-

Posts

6,063 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

Welcome back, Jim. Now....time to open the shipyard for business again

-

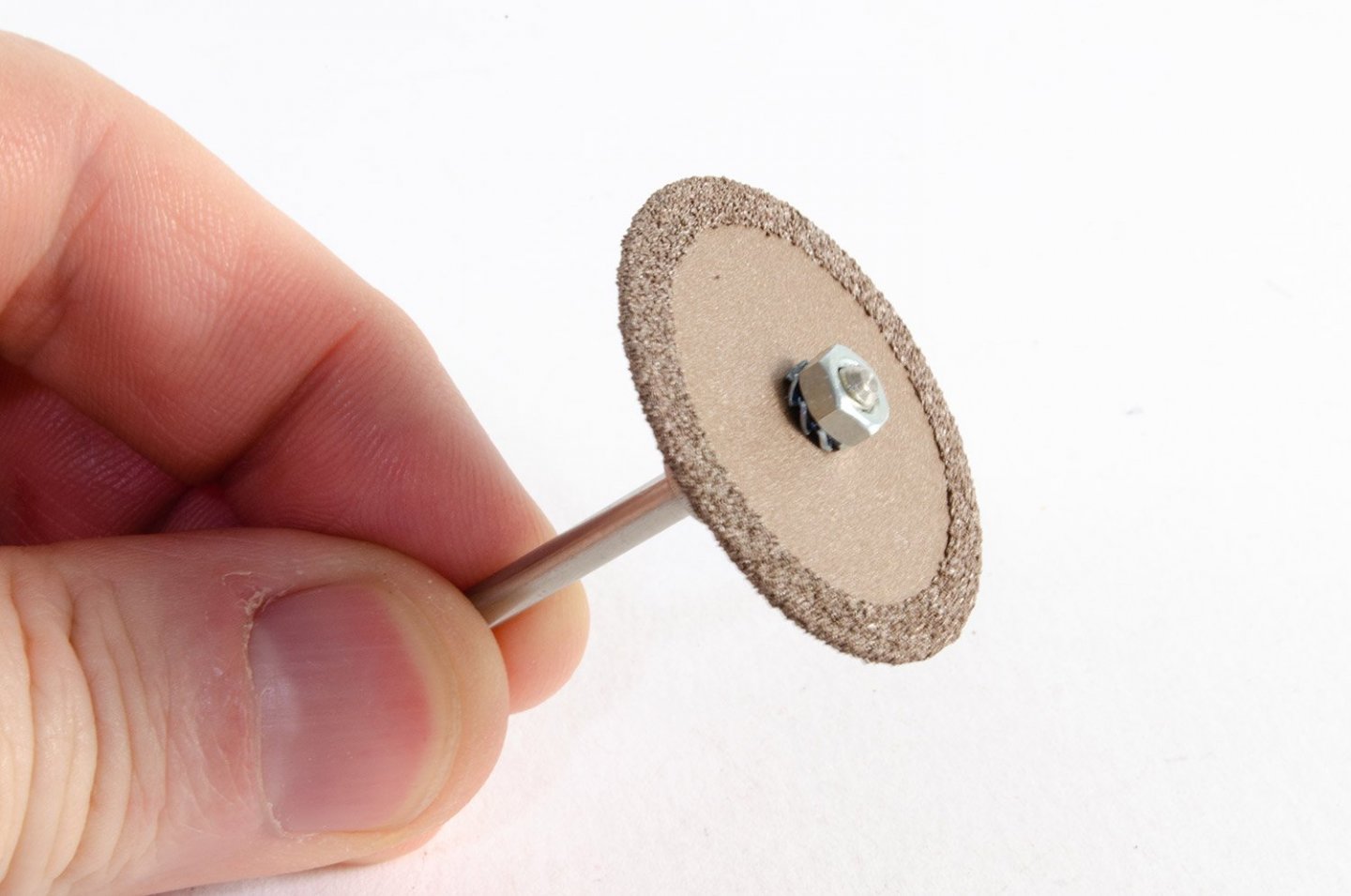

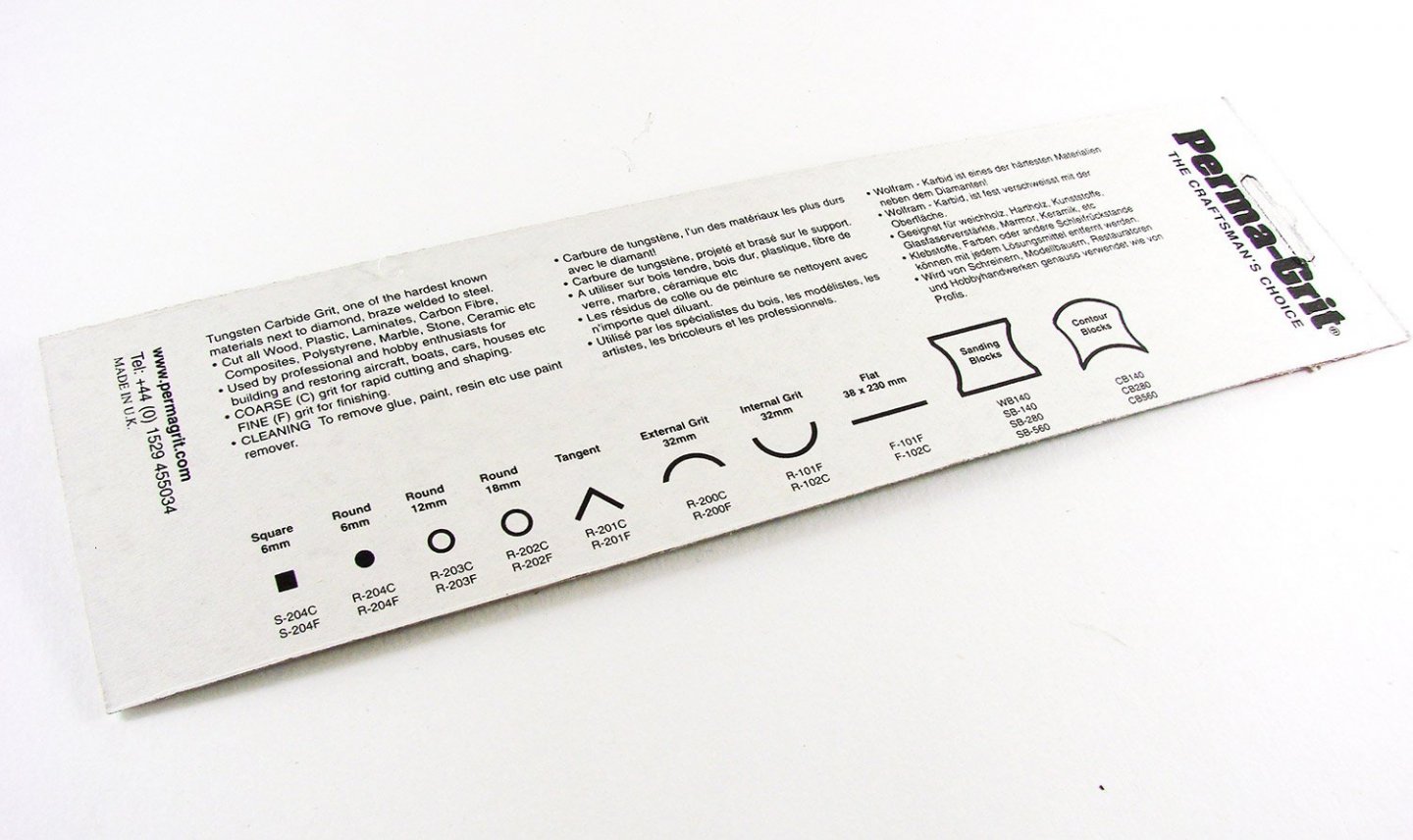

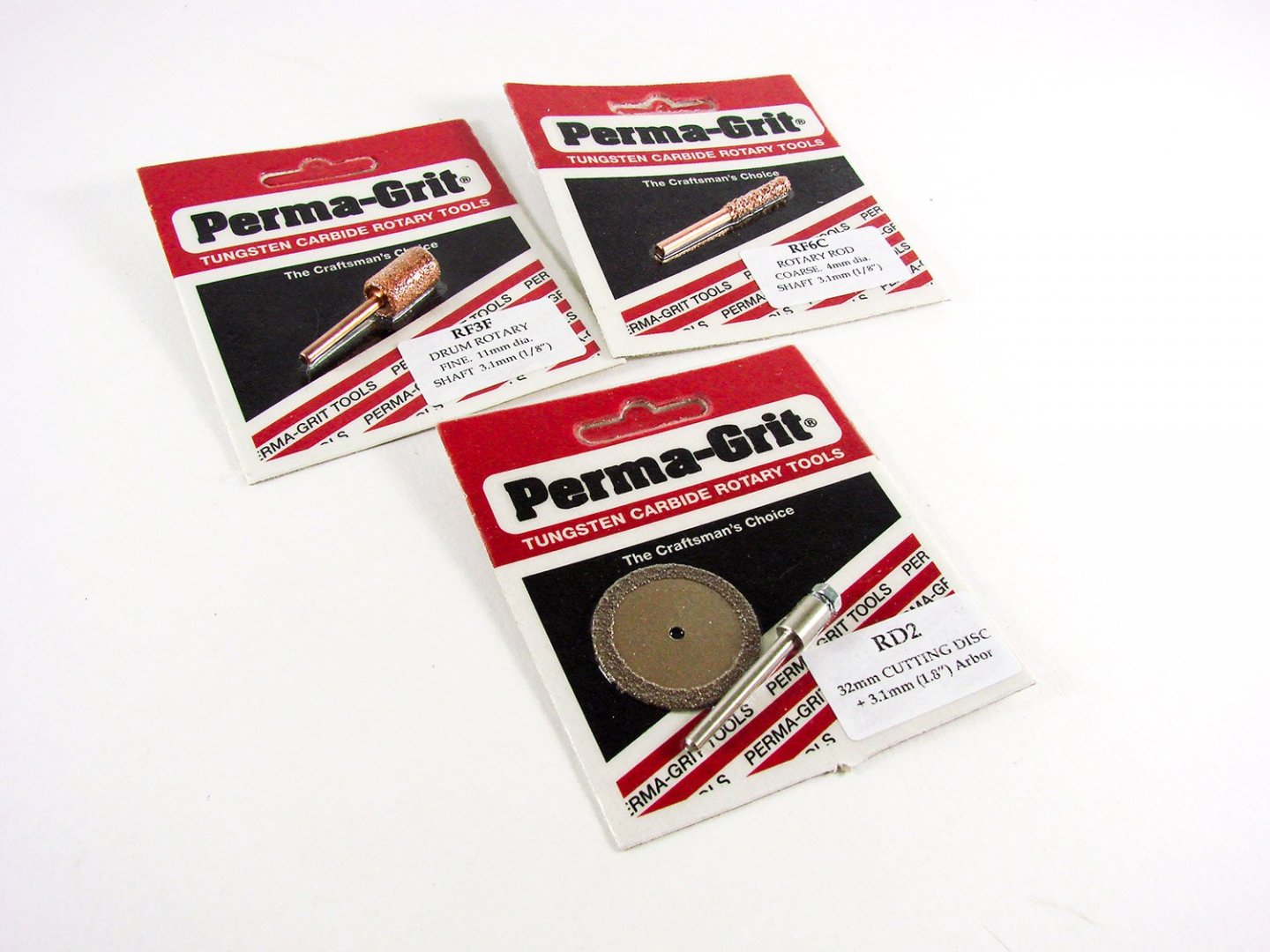

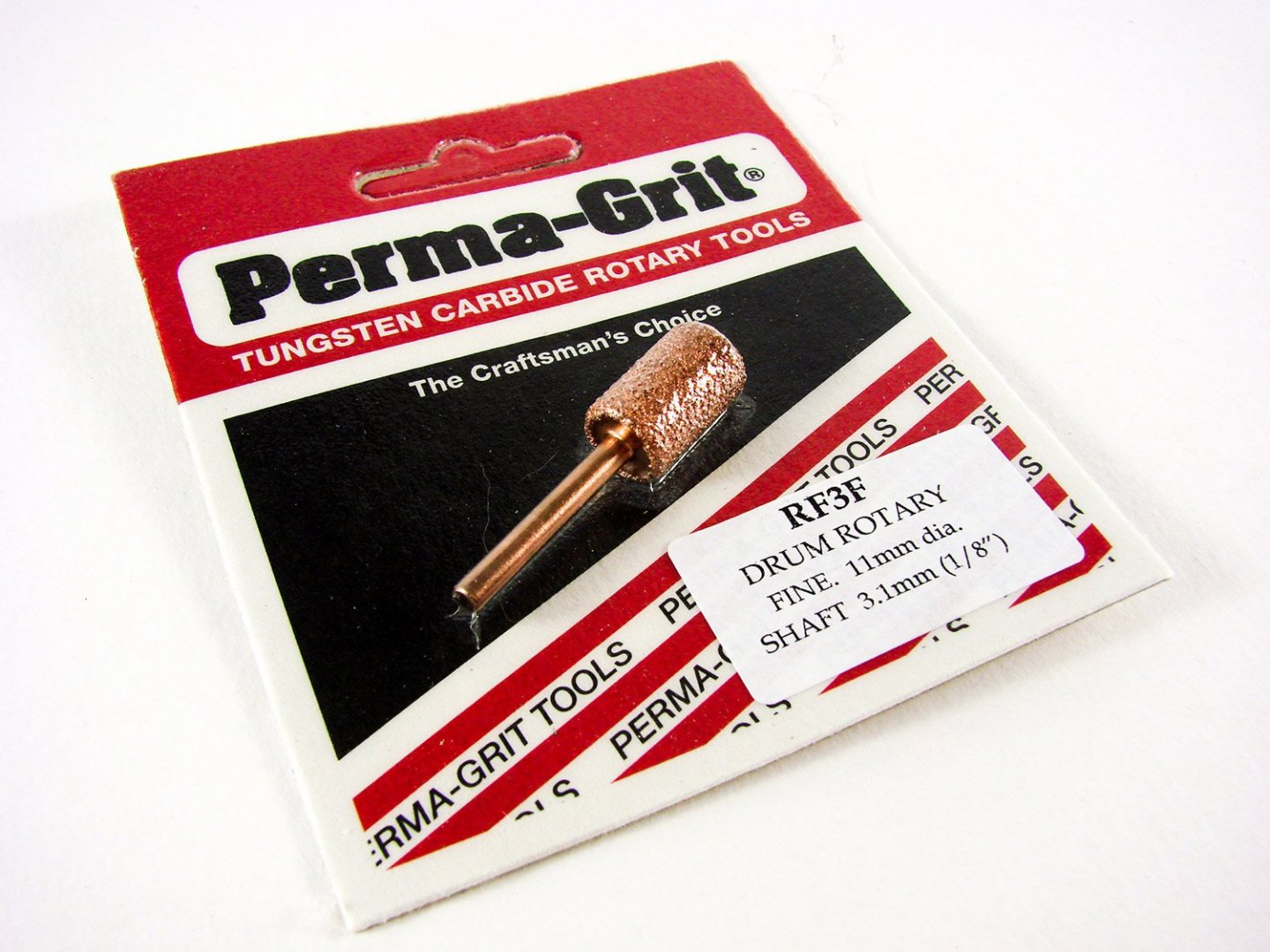

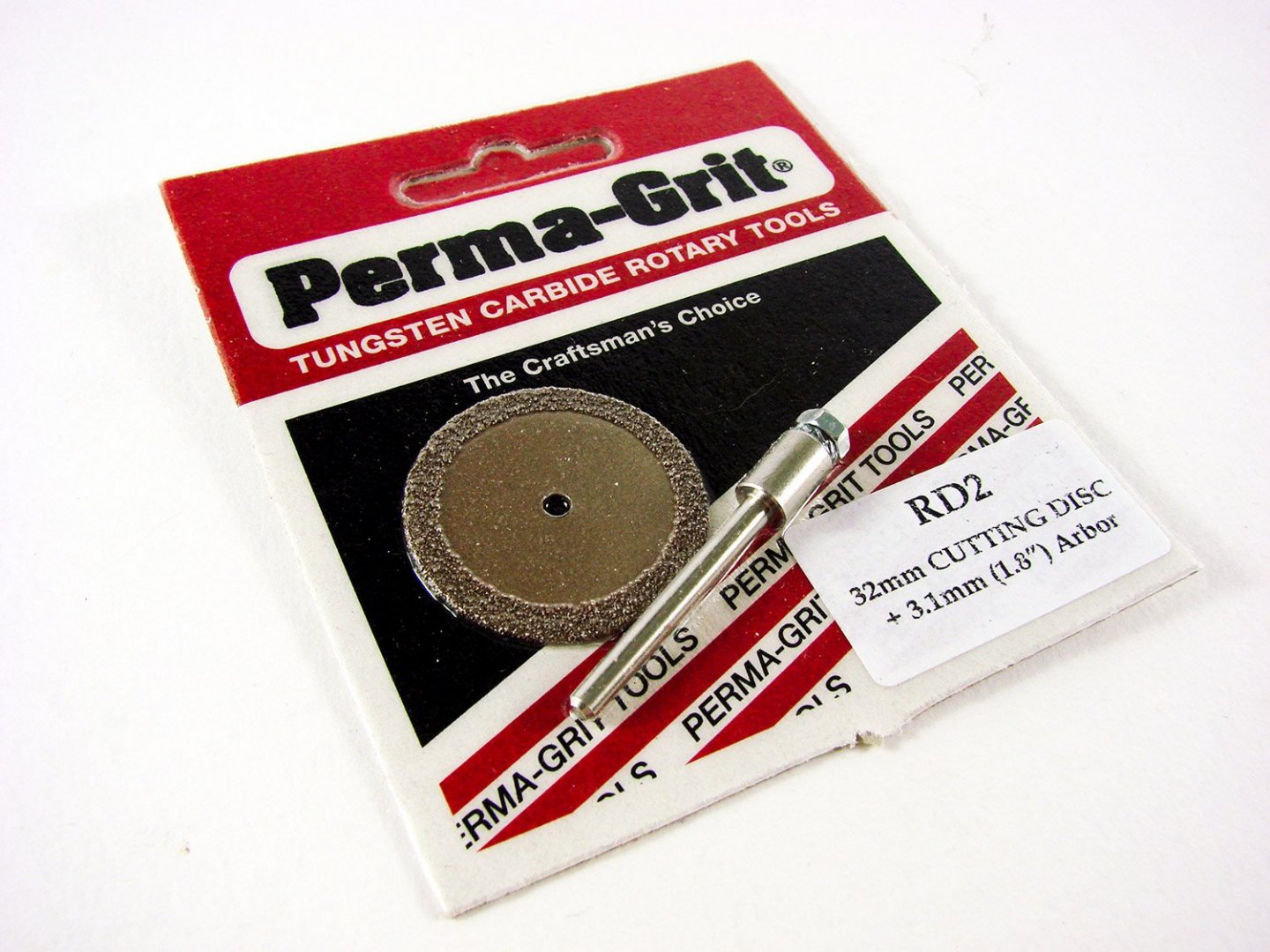

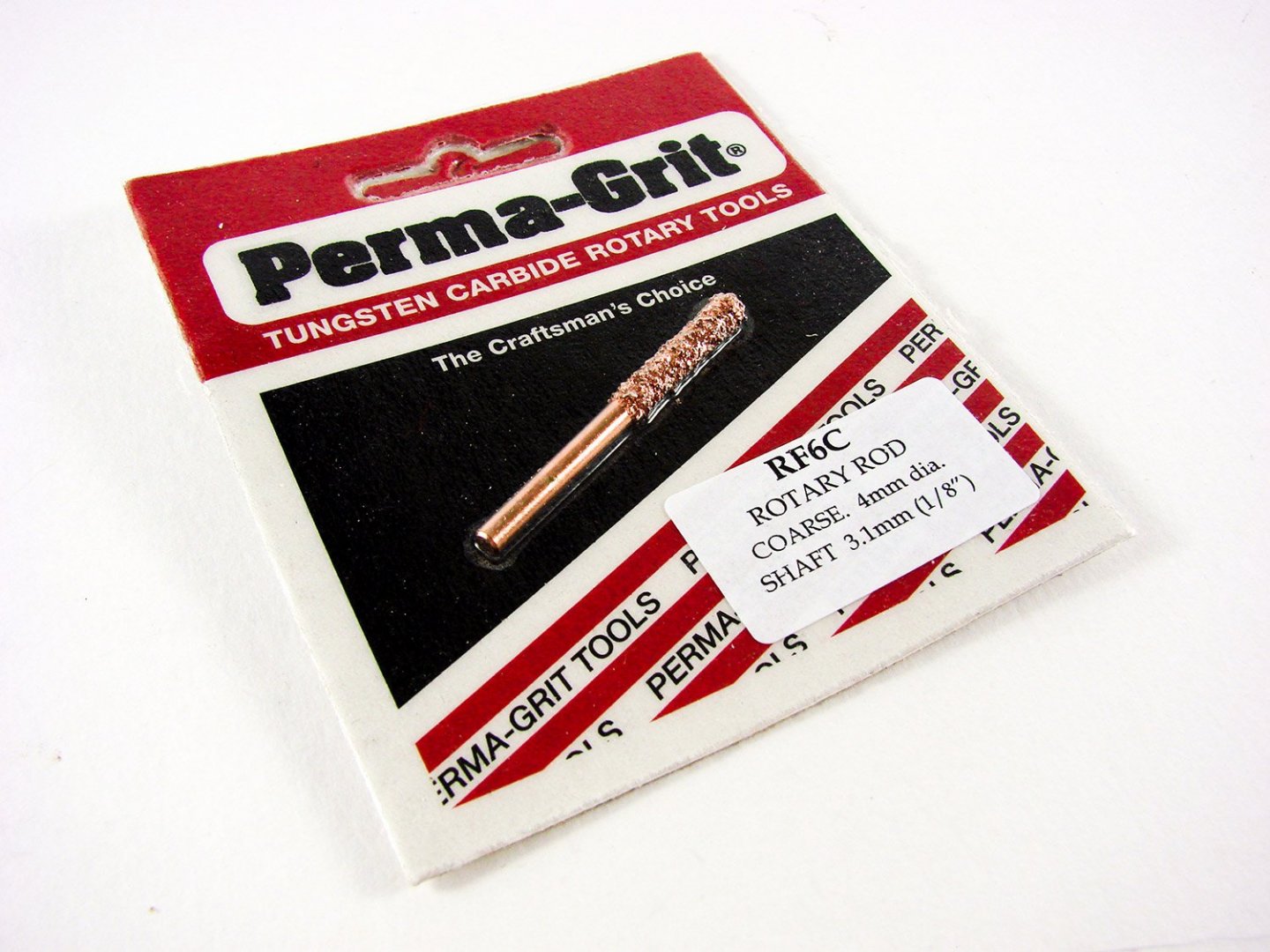

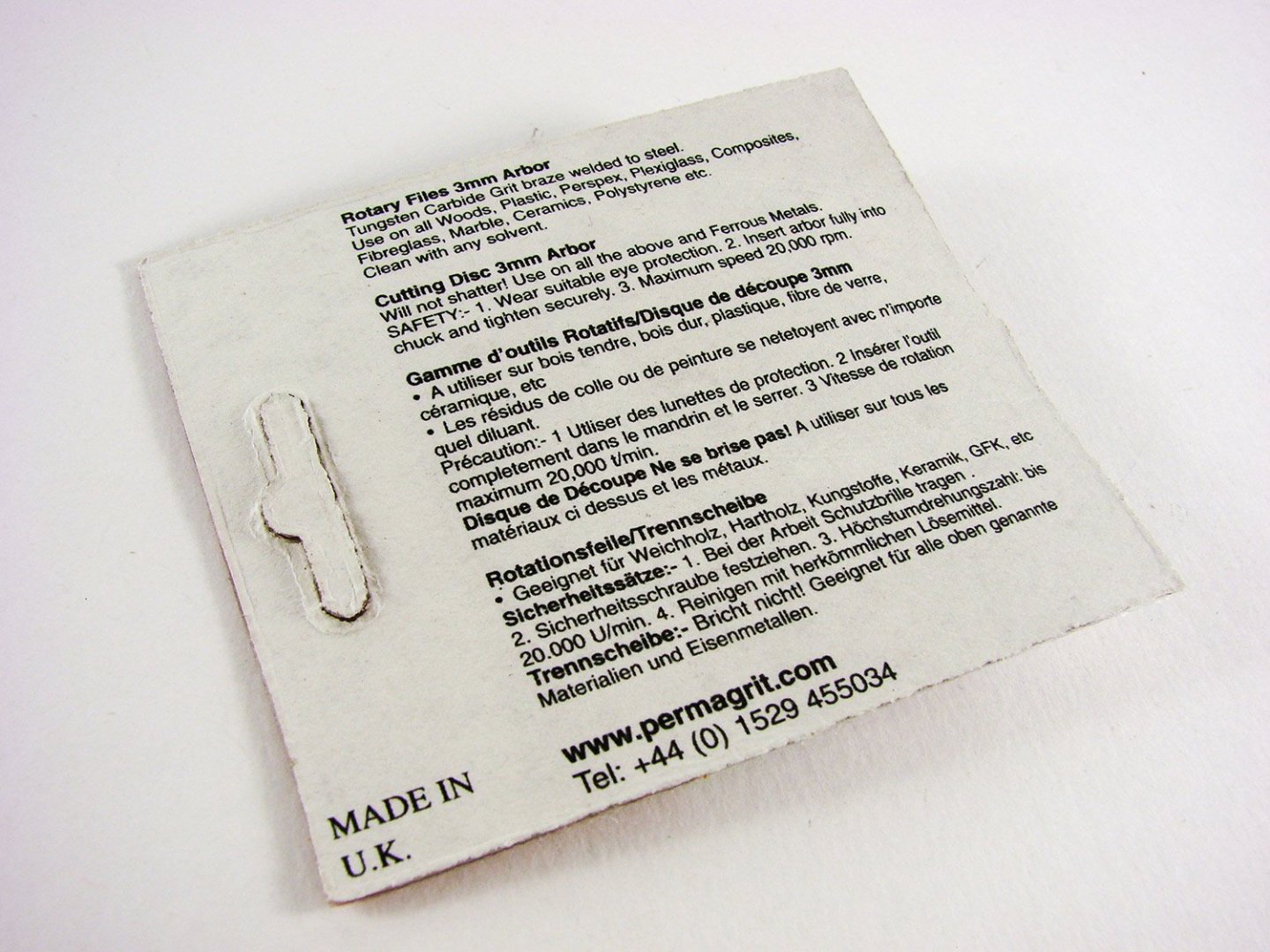

Perma-Grit Tools Perma-Grit Ltd. For purchase and enquiries, visit www.permagrit.com We all know the old adage when it comes to making purchases, ‘Buy well, or buy twice’. That is especially true with regard to buying tools. We’ve all bought things for our hobby which looked great at the time or looked like a bargain. I know that in my case, very few of those purchases were actually money well spent. One area, working with wood, that we all need to buy for, is the sometimes-onerous task of sanding our models. Over the years, I’ve learned that buying good quality aluminium oxide paper is probably a better deal than cheap silicon carbide paper. However, when it comes to specific tools to do the job, one of the best names on the market, and one of the most respected, is English firm, Perma-Grit. This company has built its reputation up over a period of almost 30yrs now, manufacturing Tungsten Carbide grit tools of different grades, by bonding it to steel under extremely high heat, in a furnace. Perma-Grit have sent us a sample of their tools which a modeller could find very useful on the workbench, and I have taken the opportunity to use a small number on my current Zulu fishing boat. Needle Files (different size shafts) In my sample pack were these four needle files. These are the 18cm/5mm shaft, and 14cm/3mm shaft. All Perma-Grit tools are packaged against a card backing and shrink sealed in clear plastic. The rear of the packet also has information relating to the specific product range. The tools you can see here are: 18cm Large Needle File (Round, fine), # LNF-ROUNDF 18cm Large Needle File (Half round, fine), # LNF-HROUND 14cm Needle 3 Square, (medium), # NF-3SQUARE 14cm Needle File, Hand (medium), #NF-HAND Firstly, a little about the grade of grit with these needle