-

Posts

1,879 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck Seiler

-

The micro drill bits Mark is talking about run from size 60 (largest) to 80 (smallest). I tend to mostly use 72 and 76, which (coincidentally) are the years I graduated from high school and college. I normally work in 1/64 or 1/72 (or there abouts) and they work well for me for eyebolts and such. I get mine on Amazon.

-

I heartily agree with Cap'n Birdseye in his recommendation. While it might not be a "first model" it makes a good early learning model. If done well, it can be a good presentation model as well. I would recommend substituting Alaskan Yellow Cedar for basswood planking.

-

Now that the St. Paddy's Day beer has worn off... I checked my pieces-parts, and it appears (with my kit) if you install the parts in the jig as directed (left and right futtocks) frame 19 is face up while frames 20 and 21 are face down. Anybody else with the kit, please confirm or refute these findings.

-

When the frames go in, the floor futtock is always forward of the first futtock. The first futtock goes into the frame assembly jig first and the floor futtock on top of these. Since the frames taper towards the ends of the boat, the tapers should be towards the "floor" side of the frame in the bow and the "First futtock" side in the stern. With this in mind (if I have figured it out correctly) the side of the frame pieces with laser markings for sanding should be face down in the stern and face up in the bow. The frame parts SHOULD be marked in such a way to ensure this occurs. Looking at the parts and how they are number (with left and right first futtock identified), it doesn't seem to be the case. As I get closer to that step, I will look closer. In the middle frames, the taper is so slight, I don't plan on fairing until the frames are in place, so face up or face down is not important. When the taper becomes severe, however, ensure bow frames are face up and stern frames are face down.

-

In my experience, VERY few people can scratch build well right off the bat. A friend of mine made a 6inch near-museum quality HMS VICTORY on his first build...but he had alot of skills. It is better to practice on an inexpensive kit, where all the angles and dimensions are already figured out, that on a model you have spent much time, effort and passion on. Another option is the "18th-Century Merchantman Half-Hull Planking Kit " sold by the Nautical Research Guild (NRG). It is invaluable in terms of learning to plank properly and can be a great display model when complete. Click on "NRG Home Page" at the top of the page. When scratch building in the manner you showed in above photos, I used Baltic birch craft plywood...usually 1/8 inch. Available at MICHEAL'S, in hobby shops or online.

-

I strongly agree with Vossy. If new to wooden ship modeling, jumping in with scratch builds can be overwhelming. Check out the topic "New to ship modelling? But what do you build first? " to get an idea of first time builds. While these first time builds are not all that glamorous, they give a feel for how the wood works and insight into the various techniques. I respectfully disagree with Gregory about the 16th Century Longboat. I found that to be more advanced in that you need to be near the top of your game with your planking. LIttle room for error. ....but your question was about tools. Some of the tools I find most valuable are; Dremel or similar rotary tool, #11 Exacto knife or similar surgical scalpel, sand paper/sanding sticks (I use finger nail Emory boards and sandpaper glued to popcicle sticks), wood glue. Clamps...you can never have too many clamps. Acquire them as you need them. Magnification.

-

Jerry's parts have arrived or should be arriving shortly, based on timing of previous shipping. I look forward to the shipyard restarting production. I wanted to take this opportunity to ask a question about real construction. Based on building practice of the day, would the frames have been bolted together or treenailed?

-

Rope walk machine

Chuck Seiler replied to Christership's topic in Modeling tools and Workshop Equipment

I second Syren Ship Model Company -

Welcome to MSW and model ship building, As CPDDET said, it is rewarding and sometime frustrating. When working compound curves, the wood often doesn't do what you think it is going to do. Fear not and worry not. Using wood glue, everything is fixable (sez the guy who has unglued most of his models at one point or another). Alcohol is your friend...scotch and isopropyl. ...and you can never have too many clamps.

-

Yowza! How much beer would that thing hold?

