-

Posts

6,062 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

Yes, Coureur and also the Amati Victory prototype. My VM Alert will have to stay in its box a while longer yet. 🤣

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Excellent work. Makes me want to start mine when Flirt is complete!

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Moved to correct forum area.

-

Moved to correct forum area.

-

Moved to a more appropriate forum area.

-

Vintage unfinished speedboat model, any ideas?

James H replied to LMDAVE's topic in Wood ship model kits

Moved to correct forum area. -

Hi Zbigniew Great to have you with us here at MSW. I very much look forward to that build log on a model based on Le Superbe.

-

ancre Coureur by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Beautiful work and a beautiful subject too. I might get the Coureur drawings from Ancre too. -

ancre Coureur by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Outstanding! Can't wait to see this with its clinker hull 🏆 -

I have actually used iron pigment on them since painting too.

- 109 replies

-

- Vanguard Models

- Flirt

-

(and 1 more)

Tagged with:

-

Crack on! Fix those parts and get planking!

- 109 replies

-

- Vanguard Models

- Flirt

-

(and 1 more)

Tagged with:

-

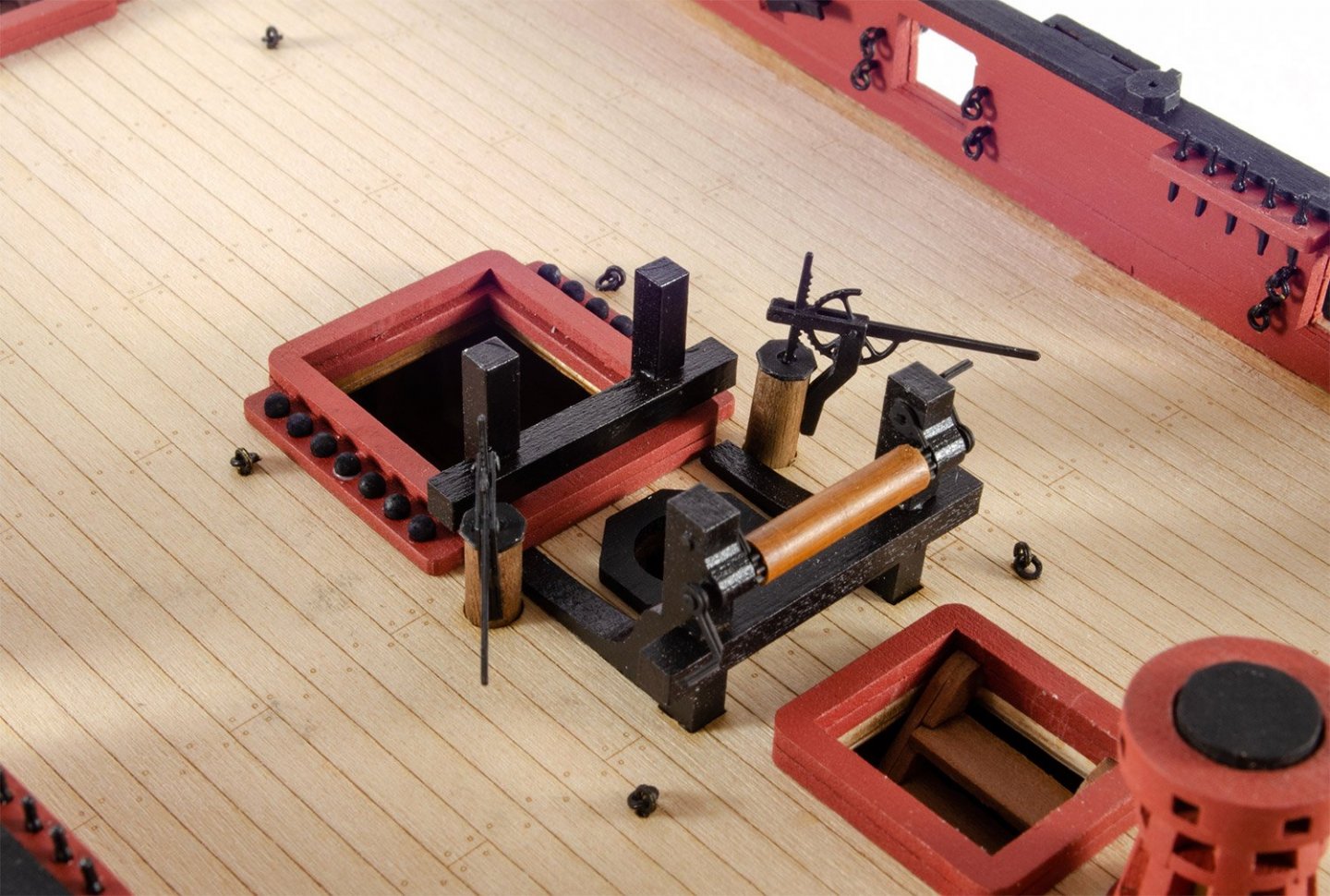

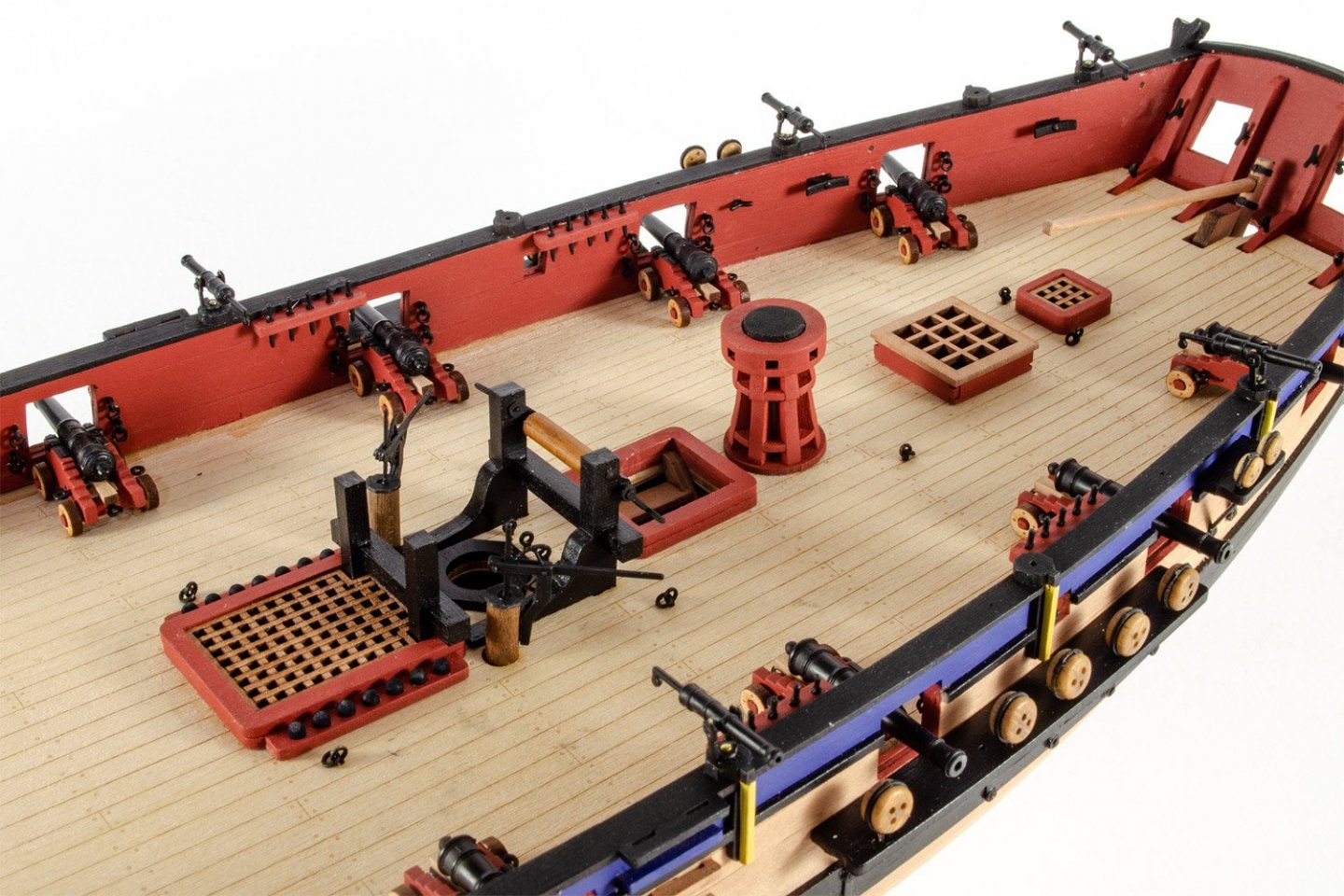

Time for an update. The hull is now pretty much built, down to the various rigging points on the outside hull. Here is another abridged series of photos which will feature in the instruction manual. It had been decided very early on that First was to look very different from Speedy. That wasn't just with the white bottom hull and earlier riggings, but also with selective