-

Posts

6,139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

I hope you'll enjoy the build. Any questions about it, and maybe anything I've not shown or later stages, feel free to ask.

-

There'll be more than one manual too. Maybe 2 or 3 manuals, depending on how Amati format it. I will try to make it as foolproof as possible, and Chris's design is such that it lends itself to ease of building. I think if you've got a few other kits under your belt, this is within a modeller's reach. Oh, and...

-

It is quite surprising just how high that waterline does go, but it's correct. There's very little space between it and the strakes.....enough for the white boot and some bare wood above it. Nice to see this coming along!

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

-

Dang, your second planking is better than mine was! What a great job you've made. Sand her nice and smooth and make sure you at least fill in any slight gaps below the waterline area (if any).

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

Now now! My dye mix looked right at the time! 😆

- 195 replies

-

- lady eleanor

- vanguard models

-

(and 1 more)

Tagged with:

-

kit review Kit Review - HMS ENTERPRIZE (1774) by CAF MODELS

James H replied to kljang's topic in REVIEWS: Model kits

Great to finally see a CAF kit reviewed here. Thanks for taking the time to go through all those boxes! -

Hope you wiped your feet on the way out 😄

-

So do I! I so want to see that kit built here. @PJG

-

Don't be daunted! We look forward to seeing you get this and crack that box open. Every build is a journey, no matter how much or little experience we have. That's part of the fun. There's plenty here who can and will help you. Remember, there's never such a thing as a silly question either. Just ask away! @chris watton designed that model too, so he'll be able to watch your progress.