files. Files with ‘fine’ grit are classed as an equivalent of UK 320 grit sandpaper. Those with ‘medium’ grit as classed as UK 220 grit sandpaper. The surface of these files is densely packed with grit, and I can’t see any of this coming away readily. Whilst Perma-Grit don’t supply a lifetime’s guarantee, if you feel that any tool from them hasn’t met your expectations, then you are always welcome to let them know of this. Cleaning the surface of these has also been thought of. These files are pretty impervious to most chemicals, so you can use acetone to remove any CA, and Nitromors/paint stripper to remove general debris. Whilst these tools can be used ‘as is’, some modellers will feel more comfortable using a handle, and I’m also one who would feel that I can exercise more control with a handle fitted. To cater to shaft size, Perma-Grit offer these two handles: Handle 3mm collet, # NFH Handle 5mm collet, # LNFH These are simple to use. You just twist the knurled ring to loosen the collet and then slot the file in before retightening. Of note here is that the red handle is hollow and can accommodate quite a lot of the file shaft so you can adjust the file to what suits you best. Sanding blocks, angles, and flat files Sanders come in all shapes and sizes, and so they do from Perma-Grit too. We have three types here, all very different and with a wide range of roles in our hobby. For your info, tools classed as ‘coarse’ have an equivalent UK sandpaper grit of 180. Angle 75 Degrees (coarse), # R-201C Flat File (fine), # F-101 Wedge Block (coarse, fine), # WB140 The Angle sander is an unusual thing. It’s very easy to hold and manipulate, with two sanding faces. This one has a coarse grit, but can also be bought with a fine grade, which, given the shape and possible modelling uses, would perhaps be a safer bet. The Flat File is simple in approach. This is long length of steel with a fine abrasive coating on one side. This could be used for getting the squareness of a freshly planked hull, removing a lot of that waste until you switch to a sanding block or just manual sanding paper. With the Wedge Block, you get something more akin to a traditional sanding block, except in metal of course. Where this