- 68 replies

-

- Morel

- Master Korabel

-

(and 1 more)

Tagged with:

-

Planking improvement

Chuck Seiler replied to Picard's topic in Building, Framing, Planking and plating a ships hull and deck

Thickness or width...or both? -

Planking improvement

Chuck Seiler replied to Picard's topic in Building, Framing, Planking and plating a ships hull and deck

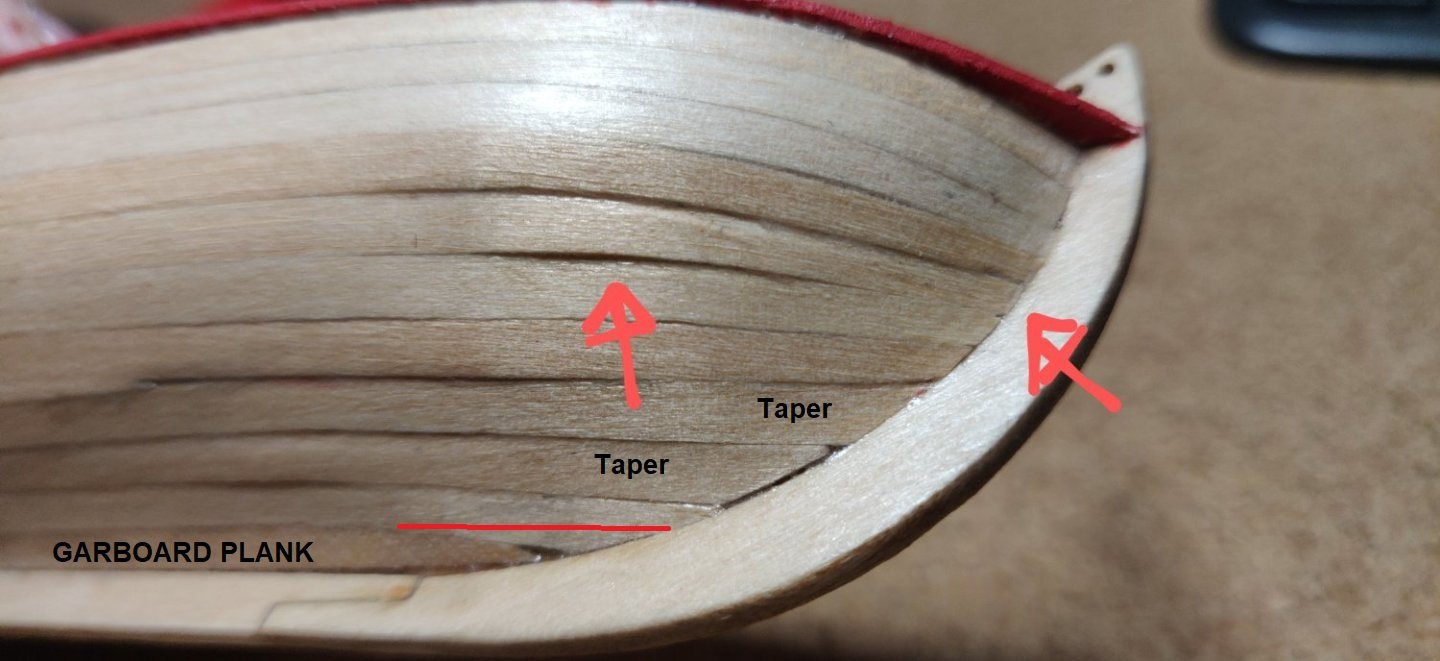

While definitely NOT an expert in planking (I struggle on a regular basis) I see some areas that might be helpful. I believe your garboard strake does not go far enough forward and bends down. I always have problems with the garbord, but getting it right is one key to proper planking. Continuing it as indicated gives a better angle for the next plank and sets up a better distance for follow-on planks. This allows the follow-on planks to be tapered to fit the hull, whether spiled or edge-bent. -

Good luck Dick. I will drop in from time to time and take a look see. You and Louis da Fly keep drawing me back here.

- 142 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.