-

Posts

2,951 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by thibaultron

-

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

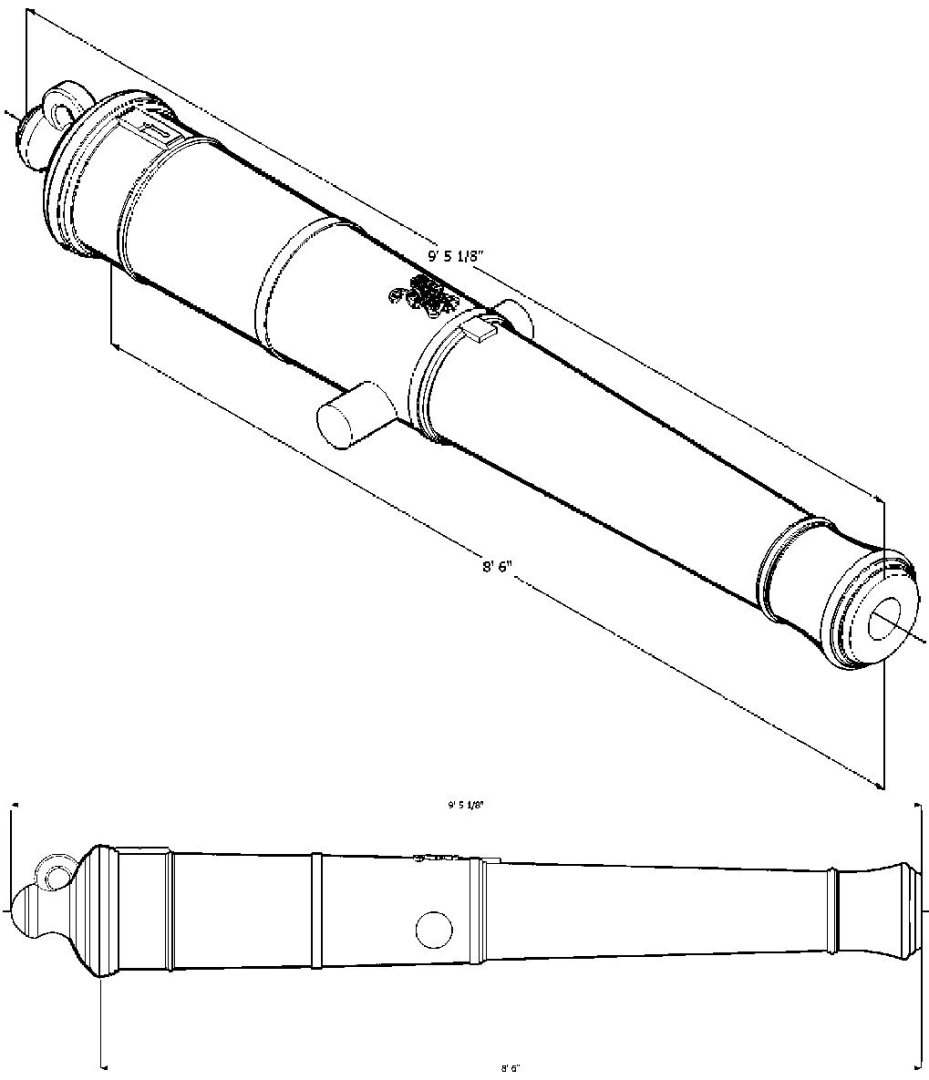

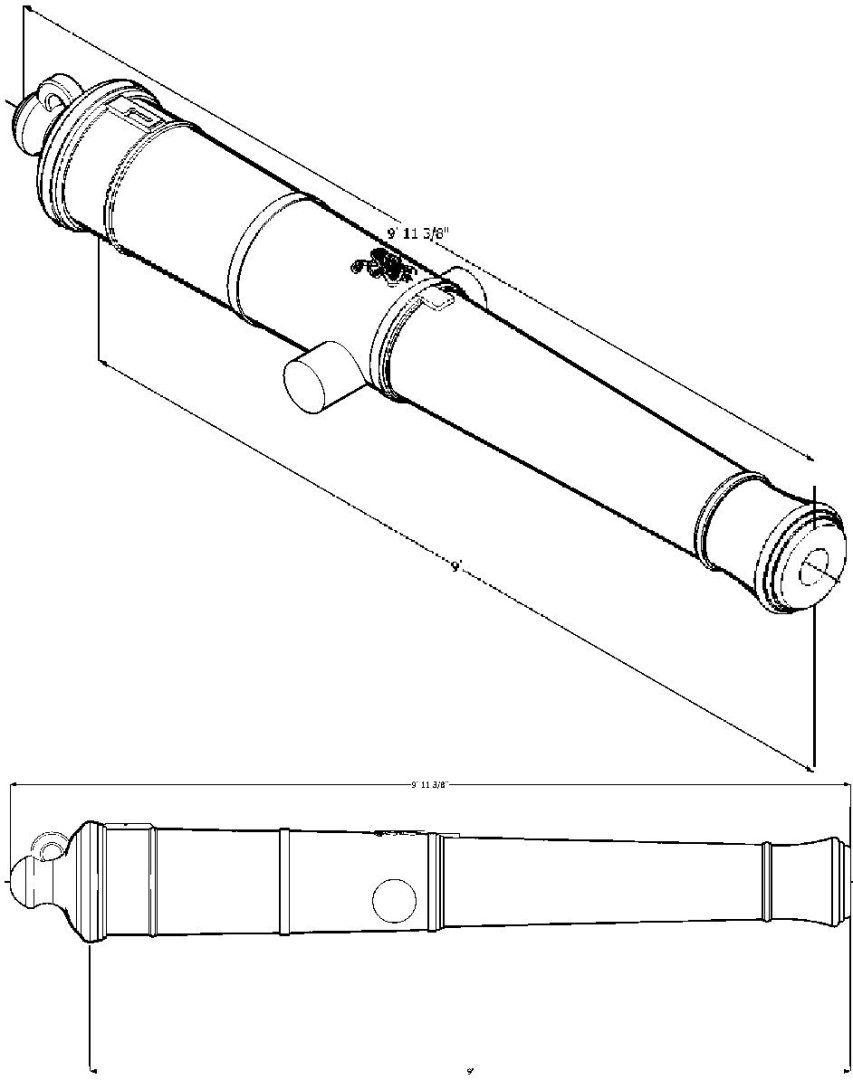

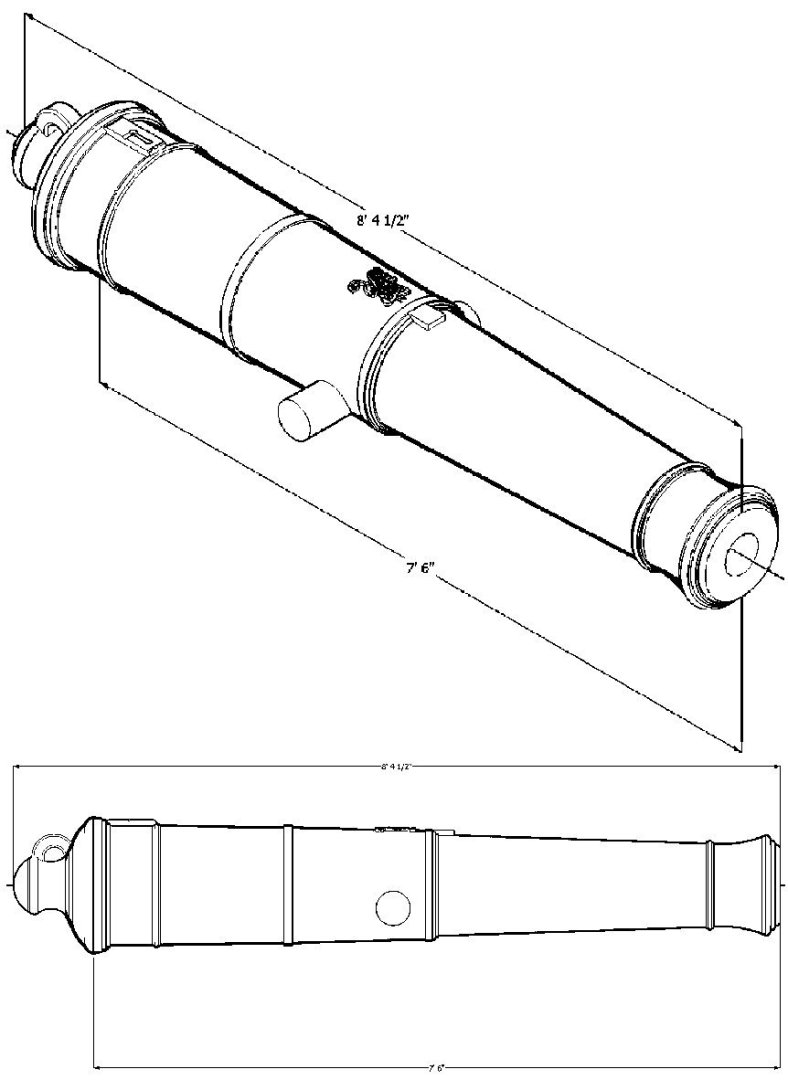

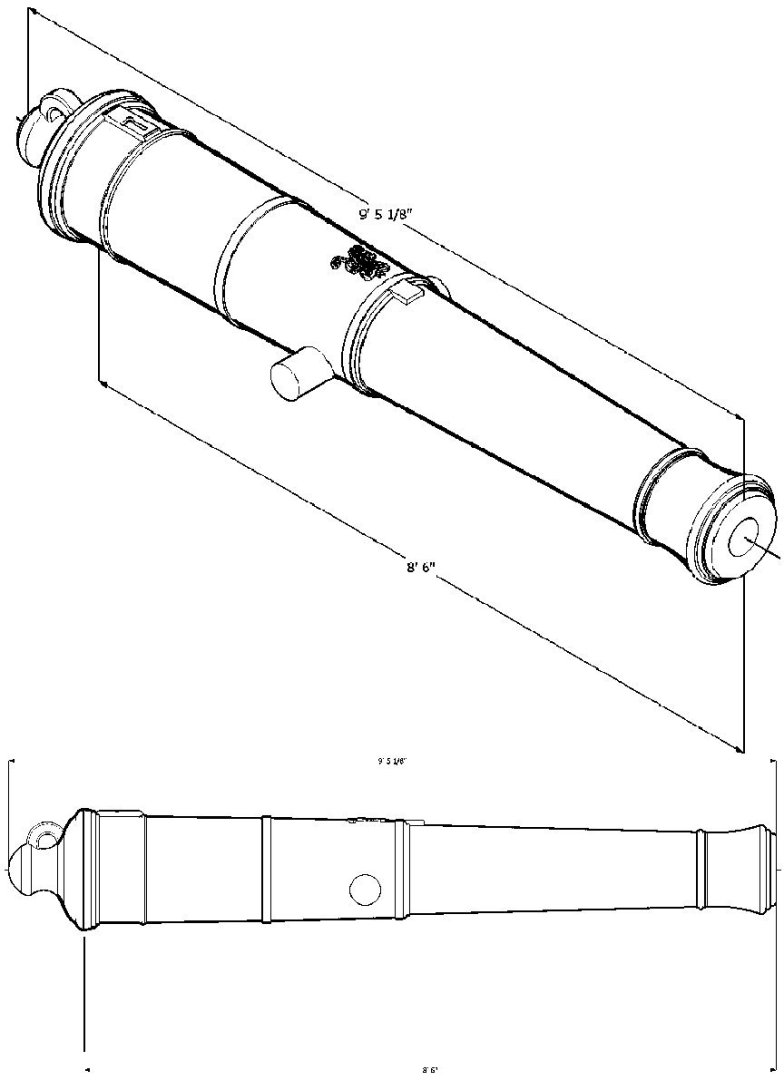

OK, the NRG class today starts an hour later than I thought, so here is the Blomefield info. These are the only sizes I had drawings for. Blomefield Pattern about 1787 Graphics 6 Pounder 84 6 Pounder 90 6 Pounder 102 9 Pounder 90 9 Pounder 102 9 Pounder 108 12 Pounder 90 12 Pounder 102 12 Pounder 108 18 Pounder 108 18 Ponder 114 24 Pounder 108 24 Pounder 114 32 Pounder 114 -

A story I heard, about 50 years ago. I worked in a defense industry, designing military radars. Gray is a very difficult color to mix consistently between batches, even commercially, Well a high ranking officer got a bug up his rear, and decided to check one type of equipment color as compared to the official paint chip he had. Sure enough none to the field equipment matched, and he went into a tirade! He demanded all that type of equipment be repainted, to match the paint chips he handed out! He said he would be back in X amount of time, and check again. Dire consequences were promised! Well the time came, and he returned. All but one of the equipment at the various locations failed, but one! Afterwards, the other locations call the successful one and asked how he had managed to match the paint chip he was given. He told them he repainted his chip at the same time he repainted the equipment!

-

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

I will be posting the Blomefield Cannons later today, or tomorrow. I have to create the Brown Pattern Cannon graphics, so they will be posted later this week, the STL files are finished. -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Spanish Cannons 1718 Pattern STLs . Spanish 5 Pounder Cannon 1718 Pattern Full Size_1642_27mm.stl Spanish 9 Pounder Cannon 1718 Pattern Full Size_1880_92mm.stl Spanish 12 Pounder Cannon 1718 Pattern Full Size_2214_83mm.stl Spanish 16 Pounder Cannon 1718 Pattern Full Size_3009_77mm.stl Spanish 24 Pounder Cannon 1718 Pattern Full Size_3353_46mm.stl -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