differs is that one side of this is fine grit for some nice finishing work, and the other side is coarse. As I’d already done the rough work on my model hull, I took the opportunity to do some fine sanding. The grit on these sure takes off material superbly, and I went very gentle with this. 6.5m Round File (fine), # R-204F If traditional style files feature in your workshop, then this one is very similar to that, being a regular looking round file with an integrally moulded handle. The whole shaft on this is coated in Tungsten Carbide and the handle is very comfortable in the hand as well as being nicely weighted. Rotary tool bits Perma-Grit sent me a small number of their most commonly used rotary tools. All of these have 3.1mm shafts and are compatible with Dremel rotary tool products. The ones I have here are: Rotary Drum (fine, 11mm diameter), # RF3F Rotary Rod (coarse, 4mm diameter), # RF6C Cutting Disc (32mm diameter), # RD2 The Drum tool is as you would expect and very similar in appearance to Dremel except that this doesn’t need to be assembled, nor will it wear out as quickly. Being fine grade, this will be perfect for the hobby, when bevelling bulkheads etc. The Rod tool is exactly that. Tungsten Carbide has been fused to the shaft, enlarging its diameter to 4mm. The one I have here is coarse but can also be purchased in a finer grade. Of course, the Cutting Disc does need a little assembly. All that’s involved is slipping the disc underneath the nut and spring washer, tightening with a small spanner. It MUST be noted the rotary tools running speeds are anywhere from 5000rpm to 20,000rpm, and they are NOT recommended for metal Whilst these tools have been supplied as separates, they can also be bought as sets. If you already have several of these tools, then the sleeves (tool rolls) can be purchased separately. I have two such sleeves here. One is designed for the larger tools, and the other for smaller tools. These are made from red canvas so are rugged, and they are secured with a Velcro fastener. My sincere thanks to Perma-Grit for sending these tools out for me to take a look at for Model Ship World. To buy these and check out the rest of their extensive range, visit www.permagrit.com

