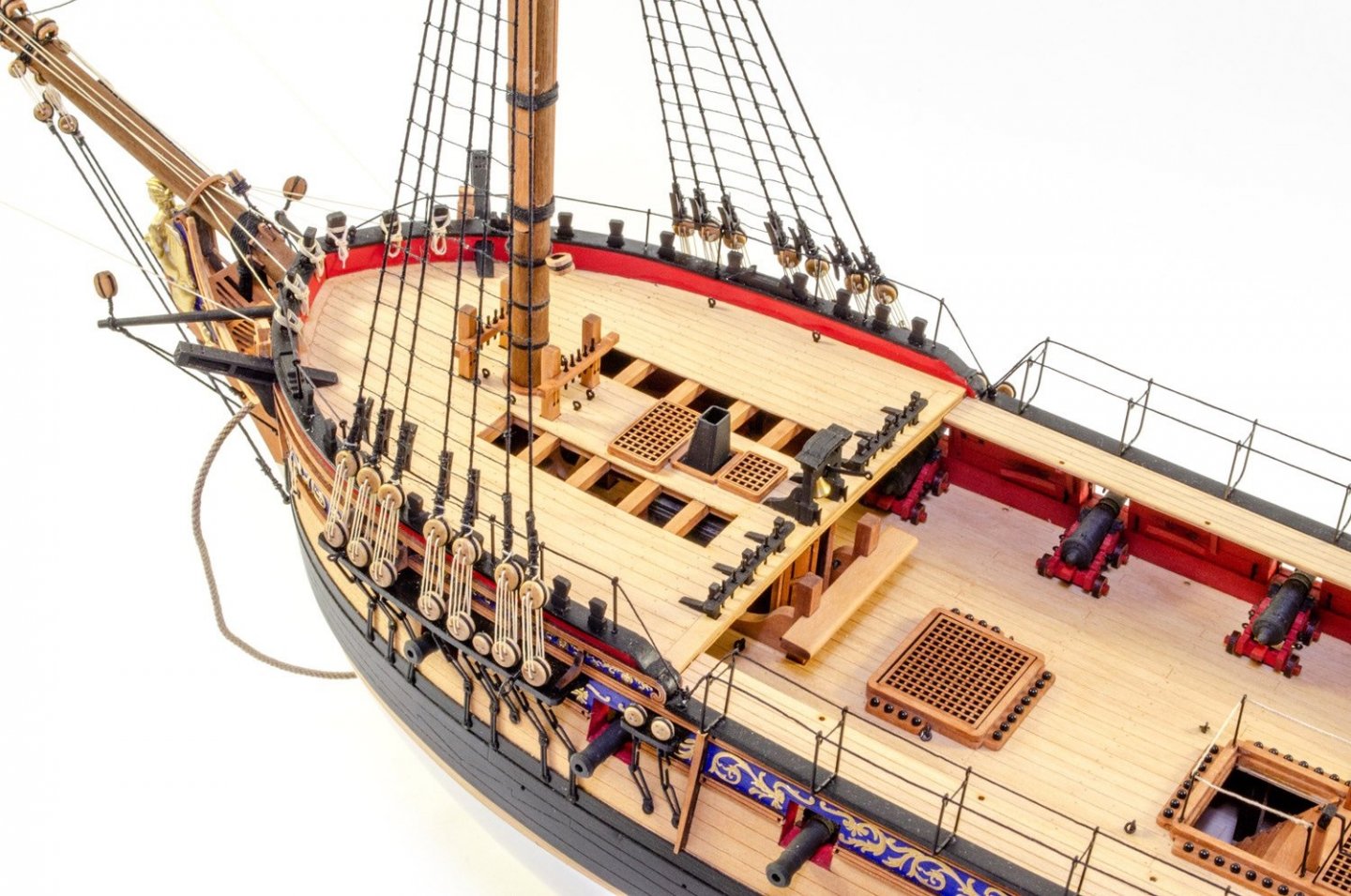

Bet you love ratlines! Weird there's a cannon sticking through the shrouds. I'd never noticed that before.