use of period colours. The kit itself is quite different to Speedy, with different materials used in places, necessitating new laser cut files specifically for this release. Instead of leaving the upper bulwarks in pear, I sat the swivel gun post support patterns against the cap rail and marked the area to be painted blue, with a pencil. The adjoining areas were then masked and several thin coats of Humbrol 25 Blue brush painted into that area. The patterns were then glued into position and the areas they lay over the gun and oar ports, snipped away and trimmed back. The catheads were now assembled and painted before being installed. These were very much a perfect fit, which really pleased me! The bow timbers and head rails were now fitted. This was probably the most fiddly aspect of the model so far, and what I thought would be a 20 minute session turned out to take about 3hrs before I was happy enough with it. I also fitted the depth markings etc. The dark area you see around these is where I've sealed them in polyurethane varnish to give them extra protection. Those areas will blend in to the last full coat of varnish I apply. Note I also added the vertical swivel gun timbers, but in Humbrol 74 Linen (ochre) to give some contrast against the other elements. Thought I'd have a small diversion and make the four anchors. The only metal in these is the ring. The stocks are also made up from two parts as per the real thing, and black cartridge paper used for the bands. All belaying pins and racks are now fitted. These are also pinned as well as being glued with PVA. I prefer this glue for things like this, as CA can fracture if stressed. As with the belaying pin racks, the channels are also pinned and glued with PVA. The chainplates in