- 17 replies

-

- permagrit

- perma-grit

-

(and 3 more)

Tagged with:

-

I've had these years and bought off a guy via email. I don't even remember the name now. Shame really as they've been great drills.

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

As soon as this is finalised, I'll do that for you.

-

Glad you're enjoying this one. It's great fun! I actually primed the hull in red oxide and noticed more plank showing than I wanted, so I've just used some thin filler paste and cut it back, ready for more primer, possibly tomorrow. I'd love to see your Speedy as a build log.

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

I've not bevelled a plank's whole length. On average, no more than 2/3 of it. Some of the initial planks (after the non-tapered) are probably only around 50% of the length.

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

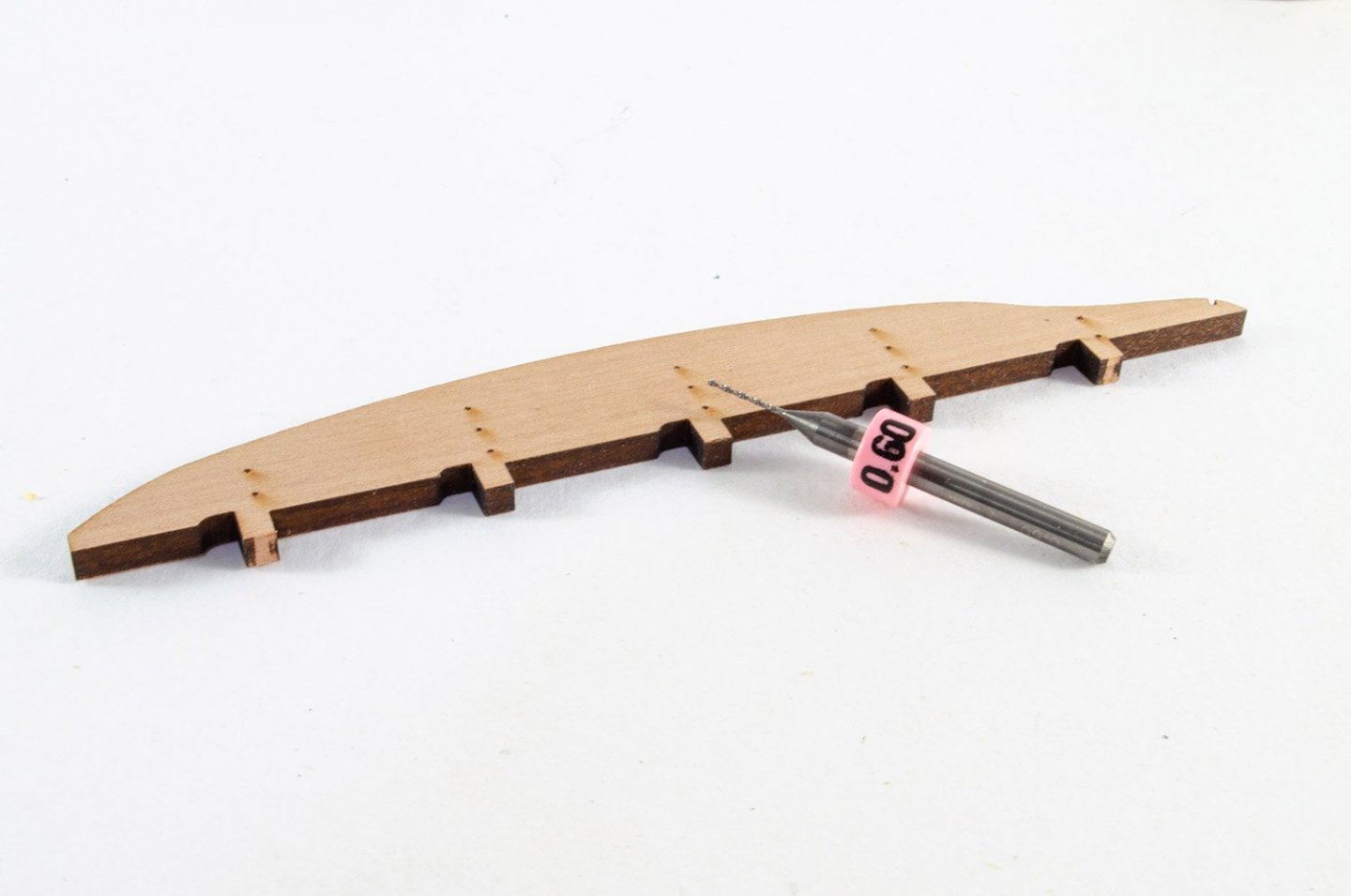

A quick update on the Zulu. The second layer of pear wood planking is now fitted. This was done with CA gel (Gorilla Glue) which is very different to how I usually work with PVA etc. Plank edges were bevelled as I went, and tapered where necessary. Once installed, the hull was sanded down with 120, 180, 240 and 320 grade papers. A small amount of Ronseal natural wood filler was also added, but that was tiny. A testament to how well this kit is designed. It was now the turn of the rubbing strakes to be fitted. The upper two, which butt right up next to each other, are walnut and semi-circular in section. A nice contrast to the pear of the hull. Three other 1mm square strakes are also added. The lower one only extends part way back down the hull. Any glue marks you see will disappear when I add the polyurethane varnish later. The rudder simply plugs into the stern post and the sockets more or less hidden by the pintles. A 0.6mm drill was used to cleanly open out the laser cut holes so I could easily fit a pin through. The pintles and gudgeons are photo-etch and glued with CA gel. I used the kit's Amati brass nails on the pintles and applied a part nail from either side so I could have the domed heads on both faces. The gudgeons have their nails etched onto the parts. More soon!

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

That looks great! I love that rich, warm tone its got.

- 77 replies

-

- morel

- master korabel

-

(and 1 more)

Tagged with:

-

Welcome to MSW! No better time than now to hunker down and post a build log!