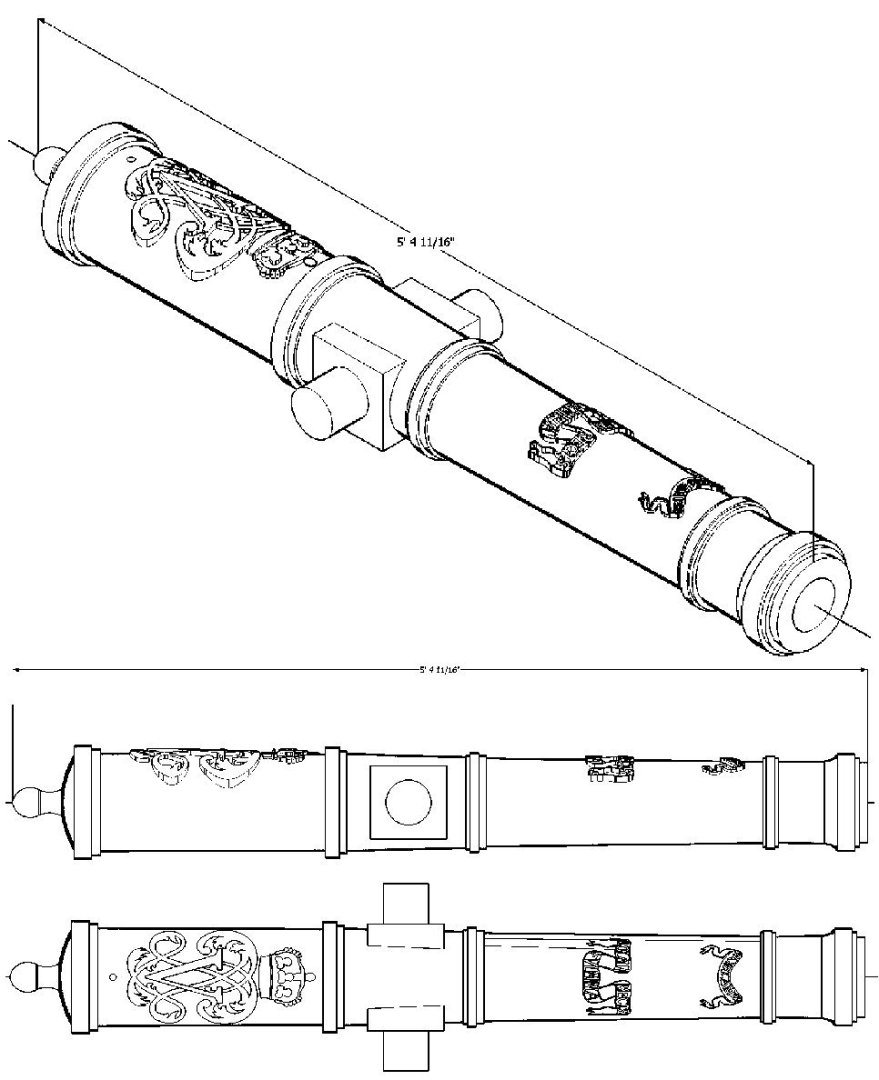

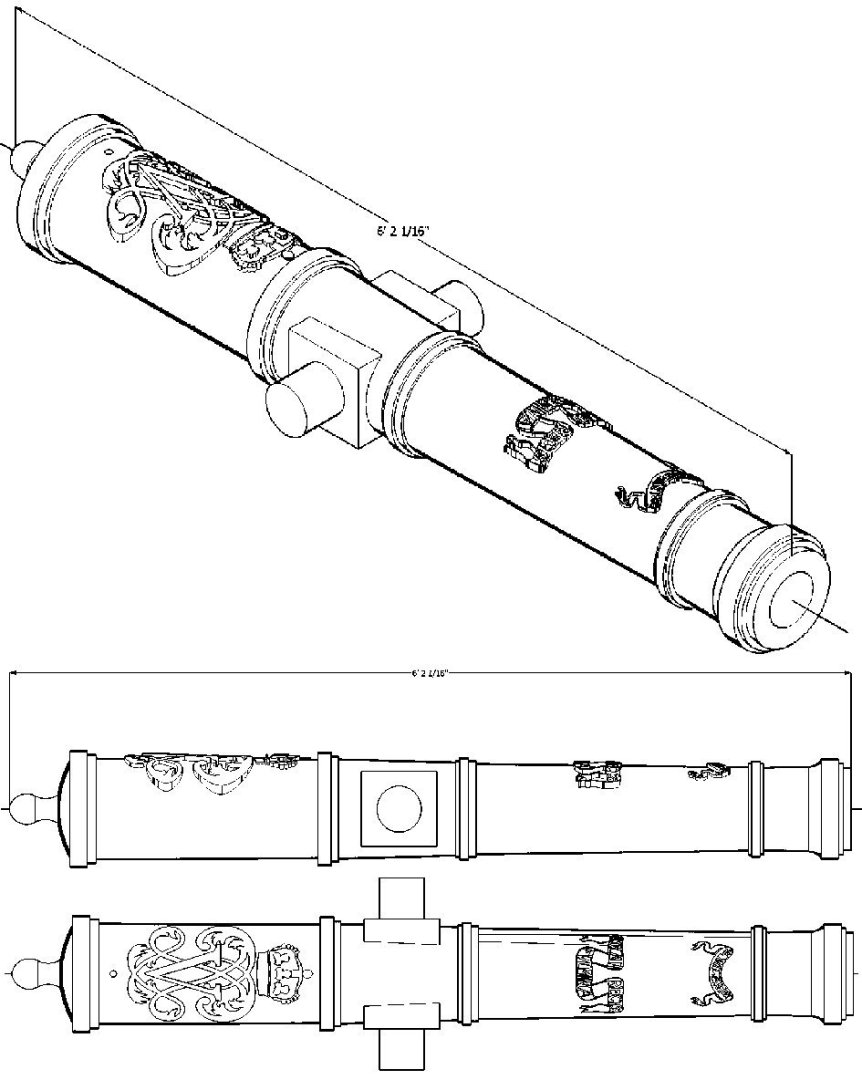

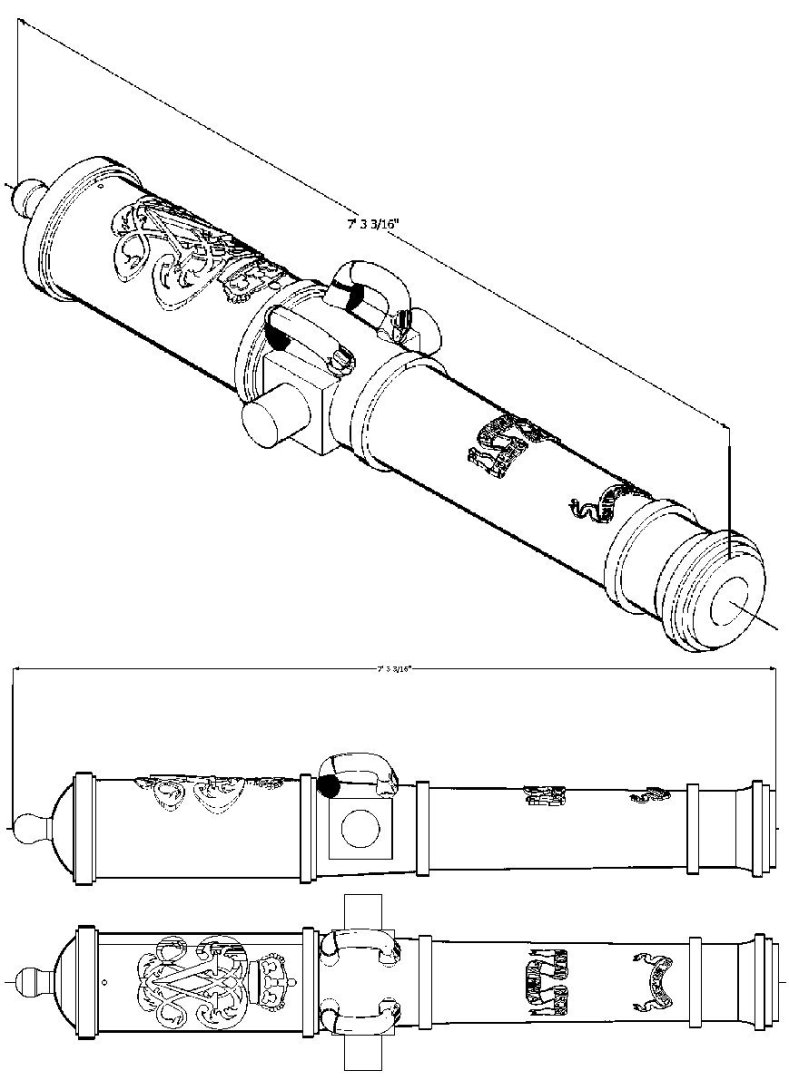

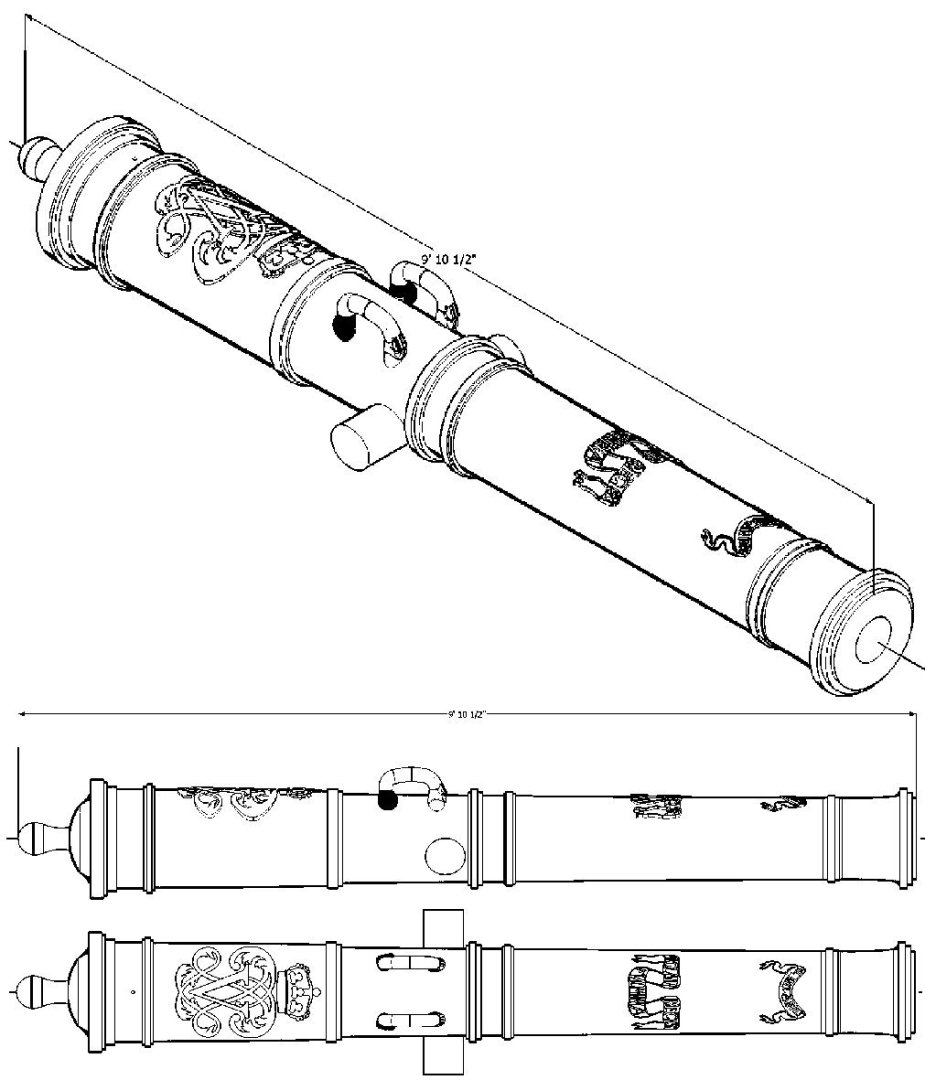

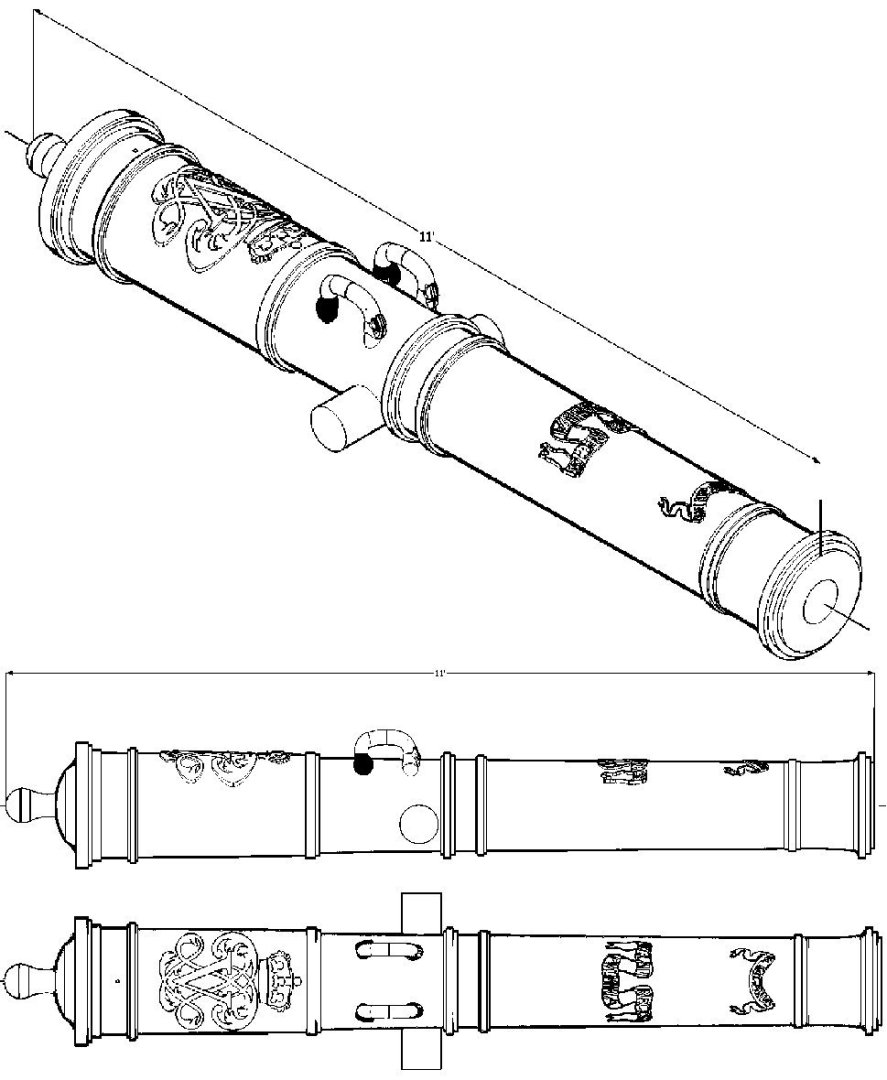

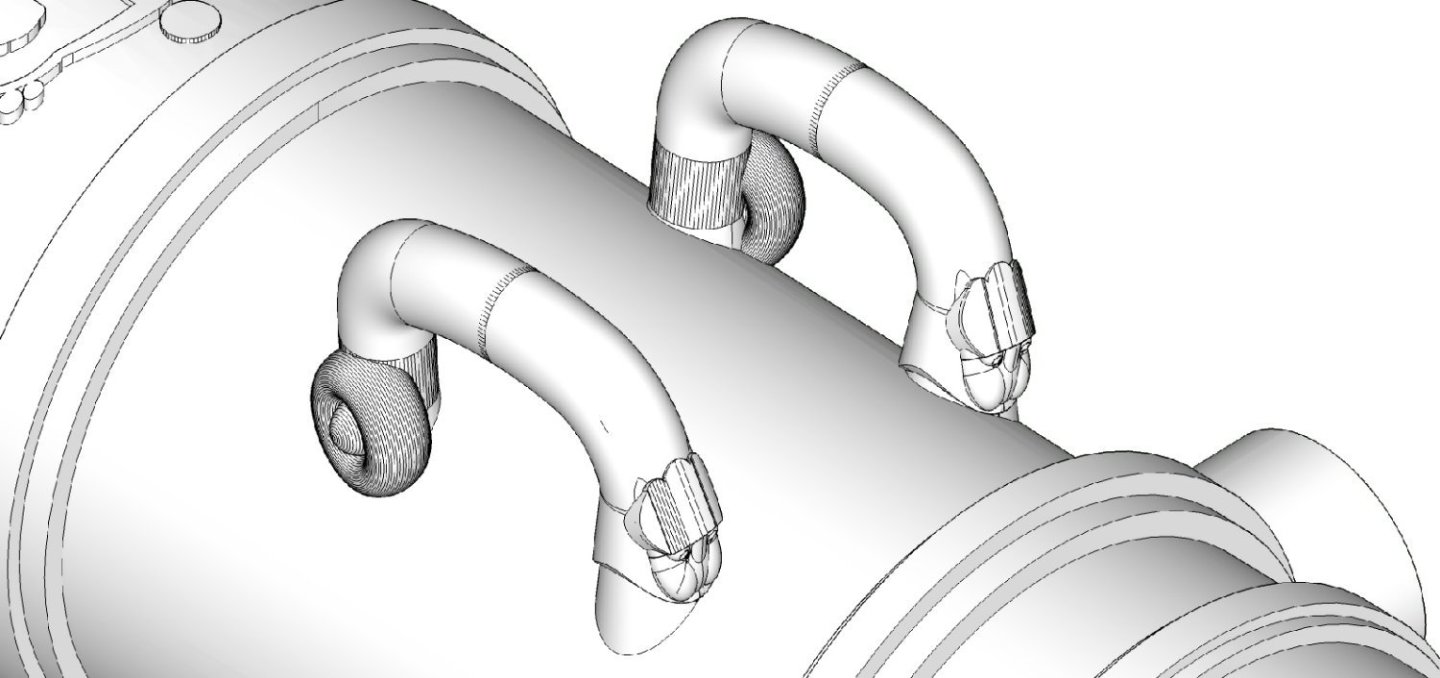

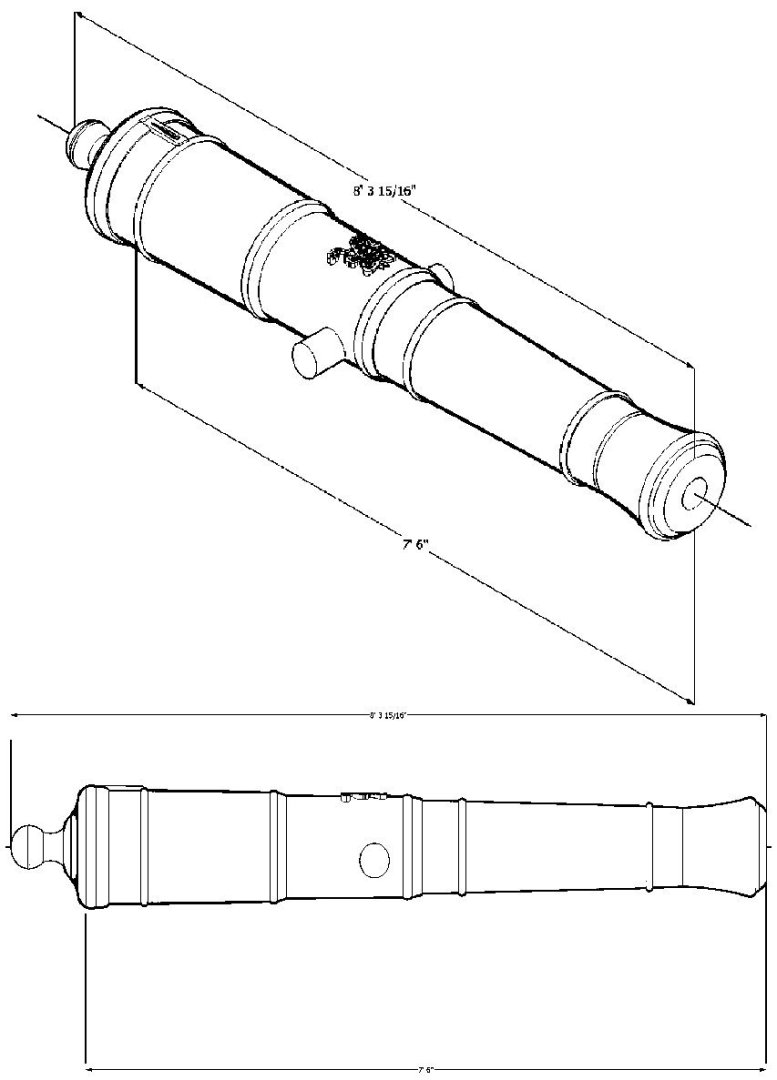

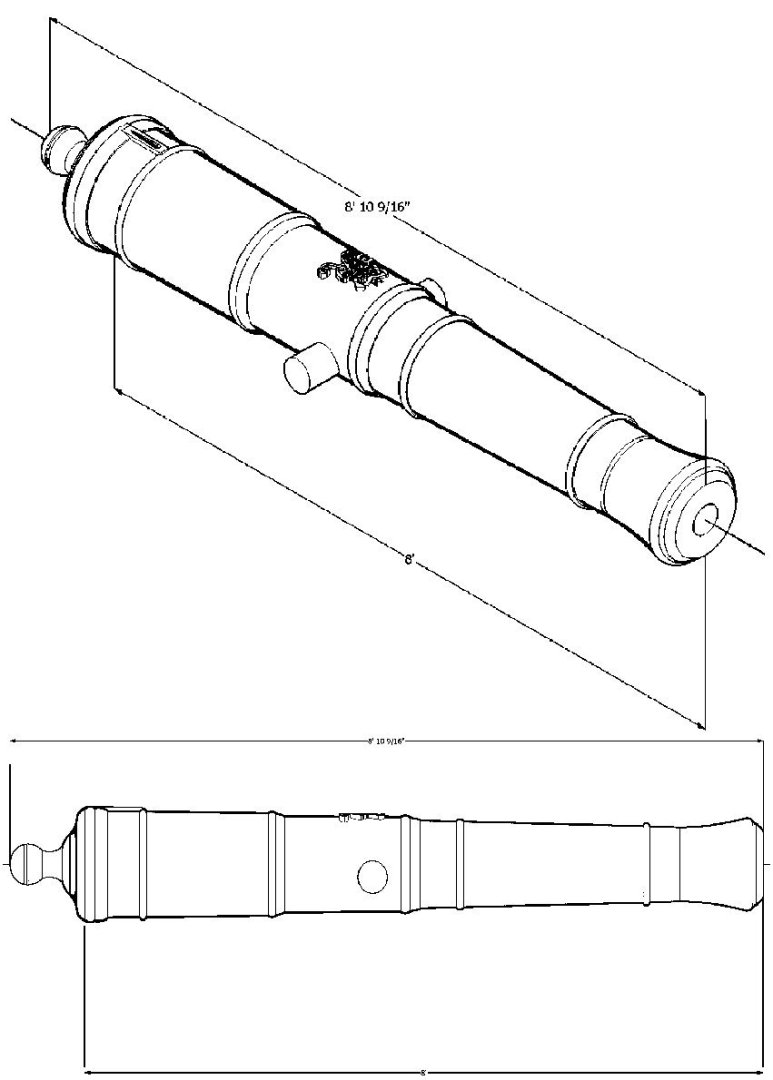

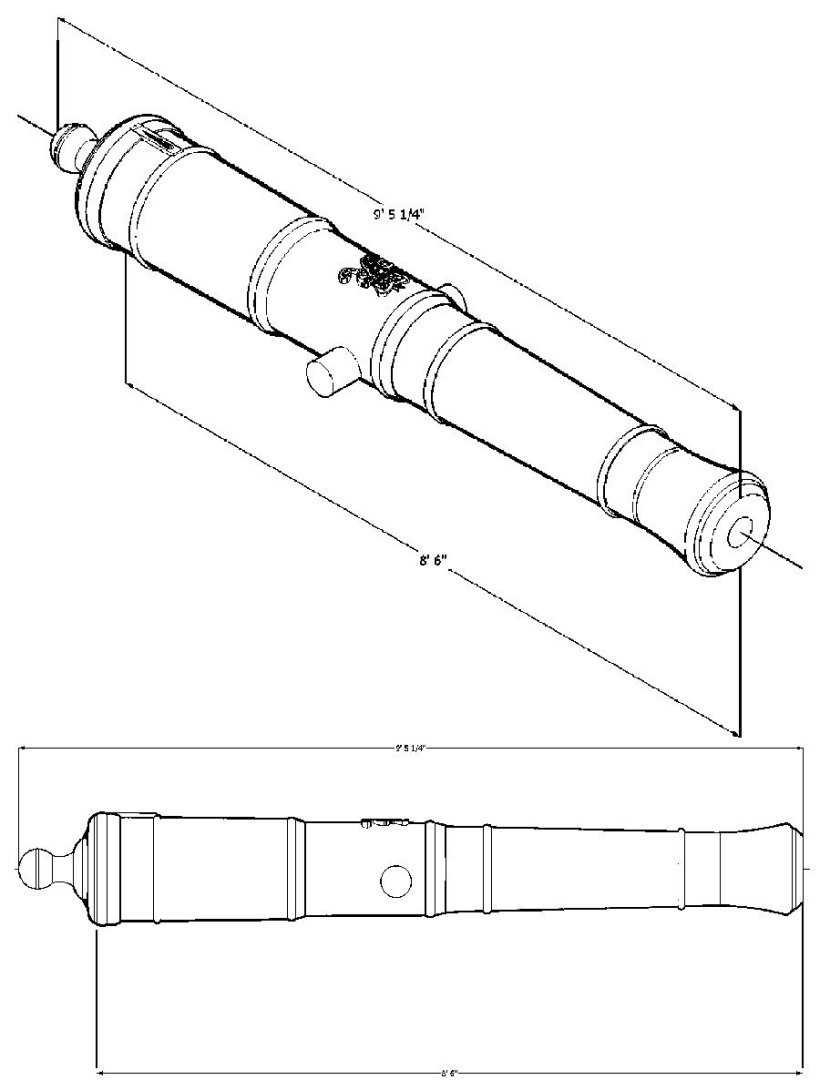

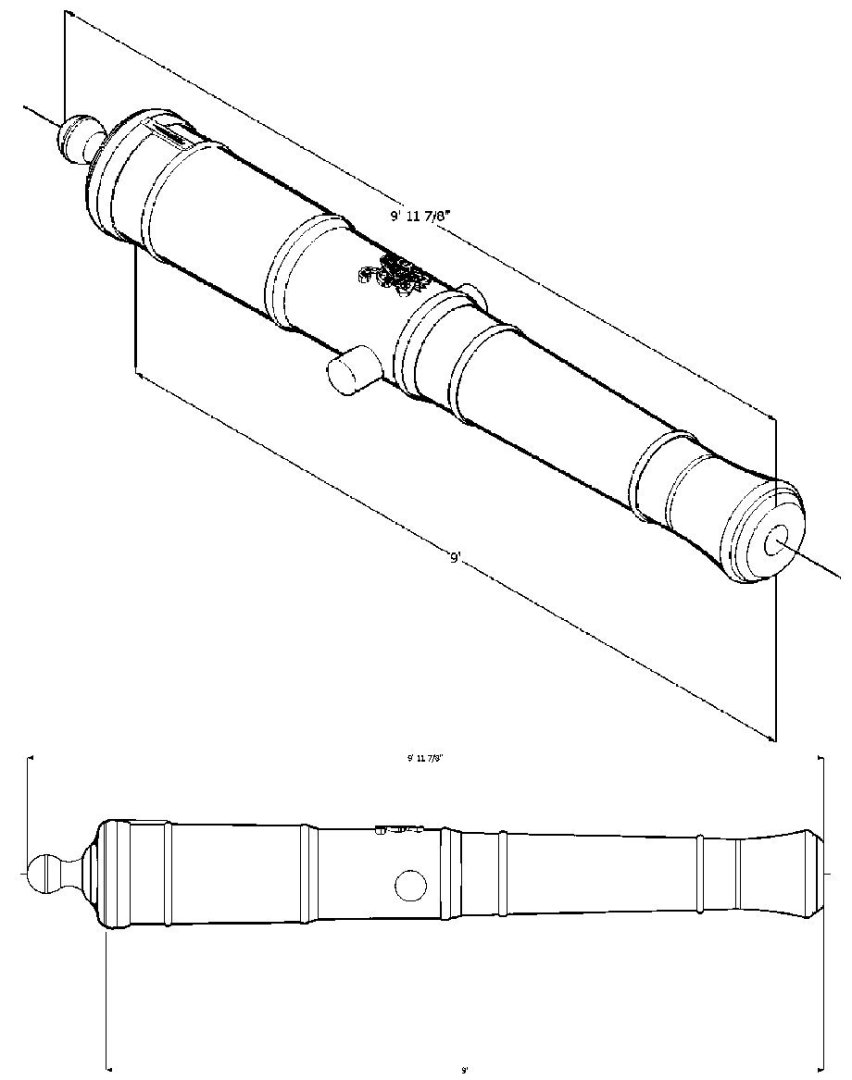

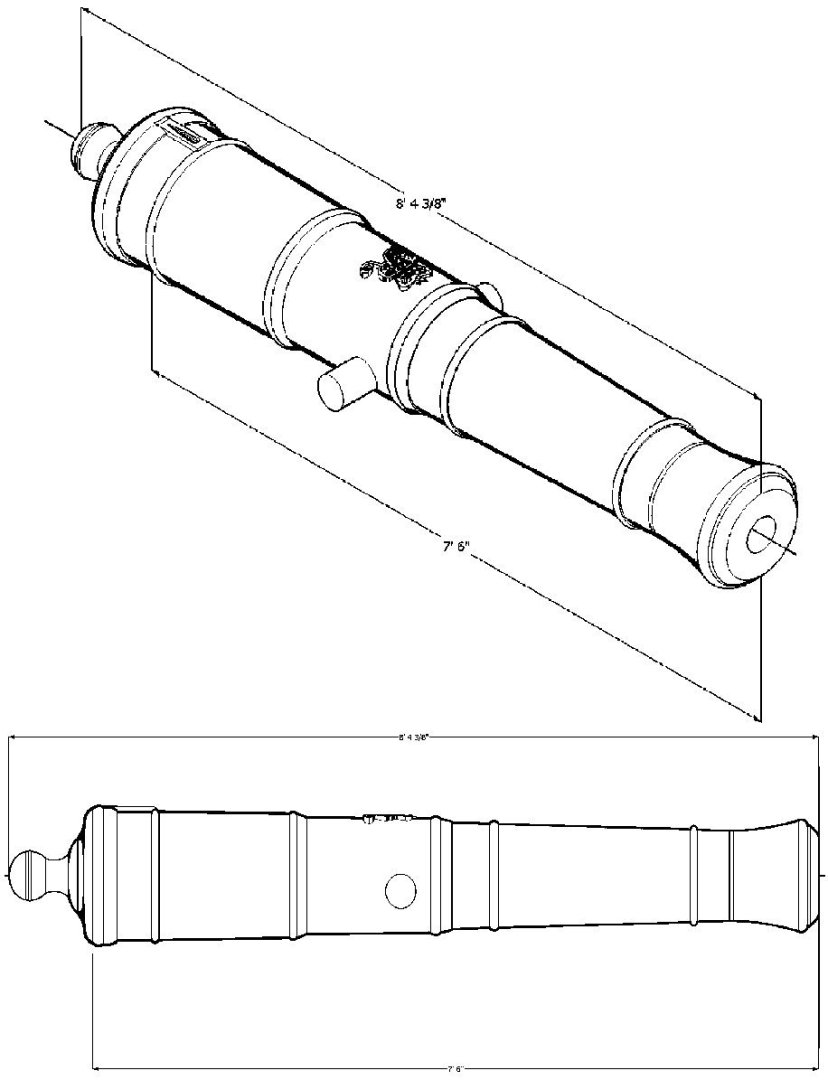

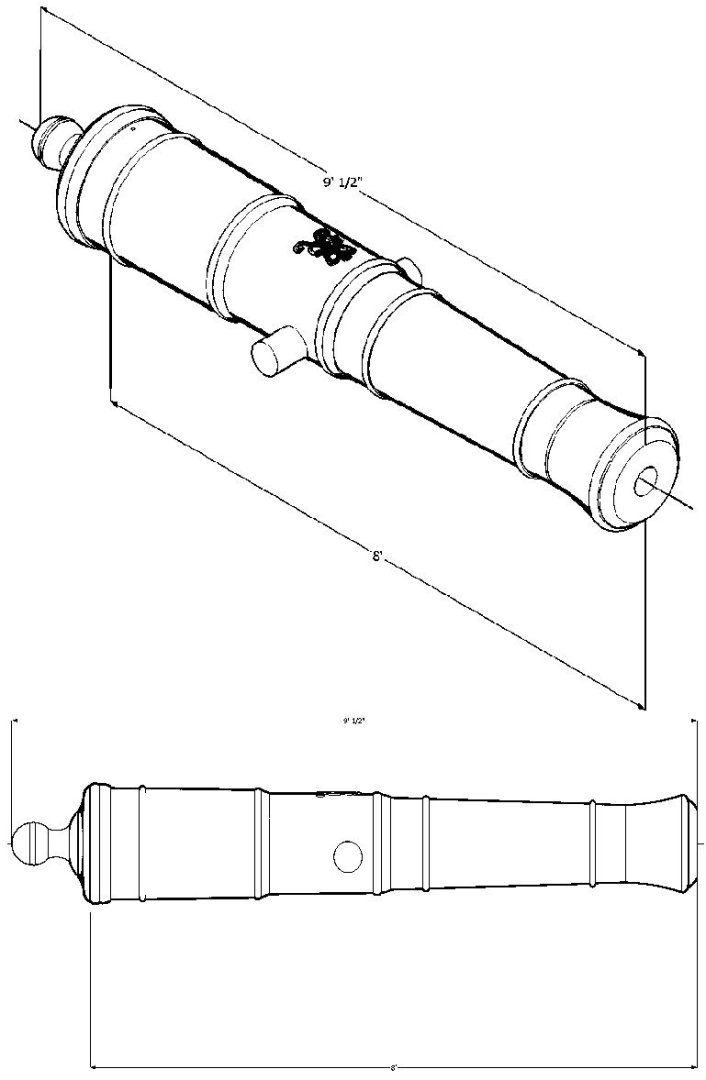

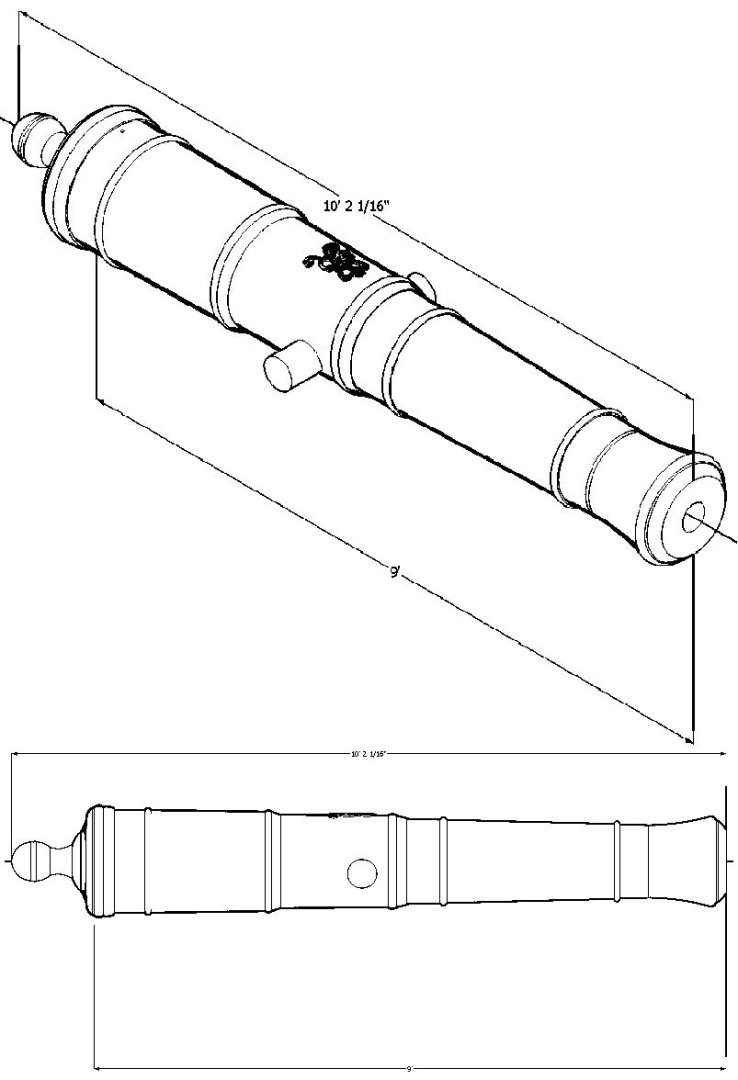

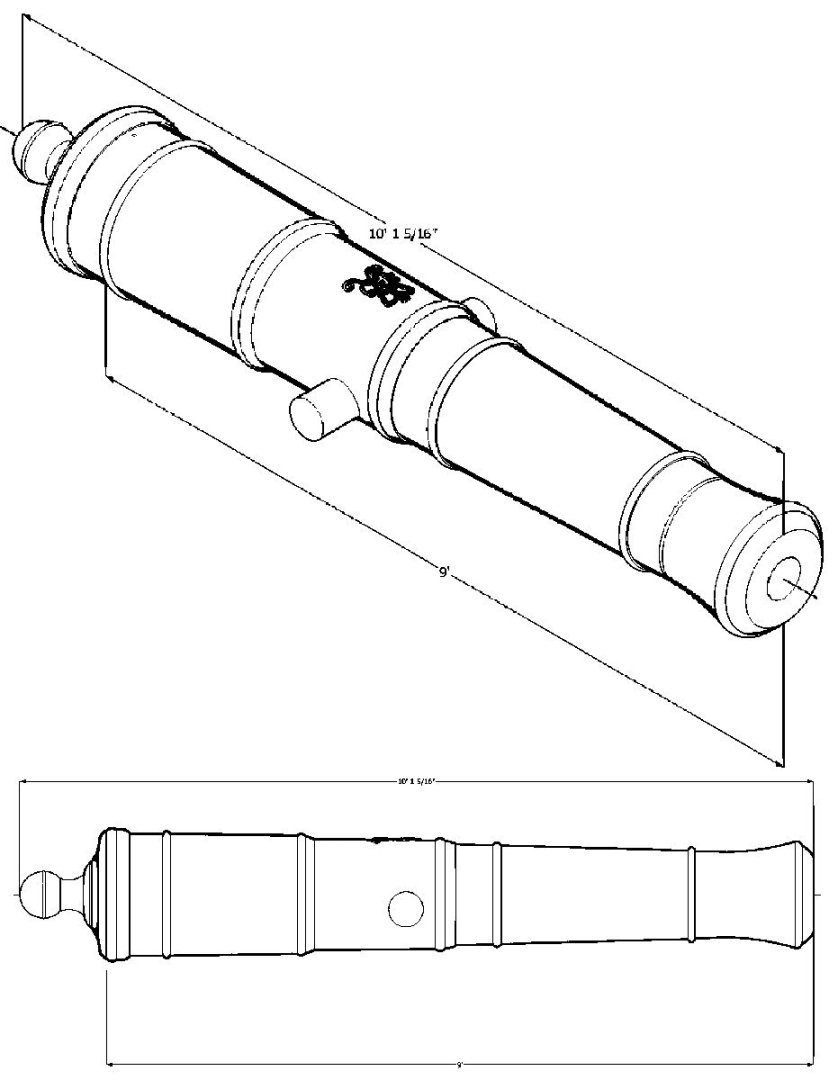

Spanish Cannons 1718 Pattern Graphics. I did not include the barrel length, as I only had drawings for one of each size. The Royal scroll and the cannon name scroll are on the barrel, but I will admit that the cannon name is the same for each STL, rather than individual names, as on the real cannon. I could only find one good photograph or drawing of this feature to trace. Yes the larger size cannons did not have the box structure at the trunions. No, I have no idea why. The handles are my best attempt at a Sea Monster motif. 5 Pounder 9 Pounder 12 Pounder 16 Pounder 24 Pounder -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

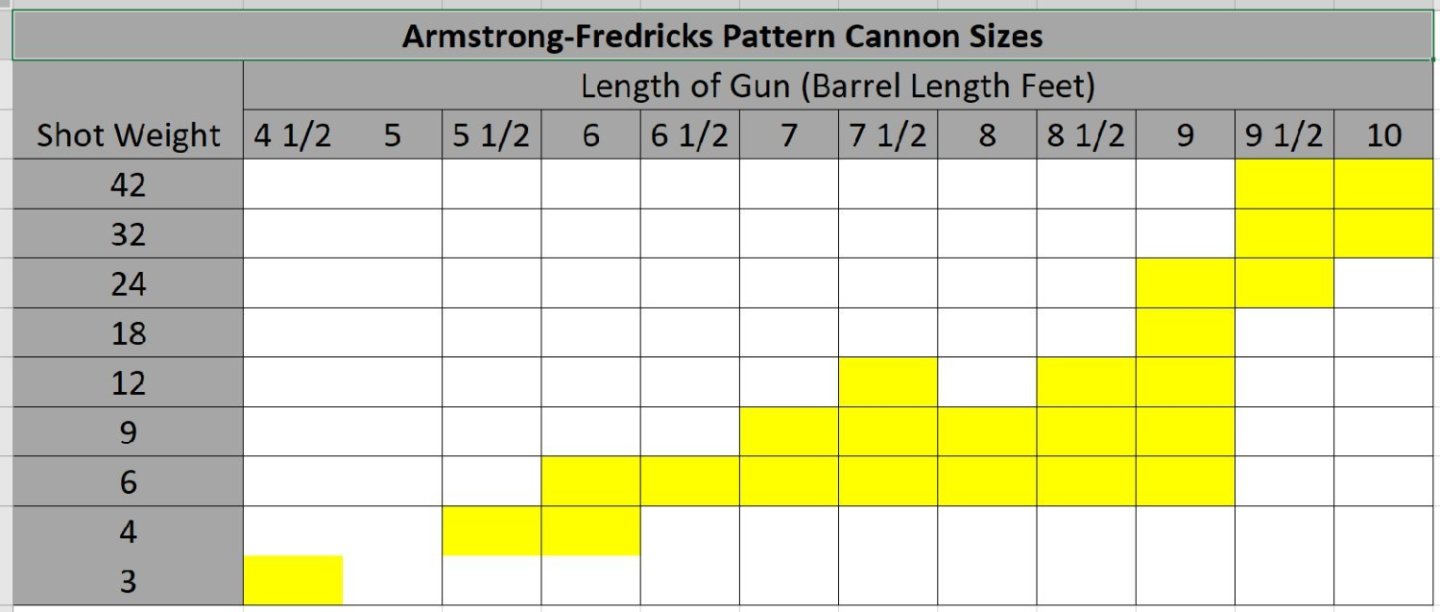

The Armstrong-Fredricks Cannon STLs - Part 2 Armstrong Fredrick Pattern 12 Pounder 102 Full Size_2890_31mm.stl Armstrong Fredrick Pattern 12 Pounder 108 Full Size_3060_30mm.stl Armstrong Fredrick Pattern 18 Pounder 108 Full Size_3099_59mm.stl Armstrong Fredrick Pattern 24 Pounder 108 Full Size_3080_94mm.stl Armstrong Fredrick Pattern 24 Pounder 114 Full Size_3252_13mm.stl Armstrong Fredrick Pattern 32 Pounder 114 Full Size_3252_13mm.stl Armstrong Fredrick Pattern 32 Pounder 120 Full Size_3423_31mm.stl Armstrong Fredrick Pattern 42 Pounder 114 Full Size_3234_00mm.stl Armstrong Fredrick Pattern 42 Pounder 120_Full Size_3404_26mm.stl -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

The Armstrong-Fredricks Cannon STLs - Part 1 Armstrong Fredrick Pattern 3 Pounder 54 Full Size_1542_39mm.stl Armstrong Fredrick Pattern 4 Pounder 66 Full Size_1885_16mm.stl Armstrong Fredrick Pattern 4 Pounder 72 Full Size_2056_47mm.stl Armstrong Fredrick Pattern 6 Pounder 72 Full Size_2056_47mm.stl Armstrong Fredrick Pattern 6 Pounder 78 Full Size_2227_92mm.stl Armstrong Fredrick Pattern 6 Pounder 84 Full Size_2399_24mm.stl Armstrong Fredrick Pattern 6 Pounder 90 Full Size_2570_56mm.stl Armstrong Fredrick Pattern 6 Pounder 96 Full Size_2742_01mm.stl Armstrong Fredrick Pattern 6 Pounder 102 Full Size_2913_33mm.stl Armstrong Fredrick Pattern 6 Pounder 108 Full Size_3084_78mm.stl Armstrong Fredrick Pattern 9 Pounder 84 Full Size_2368_81mm.stl Armstrong Fredrick Pattern 9 Pounder 90 Full Size_2538_15mm.stl Armstrong Fredrick Pattern 9 Pounder 96 Full Size_2707_35mm.stl Armstrong Fredrick Pattern 9 Pounder 102 Full Size_2876_55mm.stl Armstrong Fredrick Pattern 9 Pounder 108 Full Size_3045_75mm.stl Armstrong Fredrick Pattern 12 Pounder 90 Full Size_2550_32mm.stl -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

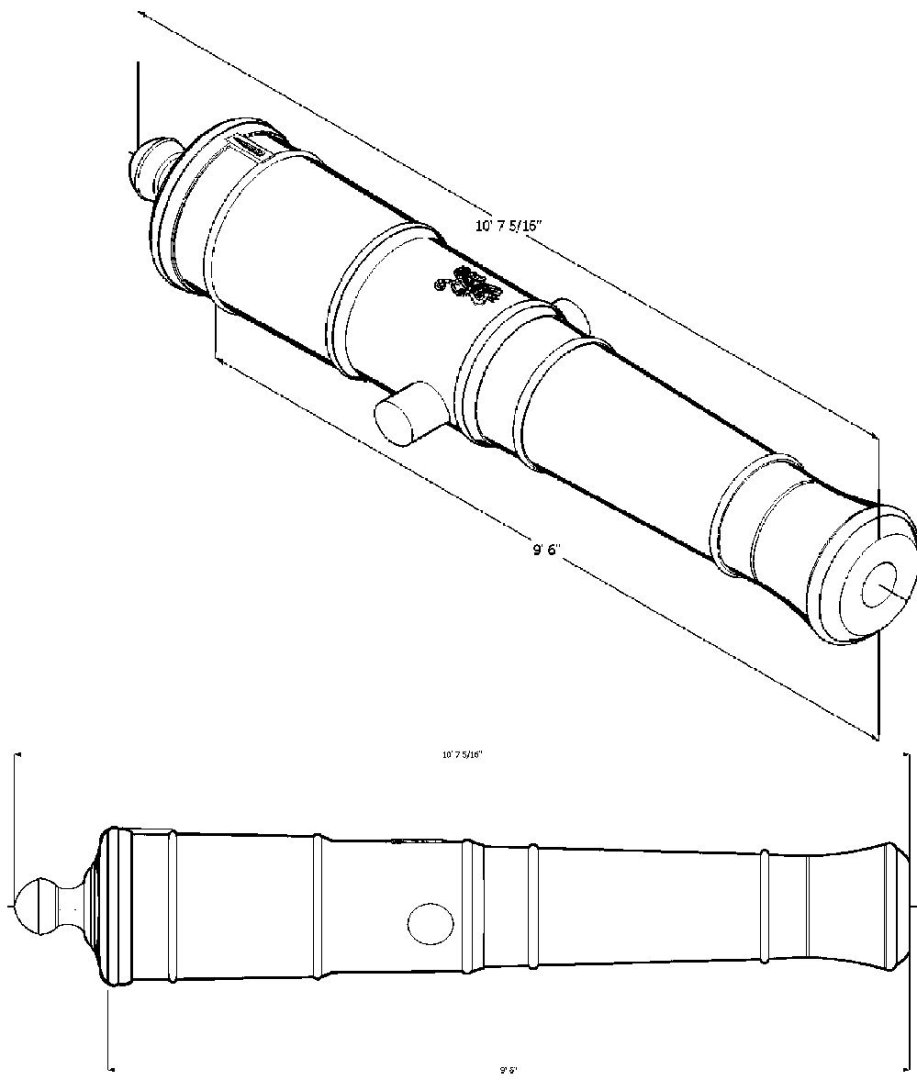

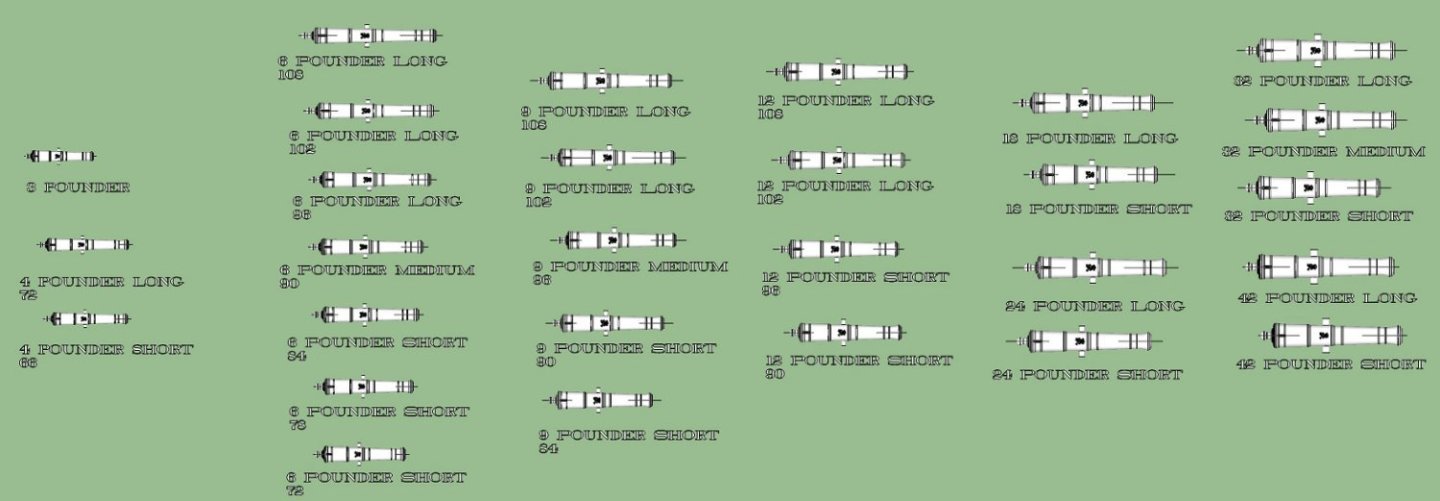

The Armstrong-Fredricks Cannon Graphics - Part 2 12 Pounder 102 12 Pounder 108 18 Pounder 108 24 pounder 108 24 Pounder 114 32 Pounder 114 32 Pounder 120 42 Pounder 114 42 Pounder 120 -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