-

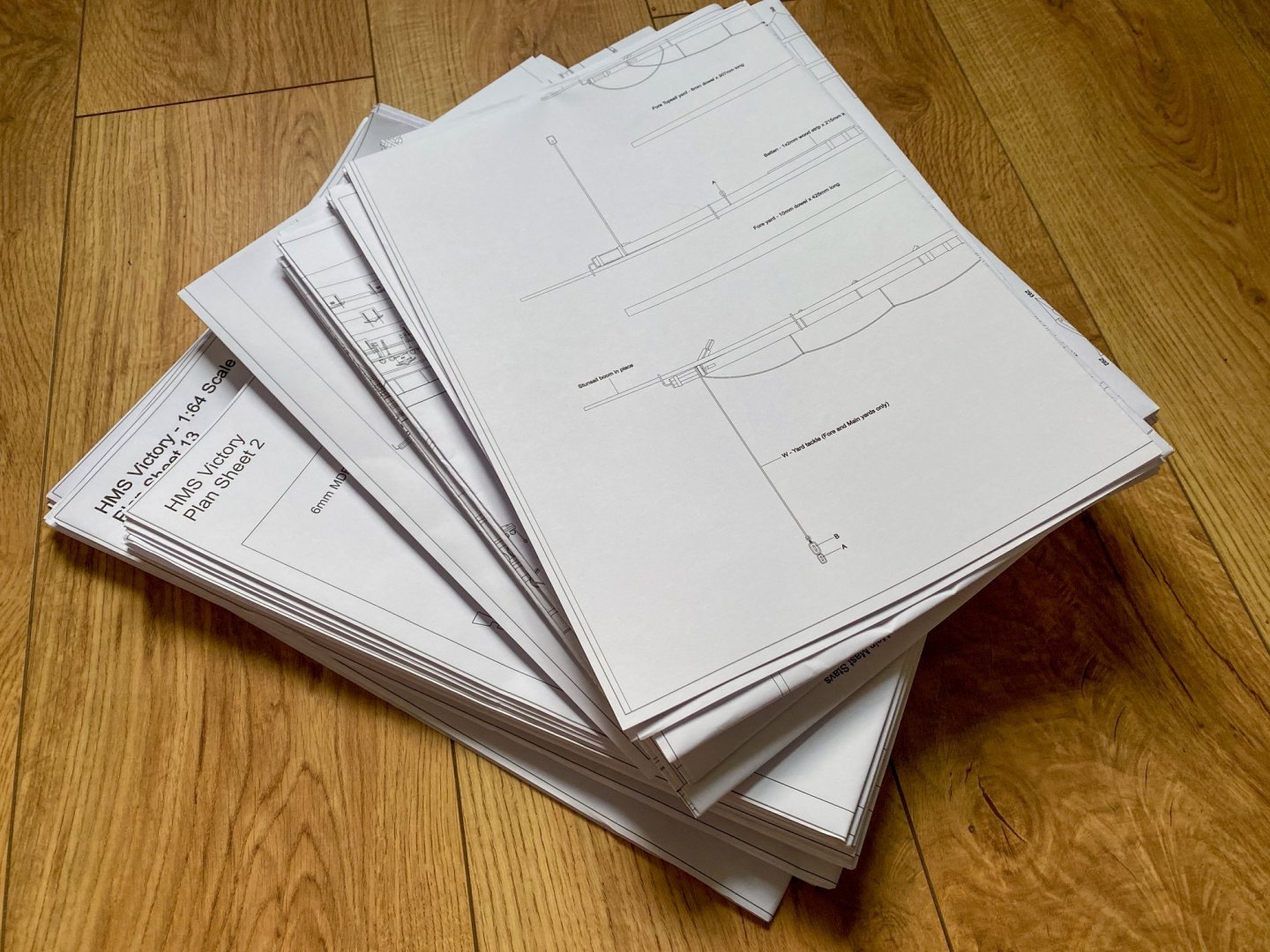

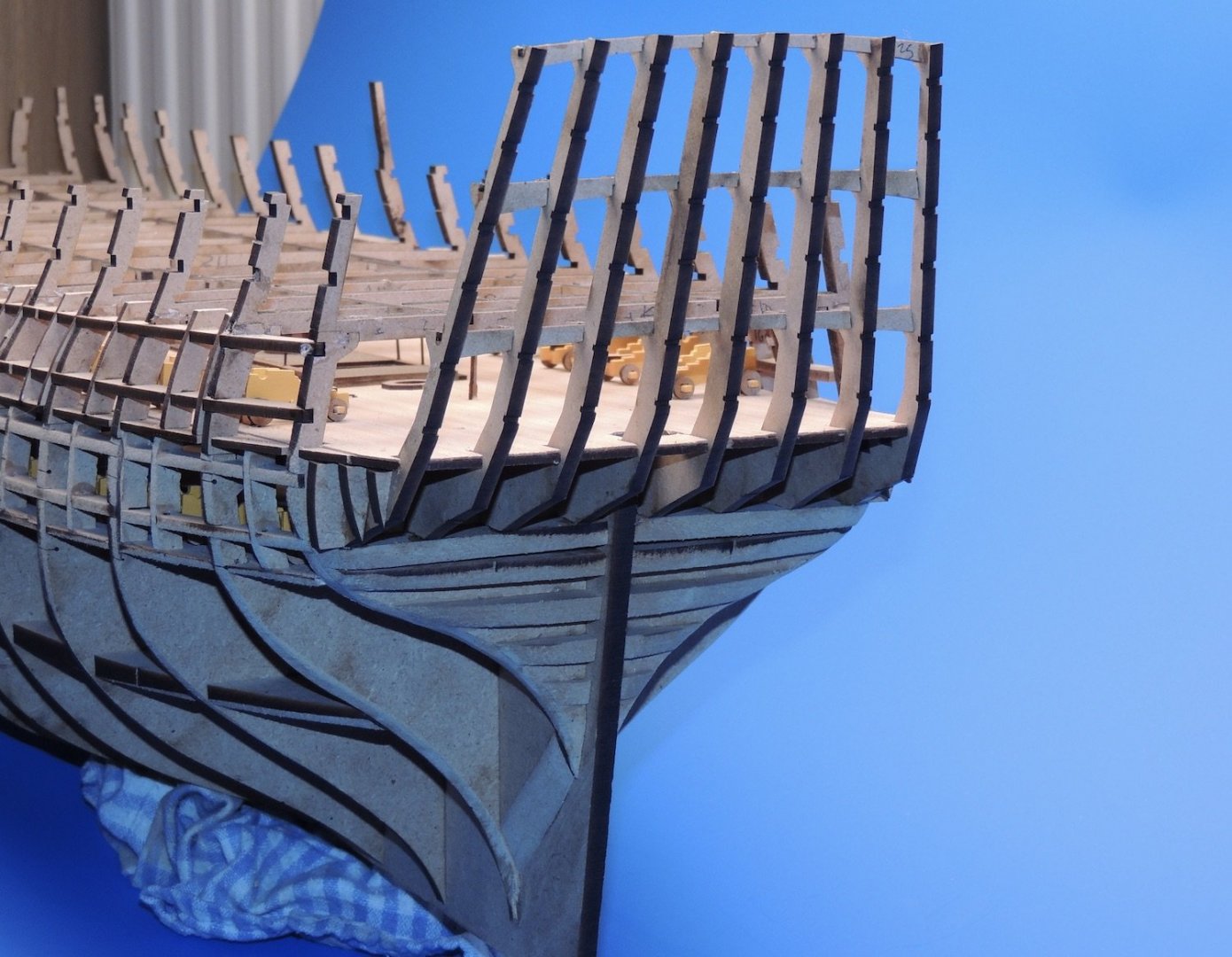

You nailed it, absolutely. If you can't have a slice of the pie, then just complain that you don't like the flavour. No doubt they'll welcome this kit once ZHL has pirated it and they are guiding folk to the pirate product page. I see you're from God's own county My favourite shire. MDF has more consistent tolerances than ply....even some of the very best quality. The Vic, for example, could not have been designed in the way it was if it wasn't for those tight tolerances of the MDF. It has several hundred interlocking joints. Chris will tell you than ply can vary quite a lot in thickness from batch to batch and even across the same sheet. Accumulation of tolerance errors would have made this model a nightmare with the modeller opening up slots etc. I know MDF isn't good when it gets wet, but do some guys build there models in a swimming pool or shower? What's this about it coming to pieces with glue? Absolute rubbish. I've used very thin MDF and PVA with no problems. I know kids who use thin MDF to make things with tons of glue, and they don't have problems either. Odd eh? ❓ Also this stuff about it not being suitable for modelling (structural). Well, you've seen the Victory prototype, Chris's other designs, so it is suitable. Some folks don't like MDF and that's fine. You hear some moan about the dust from it being nasty....well those folks need to check out the hazards associated with the resins in the timber dust they create normally, including the resins bonding ply. Several countries, for example, class all wood dust as carcinogenic. The simple solution is don't breathe in any dust you create, be it timber, ply, or MDF. Haha! Chris has explained this quite a few times, so I've just done it again for him. See above

-

I might be able to get away with some stuff that won't be seen in the manuals, such as furniture.....and possibly even lighting if I hide it surreptitiously enough.

-

No reason you can’t do that. I won’t be able to with mine as it’s for the manual, but I’ll be following the builds that eventually begin on MSW.