-

I'm reliably informed that its finished size is 608mm long and about 340mm tall

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

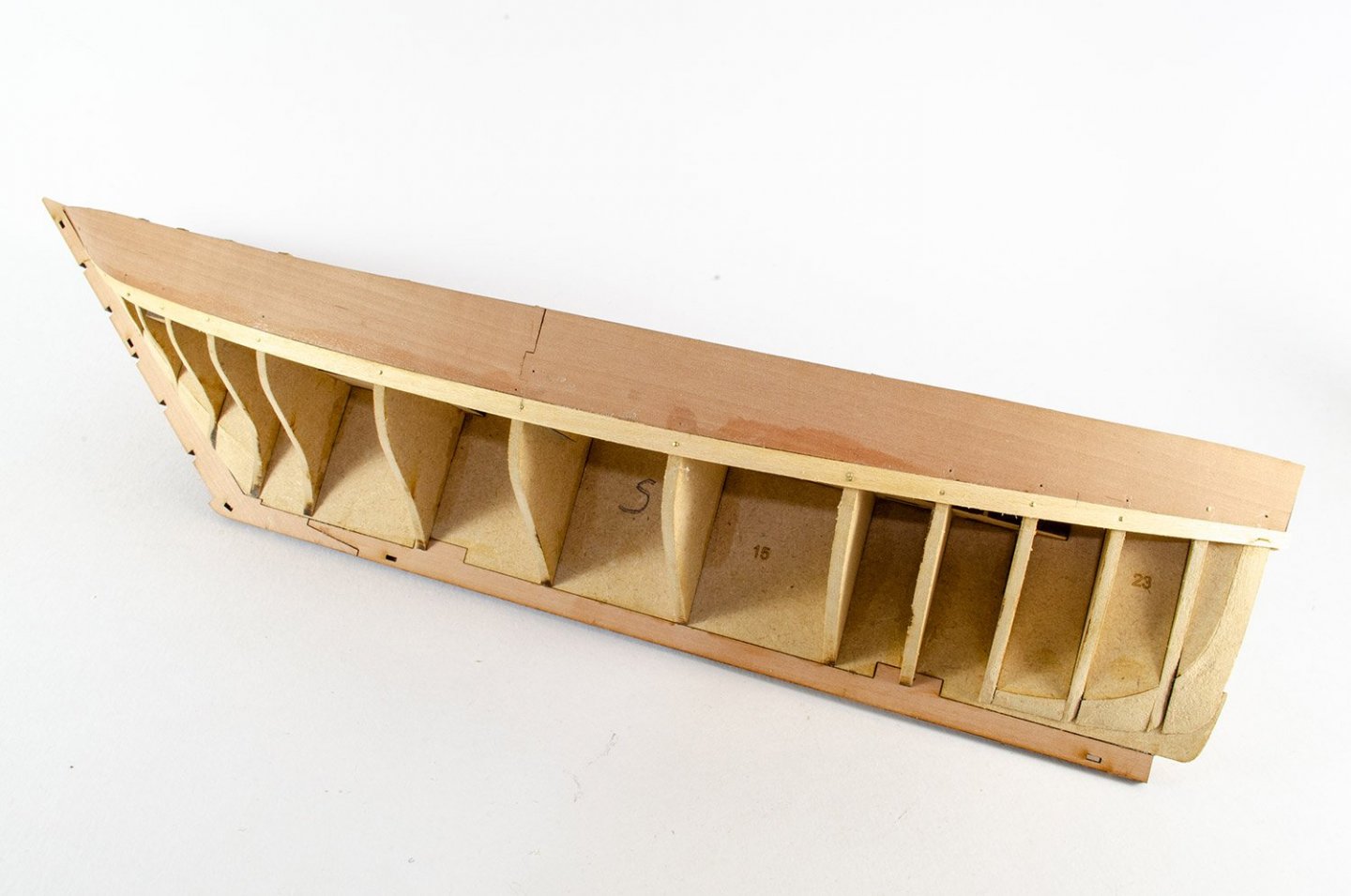

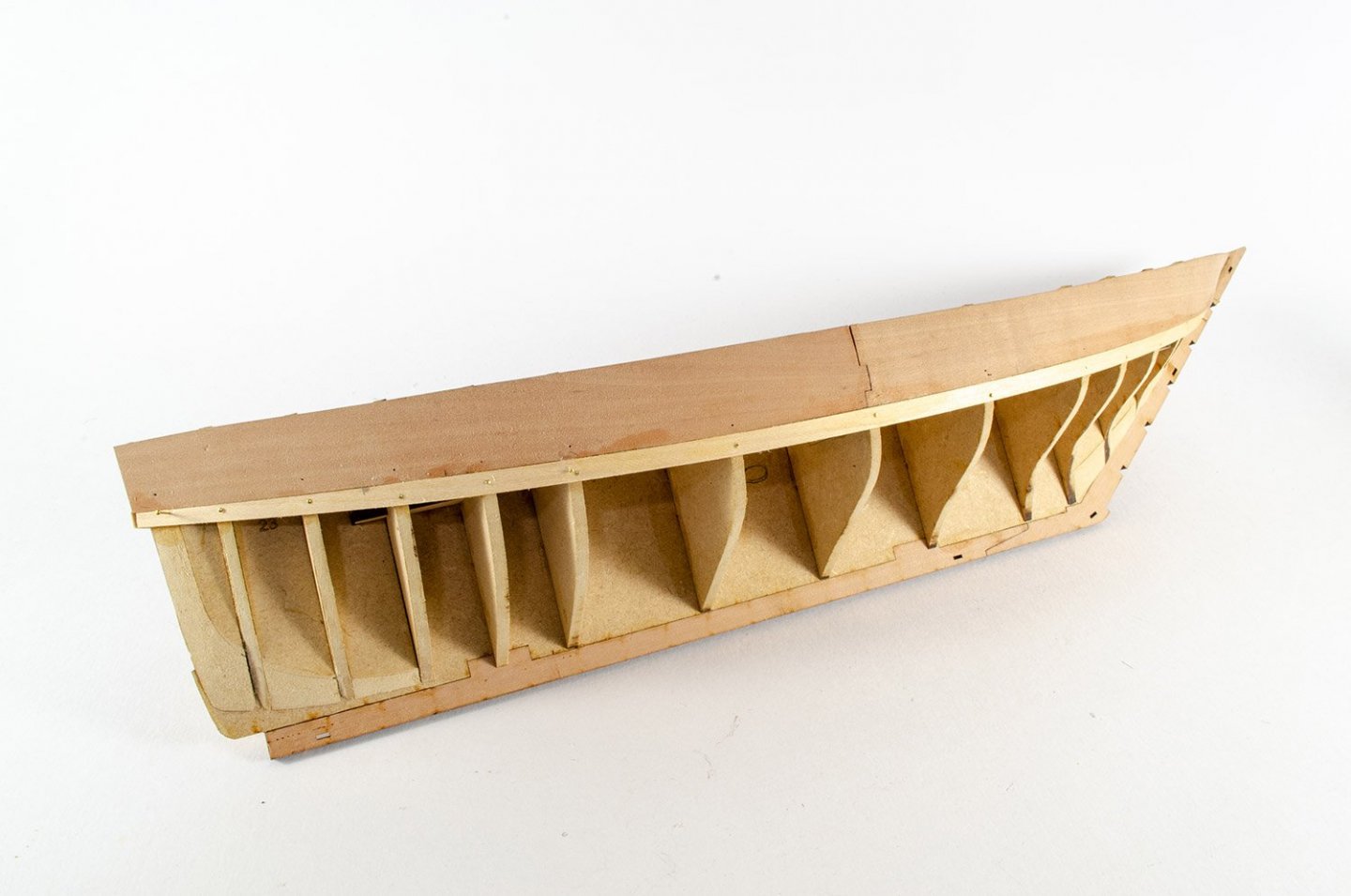

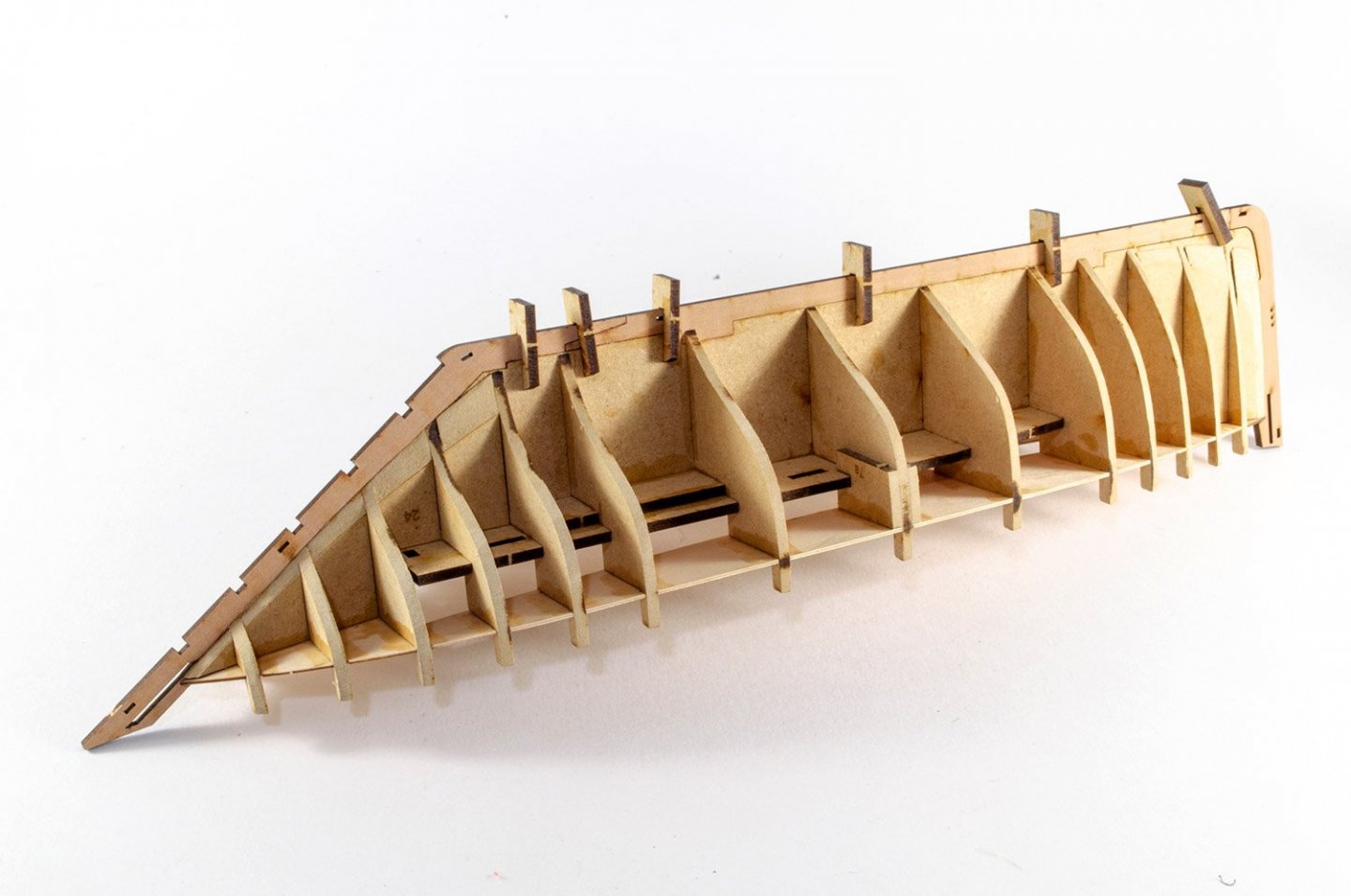

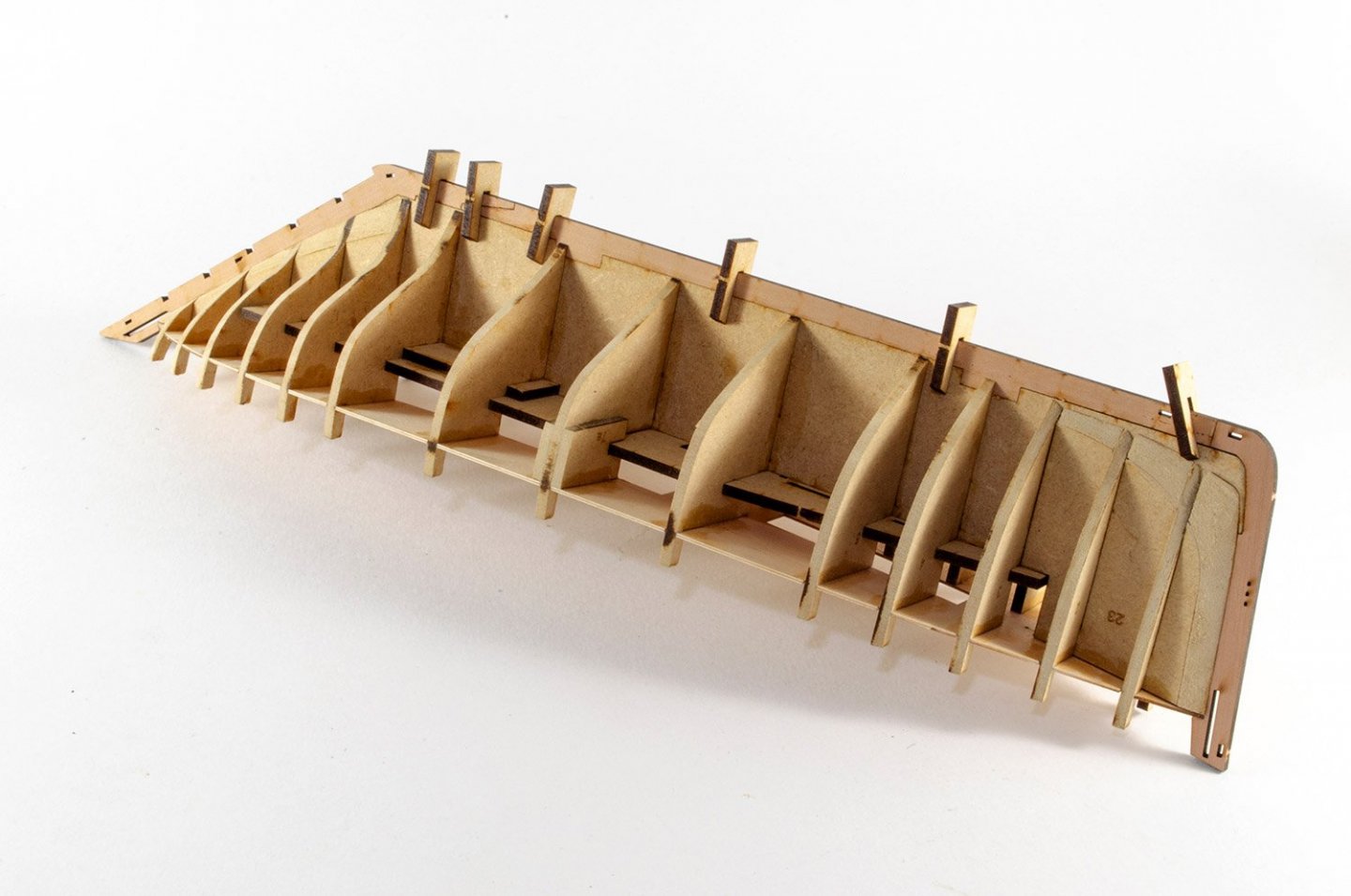

Maybe I should do a small update. I've had time to do some planking during my enforced isolation. Here you see the hull with the pear bulwarks installed. Underneath that is a lime wood plank with a naturally guessed taper. PVA is used for these, and my trusty Amati nail pusher. Limewood planks are now fitted and tapered where the natural lie of the planks overlaps the previous. That bow sure looks ugly with those over length planks. That will now be cut back and tidied up. With the bow tidied up, the stem keel section is finally glue into place. This fits like a dream with no ambiguity. The pear wood keel is to be lined with an external layer, creating the rabbet that the second layer planks will fit into. Before this though, the key parts are fitted. Those keel facing parts are now added... Here you see how the rudder sockets are created with the keel face parts. Now, the garboard planks are pre-cut. This is to help the modeller with the curvature at both bow and stern. These are an excellent fit. To start, I dry fit the stern side garboard plank. When I have achieved a good fit, I make a couple of pencil marks to absolutely determine its position. The plank is then removed and Gorilla Glue CA Gel is applied to it and the plank slipped into the keel rebate before being shaped into the stern curve. There same now applies to the stem garboard plank. This is the result. More soon!

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

Haha! I'm certainly not a professional! But thanks anyway.

- 106 replies

-

Hi Bob, I run the plank along the previous and where it stops flowing naturally and looks like it wants to run over the previous, I make a pencil mark. I then take a look at the end of the plank and see the overlap of the previous and mark it. Those marks are then joined up and cut to add a taper. Where the curve of the bulkhead demands it, I will bevel the top edge of the new plank so it butts up close. It probably isn't the best and most accurate way of doing it, and yes, I have to fit stealers into some gaps, but with the second layer, I'll make sure that anything like that is hidden under the painted area. I really should learn how Chuck does it so it's a little neater, but it works well on this and other painted hulls.

