-

Posts

6,067 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

Nice catch!

-

Orient Express Sleeping Car 1929 by James H - Amati - 1/32

James H replied to James H's topic in Non-ship/categorised builds

Not yet. I'm totally maxed out on other publishing commitments, but I really want to get back to this, and my Mary Rose. -

I used to live in Church, just next door to you. Now in Horwich. Nice to see another Lancastrian here!!

-

kit review 1:32 Fifie – The Scottish Motor Fishing Vessel by Amati

James H replied to James H's topic in REVIEWS: Model kits

I think that as long as you have some modelling skills, this could be a good first choice for a wooden model kit. -

I hope you'll share a build log with us.

-

Thanks for the link. It's very useful. I didn't mention the videos in the review, and perhaps I should, although OcCre were still building it themselves at the time with only around 40 of the 111 videos complete. I did embed the very first one towards the top of the review though, so they would have been fairly easy to find the subsequent ones.

-

Plank bending

James H replied to Timothy Doe's topic in Building, Framing, Planking and plating a ships hull and deck

Moving topic to correct area as posted in the 'Using this Forum' section . -

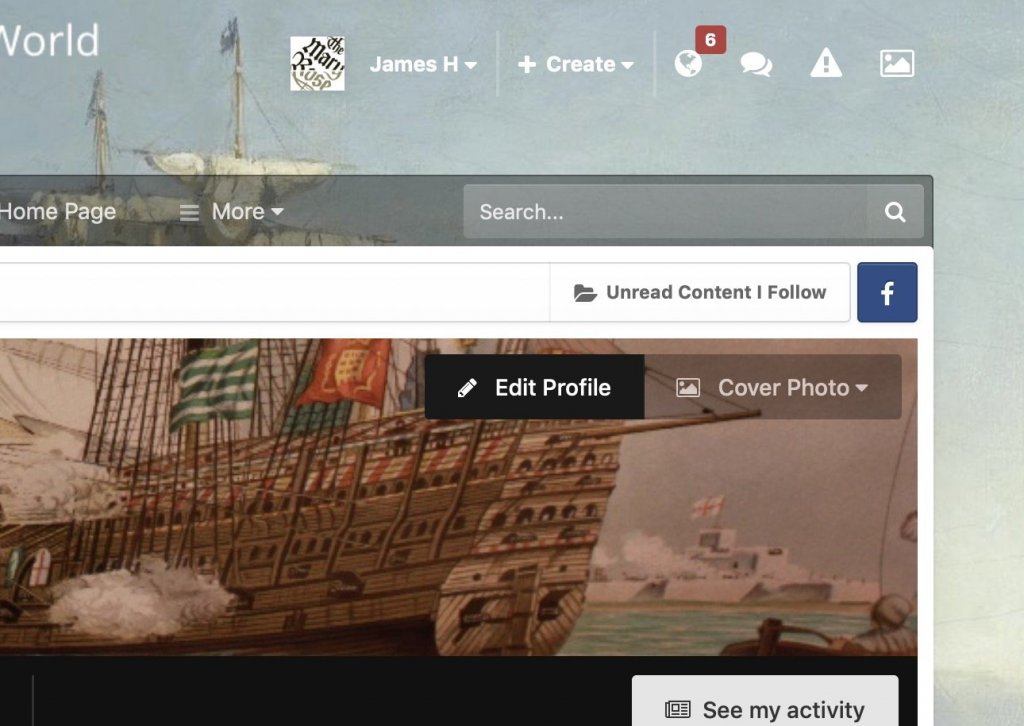

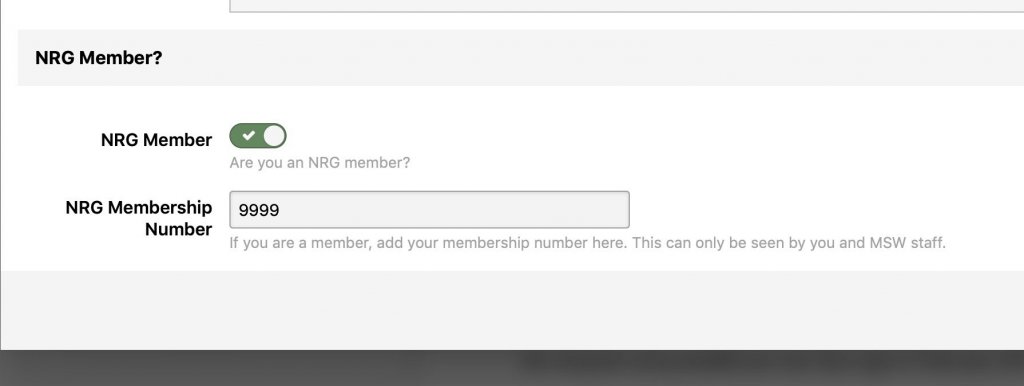

Hi all, With our last upgrade, the profile fields to display your NRG membership number under your avatar (if you are indeed a member), either became corrupted or superseded by the update. We took the opportunity to recreate these using a better system which can be found on your profile page. There is now no useless MSW member checkbox, as we know you already will be! All you now need to do, if you want your NRG number displayed under your avatar, is to go to your profile page and set the following options at the bottom of that page. Et voila! Your number is displayed below your avatar. NOTE: This number is only visible to YOU and MSW/NRG staff.

-

Nice to see you back at the bench again, Martin. I know things haven't been easy for you, and your Agamemnon is good therapy and excellent craftsmanship. A fine build indeed!

- 122 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Orient Express Sleeping Car 1929 by James H - Amati - 1/32

James H replied to James H's topic in Non-ship/categorised builds

Fully detailed due to large scale. Complete interior, turrets, engines, bomb bay etc. -

Orient Express Sleeping Car 1929 by James H - Amati - 1/32

James H replied to James H's topic in Non-ship/categorised builds

Not yet. I'm still fighting deadlines for my magazine work. I've just completed this model in 1:32 scale for Military Illustrated Modeller... -

Stepless Adjustment Circular Cutter DSPIAE Catalogue # HRC64~75 Available from Breveco Modelling for €67,50 I was recently lucky enough to be sent the Thinnerline circular cutter for test. If you don’t know what these tools do, then it’s quite simple…they allow the modeller to cut out discs in masking paper and very thin plasticard etc. from around 1mm to 50mm in diameter. Having found the Thinnerline an amazing tool, I couldn’t turn down the offer to try out the brand new DSPIAE tool kindly sent to me for review from the Netherlands, by