-

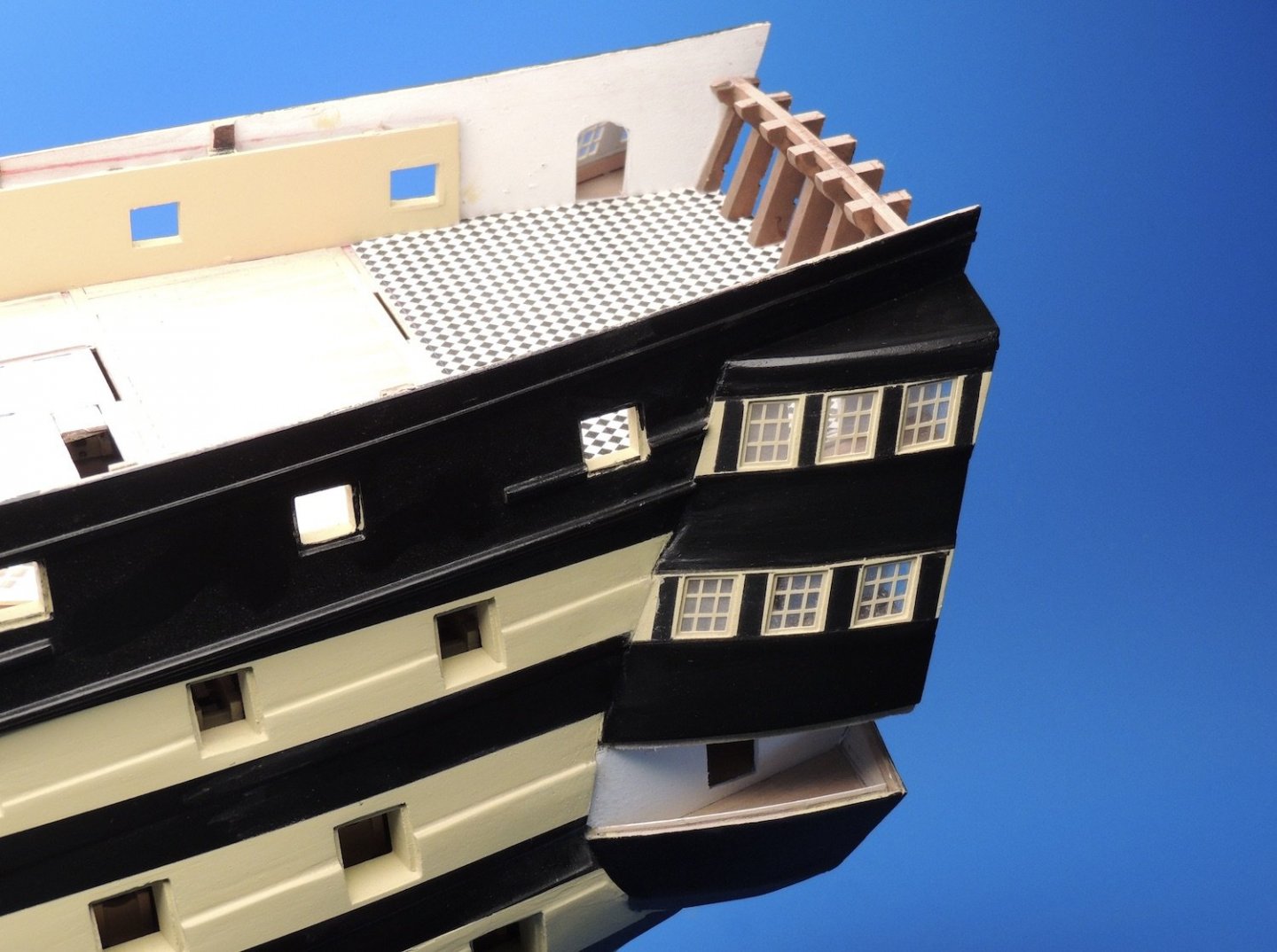

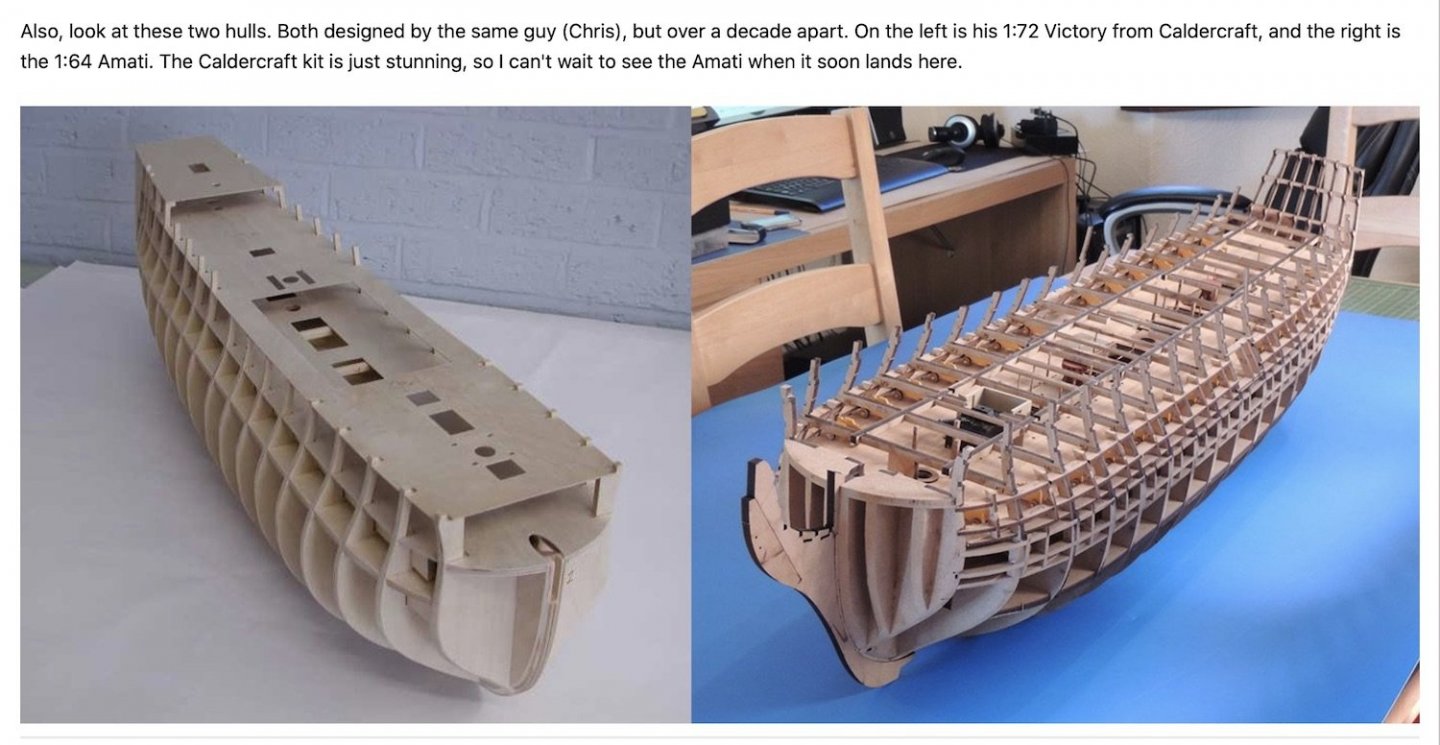

I also forgot. Unlike the Caldercraft kit, as excellent as it is, you will be able to furnish and fit out the cabins at the stern., as the decks run right through to this area. No furnishings come with the kit, but imagine putting some cabinets, tables, chairs and LED lanterns in there! Maybe there's a way I can do this without compromising anything for Amati. If I can, then I will, but it won't be seen in the manual....only on MSW! Caldercraft: Amati:

-

ancre Coureur by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

She looks impressive with masts. What's the overall size? -

I think so too. I suppose if Bismarck is popular, then Amati may want to try their hand with Hood. I imagine the development coats and initial production outlay for Bismarck will be quite high.

-