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

B-25 Mitchell "Meet Miss Runyon" by Javlin-HK-1/32

James H replied to Javlin's topic in Non-ship/categorised builds

PLEASE stay safe. Let us know how you go. -

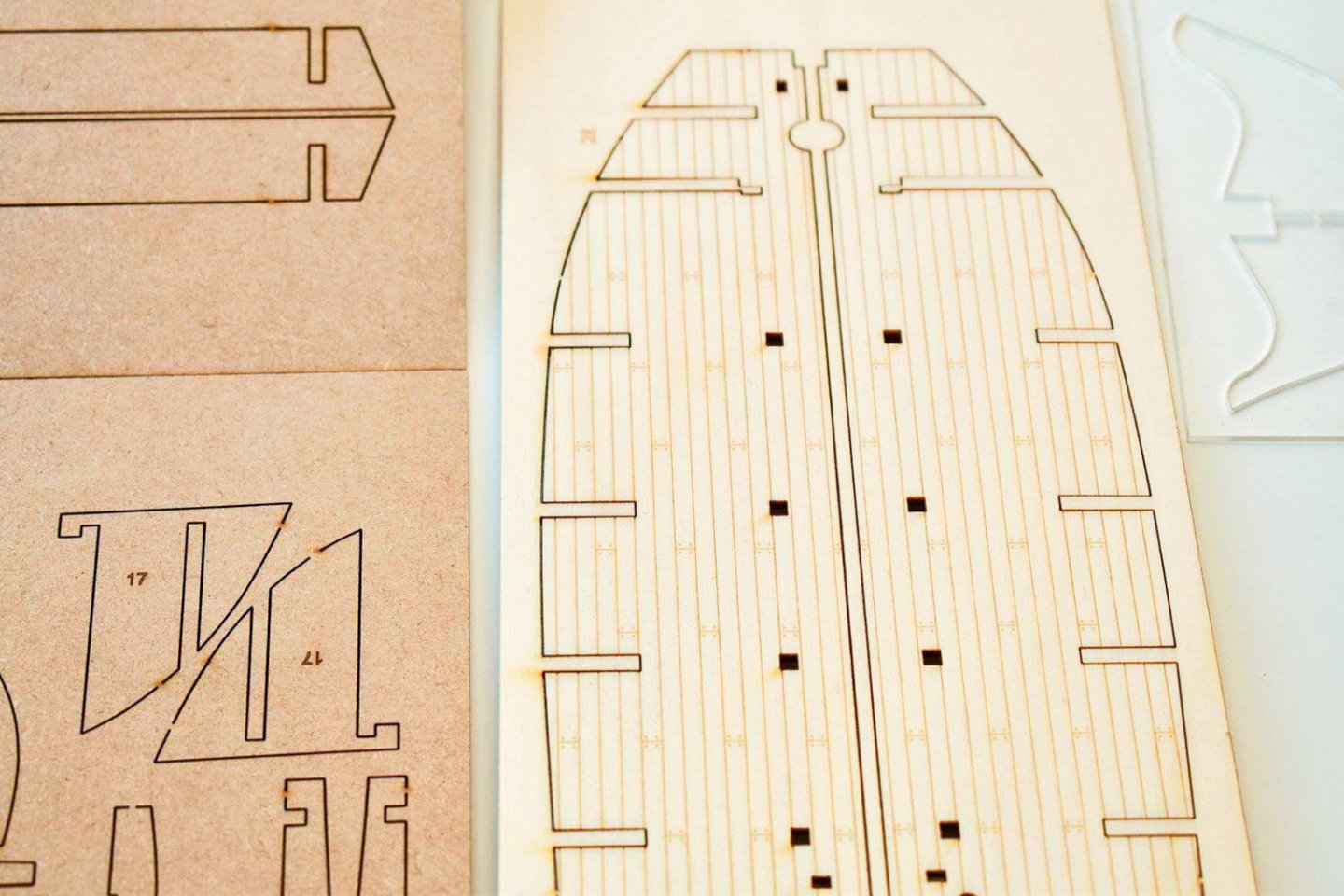

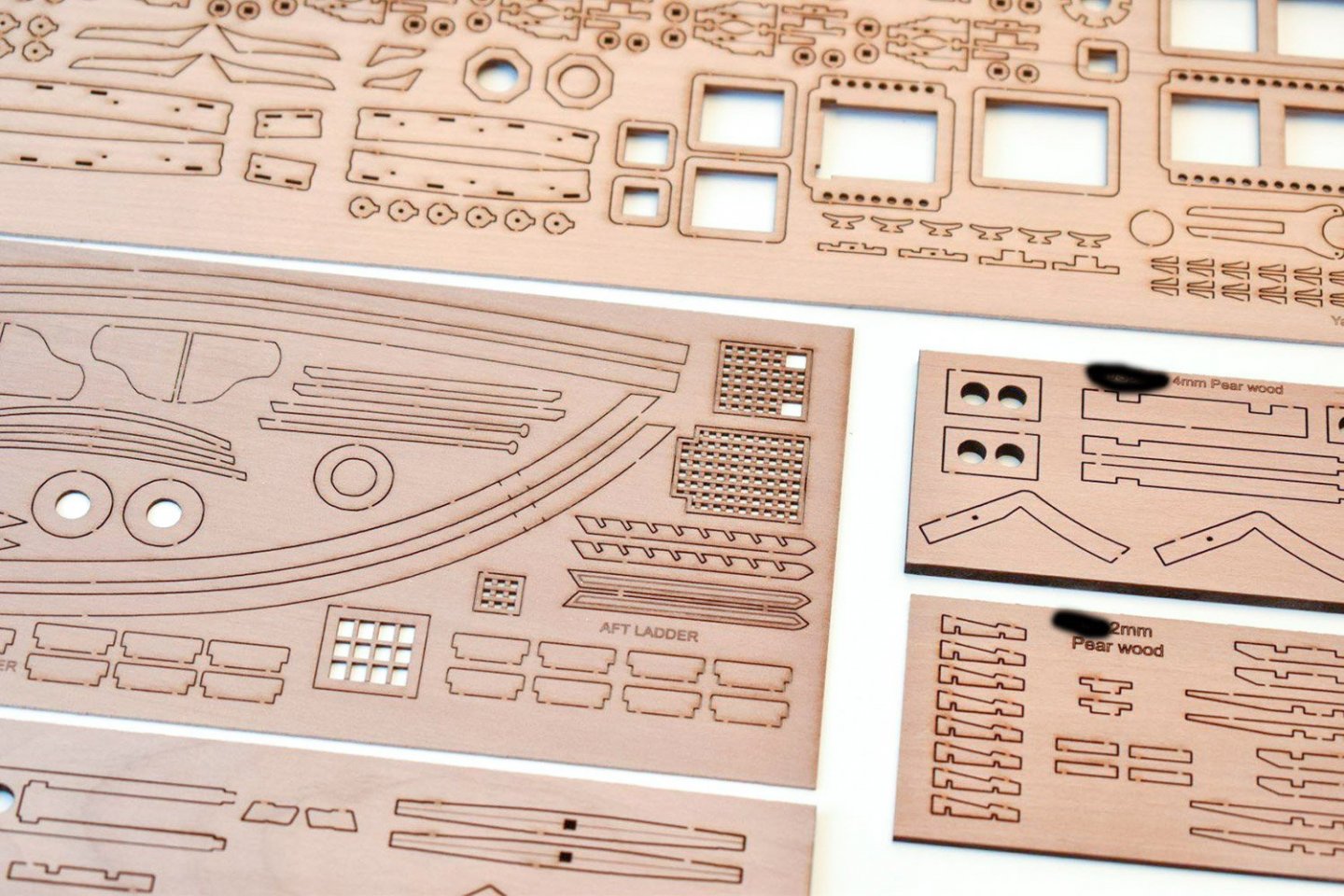

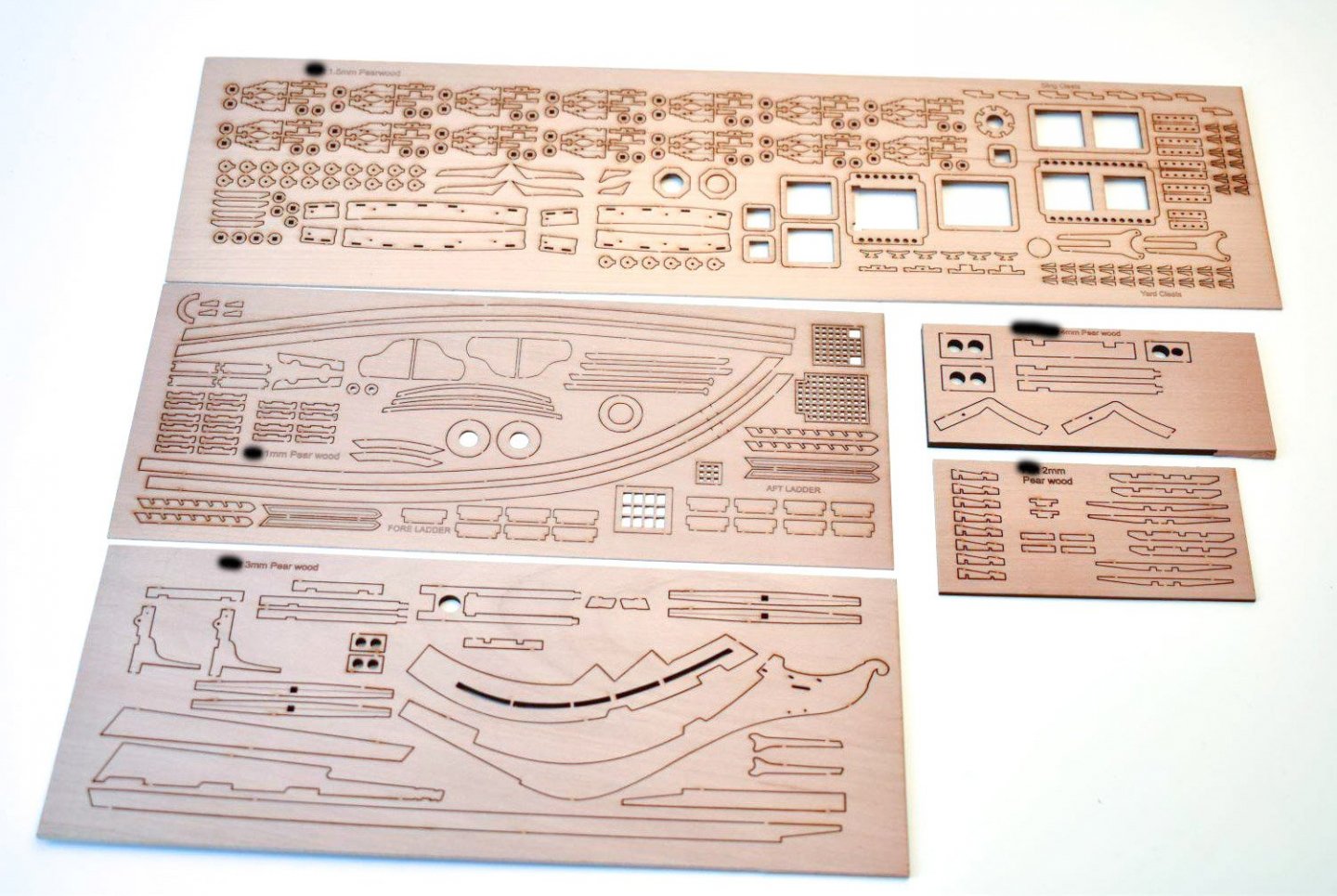

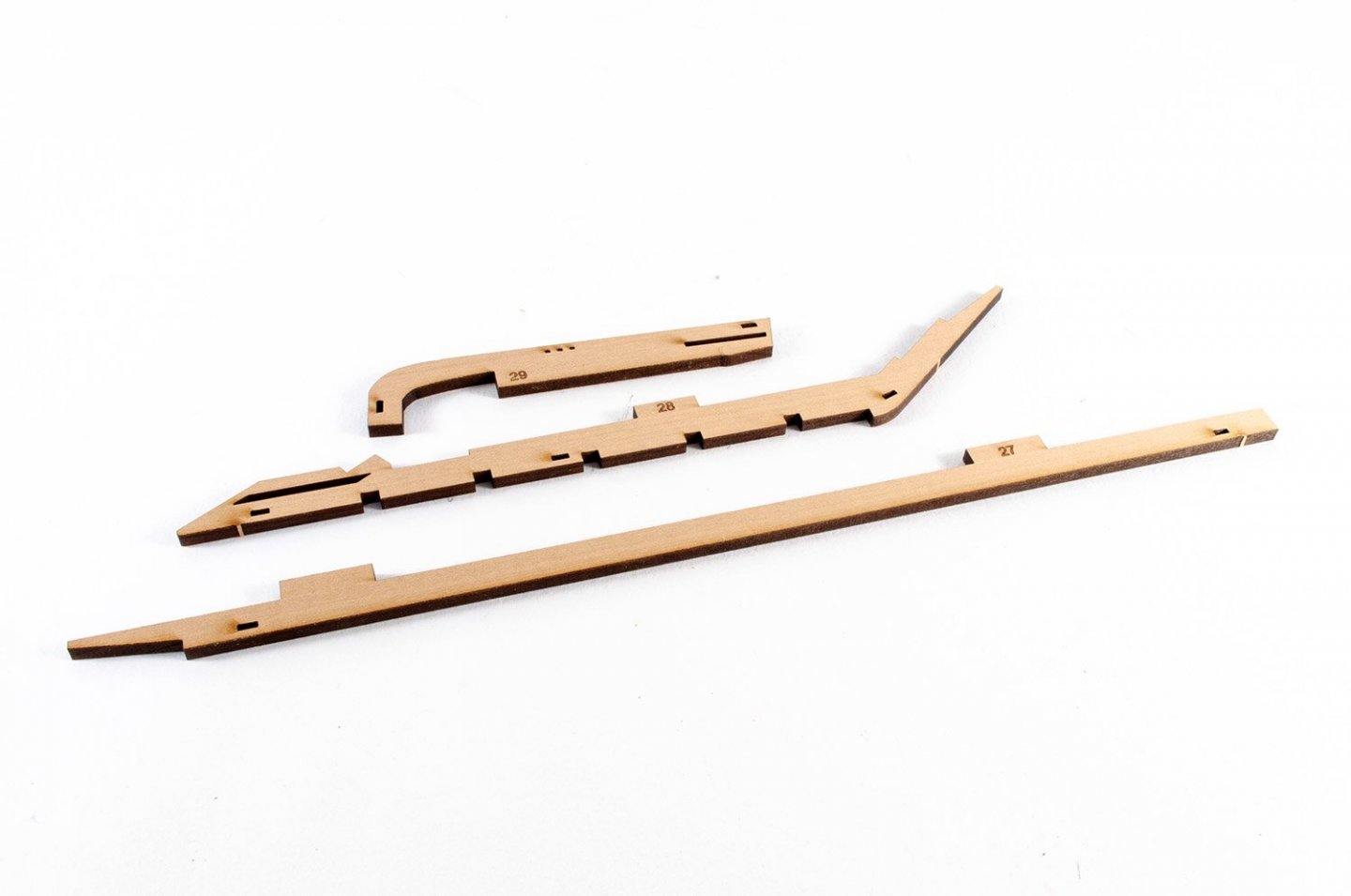

The school I work at closed today due to a confirmed case of coronavirus, and even though it will partially reopen in 2 days, after a deep clean, at-risk staff such as myself who has an underlying health condition, have been told to stay away for a month. Well, I couldn't waste any workshop time, so I got straight into the man cave and worked on Lady Isabella. Amati's sanding block had its baptism of fire when I faired the bulkheads in readiness for the planks. Thanks to previously bevelling the pre-engraved bulkheads, doing the rest only took about an hour, and in that short time I also got something to eat! The pearwood keel is presented in three parts which plug into the false keel. The lower keel and stern keel part are now glued into he hull. Even though you can't really get this wrong, the kit supplies some MDF clamps to slide over the assembly to ensure all is straight and even. In these photos, you can see the stem keel section in place, but at this stage, it must only be dry-fitted to test. The pear bulwarks are supplied in two parts per side and are engraved on the inner faces. Engraving is for the timberhead and lower/upper deck levels. These parts are 1mm and need to be soaked in water for 5 minutes before they can be manipulated. There is a slot on the stern keel into where the bulwark slides. All parts were wet-fitted to the hull