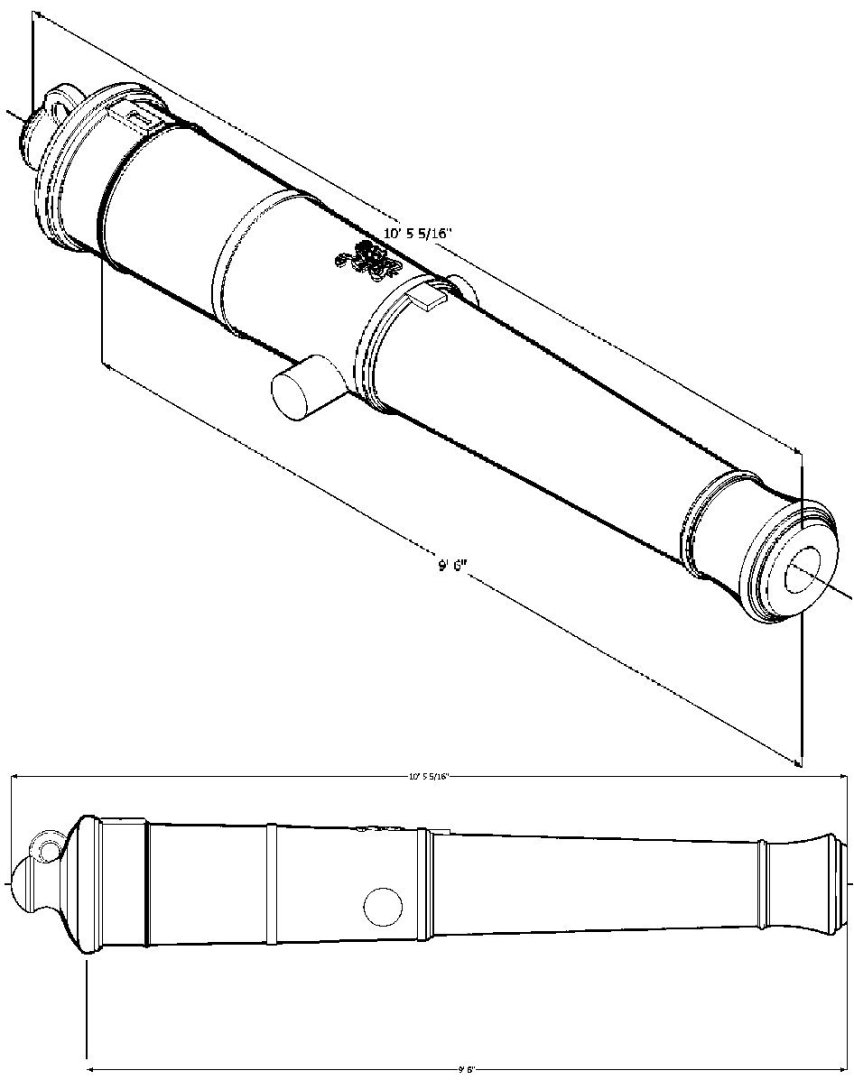

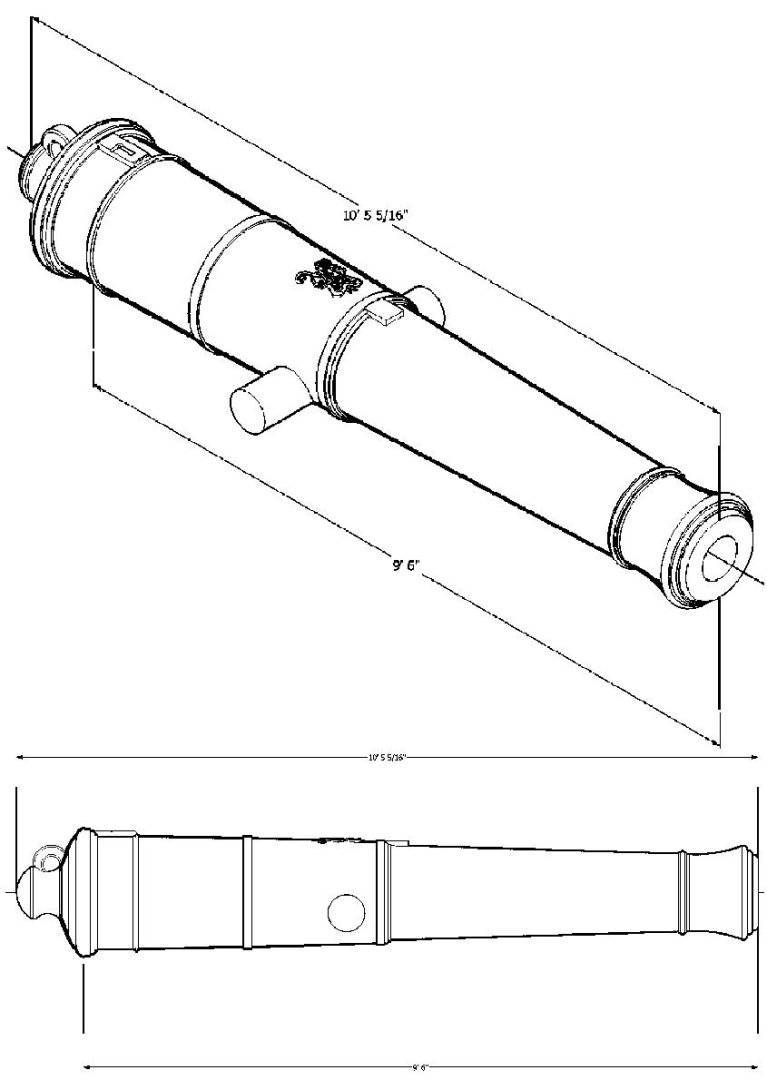

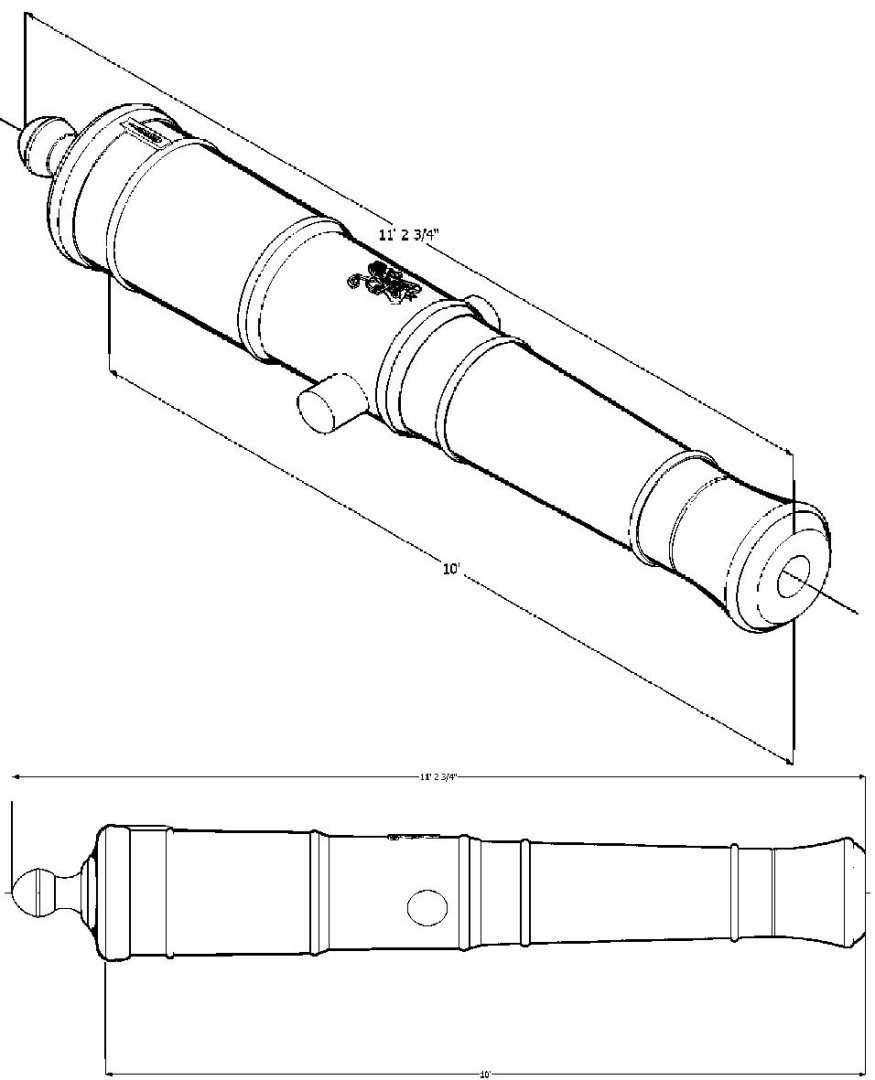

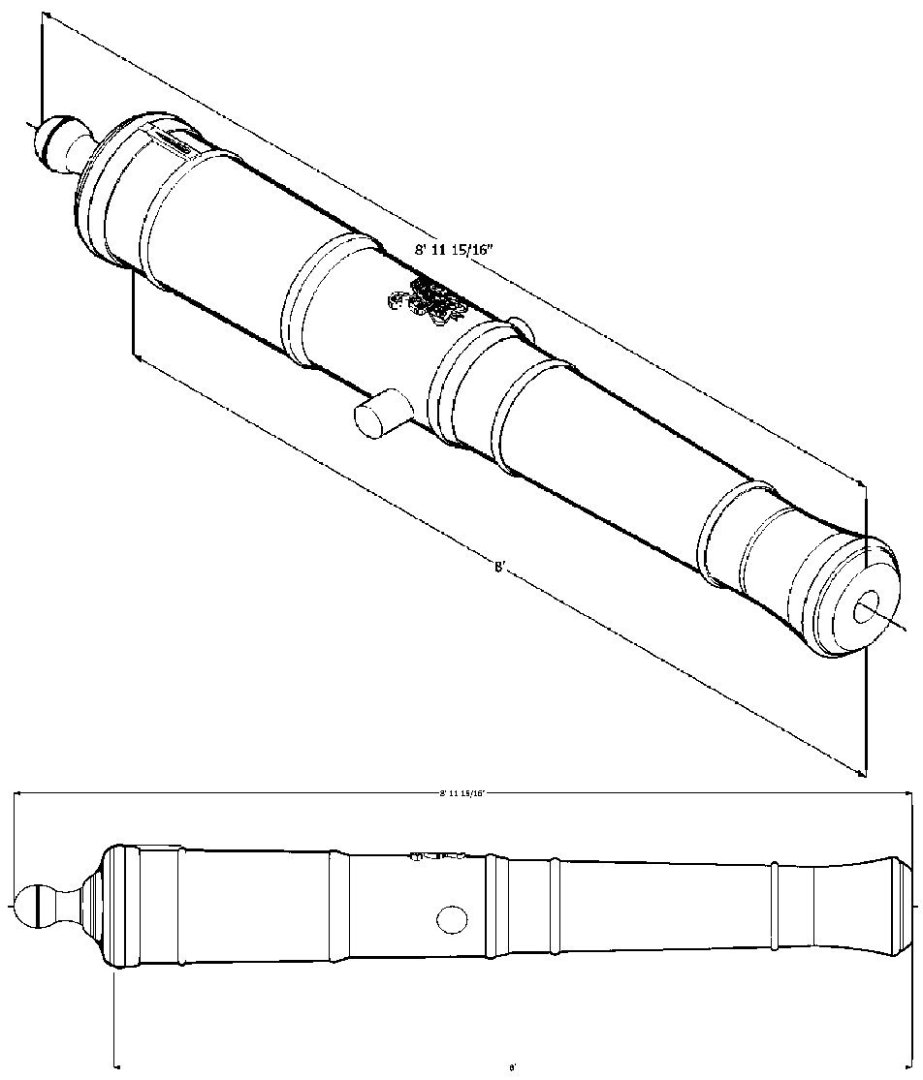

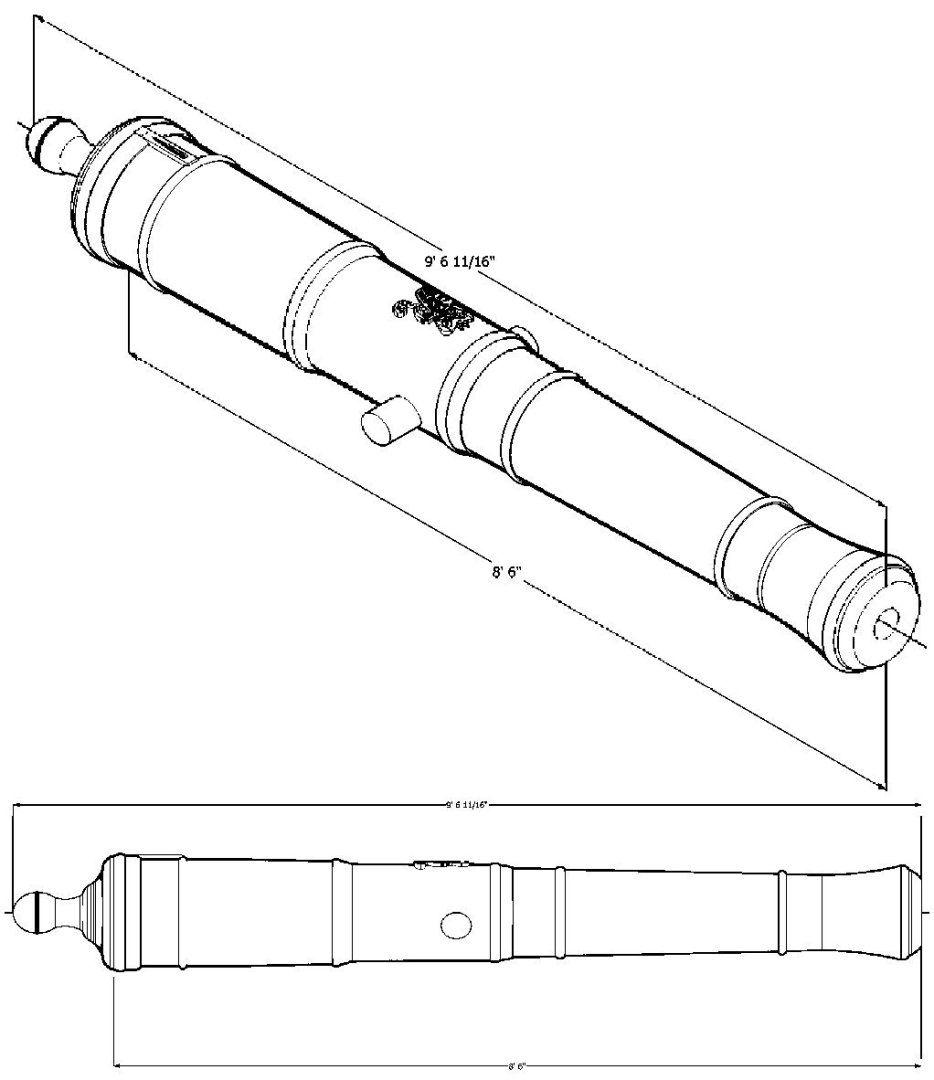

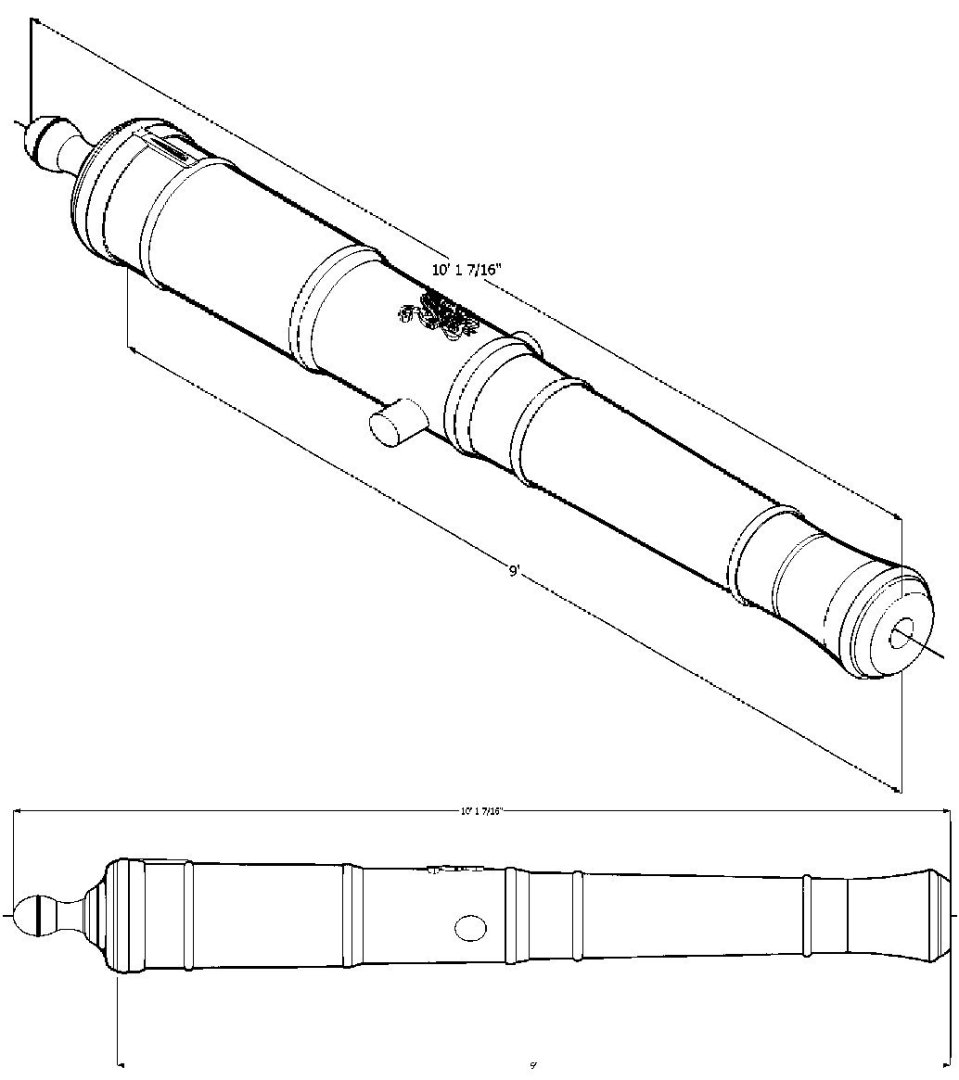

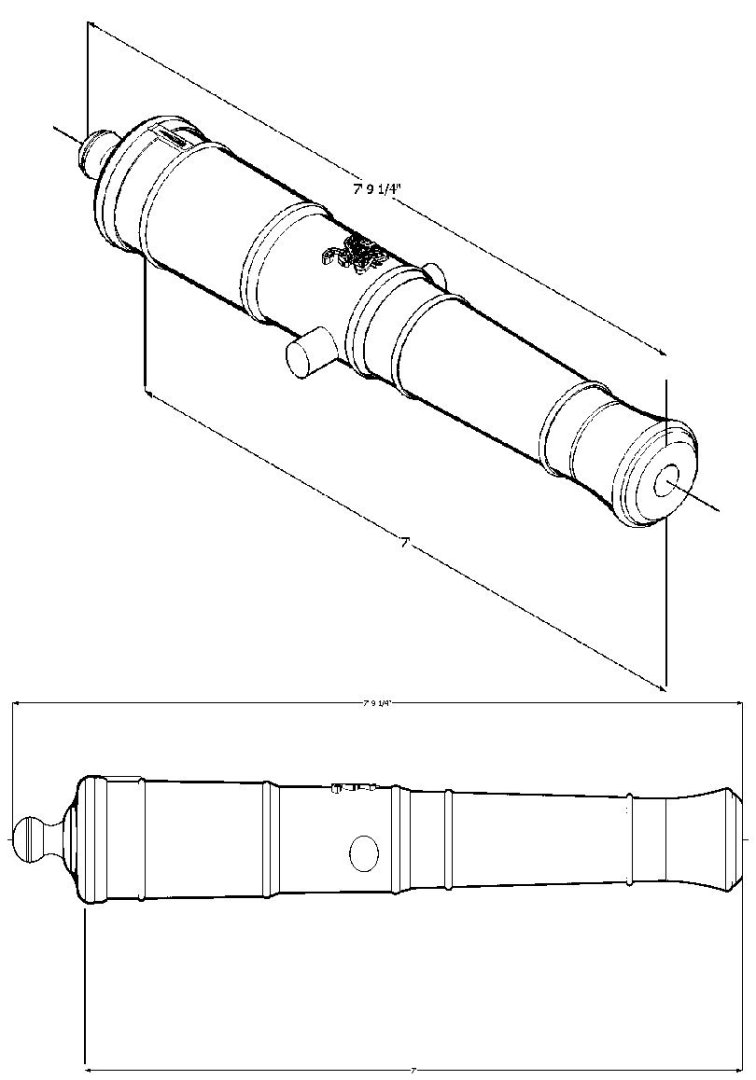

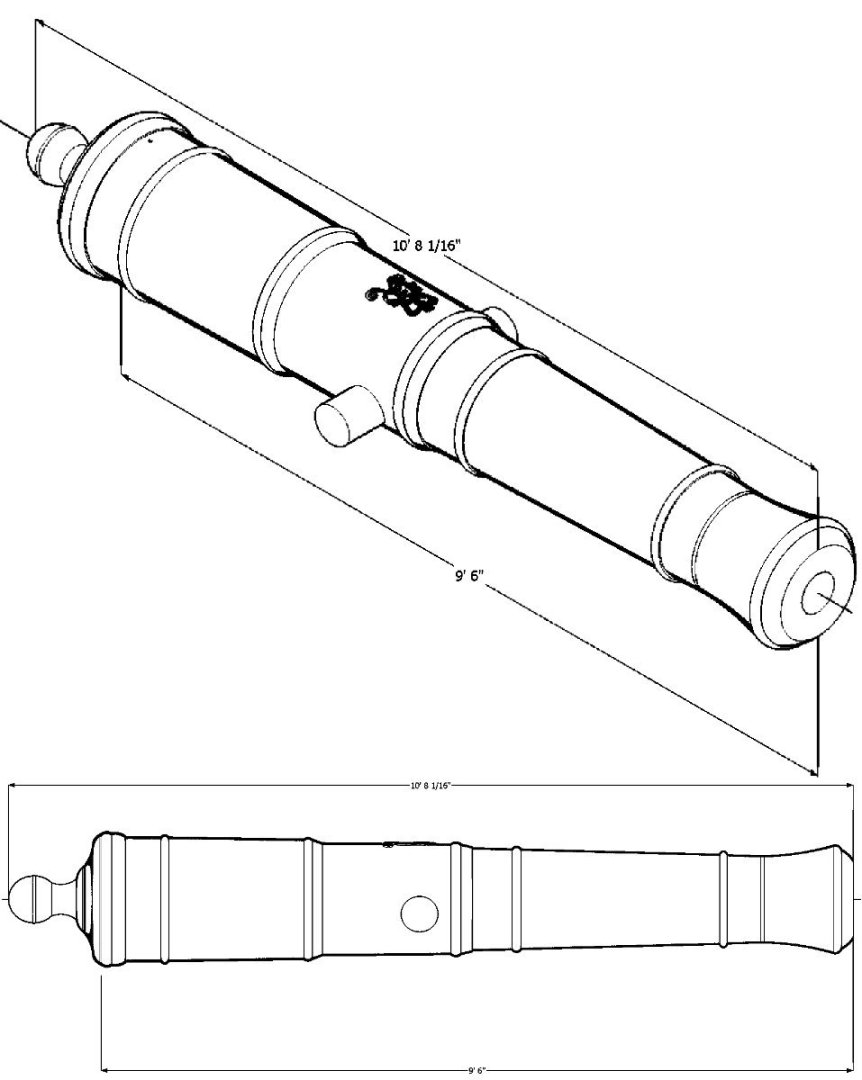

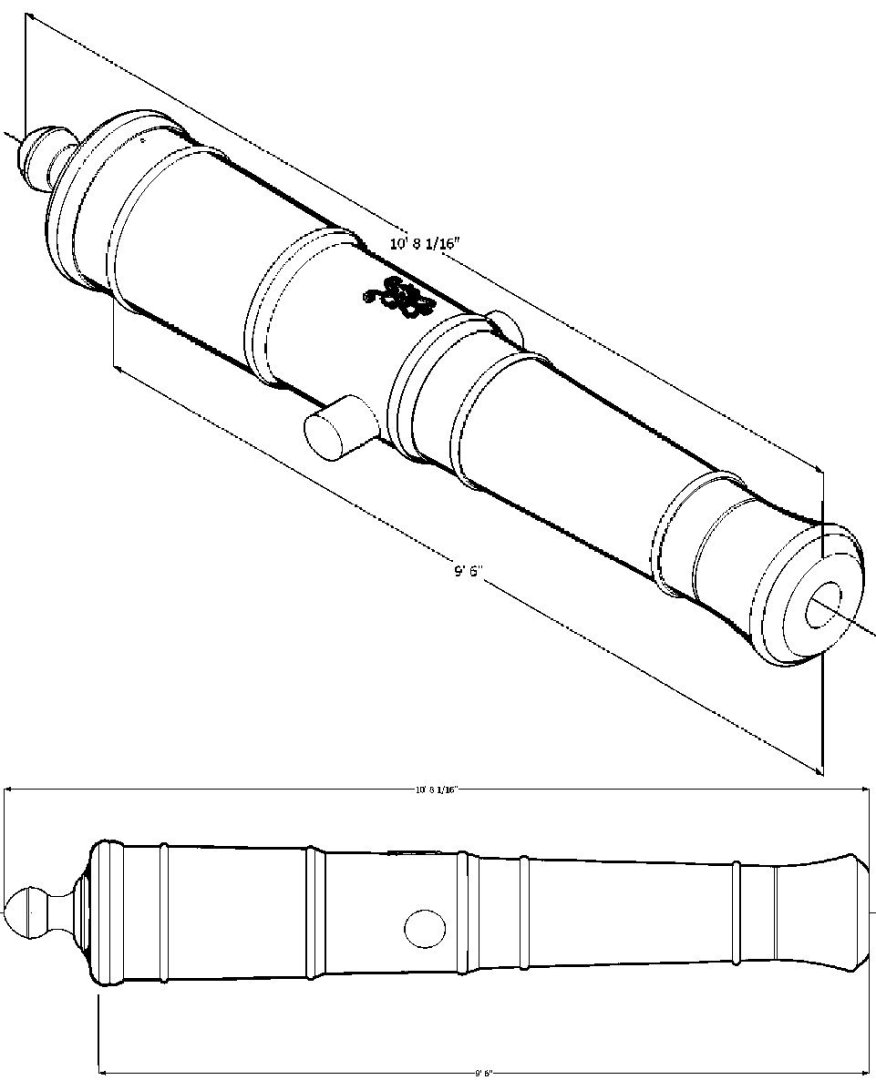

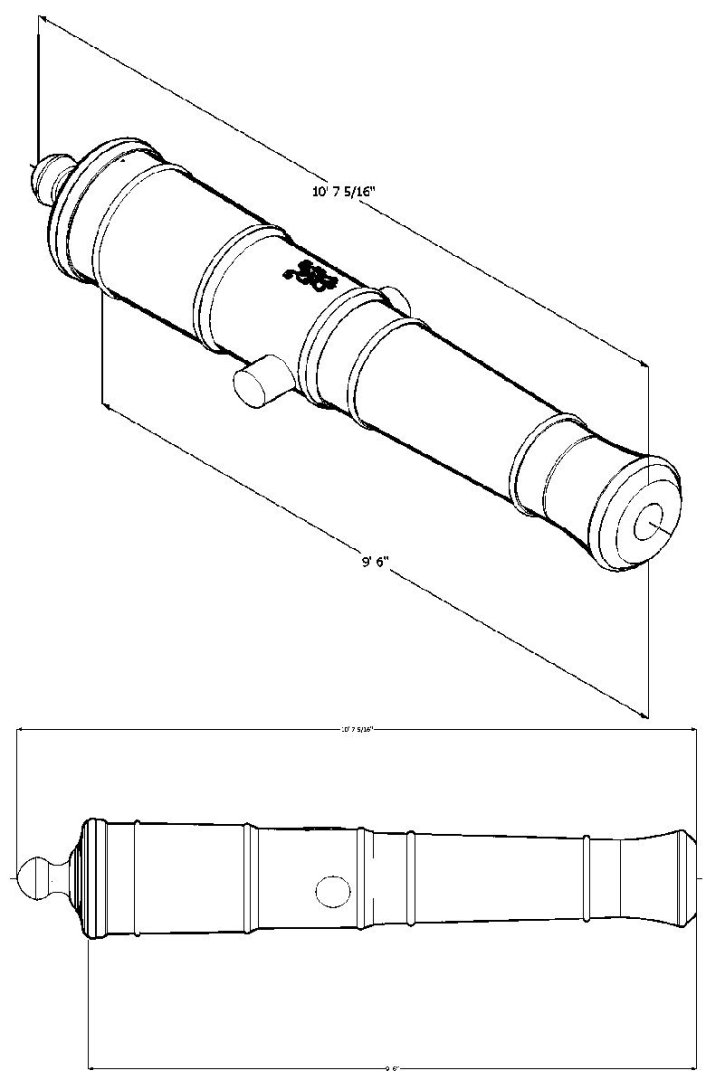

The Armstrong-Fredricks Cannon Graphics - Part 1 3 Pounder 54 4 Pounder 66 4 Pounder - 72 6 Pounder 72 6 Pounder 78 6 Pounder 84 6 pounder 90 8 Pounder 96 6 pounder 102 6 Pounder 108 9 Pounder 84 9 Pounder 90 9 Pounder 96 9 Pounder 102 9 Pounder 108 12 Pounder 90 -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Armstrong STL files Part 1 Armstrong Pattern 18 Pounder 96 Full Size_2755_24mm.stl Armstrong Pattern 18 Pounder 108 Full Size_3100_23mm.stl Armstrong Pattern 24 Pounder 108 Full Size_3080_94mm.stl Armstrong Pattern 24 Pounder 114 Full Size_3252_13mm.stl Armstrong Pattern 32 Pounder 114 Full Size_3252_13mm.stl Armstrong Pattern 32 Pounder 120 Full Size_3423_31mm.stl Armstrong Pattern 42 Pounder 114 Full Size_3234_00mm.stl Armstrong Pattern 42 Pounder 120 Full Size_3404_26mm.stl -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

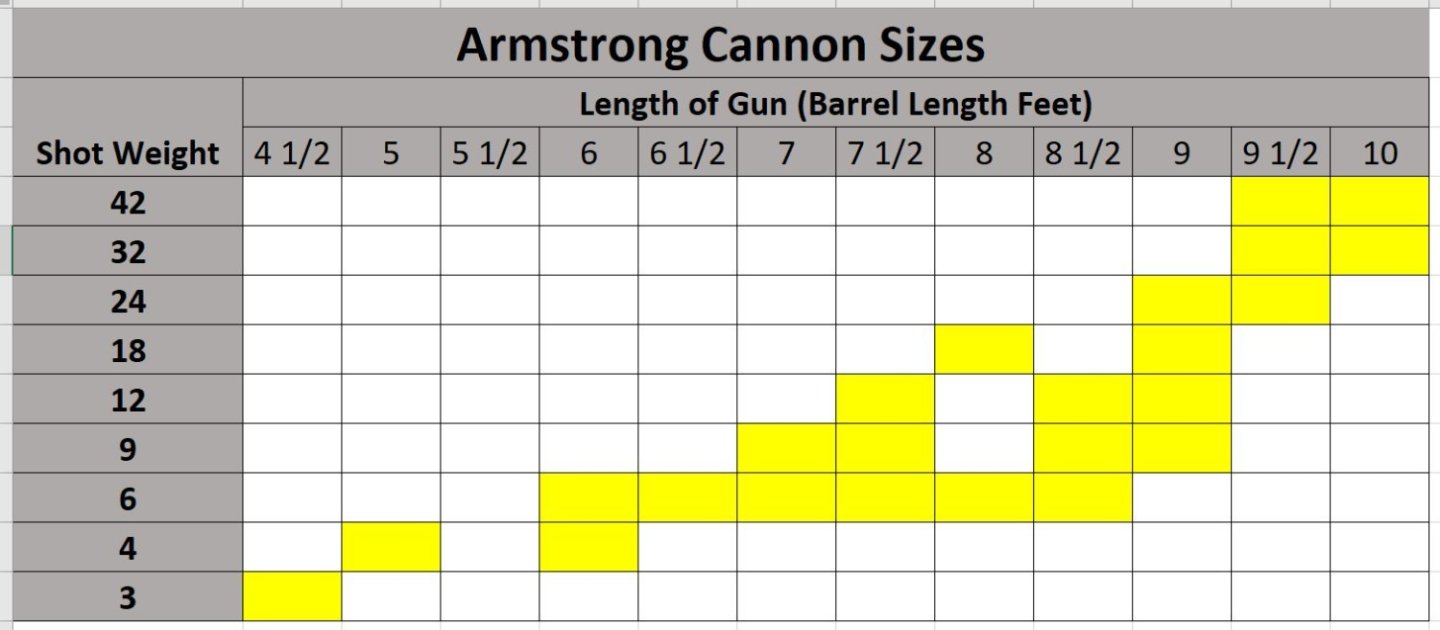

Armstrong STL files Part 1 Armstrong Pattern 3 Pounder 54 Full Size_1542_39mm.stl Armstrong Pattern 4 Pounder 60 Full Size_1713_71mm.stl Armstrong Pattern 4 Pounder 72 Full Size_2056_47mm.stl Armstrong Pattern 6 Pounder 72 Full Size_2056_47mm.stl Armstrong Pattern 6 Pounder 78 Full Size_2227_92mm.stl Armstrong Pattern 6 Pounder 84 Full Size_2399_24mm.stl Armstrong Pattern 6 Pounder 90 Full Size_2570_56mm.stl Armstrong Pattern 6 Pounder 96 Full Size_2742_01mm.stl Armstrong Pattern 6 Pounder 102 Full Size_2913_33mm.stl Armstrong Pattern 9 Pounder 84 Full Size_2368_81mm.stl Armstrong Pattern 9 Pounder 90 Full Size_2538_15mm.stl Armstrong Pattern 9 Pounder 102 Full Size_2876_55mm.stl Armstrong Pattern 9 Pounder 108 Full Size_3045_75mm.stl Armstrong Pattern 12 Pounder 90 Full Size_2550_32mm.stl Armstrong Pattern 12 Pounder 102 Full Size_2890_31mm.stl Armstrong Pattern 12 Pounder 108 Full Size_3060_30mm.stl -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Those are the factoes I used when following the spec on the site I listed. -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