Corien and Evert from Breveco Modelling. DSPIAE’s new Stepless Adjustment Circular Cutter (long name!) comes in a very attractive, robust and heavy box whose quality is pretty reminiscent of the way Apple packages its products. The box lid contains a line drawing illustration of the circle cutter, and the edge of the box has a unique 16-didgit identifier that you can use to verify that this is a genuine DSPIAE product, and not a counterfeit. Certain elements of our hobby have succumbed to piracy, so this is a very nice touch. The only thing I can pick up on is that the box lid states the minimum size is 1mm, whilst the maximum is 7.8! I am pretty sure that this is more like 50mm. The lid is a seriously snug fit, and once you overcome the suction when you remove it, you’ll find a removable tray with foam cut-outs. This contains three different cutting tools in their own plastic box, tool assembly components and a screwdriver. Yes, you will need to assemble this cutter, but it won’t take more than a few minutes. For information, the tray lid tells you the cutting angle for each blade. These are colour-coded for ease of recognition. Assembly After lifting out the tray, you will find a foam-backed instruction card, with everything clearly shown in line drawing format. The cutter is assembled in six easy stages. Unlike the Thinnerline tool which is essentially based upon a bearing, with internal parts, the DSPIAE tool is also enveloped in an aluminium case that protects the bearing. This is machined in high quality material and has a red/crimson appearance to it, applied probably through anodization. The sharp corners are then machined at 45 degrees, exposing the metal again. Very attractive indeed. The two-part aluminium housing is now bolted to the exterior of the bearing, and tightened with the supplied tools. Four grub screws are now applied, securing the bearing so it doesn’t slide. Don’t fasten these too tight. They only need to nip. Now the adjuster and gauge are fitted. I did find a washer left over and a small neodymium magnet. They aren’t on the instructions. Use After fitting the blade into the tool (yellow 45 degrees) and adjusting its position, I dial the size of circle I want into the cutter, and the cutter is sat on a sheet of masking paper. I then use the small handle to turn the inner bearing and a perfect circle is cut. It really is that simple. The gauge works so that the close to the centre of the bearing you adjust the pointer, the smaller the mask. Move it outwards towards the circumference, and your masks are larger. The cutting tools are amazingly sharp and should be kept in their plastic protectors when not in use. Conclusion Does exactly what it was designed to do, and flawlessly. An amazingly high quality tool for which you will find endless masking applications in your hobby, from wheel hubs to inner radius curves for canopies etc. You really should treat yourself! My sincere thanks to Breveco Modelling for the opportunity to try out this new tool. To buy it directly, click HERE.

-

tool review Photo Etched Parts Bender

James H replied to James H's topic in REVIEWS: Model Shipwrighting Tools, Parts and fittings

I'll post that review for you right now

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.