this kit are provided as single pieces. You need to open them up to sit the deadeye in them, then close back up. Some touching up with black paint is also required. All chainplates are now fitted and pinned to the wales. All my previous work in making the deck fittings and furniture can now be put into play. The small steel balls for the cannon shot, are burnished in metal blacking fluid. And here we are so far! Hope you like it.

- 109 replies

-

- Vanguard Models

- Flirt

-

(and 1 more)

Tagged with:

-

kit review 1:50 Brig Aris by Navarino Models

James H replied to James H's topic in REVIEWS: Model kits

Not an assembled model. Maybe you should try a couple of easier vessels and then the Brig Aris? -

HMS Terror by Mish - OcCre - 1:65

James H replied to Mish's topic in - Kit build logs for subjects built from 1801 - 1850

Nice to see this coming along again. -

contact adhesive

James H replied to Liad's topic in Building, Framing, Planking and plating a ships hull and deck

Moved to correct forum area. -

Moved to correct forum area...

-

Sure can! It's Plastikote red oxide primer. I generally give all parts a finish with 320 grade paper and then spray. If necessary, I will sand an d reapply. https://smile.amazon.co.uk/Plasti-kote-25002-400ml-Primer-Oxide/dp/B006XBST08/ref=sr_1_1?dchild=1&keywords=plastikote+red+oxide+primer&qid=1590226003&sr=8-1

- 109 replies

-

- Vanguard Models

- Flirt

-

(and 1 more)

Tagged with:

-

They sure are fiddly. I find the stern more difficult than the bow, and this one is planked with 2mm x 1mm strips (narrower than Speedy's 3mm strips). Still, it should look ok when done, fingers crossed.

- 109 replies

-

- Vanguard Models

- Flirt

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.