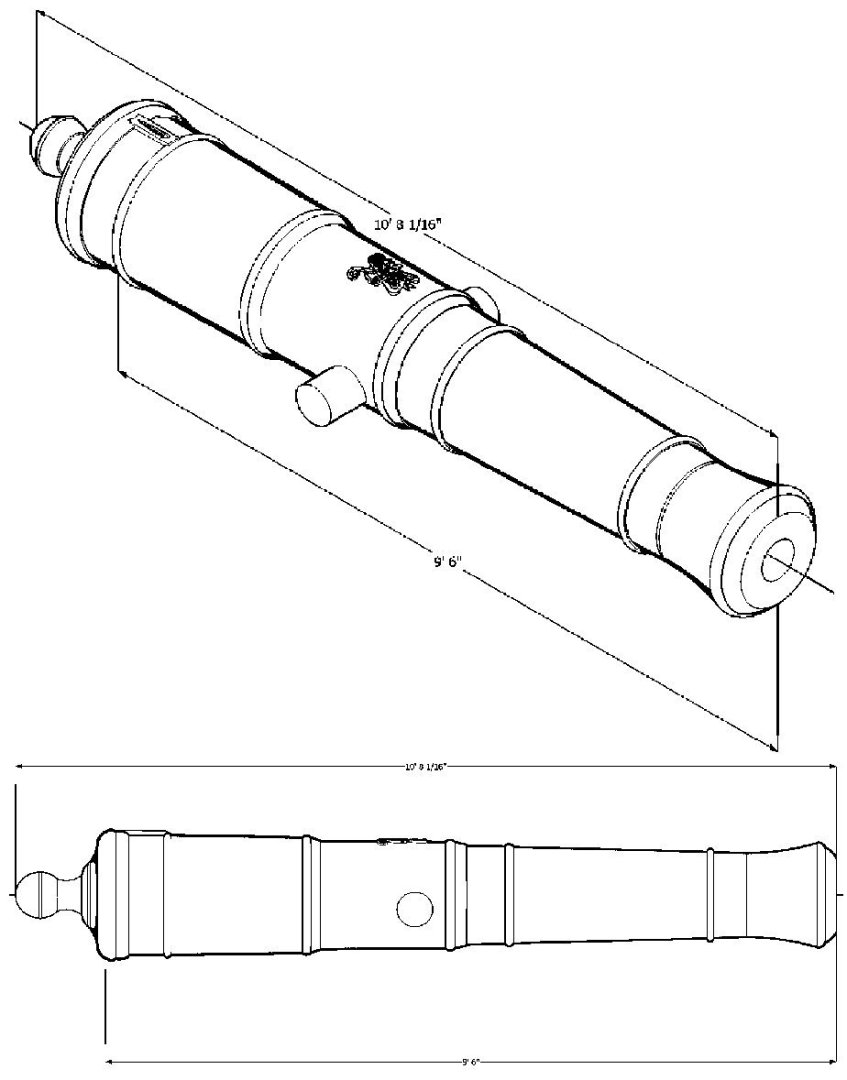

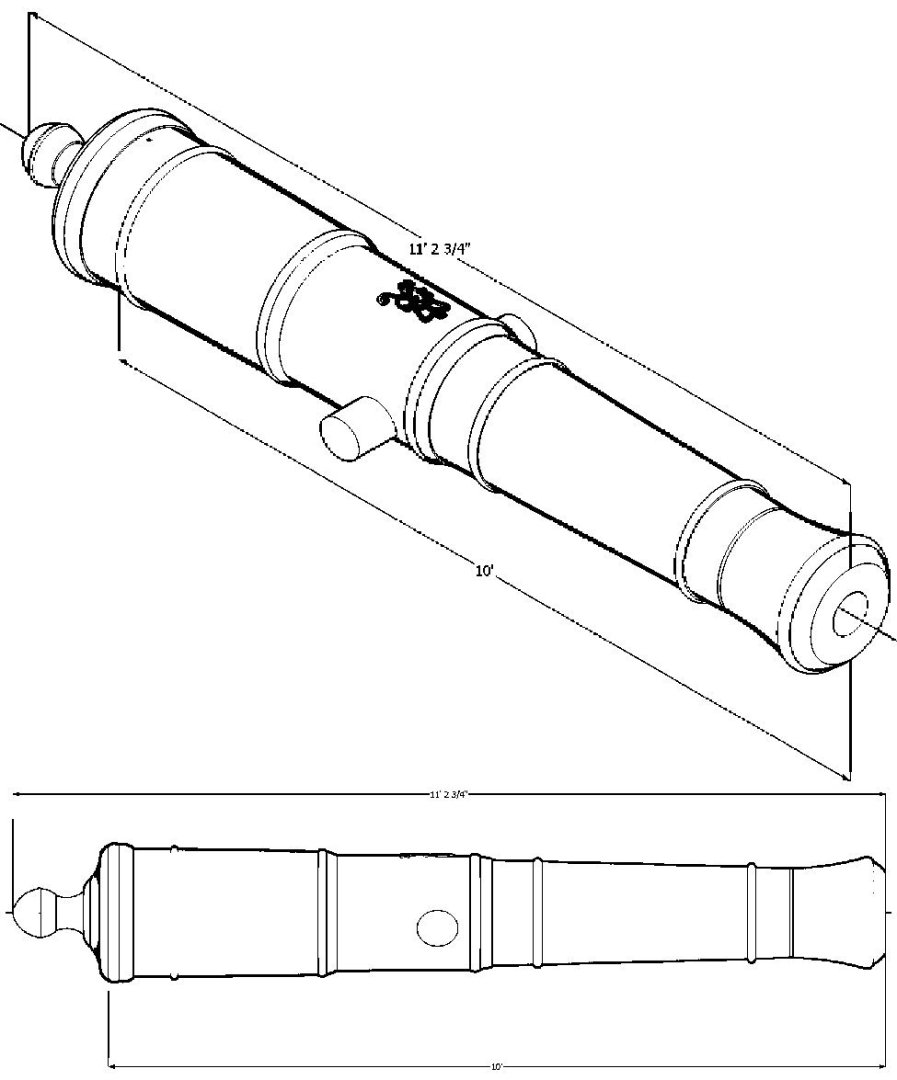

Armstrong Cannon Graphics - Part 1. 18 Pounder 96 18 Pounder 108 24 Pounder 108 24 Pounder 114 32 Pounder 114 32 Pounder 120 42 Pounder 114 42 Pounder 120 -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