and left to dry before removing. All parts are now fitted to the hull with Titebond glue, making sure the deck level is correct along the length. It's worth mentioning there is also a slot in the stem keep for the bulwark, but this isn't critical because the bulwarks are left slightly long to allow for any variation that the modeller might accidentally introduce. Some brass pins were pushed into the lower edges of the bulwark so the properly touched the bulkheads. Clamps were used above decks. Whilst this lot was drying, I thought I'd work on the superstructure. There are some little pear pegs that fit into the MDF core. These are pushed into place and then the external pear fascias are glued. The fit is a little tight but that's so you get everything properly aligned. Next.....planking.

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

ancre Coureur by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Ok....you have my attention -

kit review 1:8 Ferrari Timossi Racer ‘Arno XI’ (Special Edition)

James H replied to James H's topic in REVIEWS: Model kits

The real hard slog is done for you. This certainly wouldn't take you anywhere near as long as a masted ship.- 12 replies

-

- hydroplane

- arno

-

(and 2 more)

Tagged with:

-

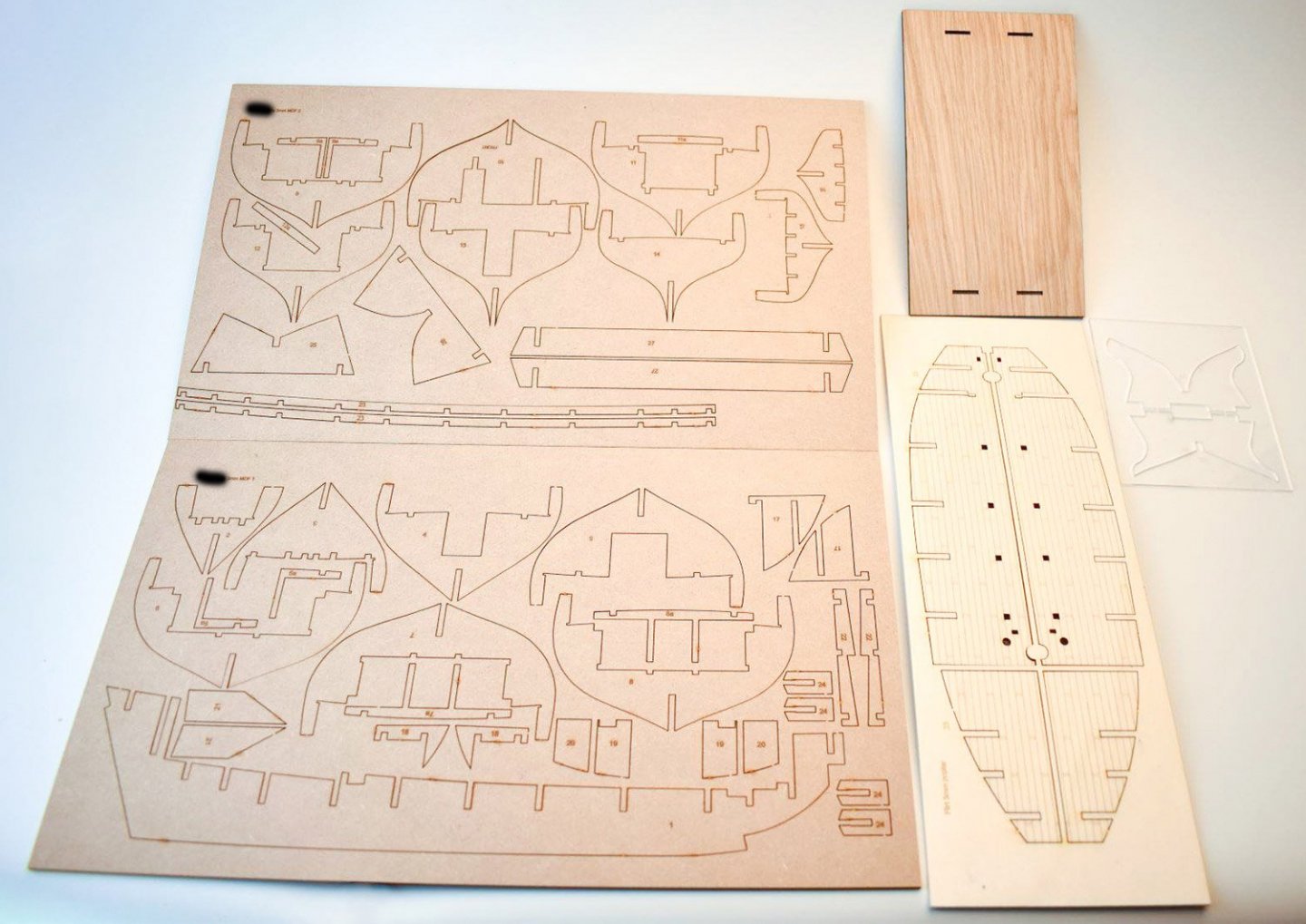

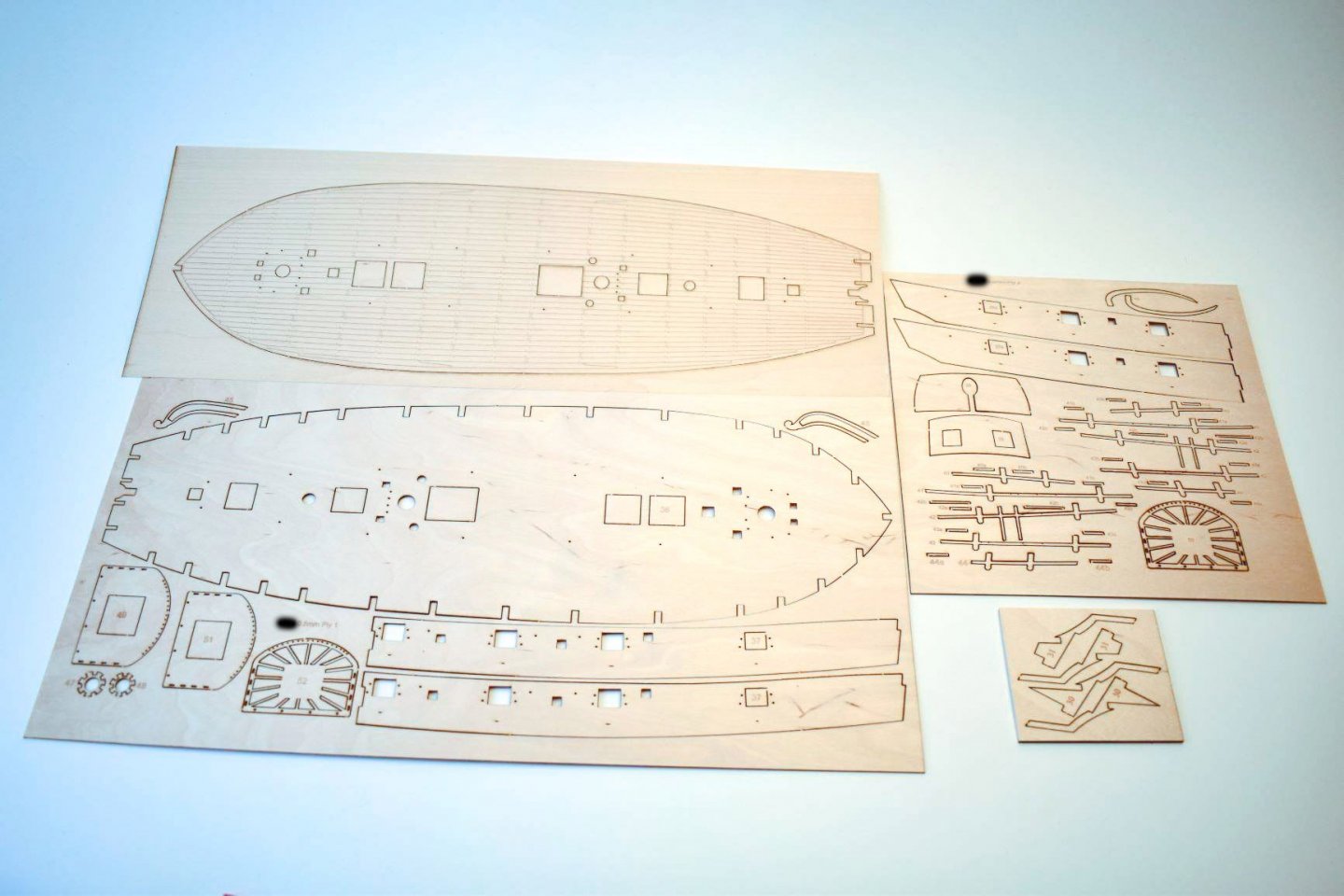

kit preview 1:64 Zulu fishing Boat - Vanguard Models

James H replied to James H's topic in REVIEWS: Model kits

I absolutely agree. It's a lovely build too, with everything doing exactly as it should in terms of fit. Fishing boats are my guilty little passion. There's a romanticism about them and the hard lives of the crews who bring us our fish suppers.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.