Ok...some answers. Bismarck is now scheduled for Autumn, possibly around October. As for HMS Hood, Amati aren't sure on that, as far as popularity goes. German battleships always sell, irrespective of the sales region, but that may not translate into HMS Hood.

-

Not sure about the Hood. I can ask. Very good question! I'll try to get an answer for you. This virus has screwed all sorts up!

-

I'm told the stuff is being packed/kitted to ship out, so I should be able to give you a glimpse of that triumvirate soon

-

And I have them all here. Amati are also aware of the accusations posted on the piracy site, and are watching.

-

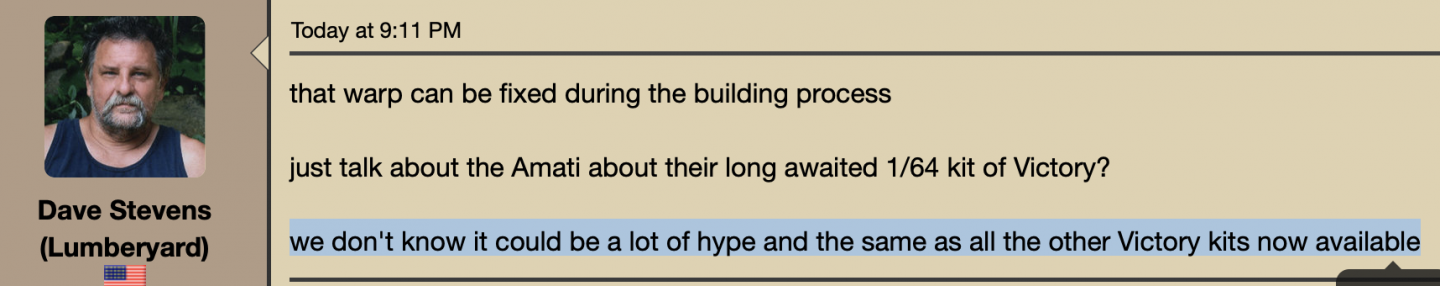

The ramblings of a demented, delusional and piracy-advocating moron... See for yourself, and make your own mind up... Er, yes Dave Stevens...ok!

-

Ignore these morons on the piracy site too... They are watching this topic and obfuscating. Er yes, ok.....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.