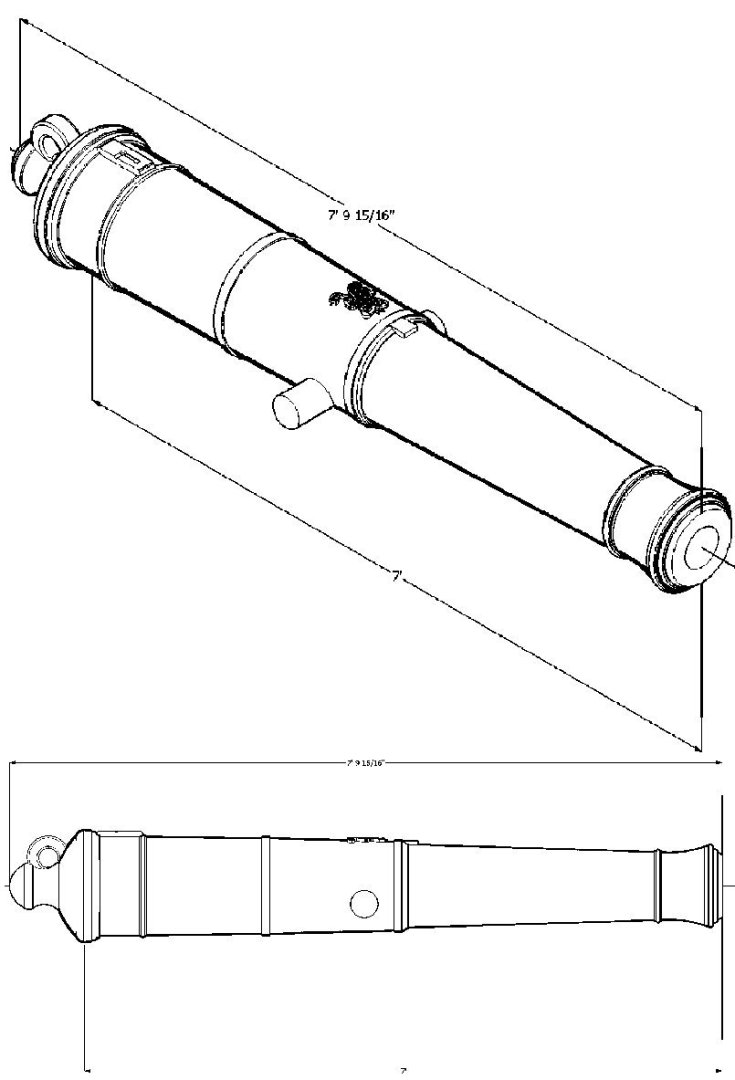

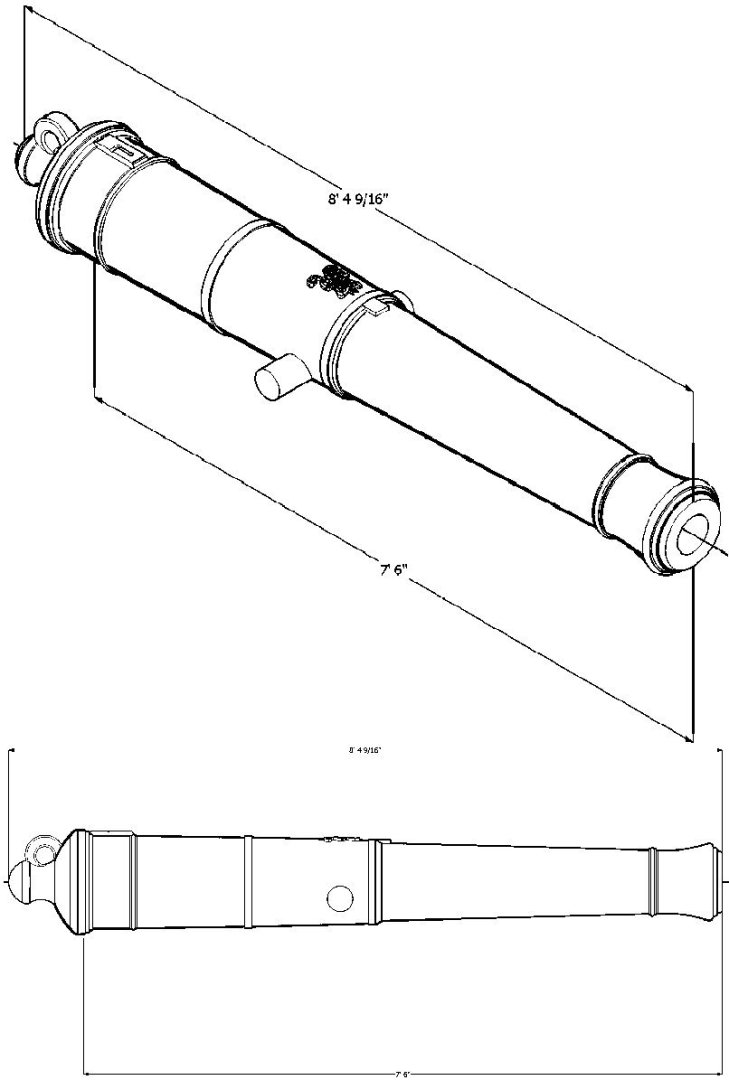

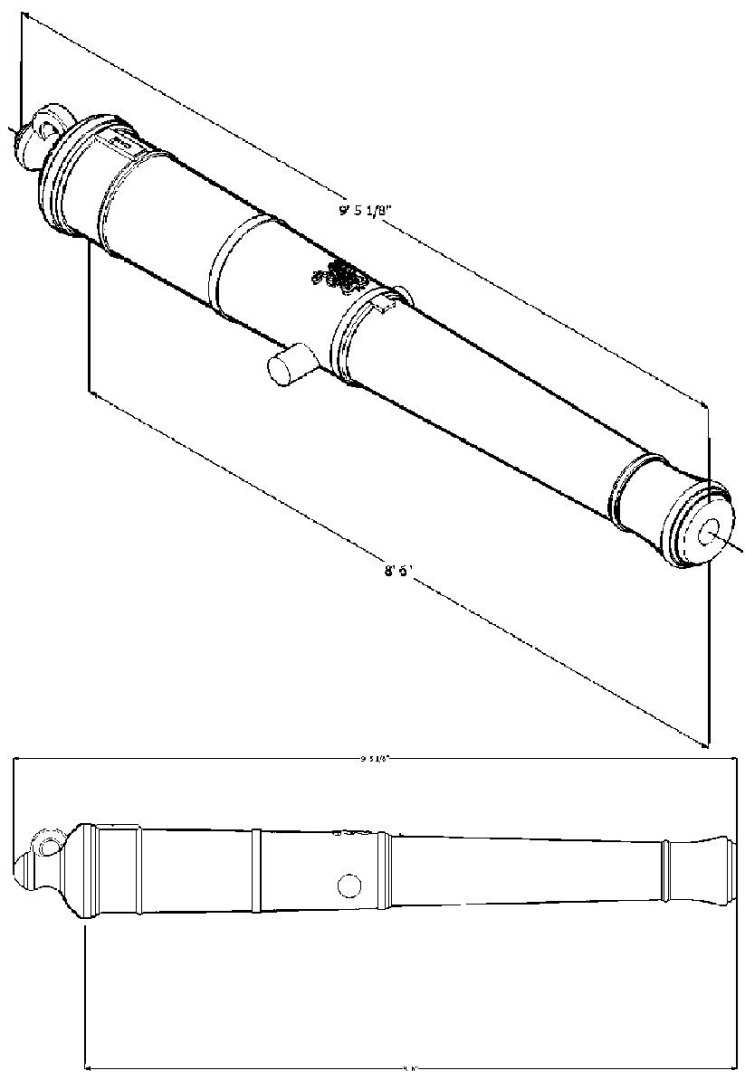

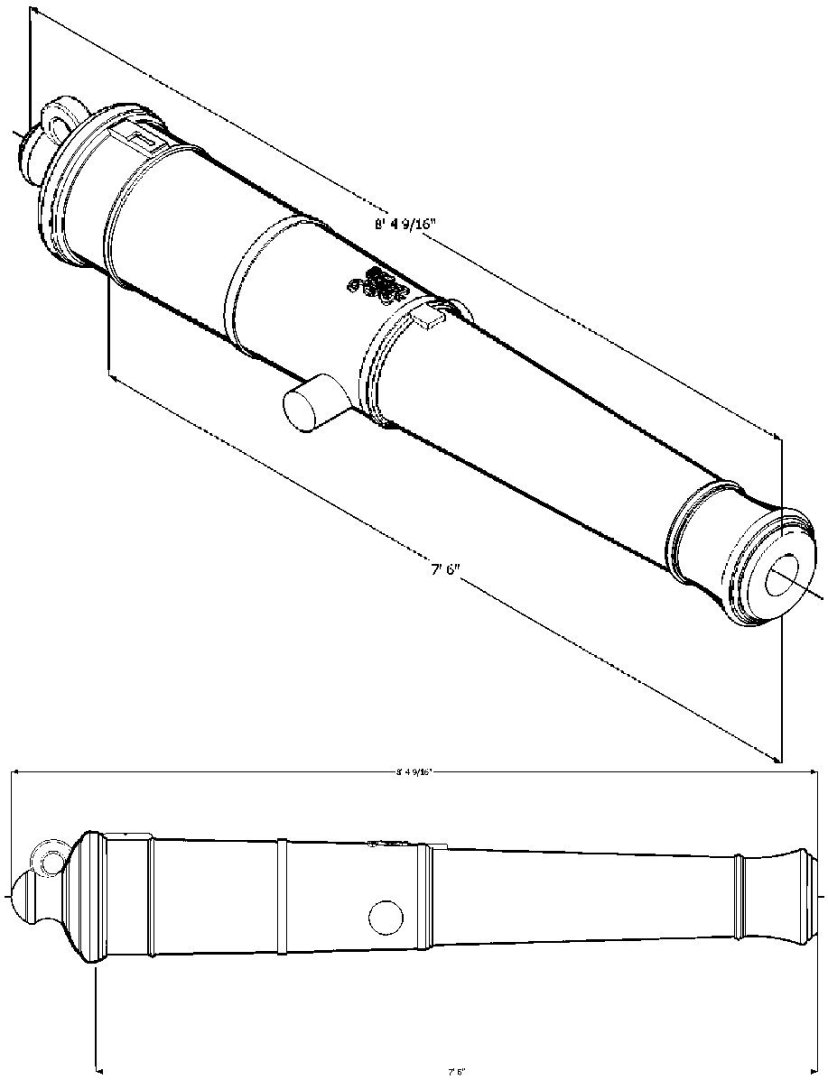

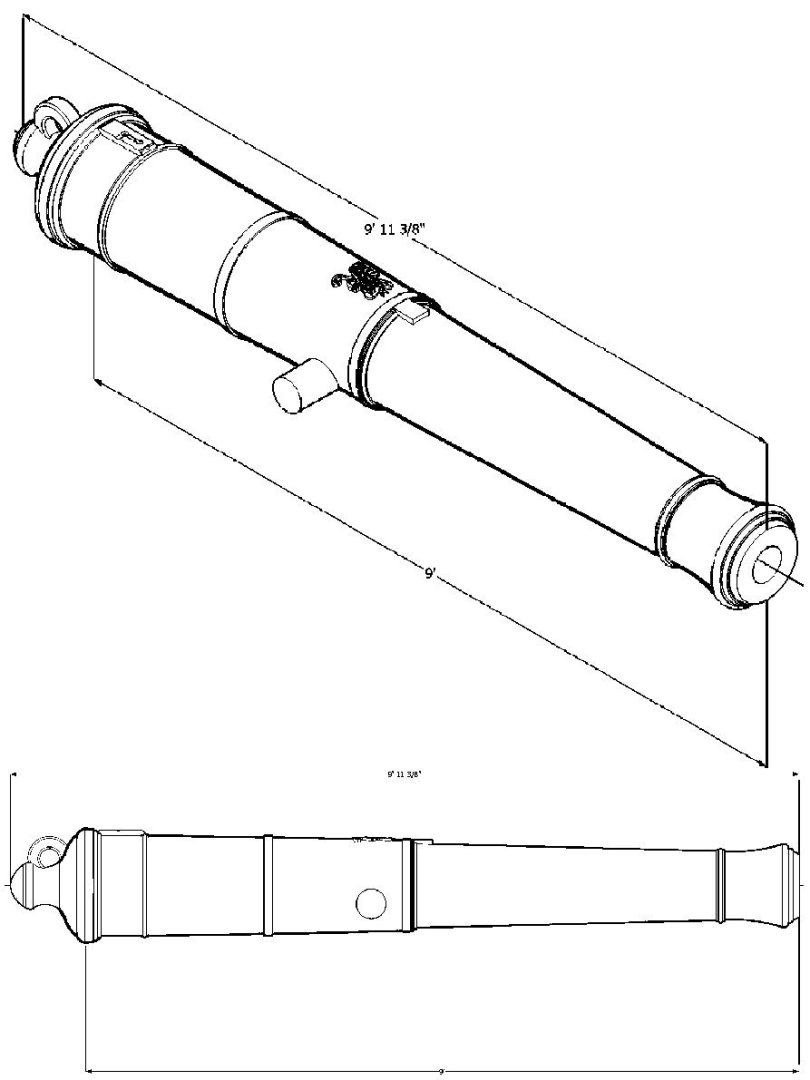

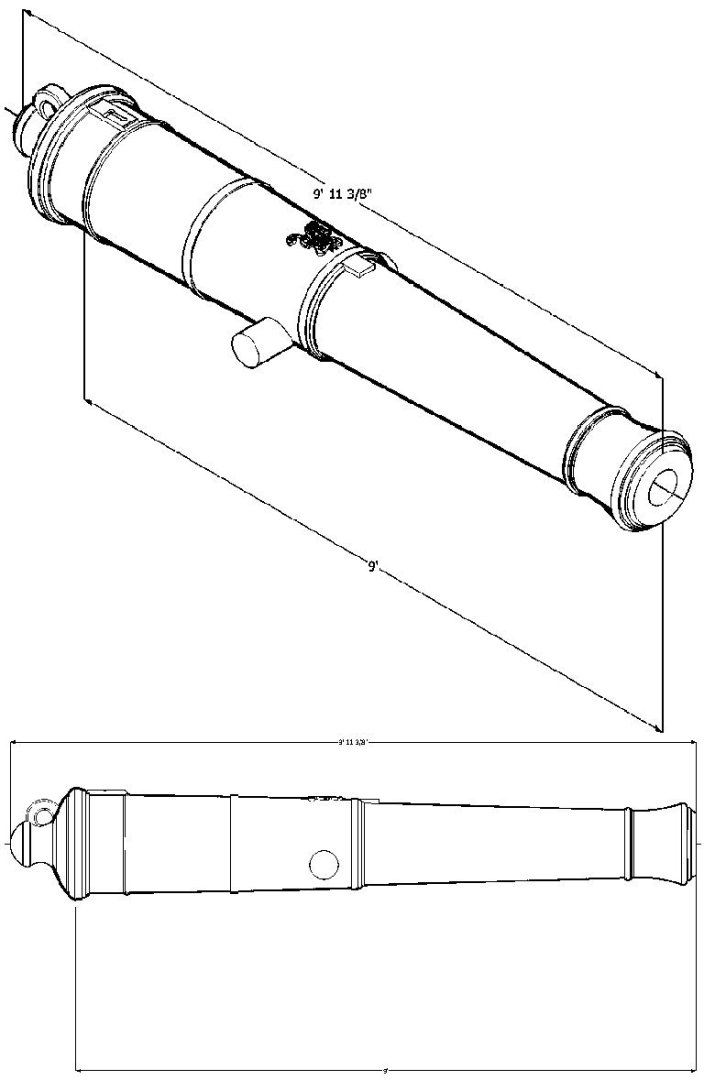

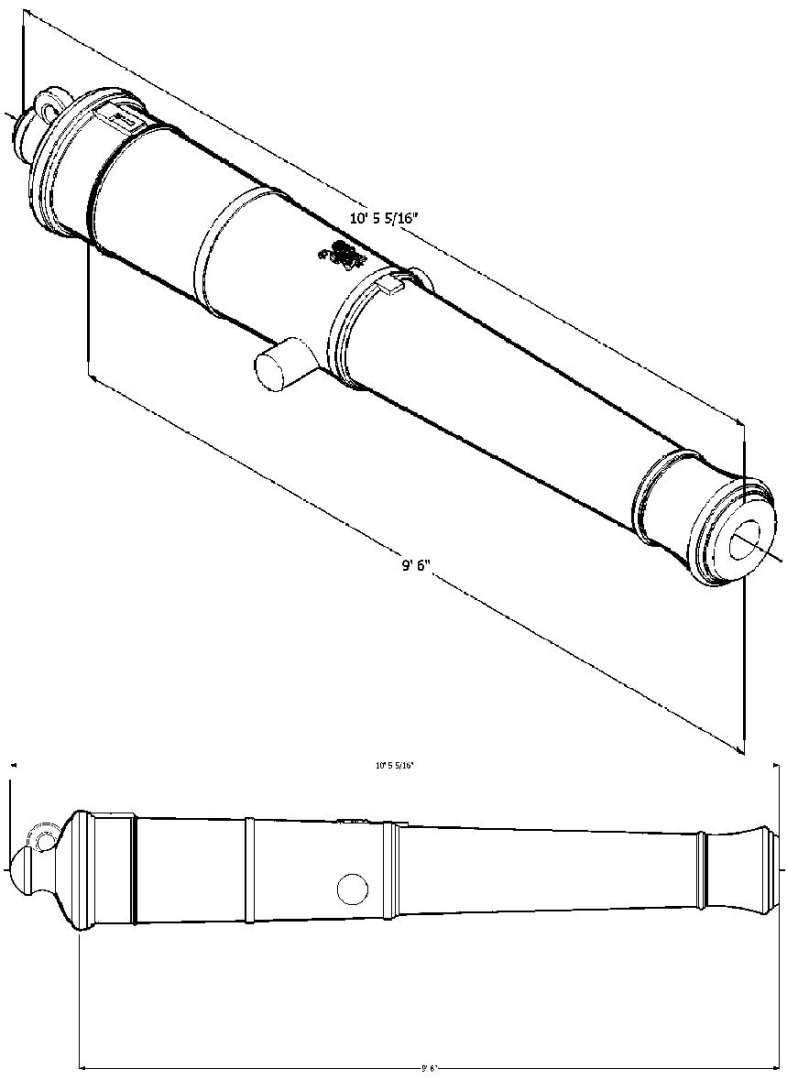

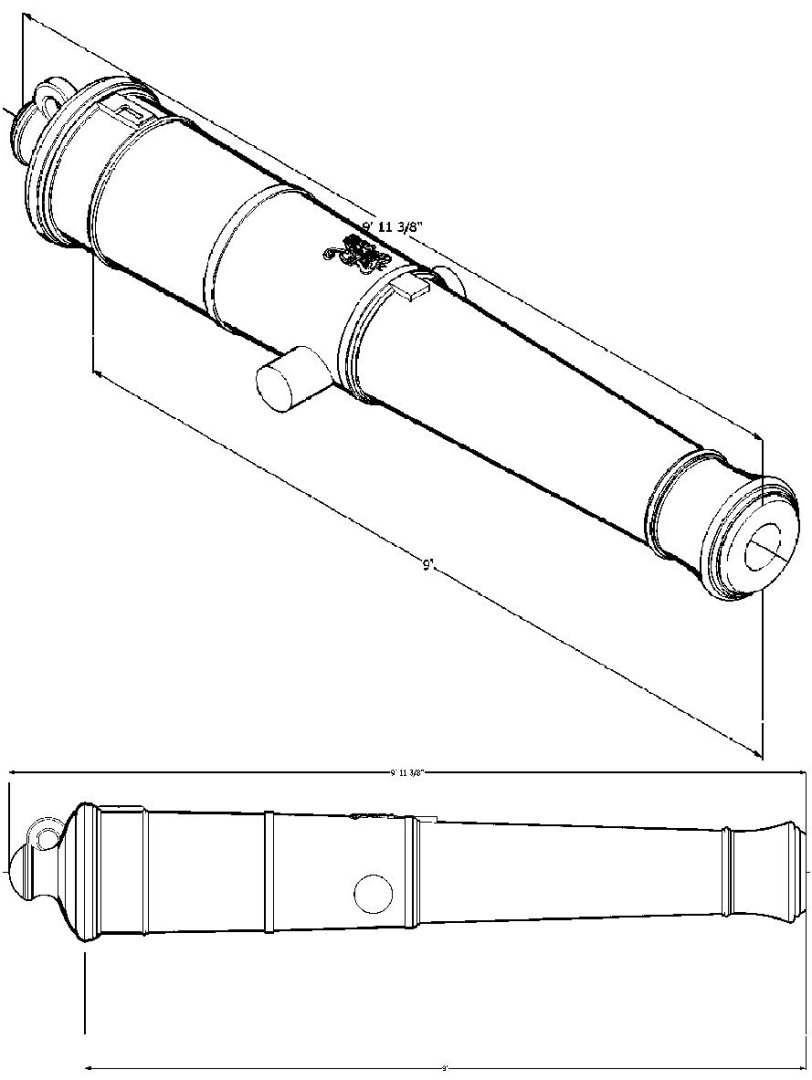

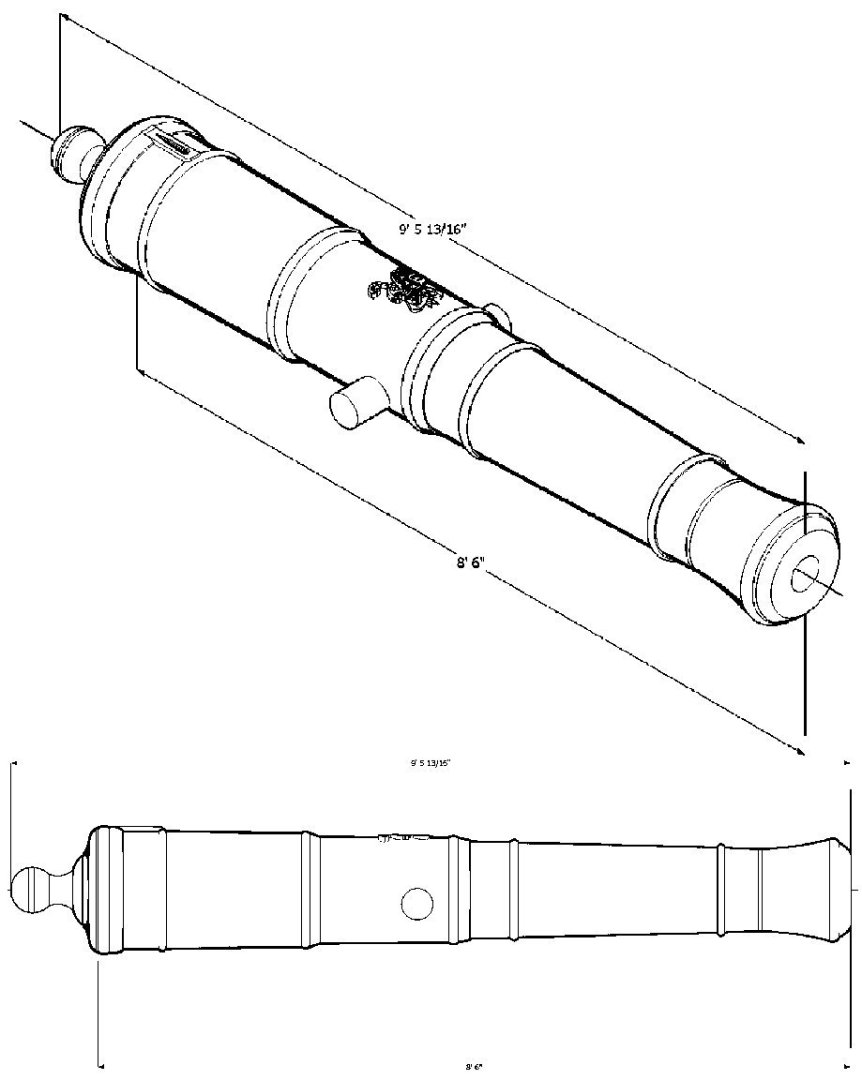

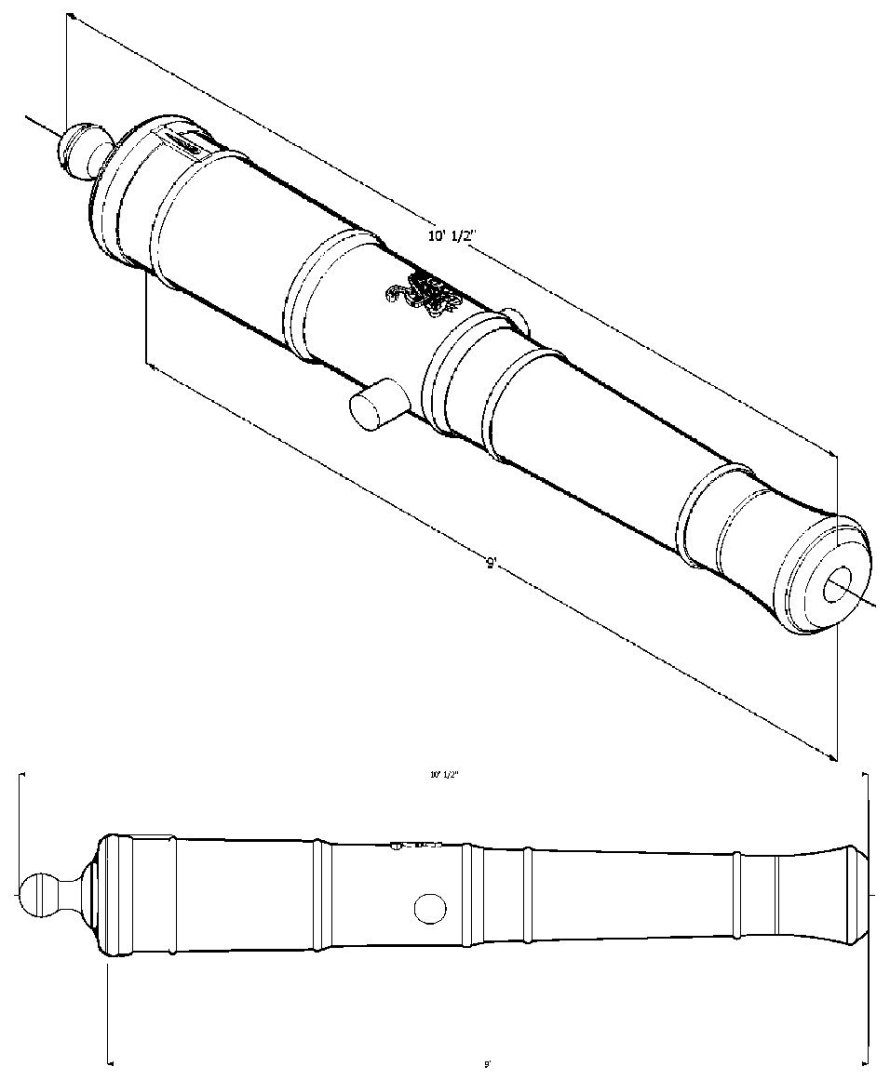

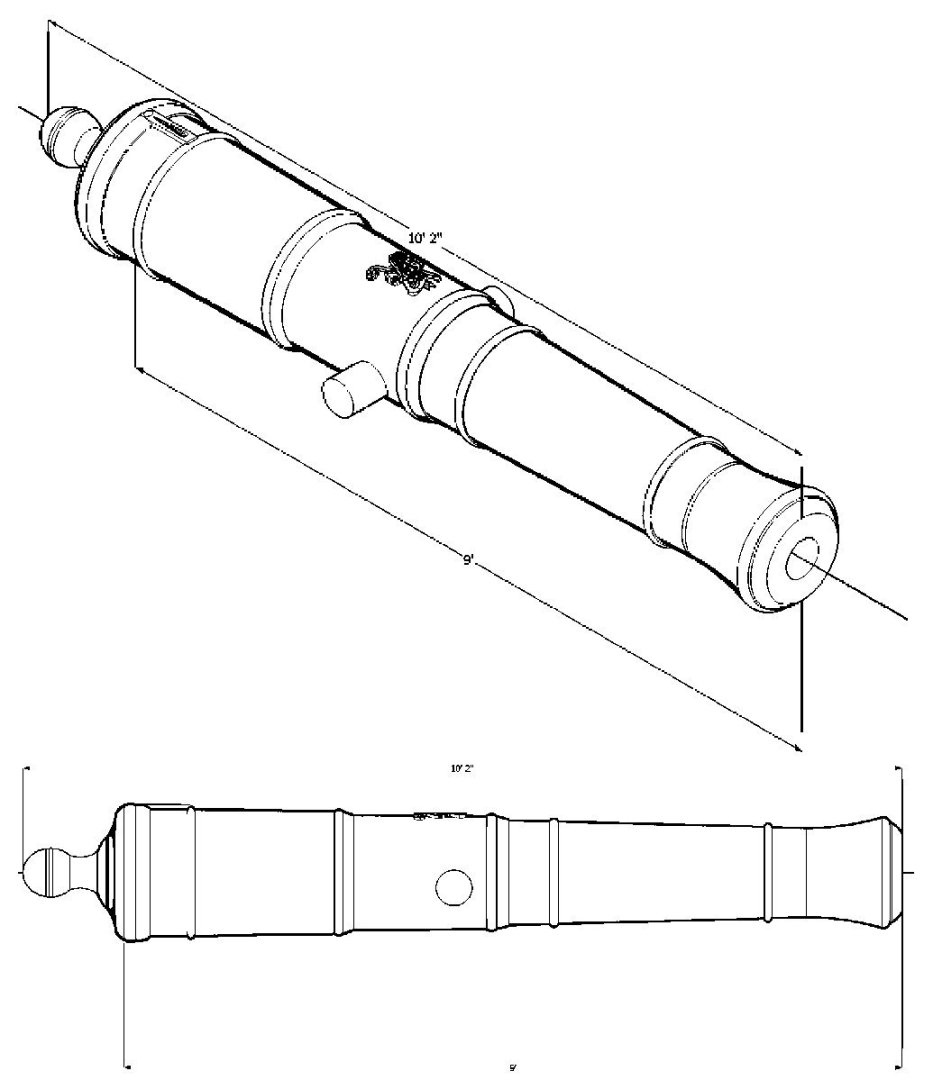

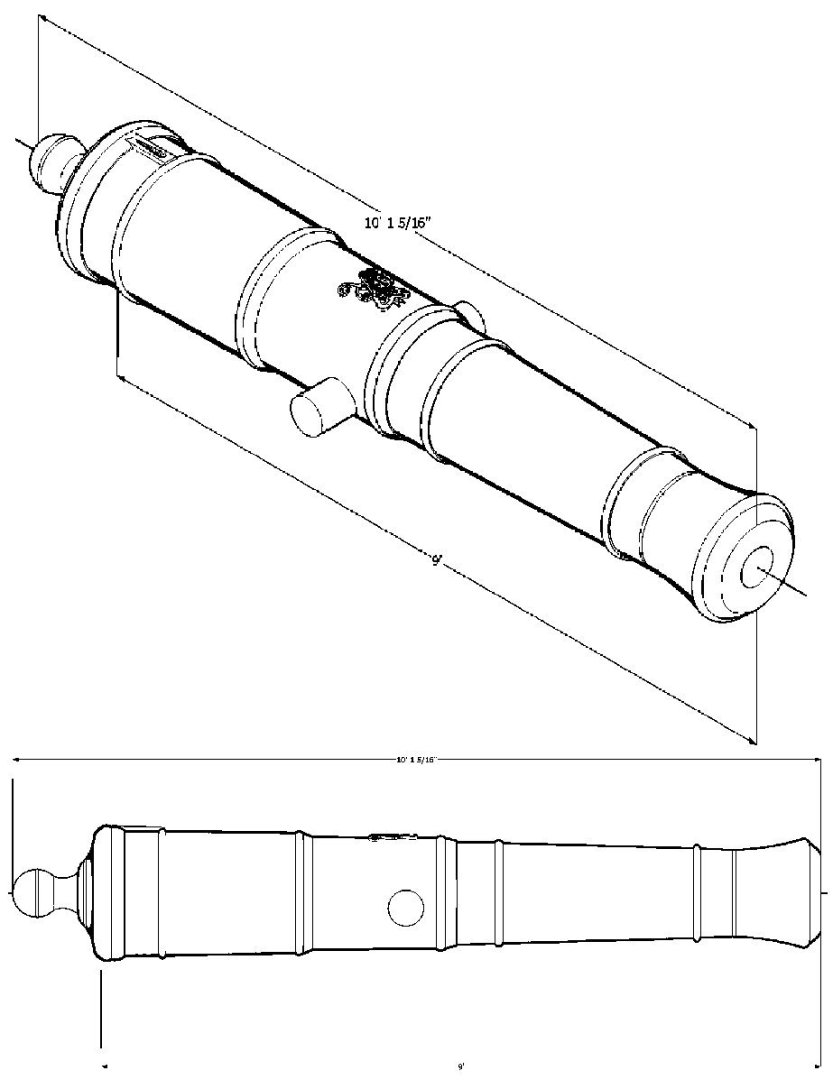

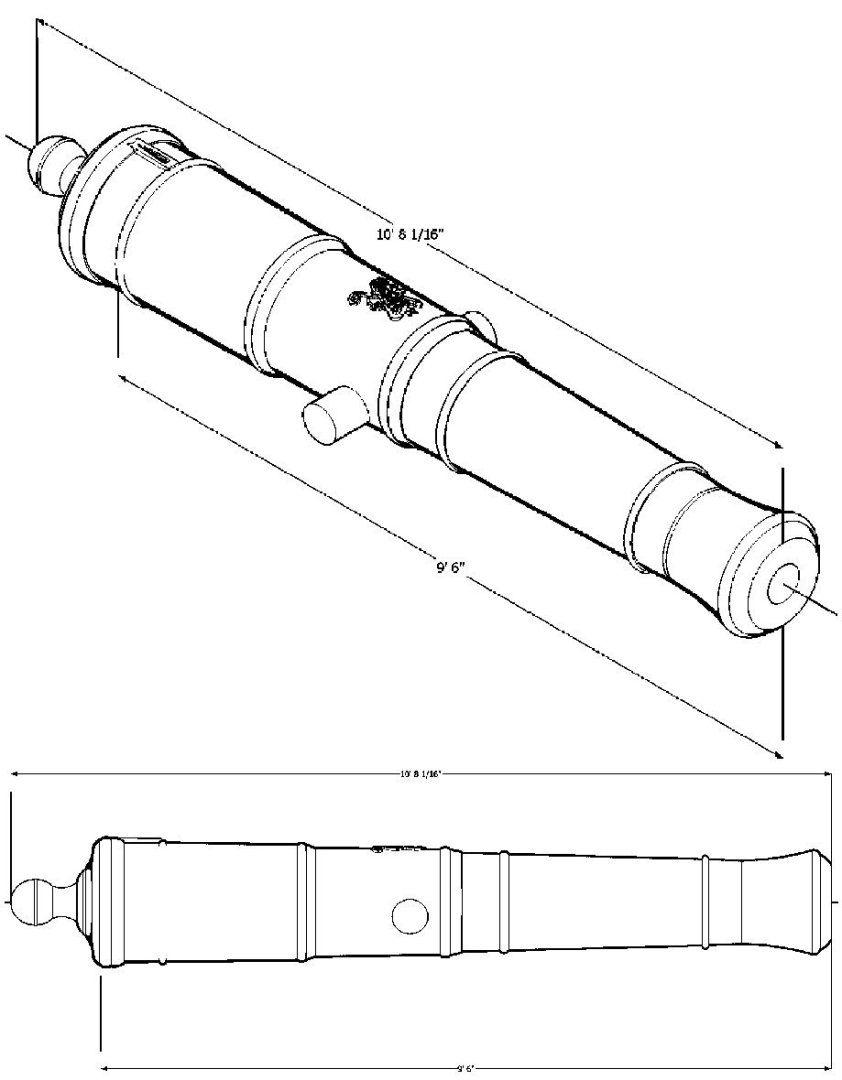

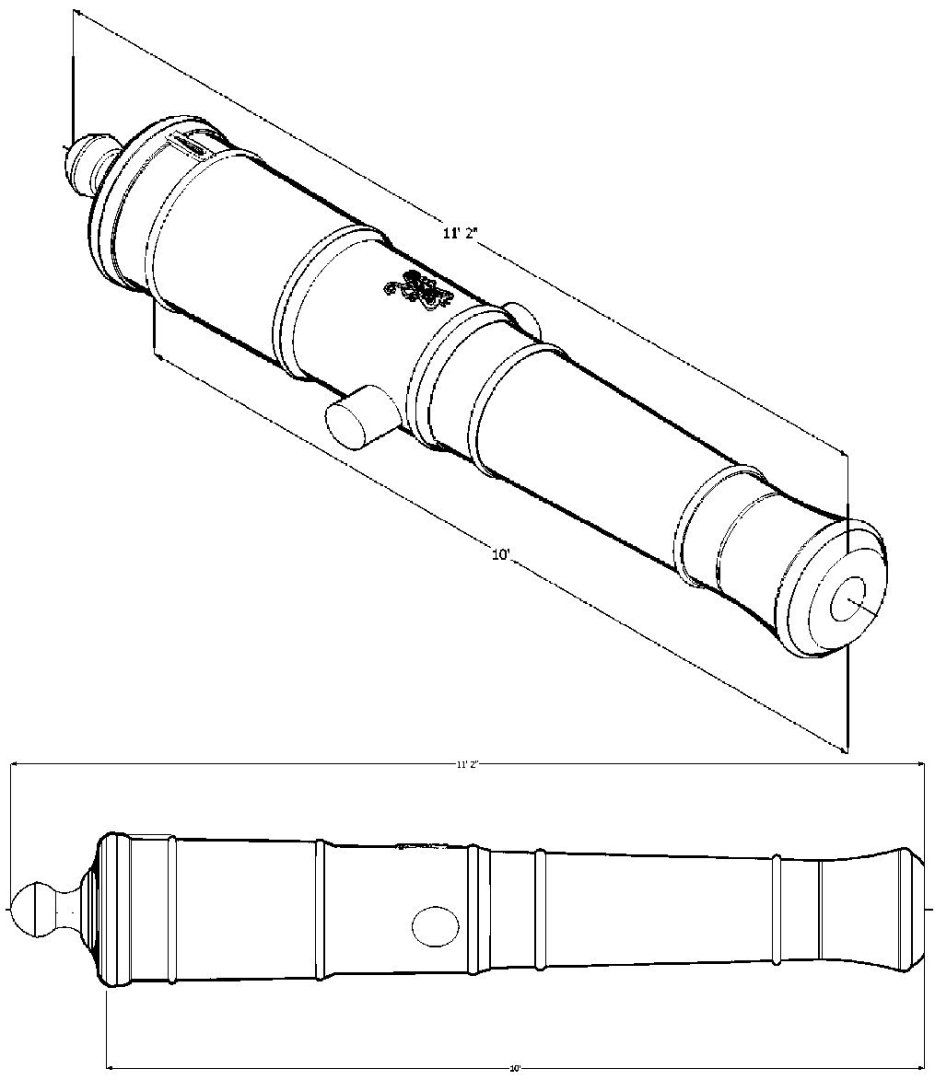

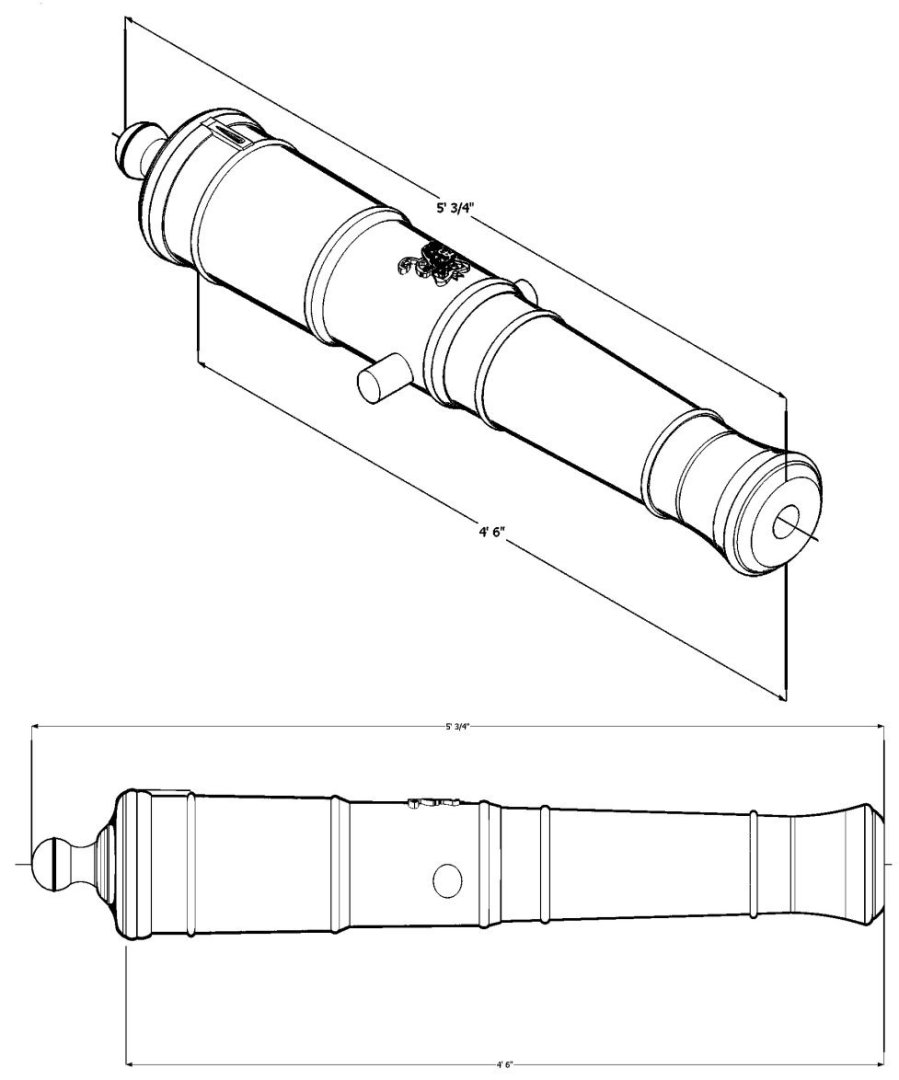

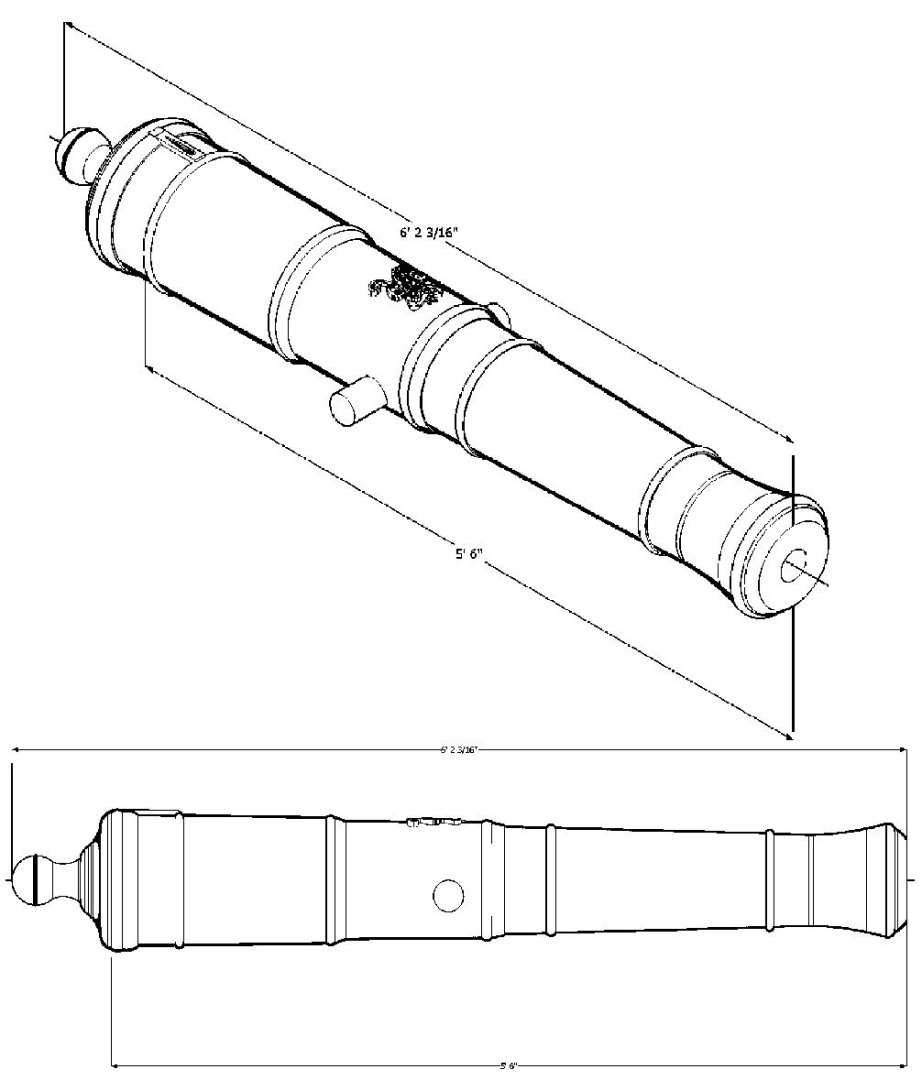

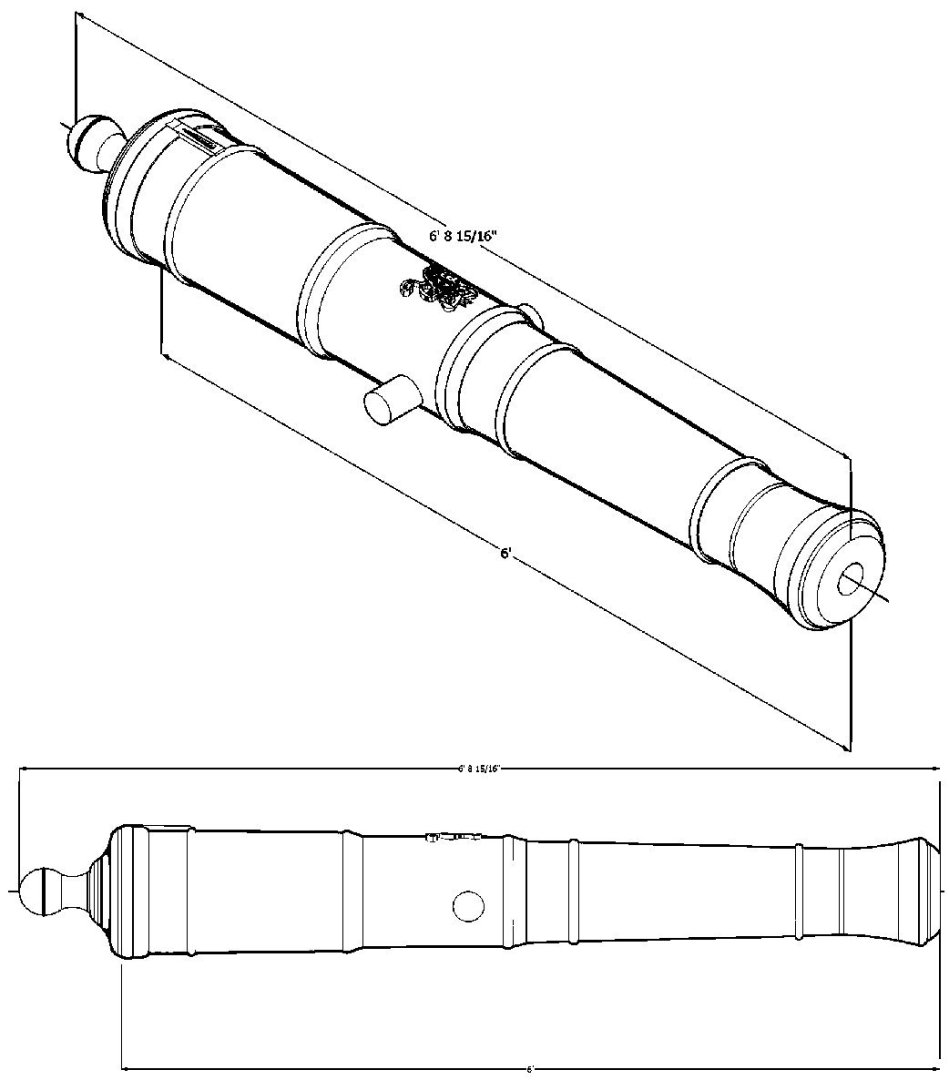

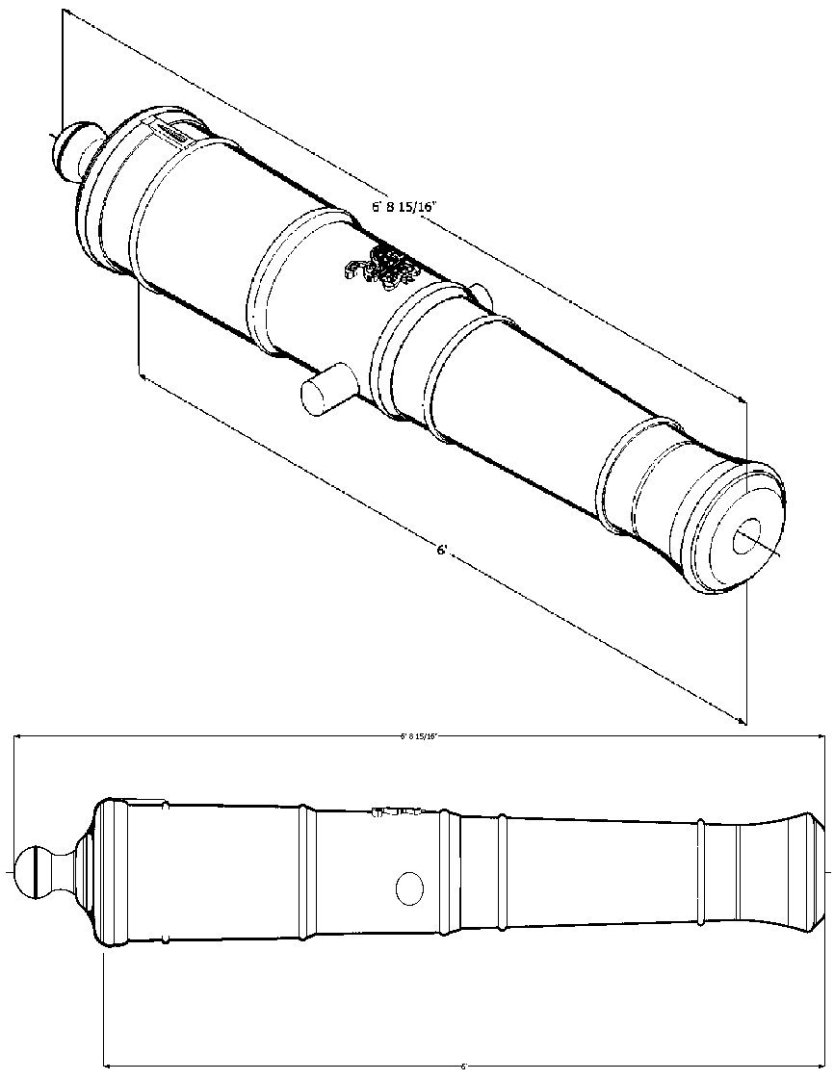

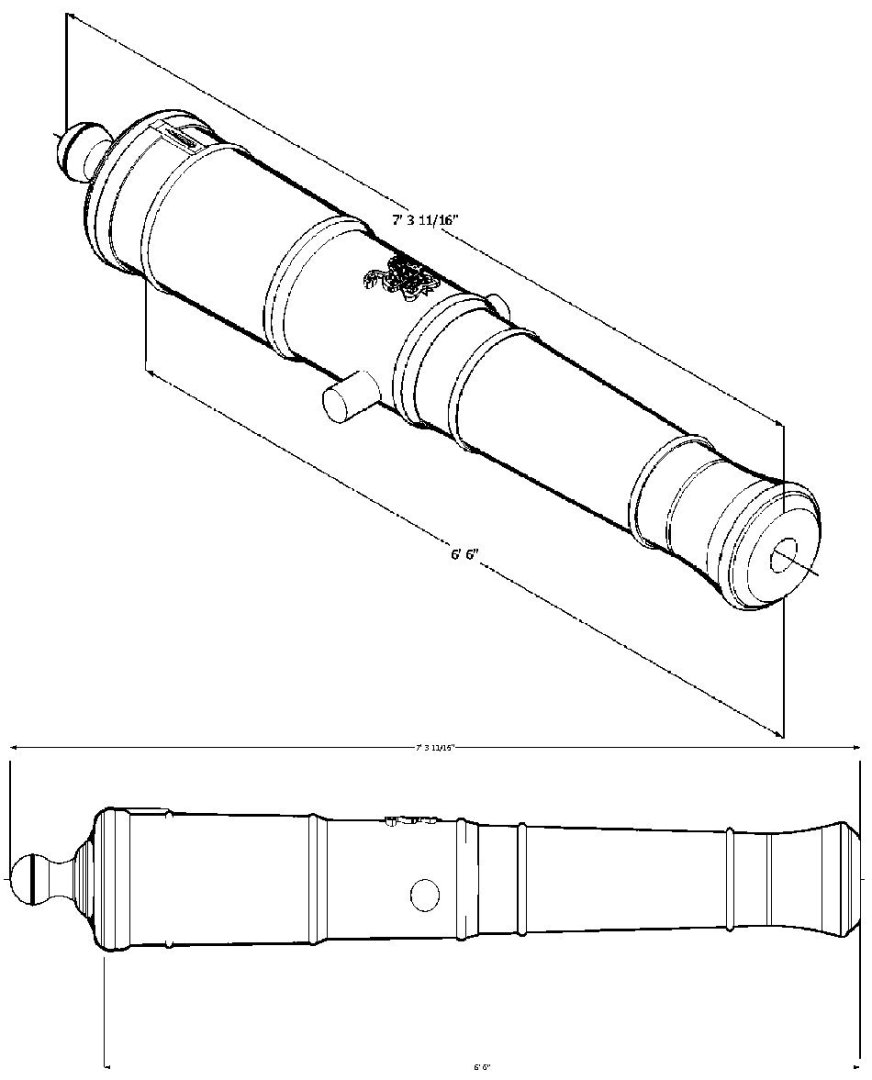

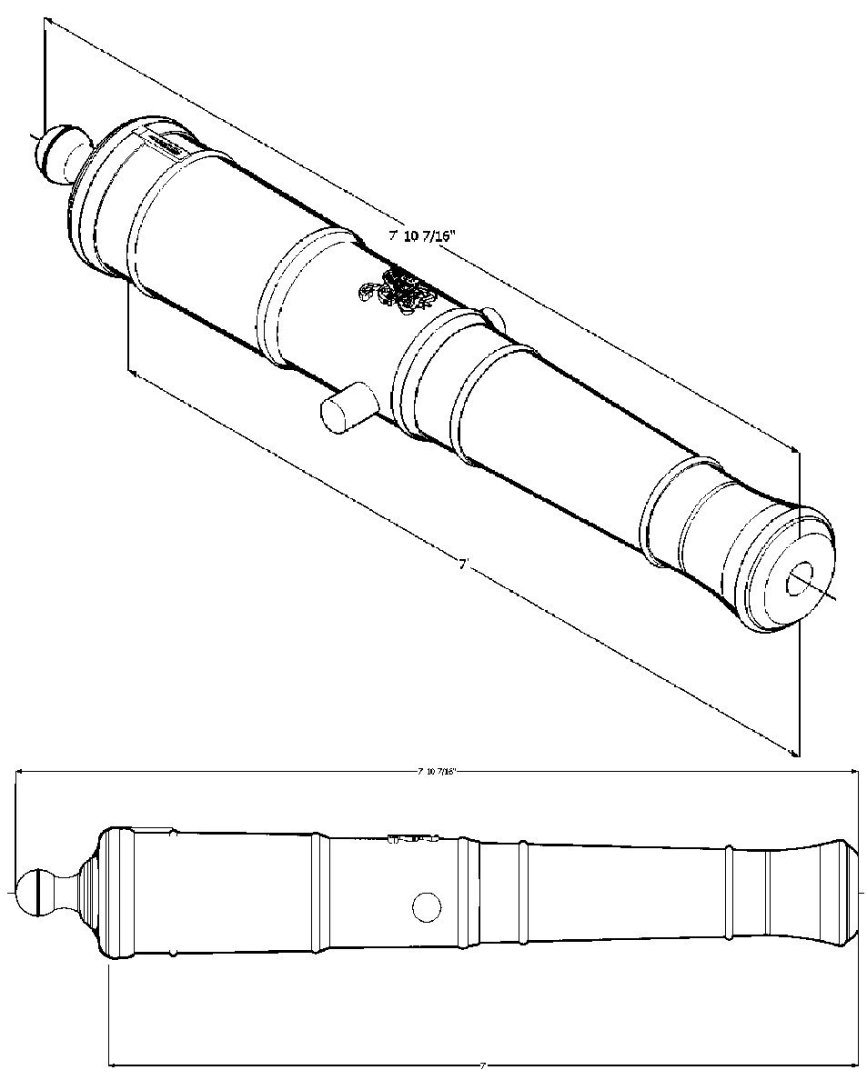