-

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

oh...and this has shrouds and ratline too 😝

- 36 replies

-

- vanguard models

- Erycina

-

(and 2 more)

Tagged with:

-

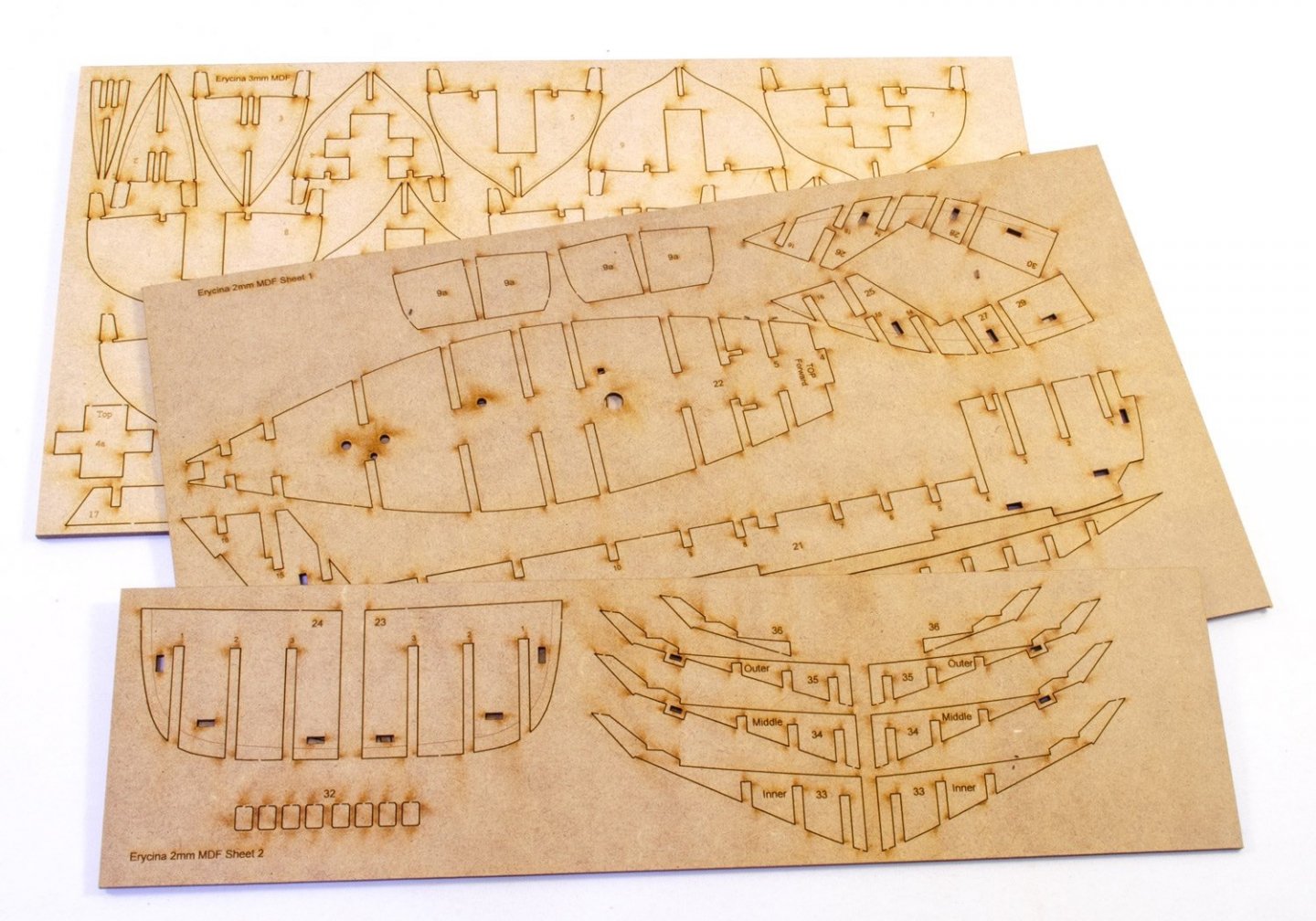

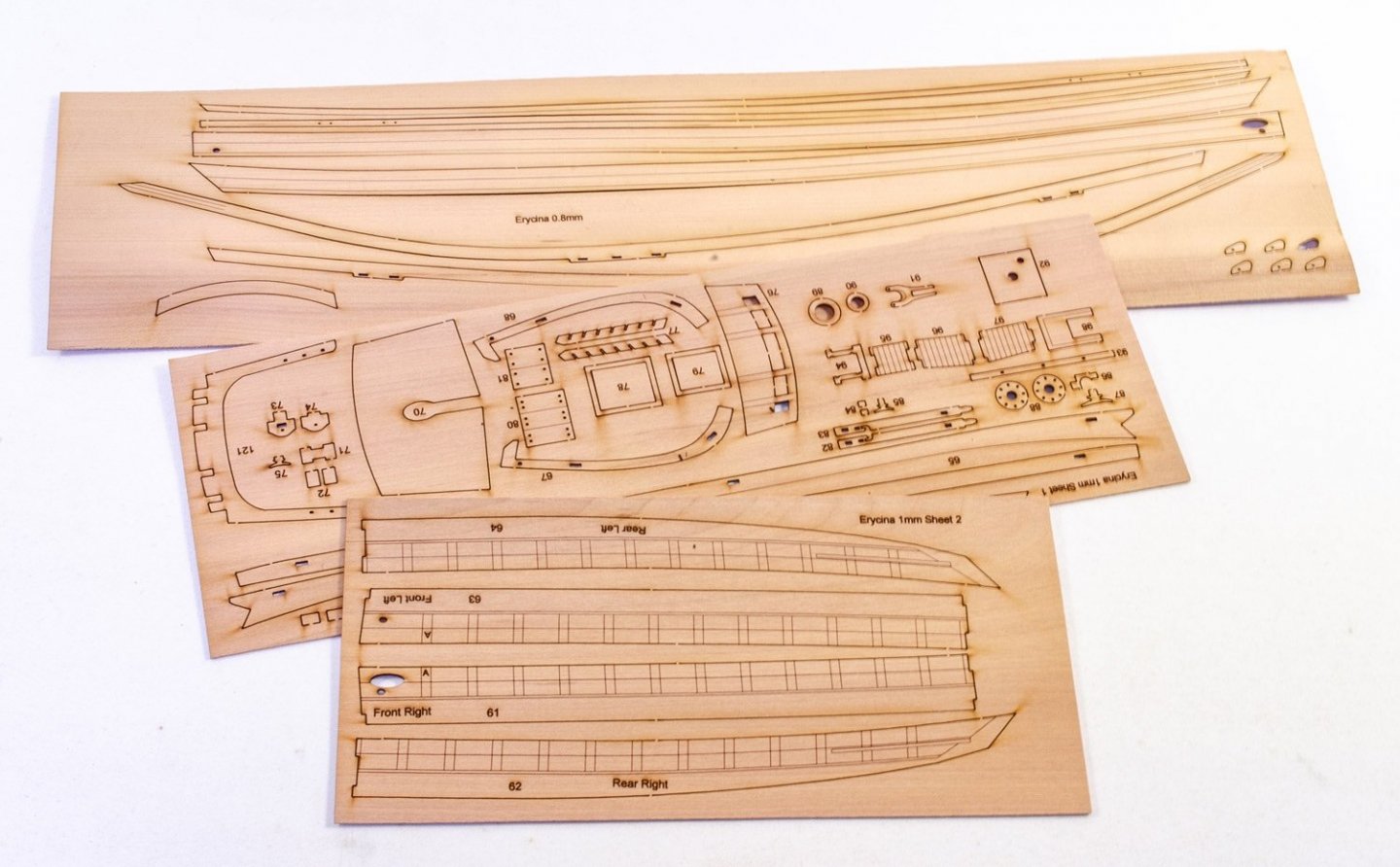

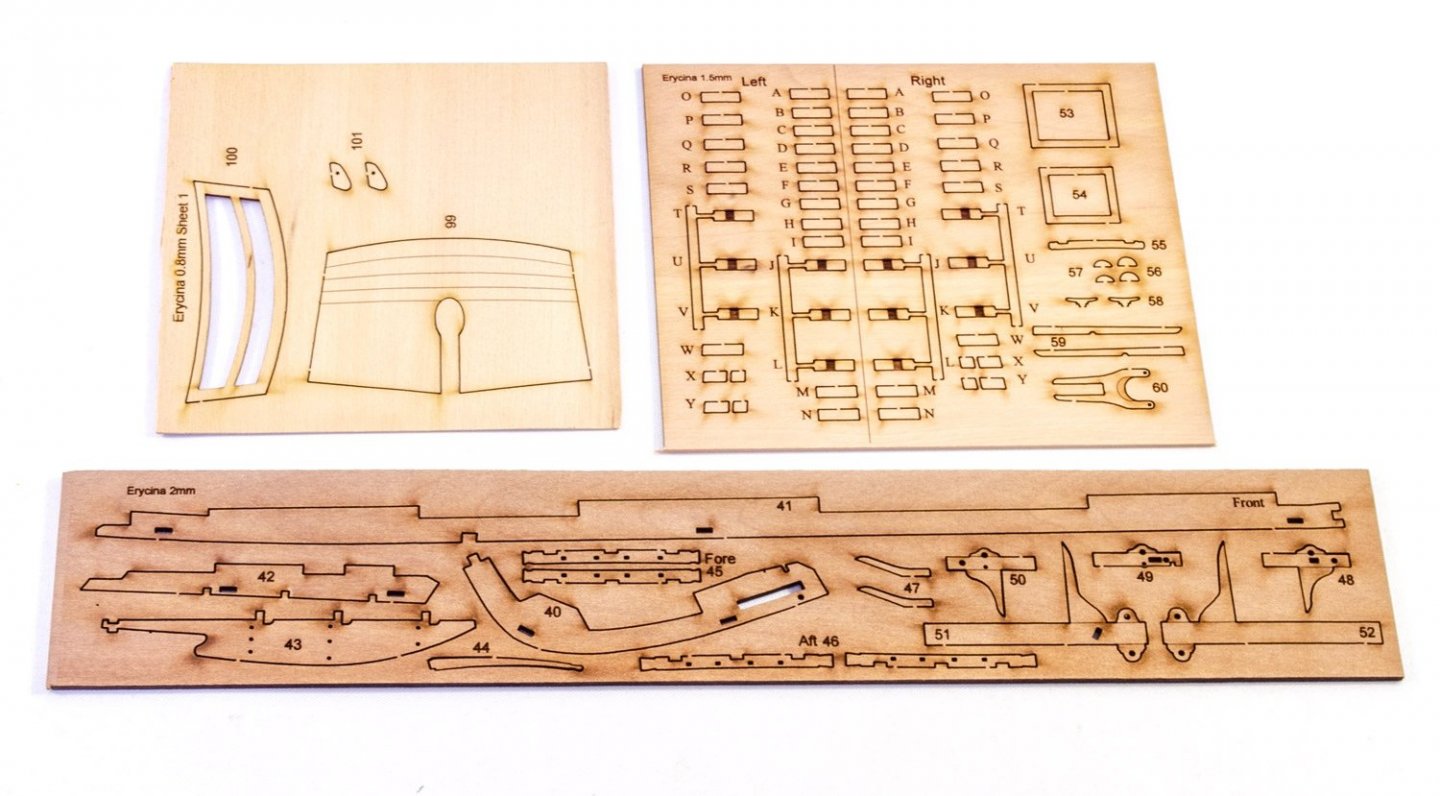

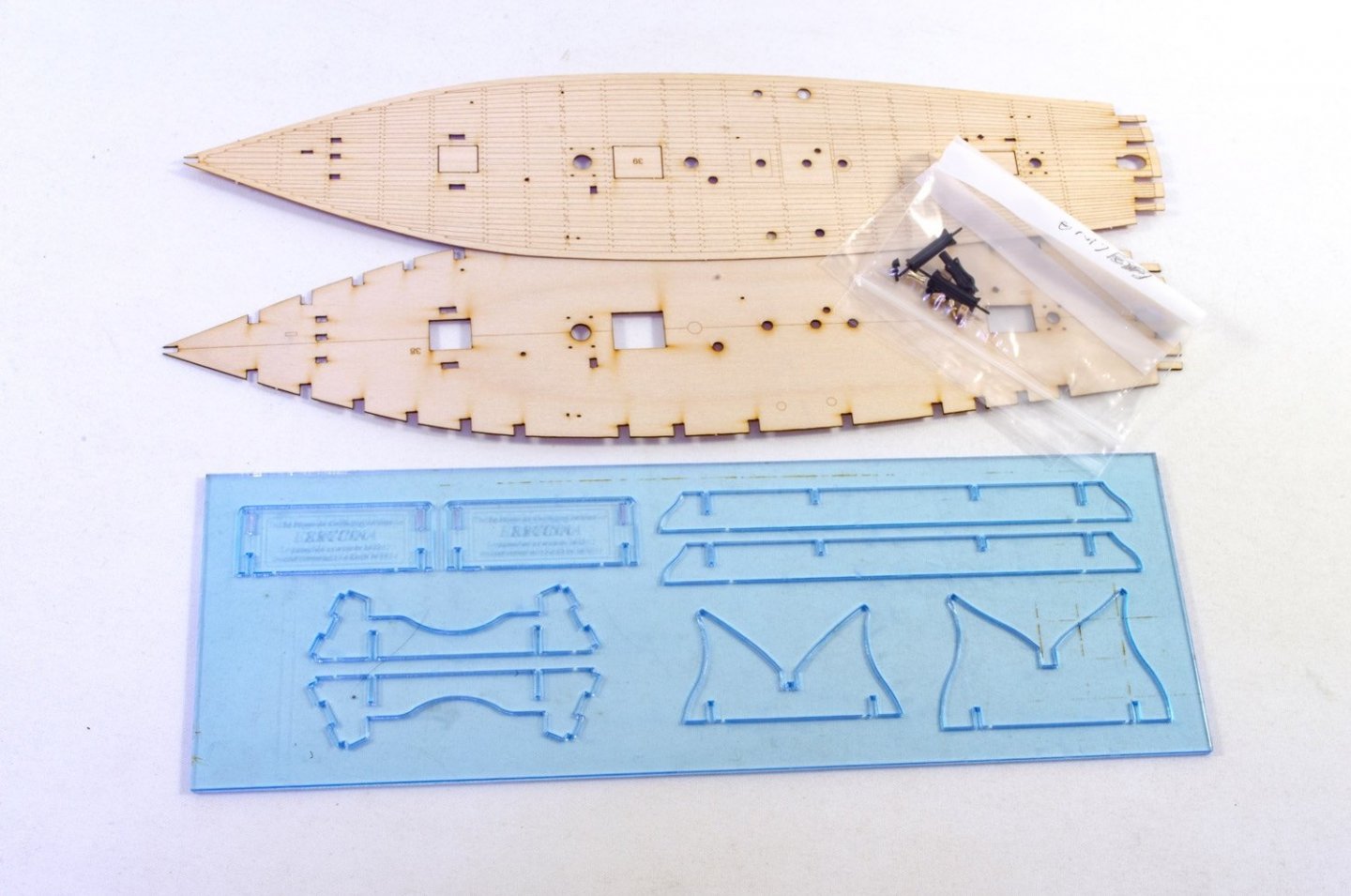

Erycina was a Plymouth Ketch-Rigged Trawler, launched as a cutter in 1882 and converted to a Ketch in 1894. This is one of three next subjects from Vanguard Models, following on from their previous Fifie and Zulu fishers. I'll be starting build logs for the other fishers when I'm ready. One of those, Nisha, will be built concurrently with this one. Out of Erycina and Nisha, Erycina is the large one, as you'll see from