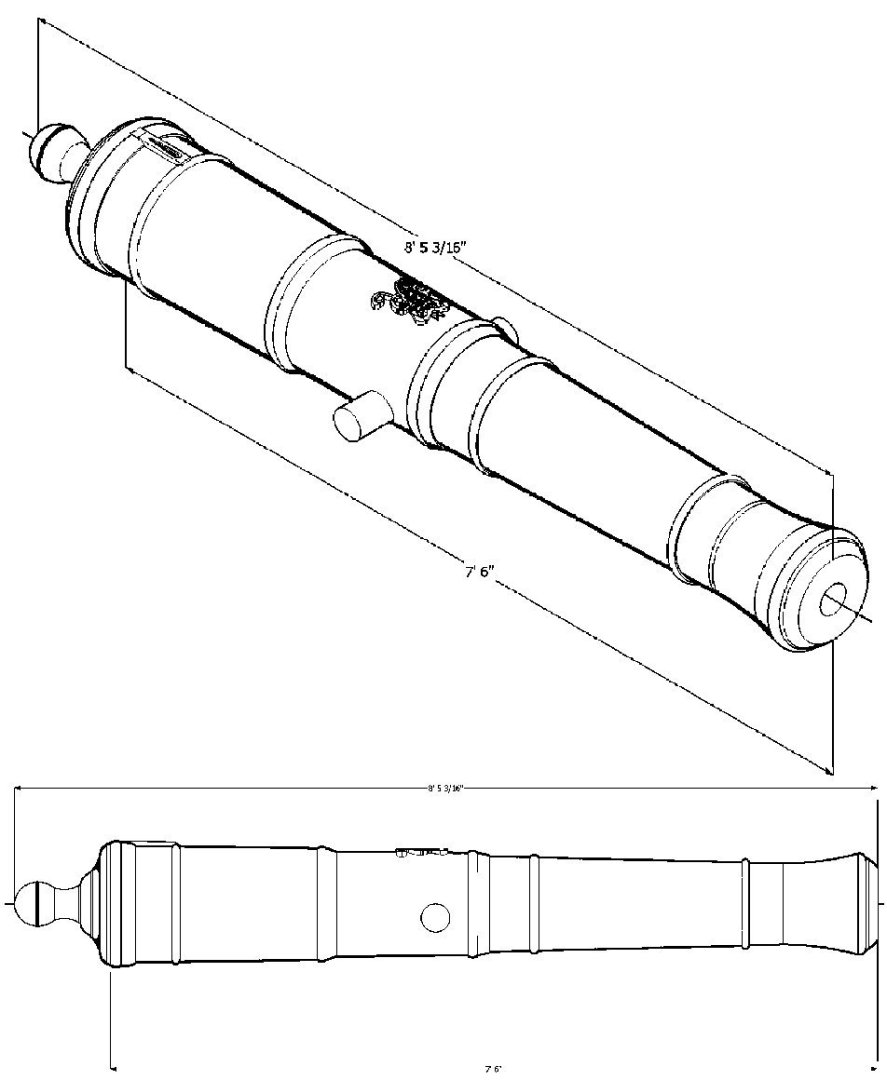

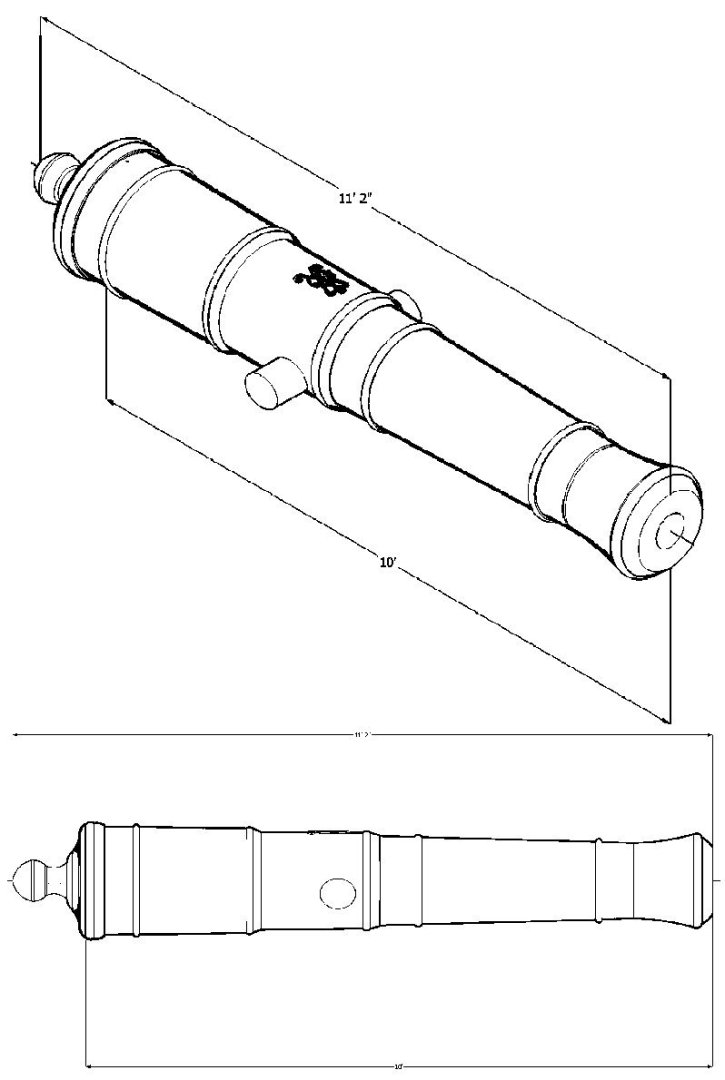

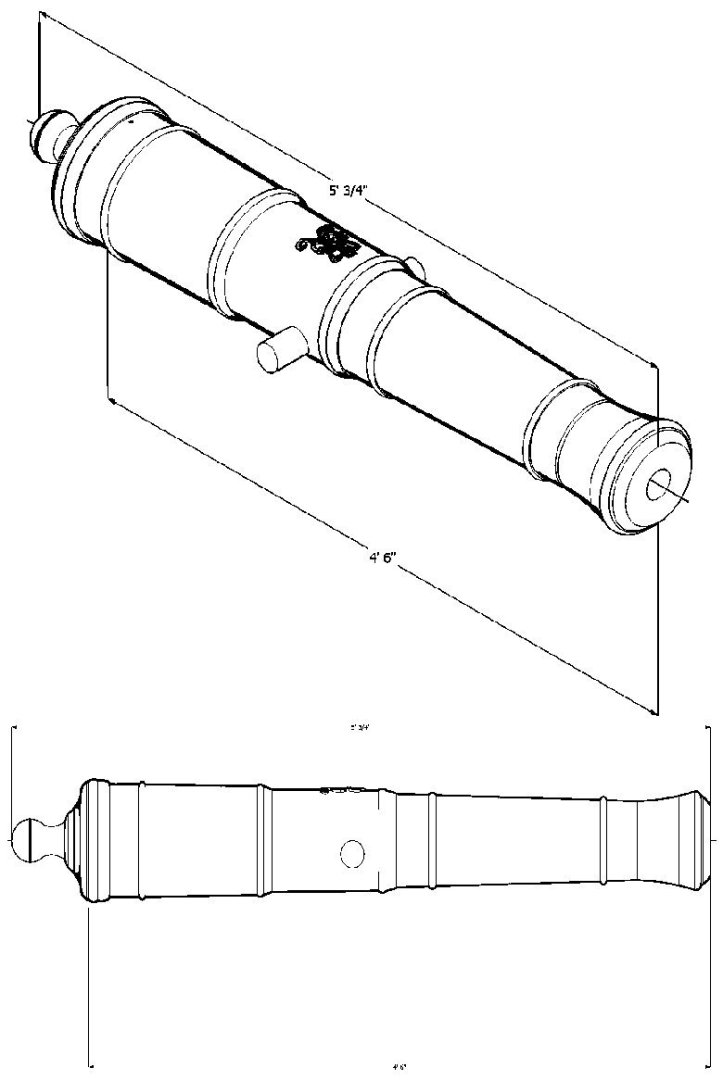

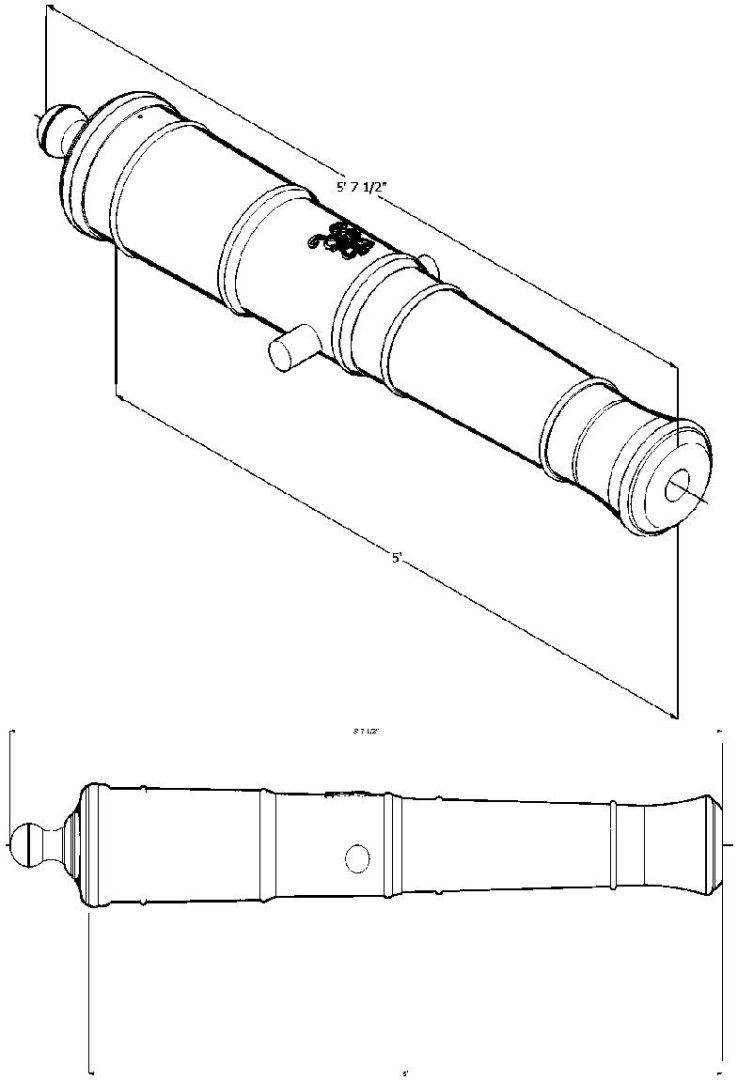

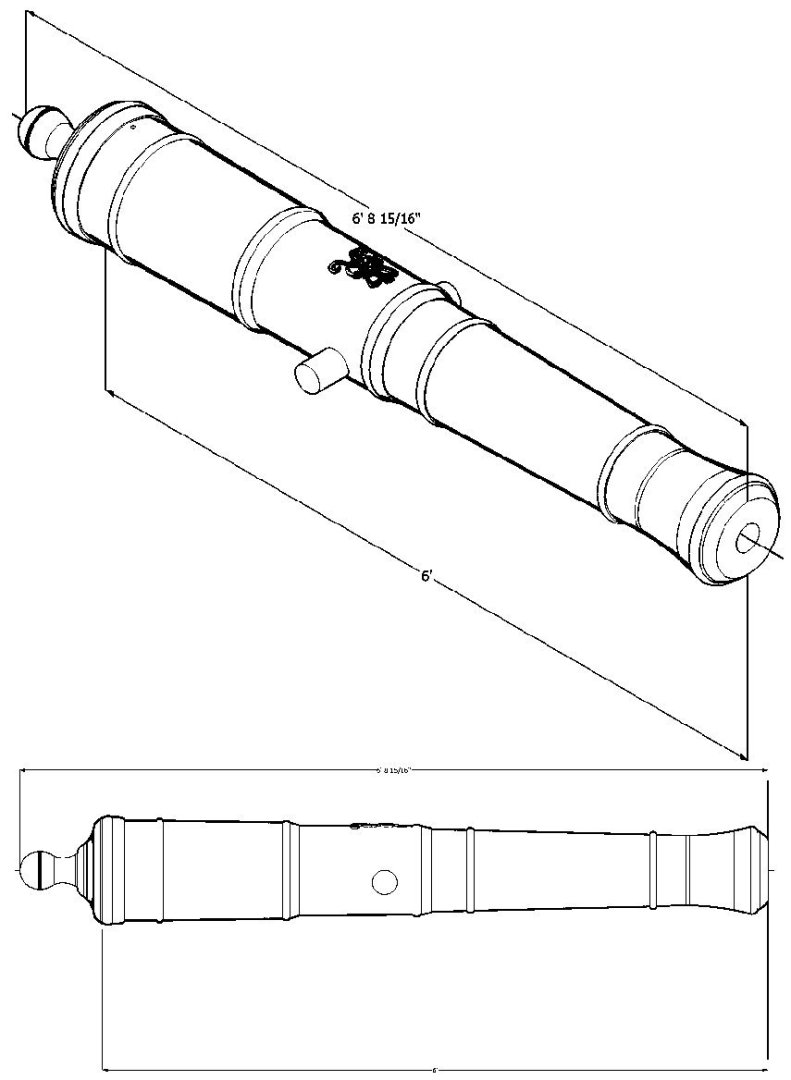

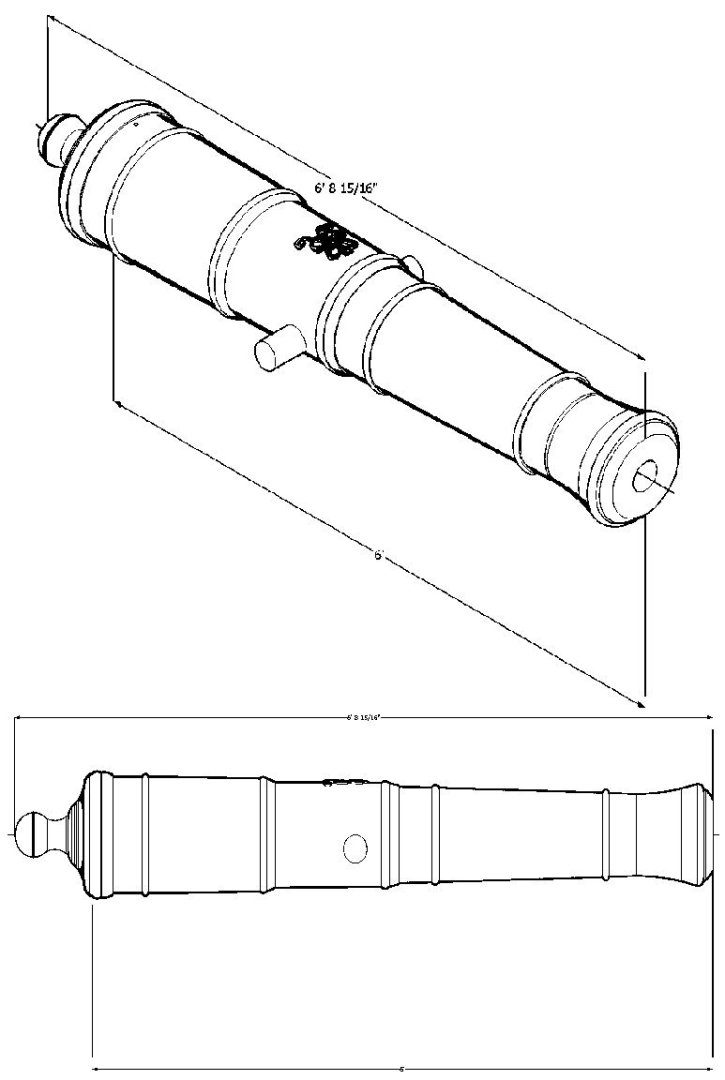

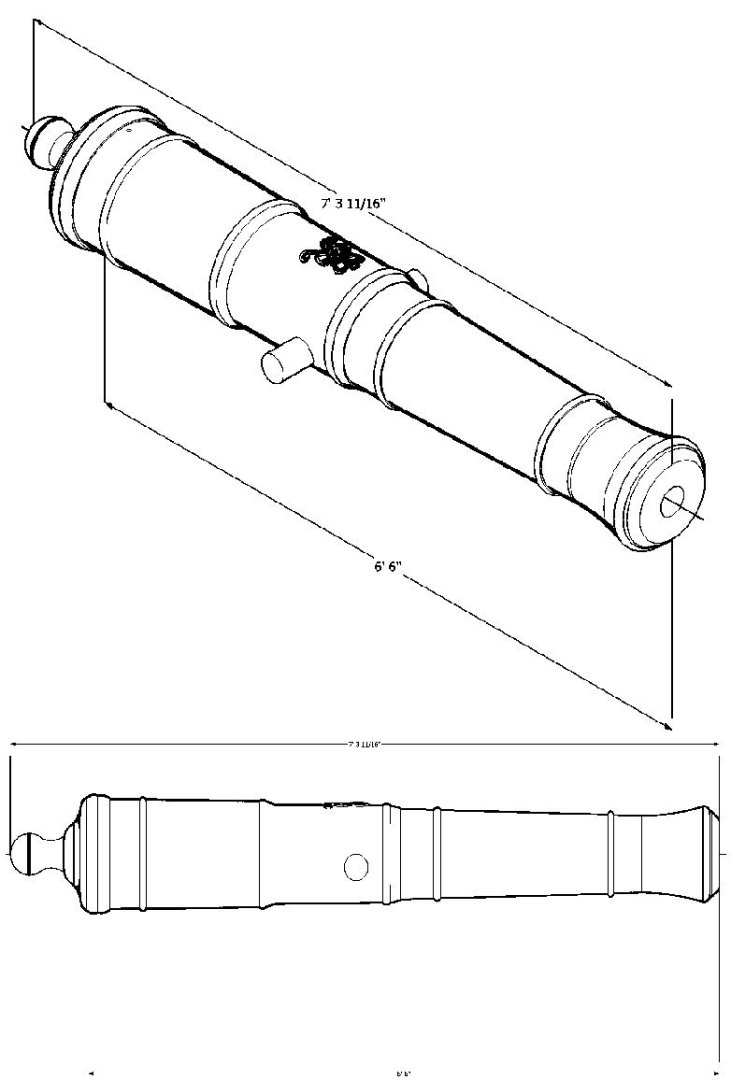

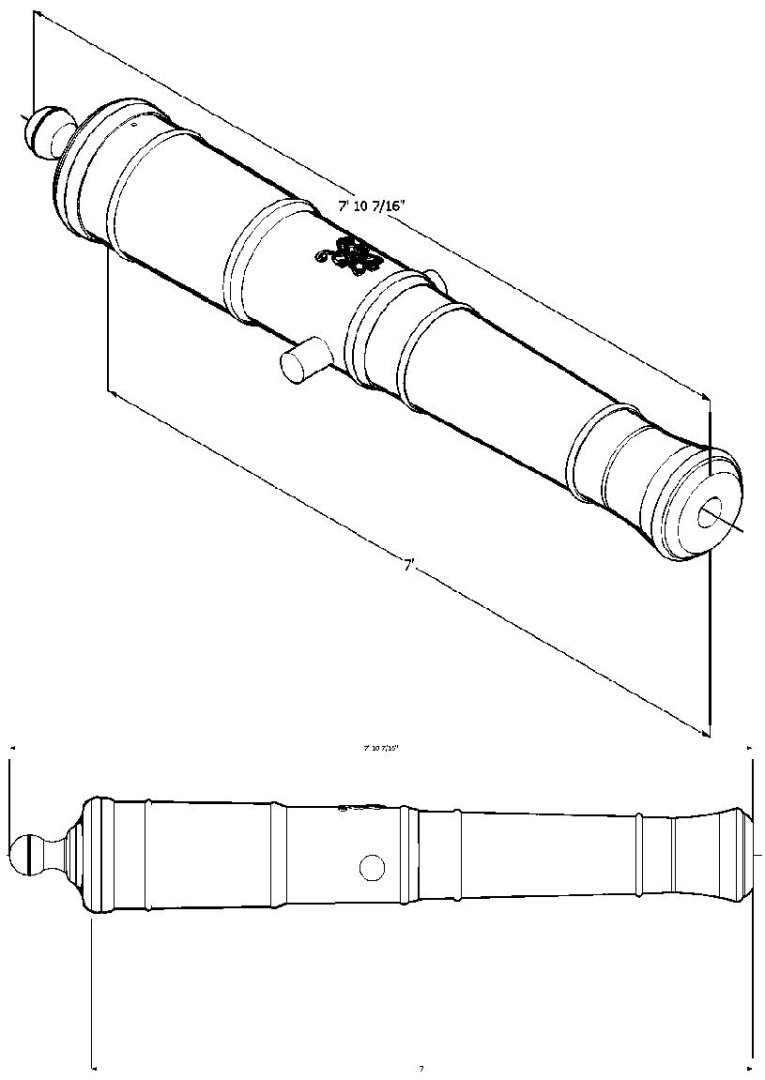

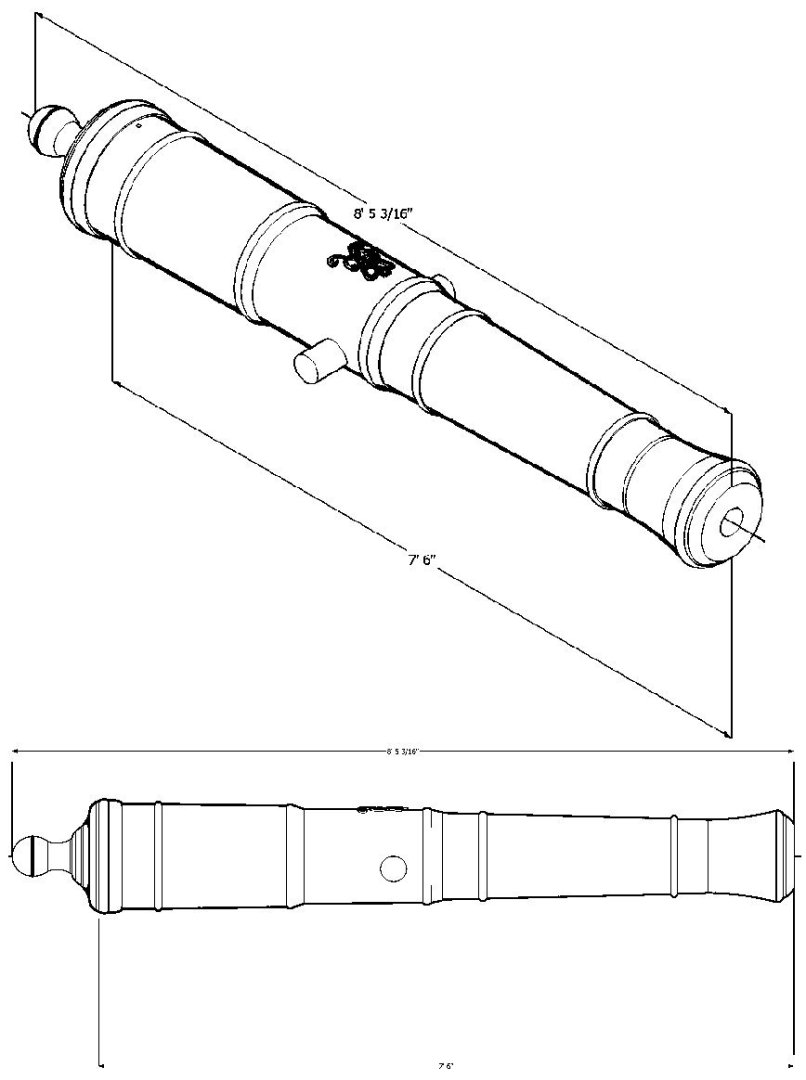

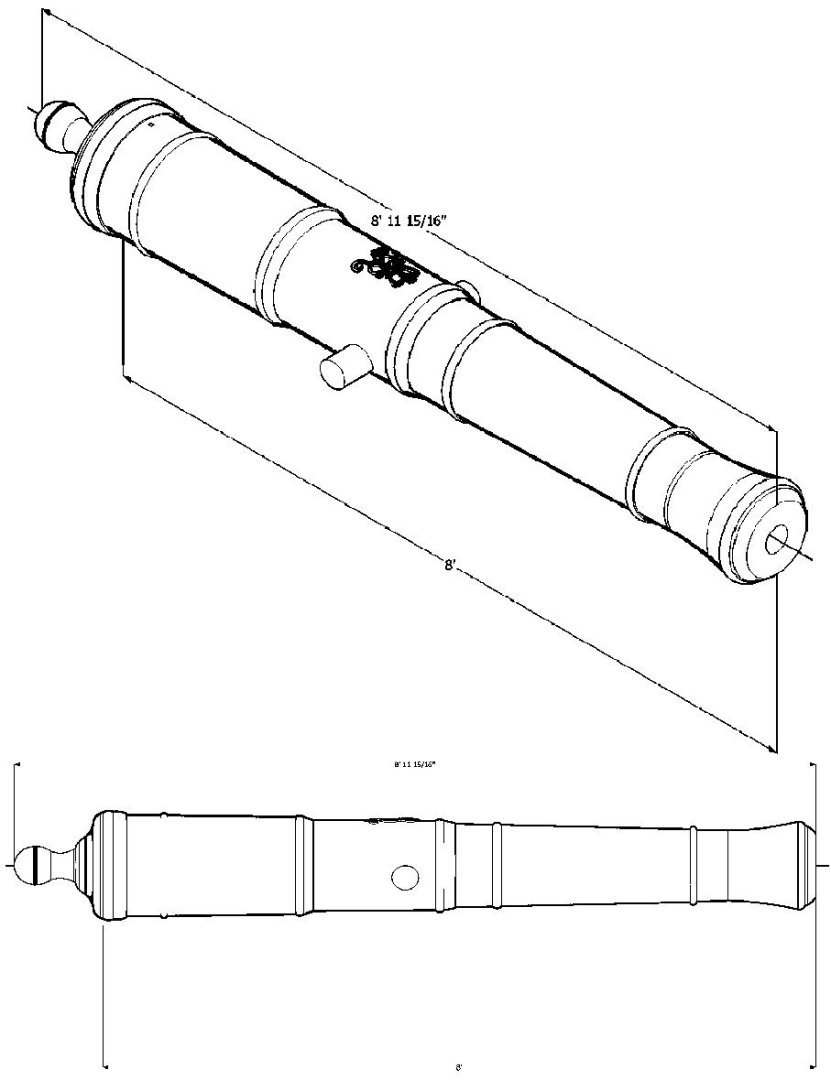

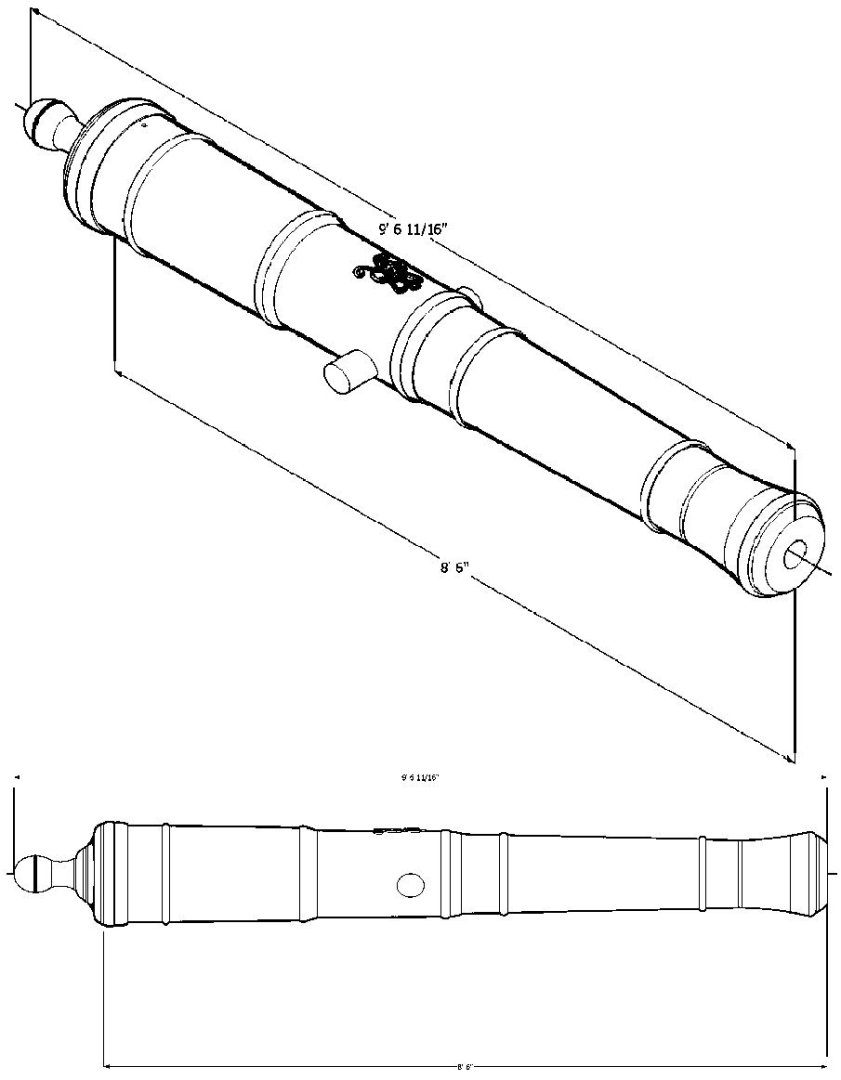

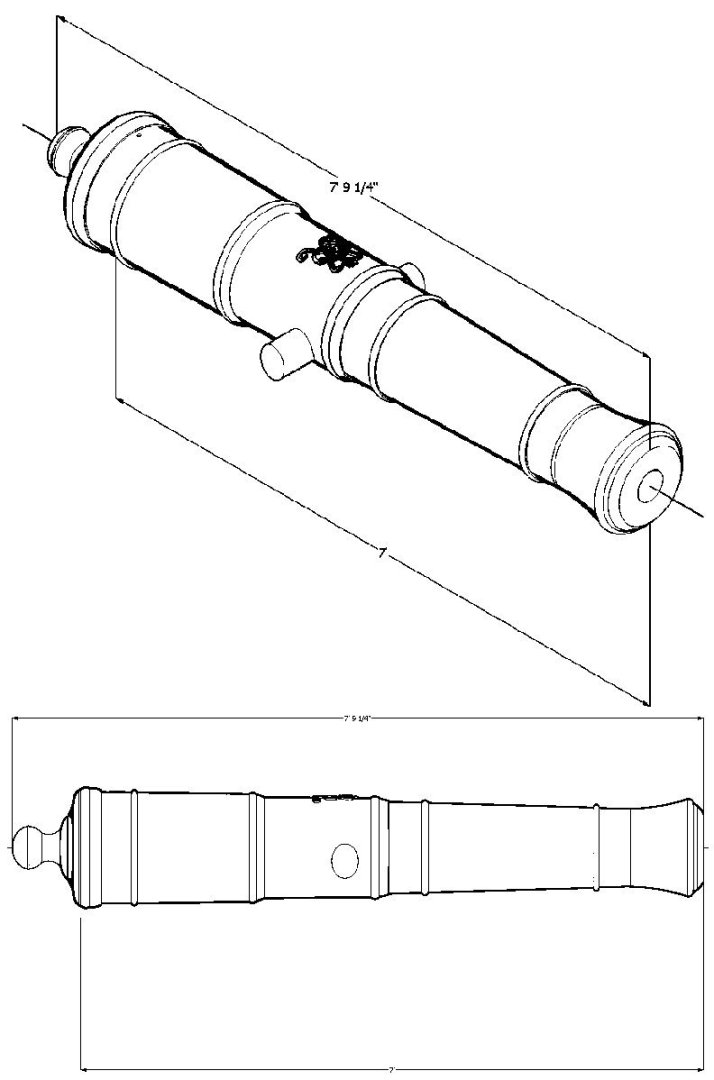

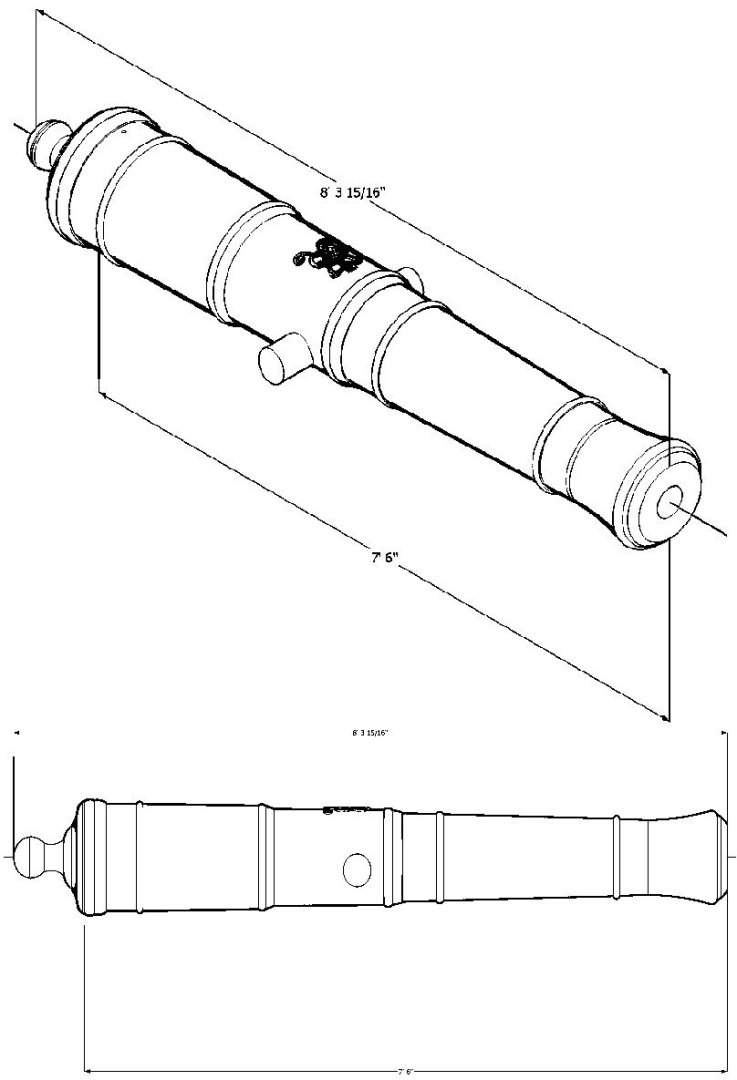

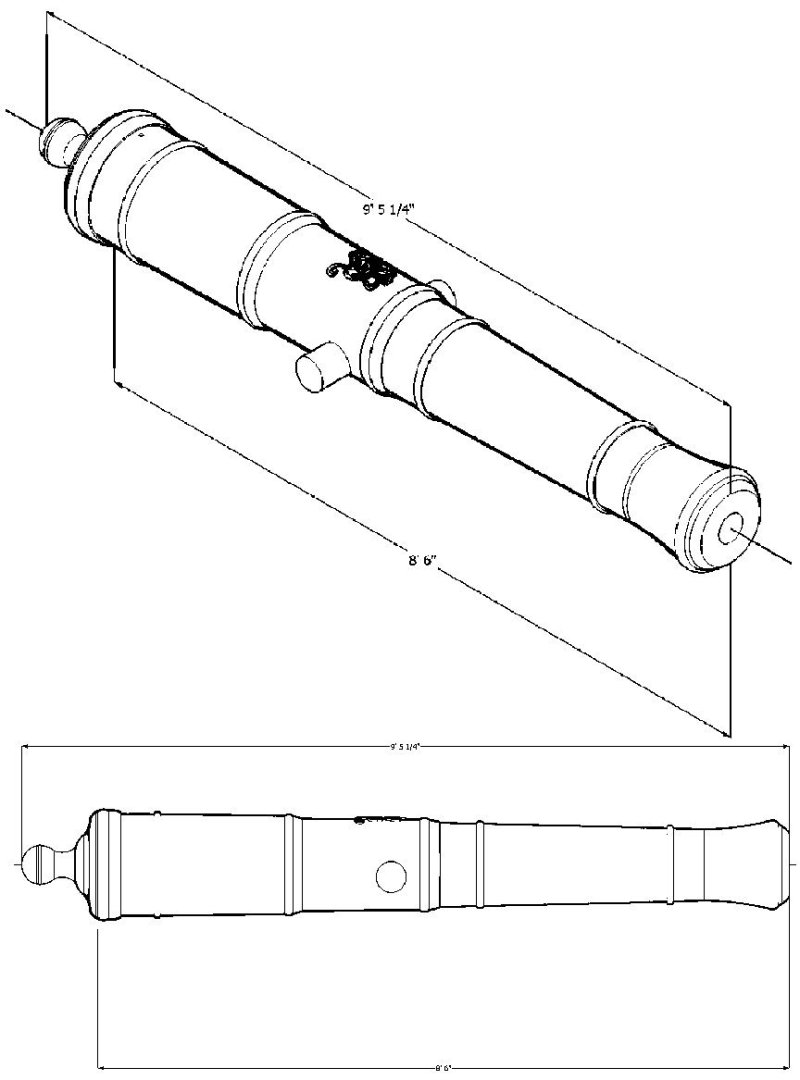

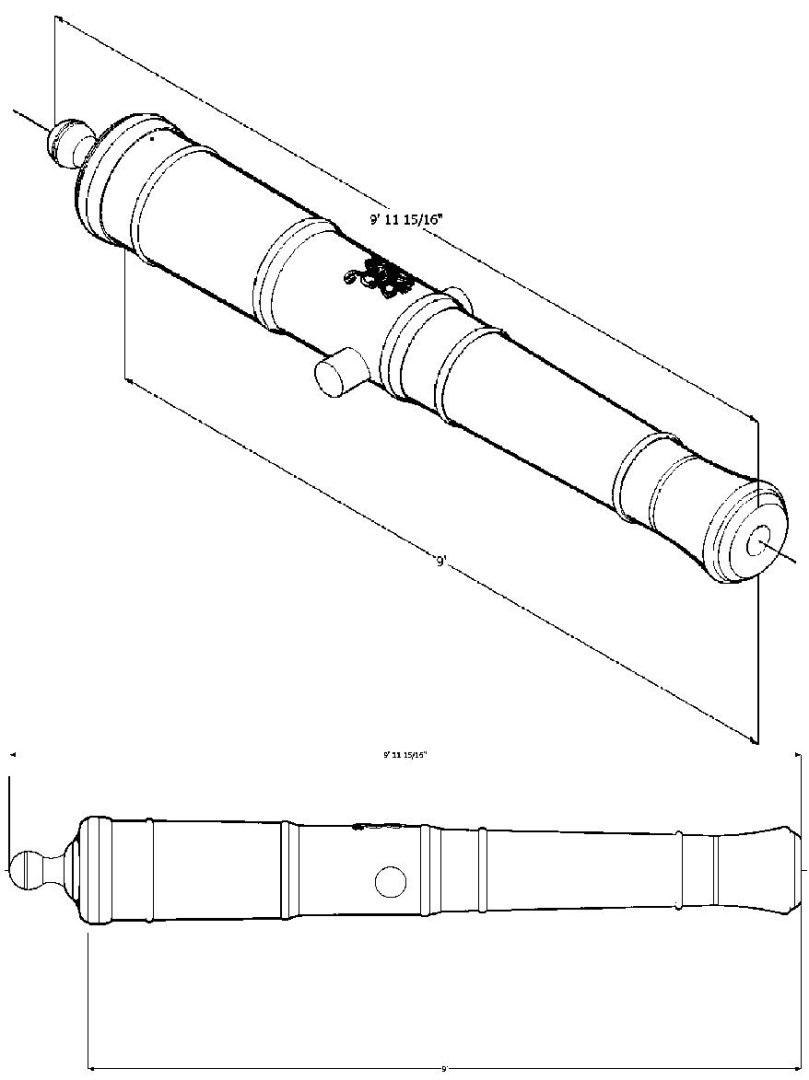

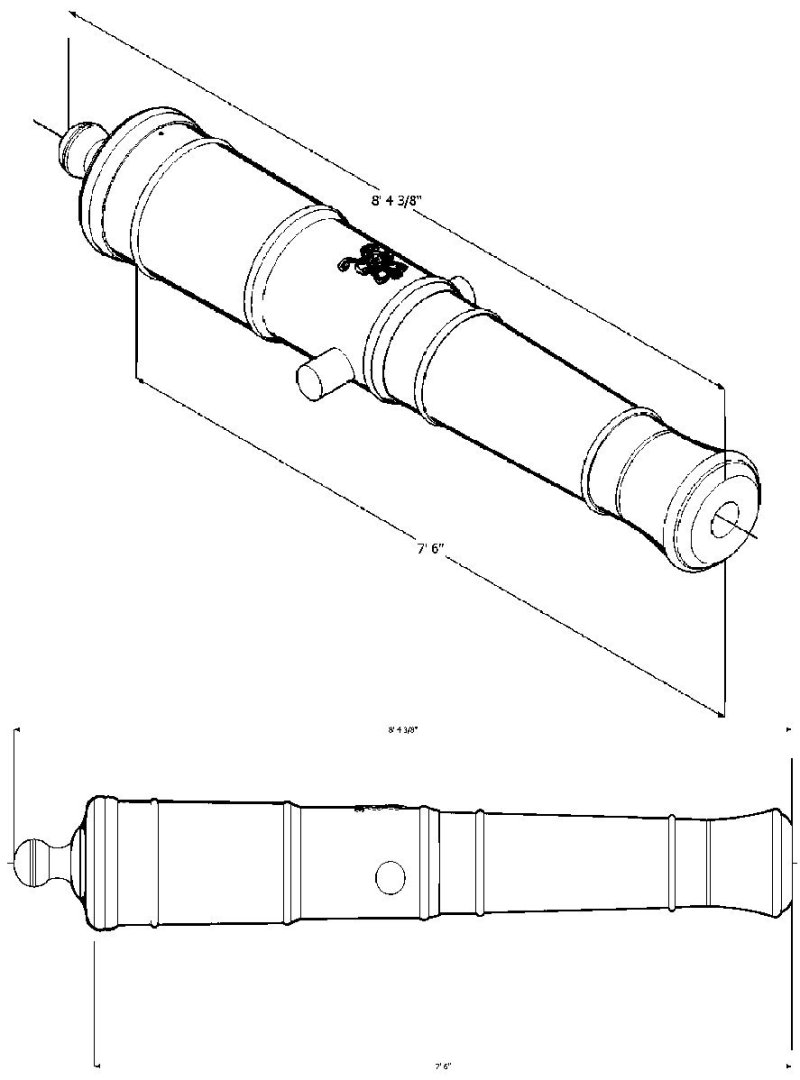

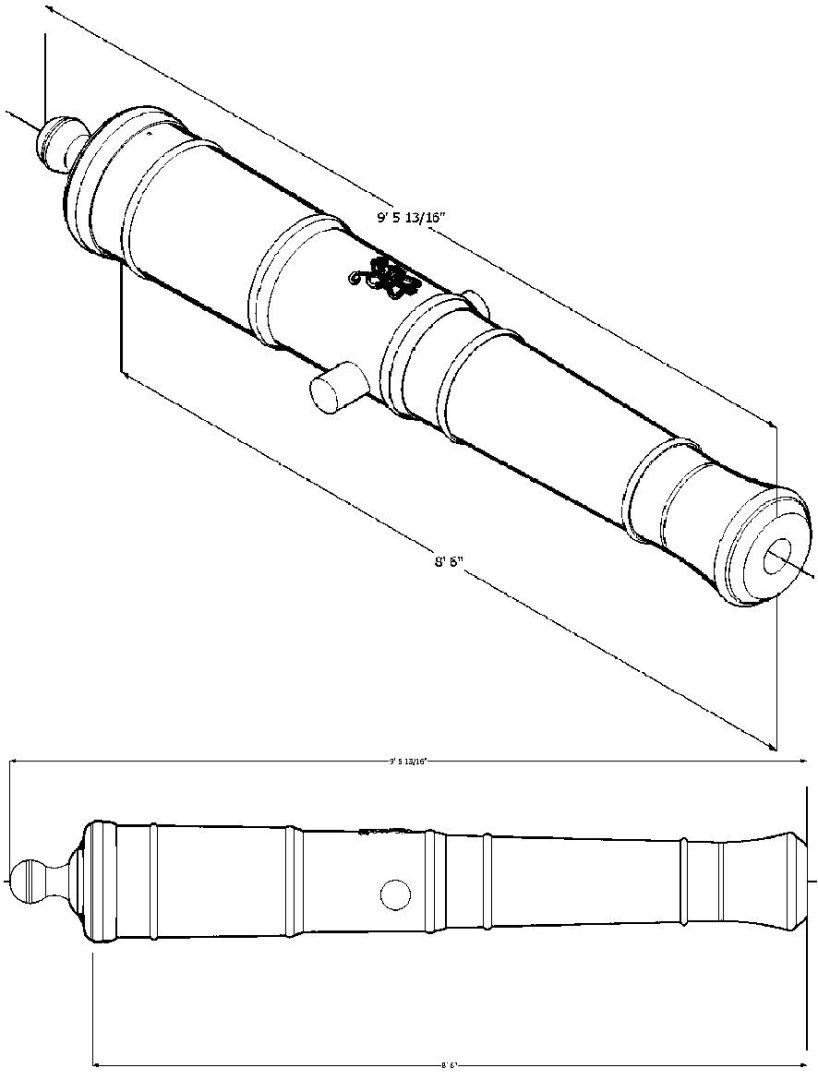

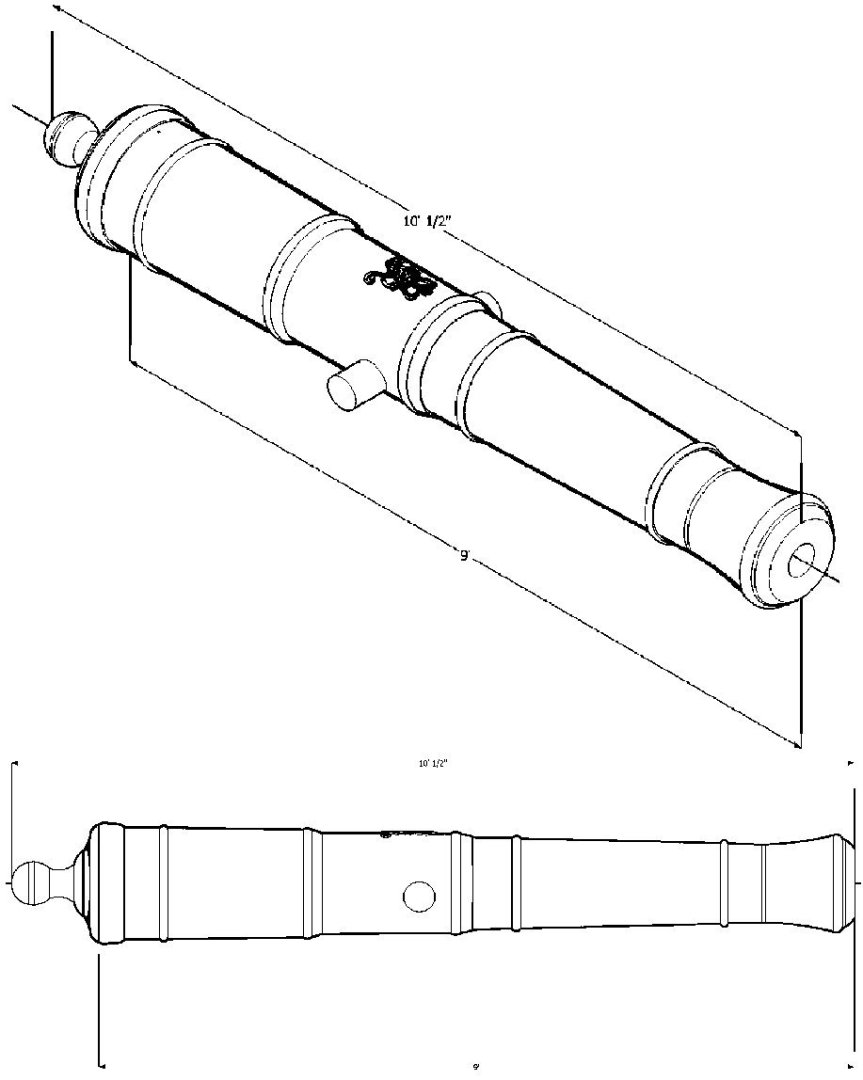

Armstrong Cannon Graphics - Part 1. I added the barrel lengths to the graphics, and converted them the black and white, so the dimensions showed better. 3 Pounder 54 4 Pounder 60 4 Pounder 72 6 Pounder 72 6 Pounder 78 6 Pounder 84 6 Pounder 90 6 Pounder 96 6 Pounder 102 9 Pounder 84 9 Pounder 90 9 Pounder 102 9 Pounder 108 12 Pounder 90 12 Pounder 102 12 Pounder 108 -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

I've finished redrawing the Armstrong and Armstrong-Fredricks cannons, basing them on the breach diameter and length specifications at the Web Site: https://www.arc.id.au/ArmstrongPattern.html I used my existing drawings and scaled them accordingly. This is the last round, and I drew all the sizes shown in the chart for the Fredricks, and the sizes of Armstrongs listed by Lieste in a previous post. Below are the two charts, the graphics and STL files will follow in subsequent posts. -

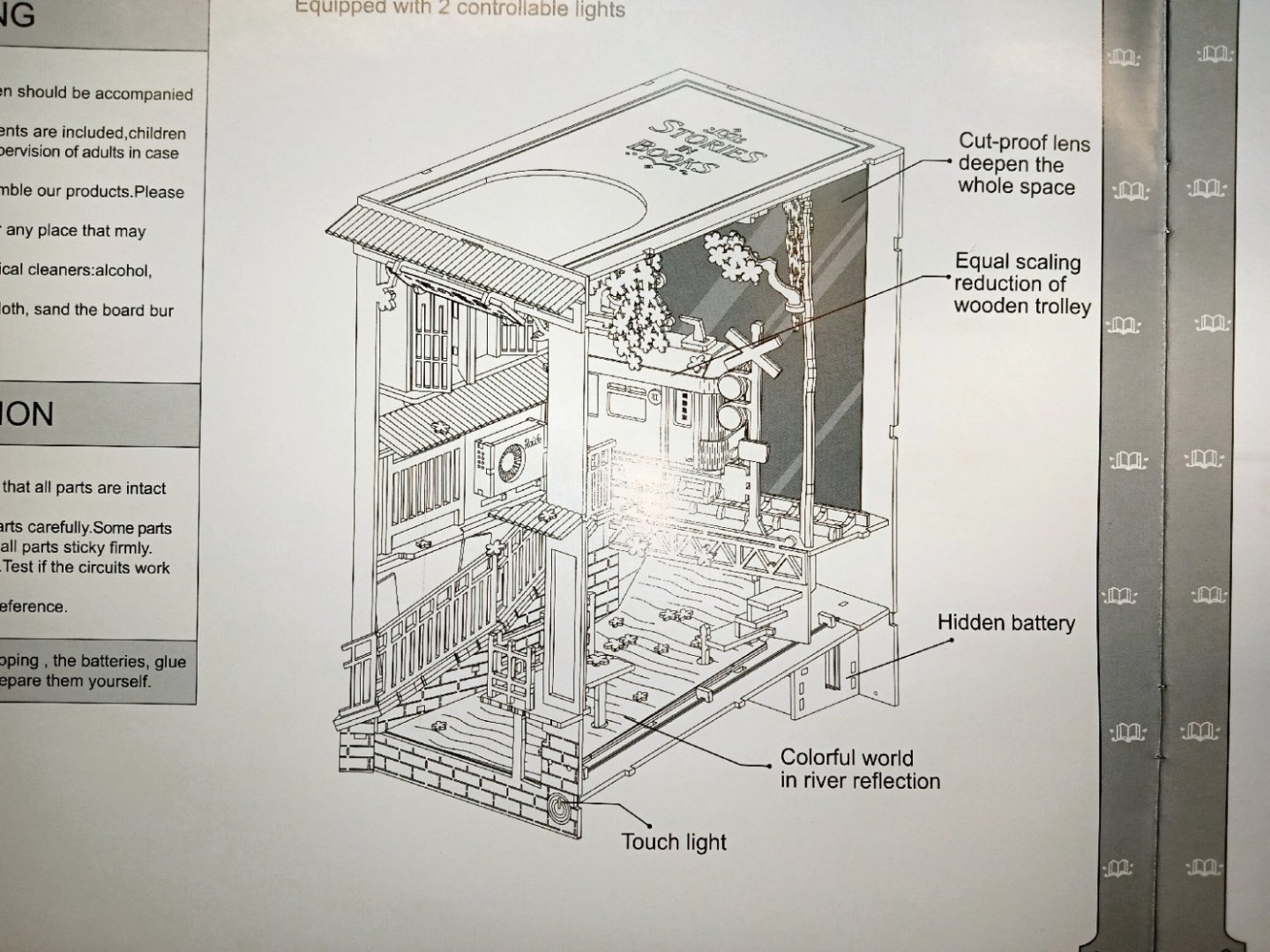

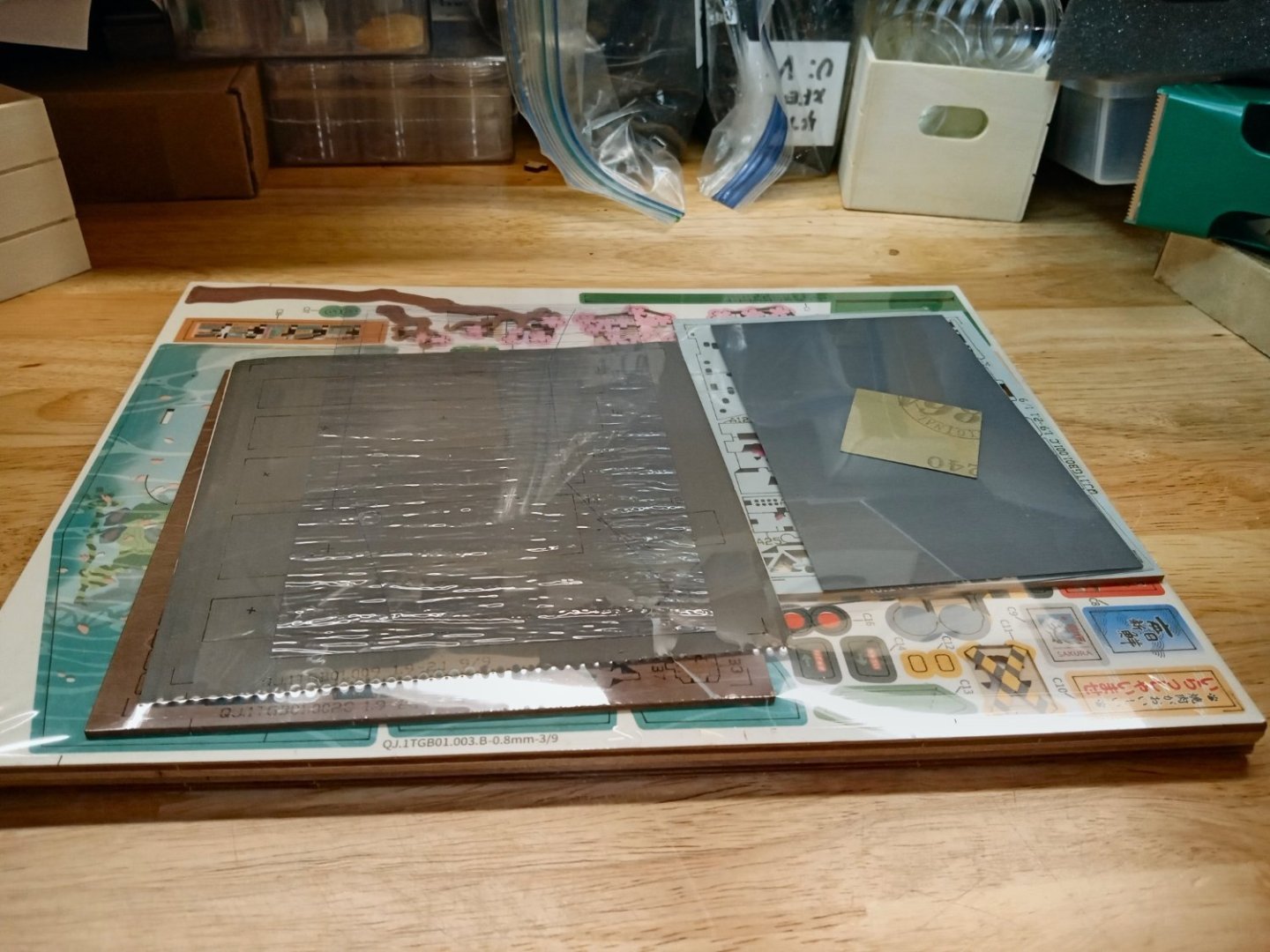

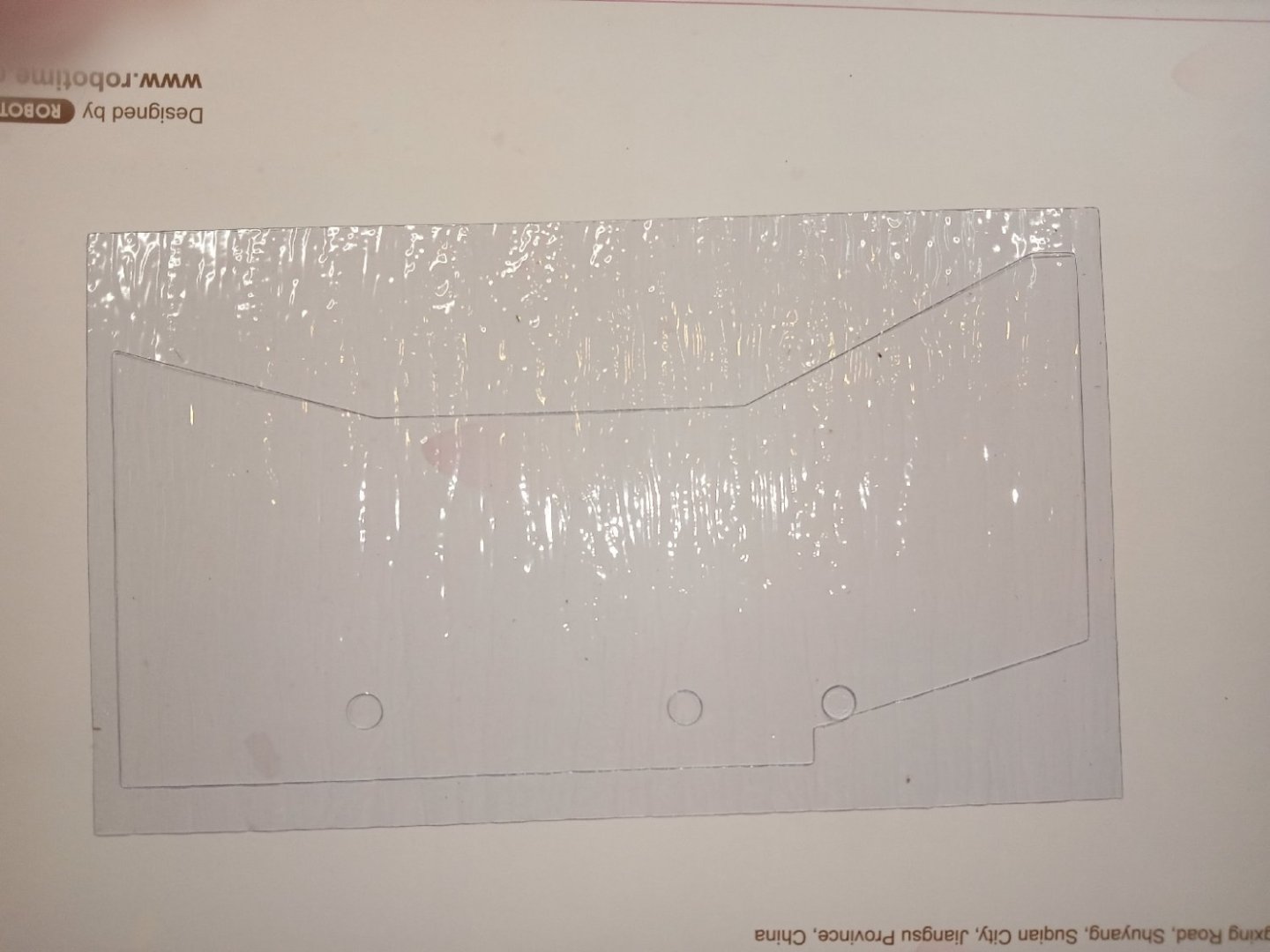

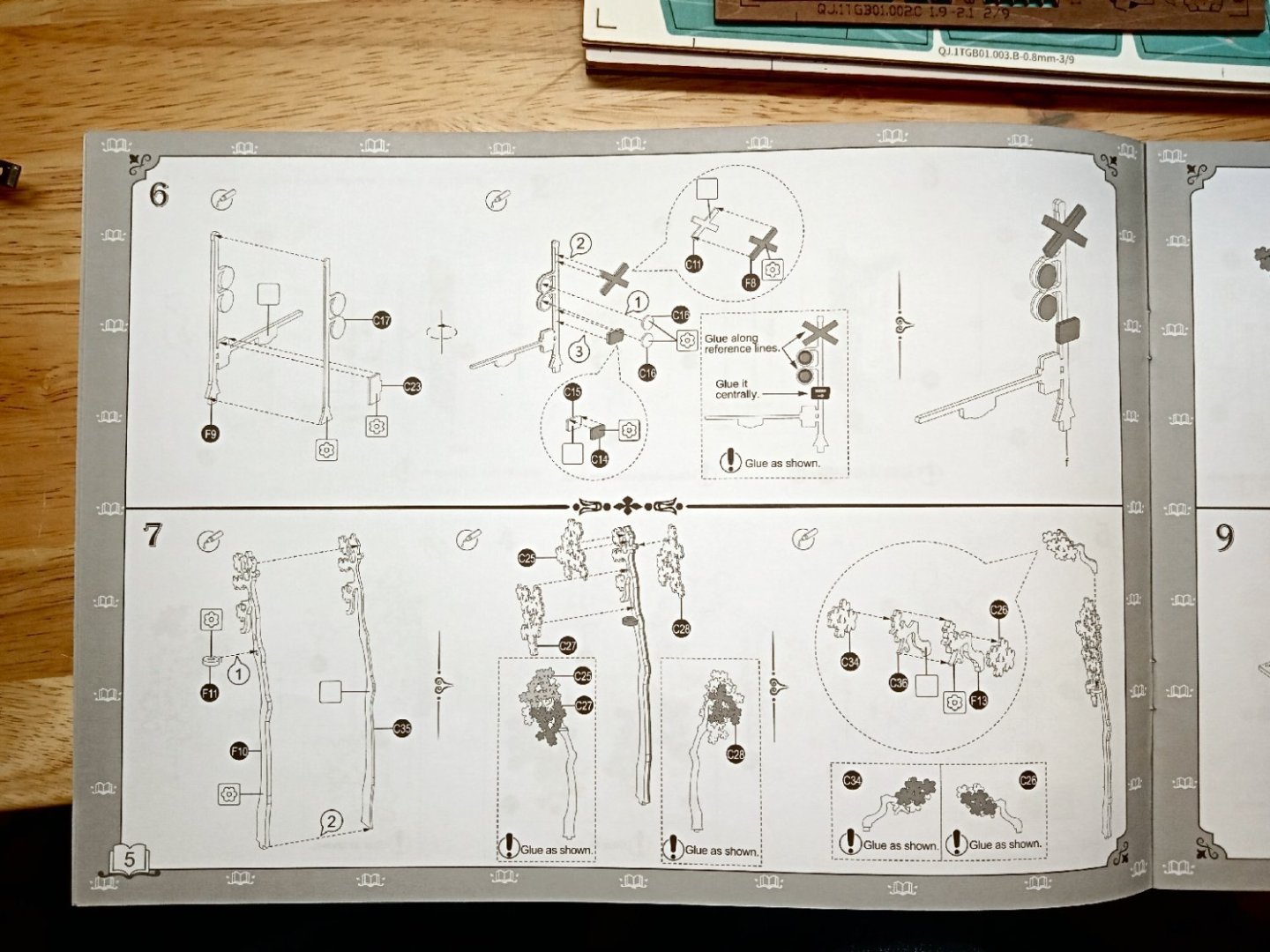

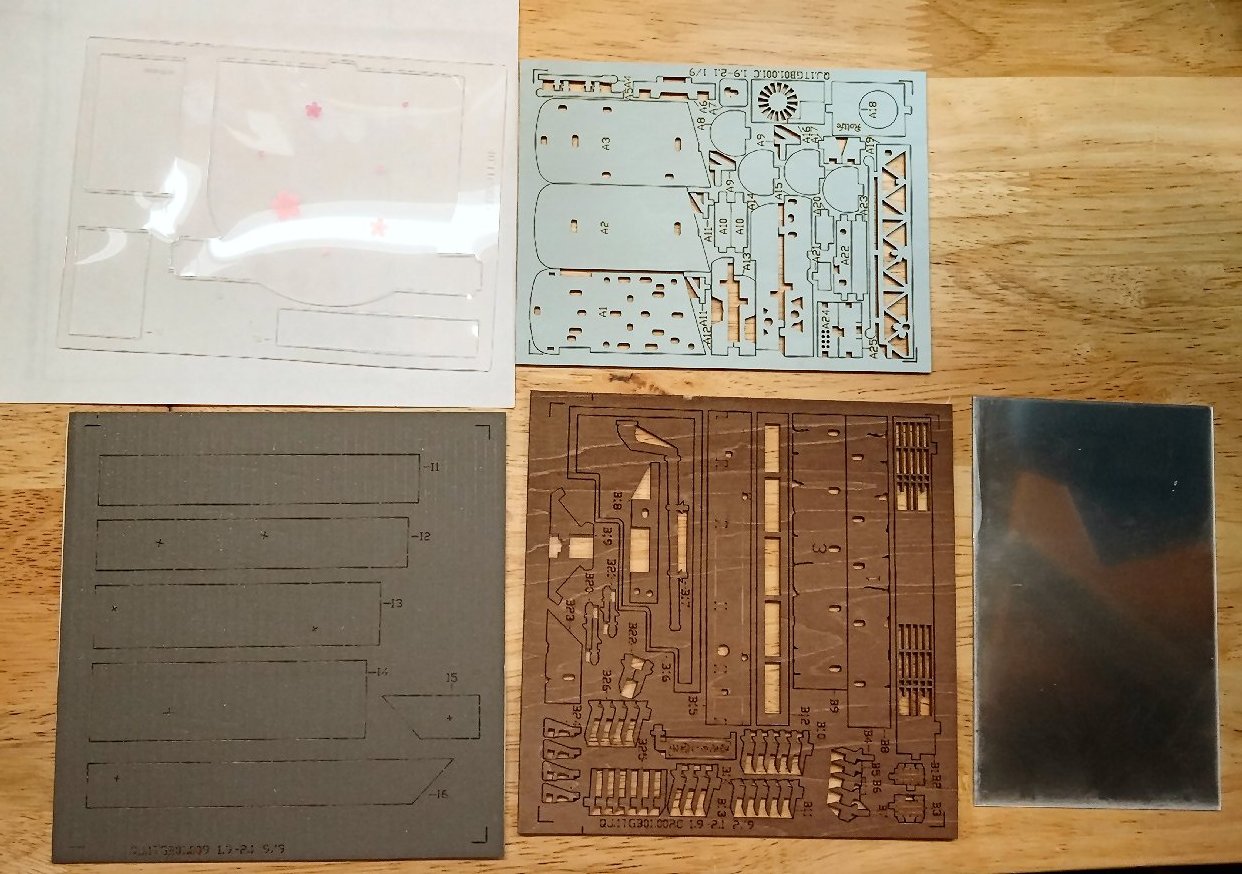

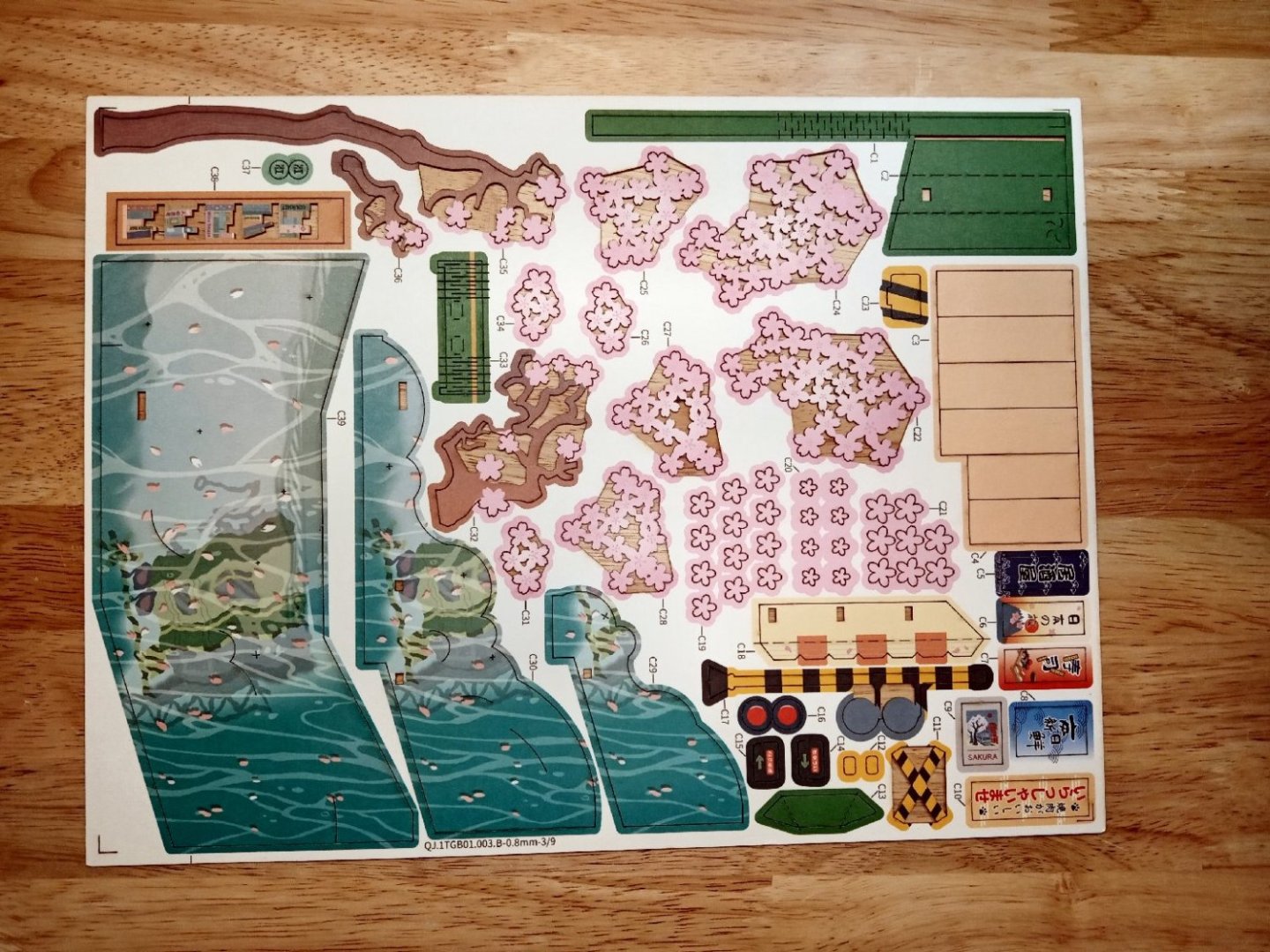

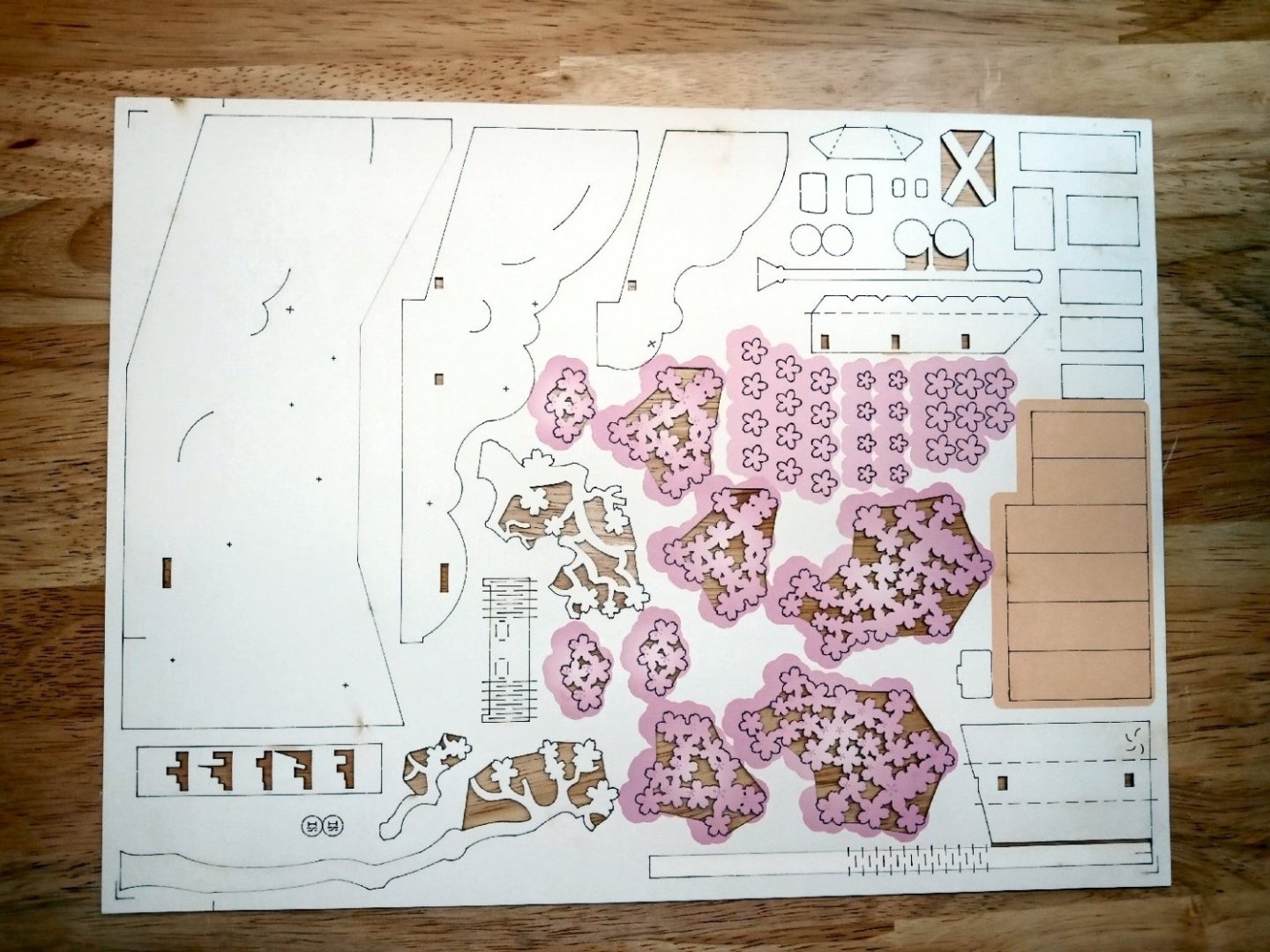

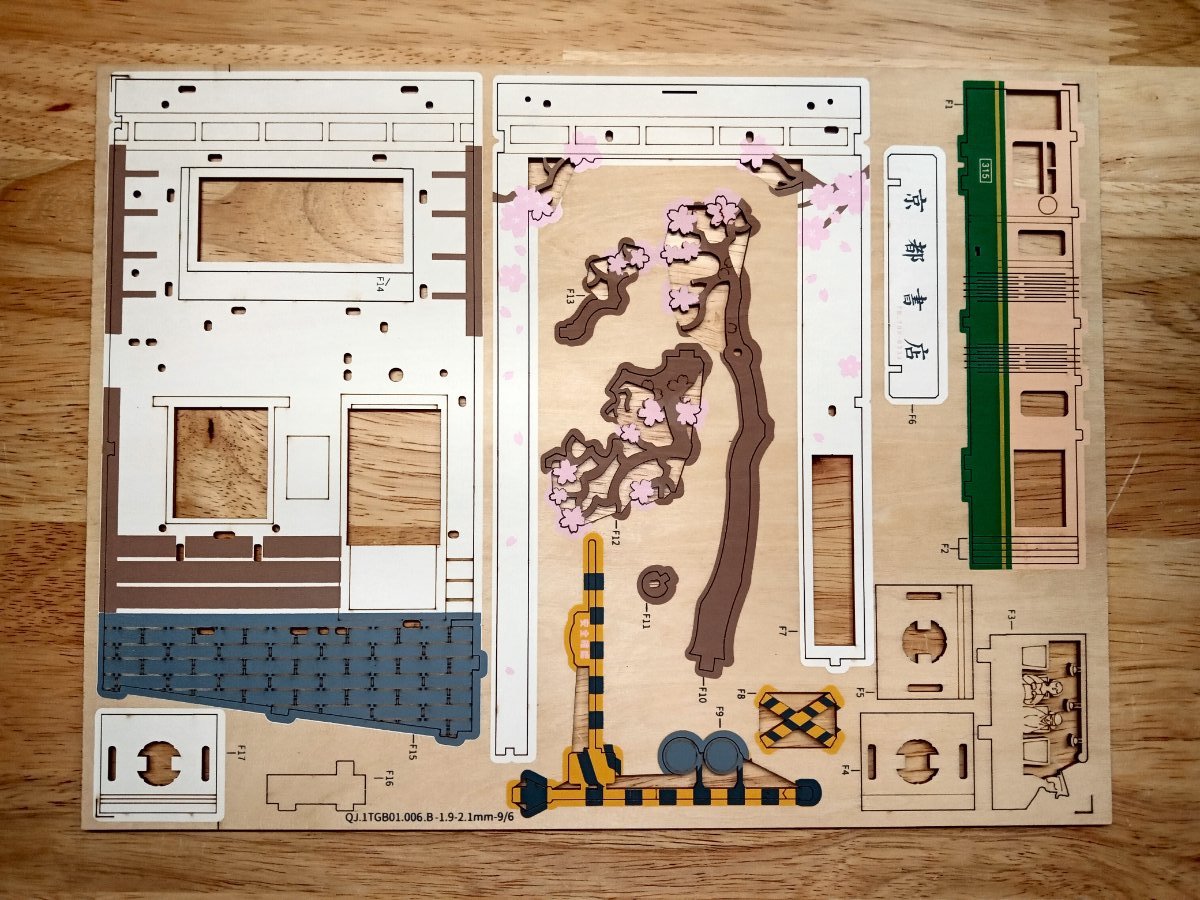

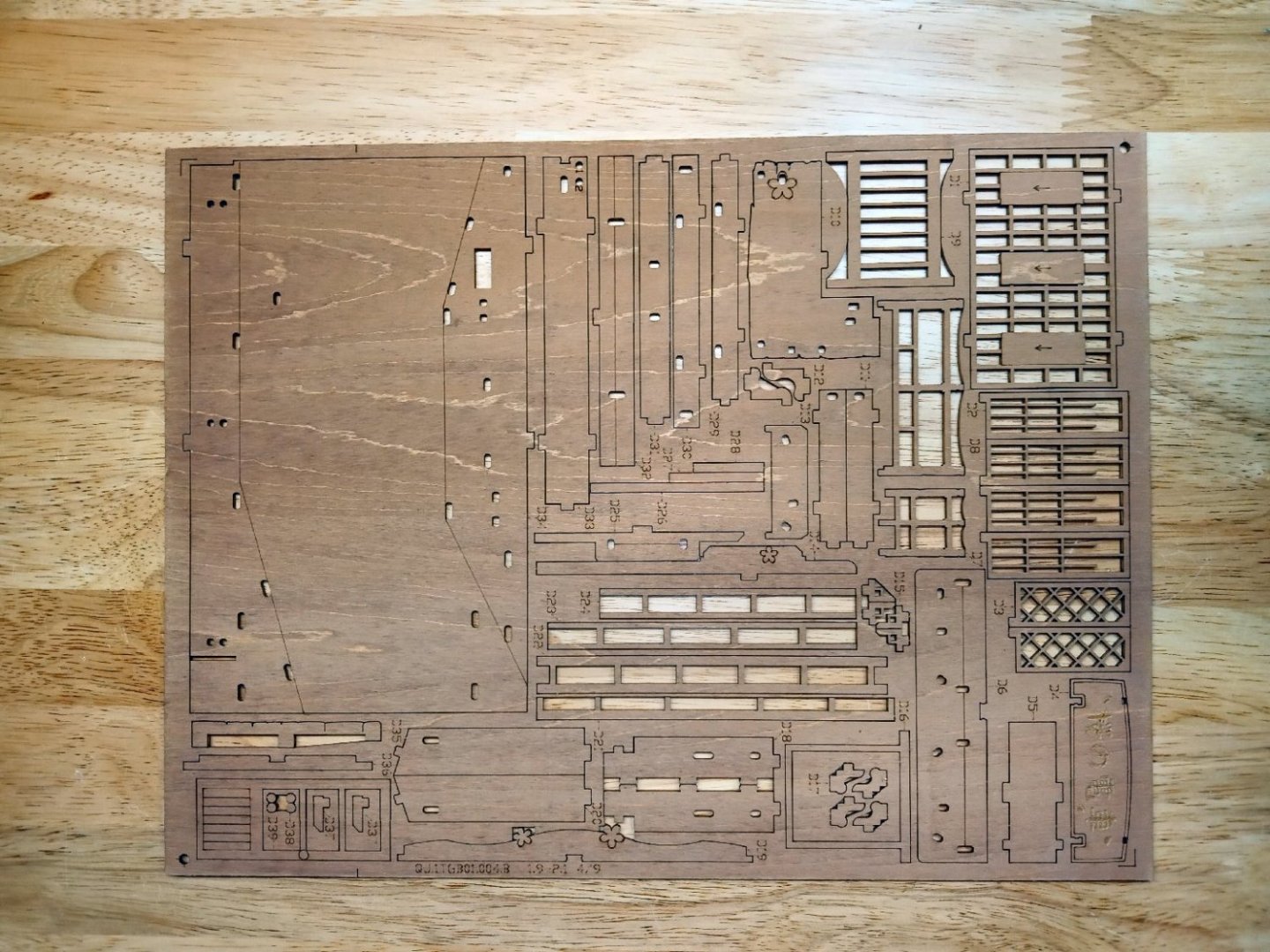

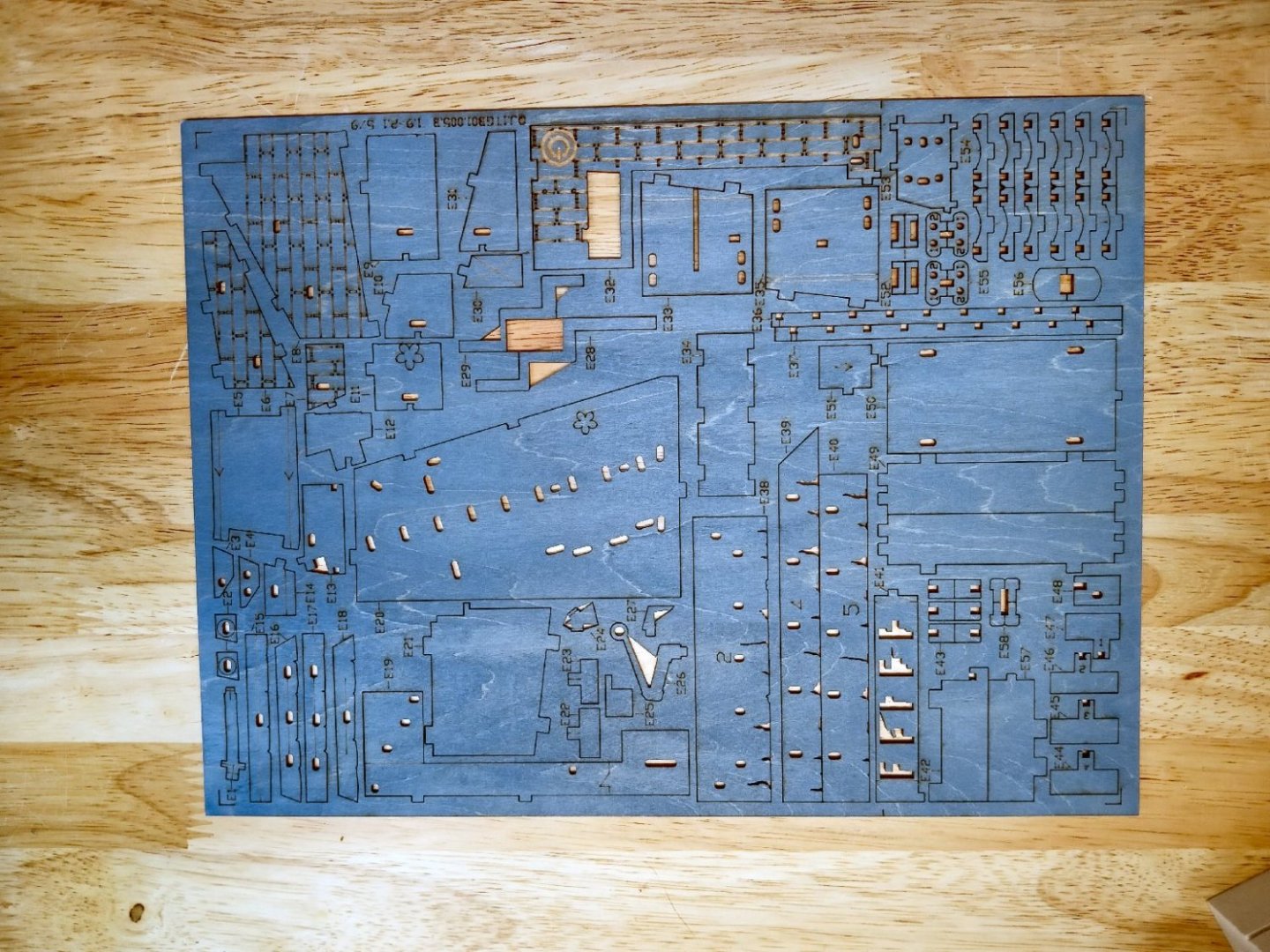

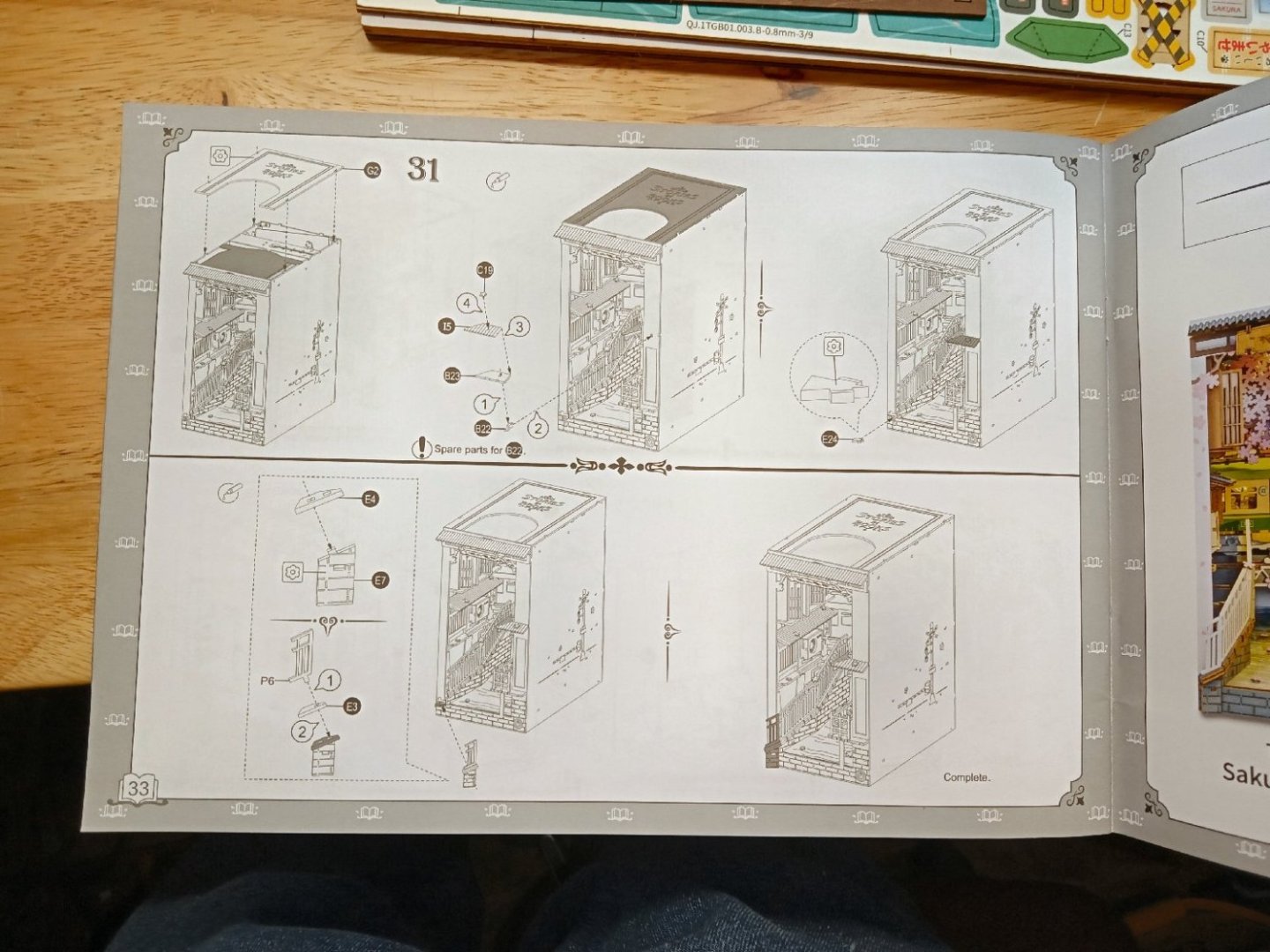

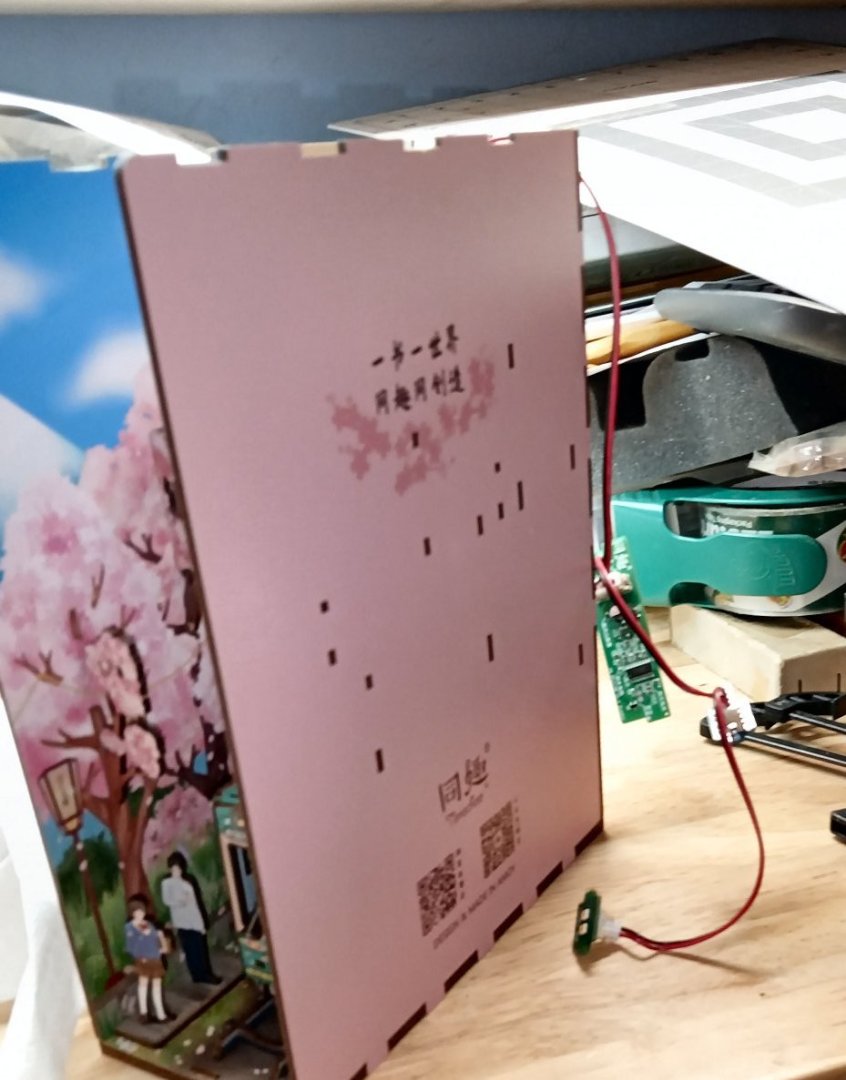

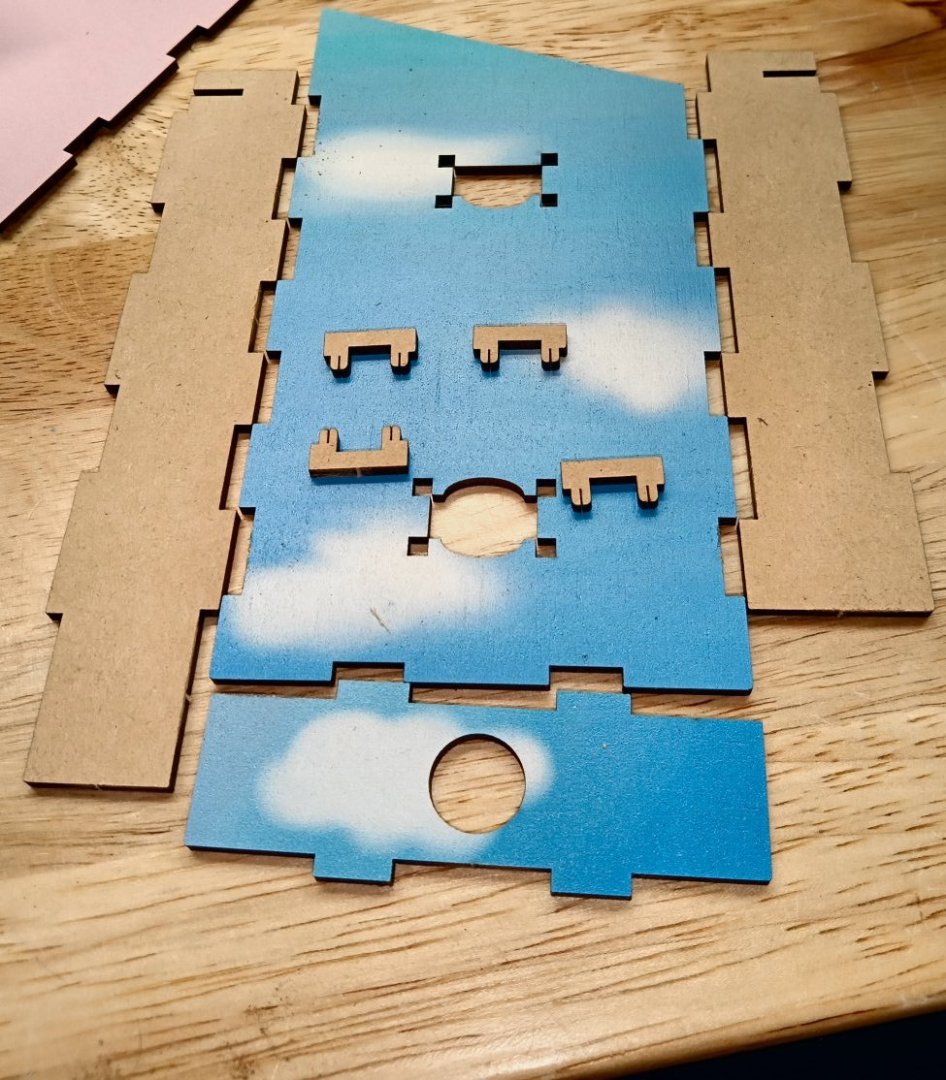

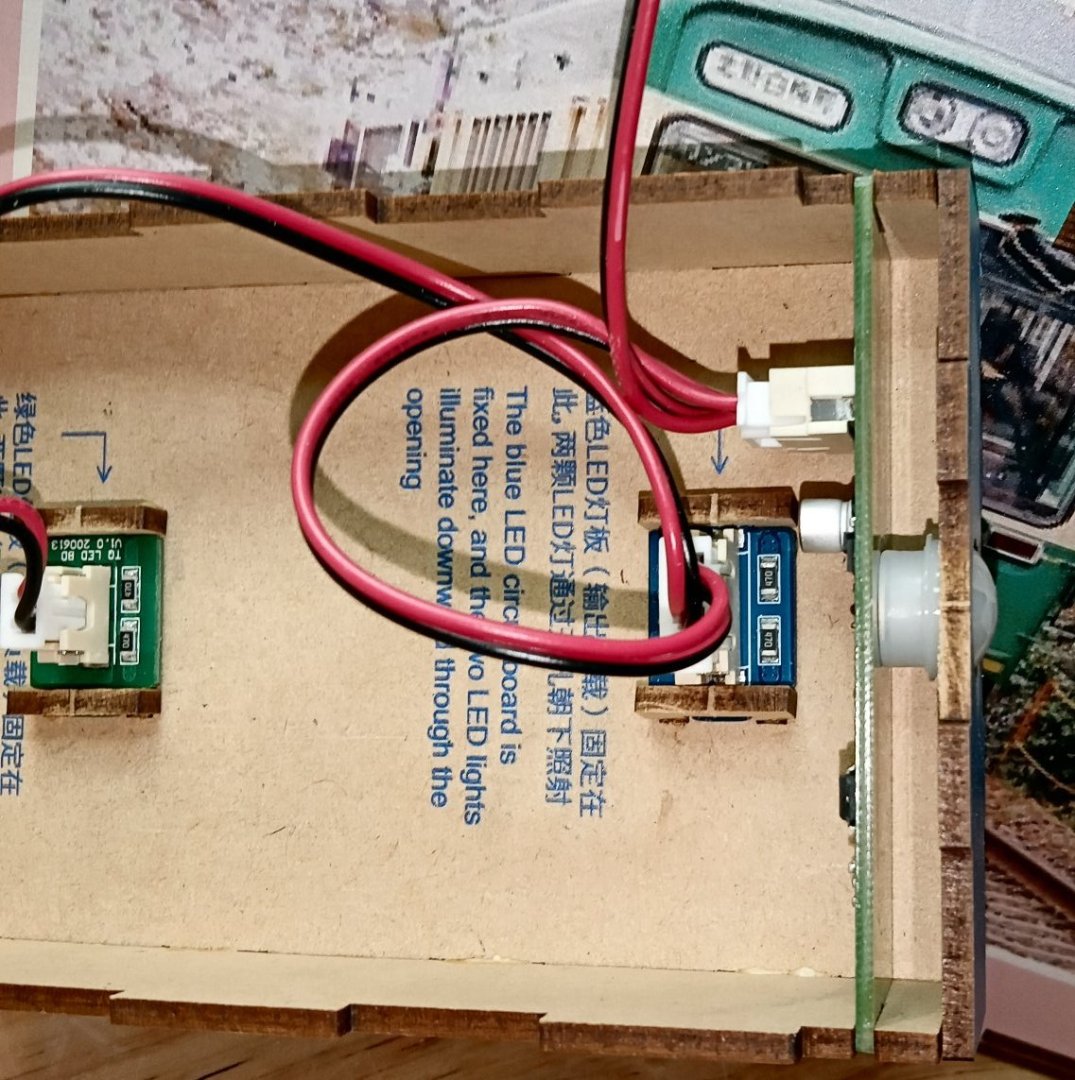

Part_001 I decided to build the companion diorama to the previous “Sakura Travel” Book Nook book sized one. “Sakura Travel” depicted a tram coming out of the diorama, this one shows a similar tram crossing a street at the back of the scene. I would rate this one as a medium skill kit, for one listed as for age 14 and above. There are the structures along the street, the two-layer pond, etc. enough detail to rate a 33-page instruction manual, rather than the two sheets of small poorly printed instruction sheets the previous kit had. Some the high skill level ones are the equivalent of a complex Card Airplane kit, with lots of printed sheets where you must cut the details out. I have one which is a library where you need to cut out the book covers. This kit has a rear mirror to add depth to the scene. The finished diorama has some exterior structures at the front. Two structures are sections of roof overhang, and the two are a porch with a railing and the end of the stairway, with railing. The top features a clear “window” allowing for better overhead room lighting. The river/pond has a colored bed with a clear rippled plastic water surface, raised slightly, to show some depth to the “water”. This shows the back of the box, with a drawing of the interior of the kit. Sorry for the one glare spot. This kit has a recessed area at the bottom, rather than a solid piece. The overhead window is the arch shaped area at the front of the top, glazing is provided for this area. The kit has all the plywood and cardstock pieces shrink-wrapped together. This is the rippled water surface. The three holes are for piers that support one of the structures. They even supply a small (about an inch and a half square) piece of sandpaper to smooth rough edges. Here are a couple of shots of the instruction book. This shows the mirror, a sheet of wooden railings, and window frames (etc.), textured (though you can’t tell in this photo) roofing, a sheet of painted wooden parts, and the clear glazing for the window in the top of the case. This sheet is laser cut cardstock, with printing on both sides, where the parts are double sided. The individual blossoms are glued a various location to represent fallen blossoms. Next is a plywood sheet of parts, again, painted on both sides where needed. My only real beef with this kit, is that unlike the "Sakura Travels", the people in the tram are not painted. I'll have to fix that, so the two match in appearance. Here is another sheet of wood parts. These sheets are the book cover/case parts. This sheet has various masonry and other blue parts The last photo is the parts tray. The parts are the LED light harness, a glue tube with a fine tip, fabric feet, some additional railings, and a handful of angle brackets, used to reinforce the case. One disappointment to me is the fact that the two kits in this series use different voltages for the LEDS. This will complicate the building of a power supply to replace the battery packs in the number of kits I have.

-

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

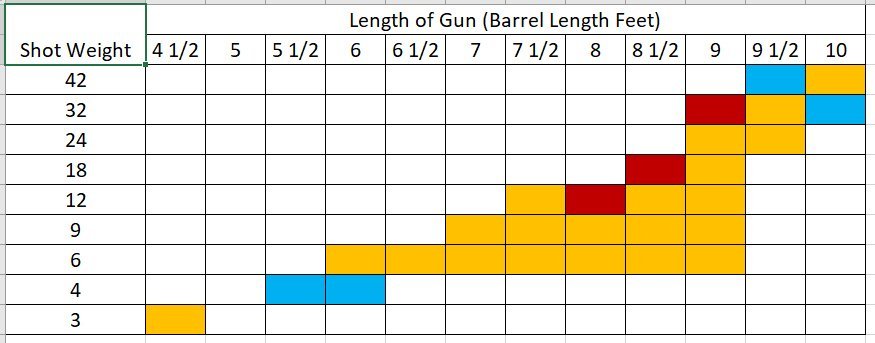

Here is a chart of the Fredrick Cannons that will be available: The Orange blocks are cannons listed in the 1760 list, the Blue are those added in 1764, The Red are cannons that were shown in the drawing I used. This chart is from the Web Site I found. I will make a similar chart for the Armstrongs listed in an earlier posting in this thread. The Armstrongs will be the same cannon designs, but with a touch hole, rather than a flash pan. -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

I finished redrawing the Armstong-Fredrick pattern cannons, using the specifications I found on the Web. They had pixilated drawings on the site and I used those to double check the results. The cannons now provide files for all the 3 Pounder to 42 Pounder cannons listed. There were additional sizes shown on the original drawing I used, so I've left them in this set. Over the next few days, I will generate the 3D files for all the cannons. The measurement shown in the graphic labels are the barrel length, not the overall length. -

Part 05 After another unexpectedly long stay in Florida, helping family, I’ve finally gotten back home and to finishing the Book Nook model. The next step was to peel the protective covering off the mirror and install it. The mirror slides at an angle into the slots in the side pieces. This shows how the mirror creates the second tram car, and extends the scene depth. The wiring harness was pulled up and over the model side, before the mirror is installed, for access later in the construction. This is a photo of the parts that make up the “Ceiling/Light Box” of the diorama. The clips hold the LED assemblies in place inside the box. Note that when assembled the slots in the sides will be facing forward to hold the sensor module. Here the LED modules have been installed, with the staples glued in place. Here too, the care they put into the design shows with the detailed instructions for placing the modules. The placement is important as the two modules have slightly different illuminated color shades, as will be shown later. The fit on the box parts was extremely tight, to the point that I had to use clamps to pull all the tabs fully into place, as shown in this blurry photo. A good idea for a hanging assembly. I also glued the tabs between the base (sky colored piece), and the sides. As I mentioned earlier there is a motion type sensor board that fits at the front of the light box. It is shown installed here. The sky-colored front piece locks it in place. I did not glue the front piece in place, I left it removable, in case I need to work on the board (unlikely) in the future. The lights are for interior illumination only, to properly view the diorama you need room lighting to see the front details. This picture shows the ceiling lights, if you look closely, you can see that the foreground and background lights are slightly different shades. This photo shows the model from a more normal viewing angle. I glued the light box to the sides of the case, carefully insuring alignment with the matching tabs on the sides. Right! When I went to install the top, one side broke loose. One out of two ain’t bad. What I should have done is place the glue further down on the sides, and temporarily installed the top, clamped it in place, and then continued. This is what I did to fix the one side. This is the initial clamping attempt. After that fubar, I let the glue dry, and placed the top on. Again, as with the front piece, the top was not glued, to allow me future access to the wiring. The top was another tight fit requiring clamps to fully seat the tabs. You will notice that the tab slots on the sides of the top piece, are double wide, as they hold both the light box and side panel tabs. Here is the finished display, lighted and with room lighting. My next one of these Book Nook type models will likely be the companion piece to this two-piece set. It shows the side of the tram at the back of a street scene. I will also need to come up with a front cover to keep the dust out.

-

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

I went htrough the Fredrick cannon specifications I found online, and determined that once a specific size cannon was drawn, say one length of 6 Pounder, the diameters of the various sections of the other 6 Pounders were all the same. The lengths of the sections (First Reinforce, Second Reinforce, etc.) were then changed to a fixed proportion of the barrel length. I am in the process of drawing the "missing" cannon lengths for the Fredricks. If anyone can verify the available sizes of the Armstrongs, I will fill those in also. The diameters were also not directly proportional between say a 42 Pounder and a 12 Pounder, there were "Fudge Factors" for some of them. For example the specification for one diameter is listed as 36 units for all cannon sizes in the text, but then a chart is provided that gives a different number of units for that value, depending on the Poundage of the cannon. For example the units for the 42 Pounder is 32 rather than 36, for that value. I will be going through all the cannon sizes and checking the drawings against this spec, and getting them as close to this spec as reasonably possible. -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Than Thanks for the correction! -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Here is a graphic of the drawing I was given for the Armstrong Pattern Cannons, with barrel and overall lengths. They closely match the data I have for the Fredrick Pattern Cannons, which were basically the Armstrongs with flash pans added. This is the best resolution I can post with the 1600X1200 pixel standard of the forum. If you have good drawings for other sizes of Armstong, I will consider drawing them. The drawing I have for the Fredricks is similar, with a few changes in the number of each size cannons. The data I have for the Fredricks, is just that data, the drawings are too pixelated to use. I will have to generate new drawings from the Fredrick Standards, and that will take time. If all the Armstrong and Fredrick cannons were produced in the same sizes, and you have data to show this, I can eventually produce all those sizes. It has not been a trivial task to CAD the Brown, Armstrong, Fredrick, Blomefield, and 1718 Spanish cannons, please cut me some slack. -

3D Printing Cannons in Resin

thibaultron replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Armstrong Pattern 18 Pounder Long Full Size_3099_59mm.stl Armstrong Pattern 18 Pounder Short Full Size_2946_93mm.stl Armstrong Pattern 24 Pounder Long Full Size_3252_13mm.stl Armstrong Pattern 24 Pounder Short Full Size_3096_55mm.stl Armstrong Pattern 32 Pounder Long Full Size_3252_13mm.stl Armstrong Pattern 32 Pounder Short Full Size_3098_80mm.stl

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.