a cut test prototype in a photo below. Again, construction is an MDF core, with lime/pear planking and an engraved maple deck. There will be sail sets available for these. Here is Erycina! Here's some photos of the initial test prototype which is refined to make the production parts. Erycina is of course the larger vessel: My HMS Sphinx is now in the last days of work, so I'll be taking a day or so off afterwards to indulge in my PlayStation5 and mindless killing in Assassin's Creed, then work on this will begin. Until then, here are the parts (minus planks). More when I have it

- 36 replies

-

- vanguard models

- Erycina

-

(and 2 more)

Tagged with:

-

Yes, I varnished as I went along. I part-varnished the deck, excluding an inch along each side. When the cannon were glued down to the bare wood deck, I then infilled those areas in varnish. A little time-consuming, but quite easy. I didn't want to glue anything down to an already varnished deck, for the sake of joint integrity.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

A number of the plans are supplementary as you'll see the whole build through the manual, but you can at least refer to the plans too for peace of mind. As far as I'm aware, there is no coating on the brass. I tend to prime the brass with Tamiya Fine Surface Primer before I add paint. That stuff has a good bite to the surface.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

I usually dilute about 50:50, depending on glue/varnish type.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

HMS Granado 1742 Kit - CAF Model - 1:48 Scale

James H replied to cafmodel's topic in Wood ship model kits

That looks wonderful work, Tom. Is this far off release now? -

I'm about a week or so off completing Sphinx, so thought I would post a few progress pics here showing shrouds and shroud cleats in place. I really, really love ratlines. Did I ever tell you that? All 1270 of the lovely little knots.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Fairing those parts 'off model' is only about removing a rough quantity of material so that it's easier when you have everything together. The quantities you see me removing in the manual were further faired in when the full was ready for overall fairing.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.