-

Posts

947 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by cobra1951

-

I will keep a look out and if you do i may borrow your idea

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

Heavy is good IMHO as it gives a nice stable base for the hull. Not much good for me at the moment though with my Endeavour as there is no stem fitted till much later on so there is nothing for the Bow end of the slipway to hold on to. Might get one later once the stem has been fitted

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

I was thinking about getting one of those building slips from the UK Hobbyzone dealer, it looks like a nice piece of kit

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

The upside is the longer you take the better the end product

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

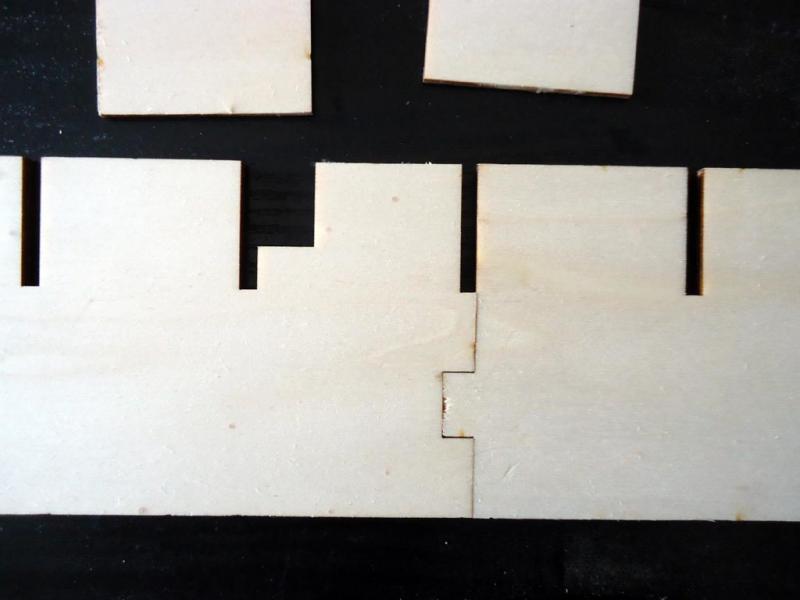

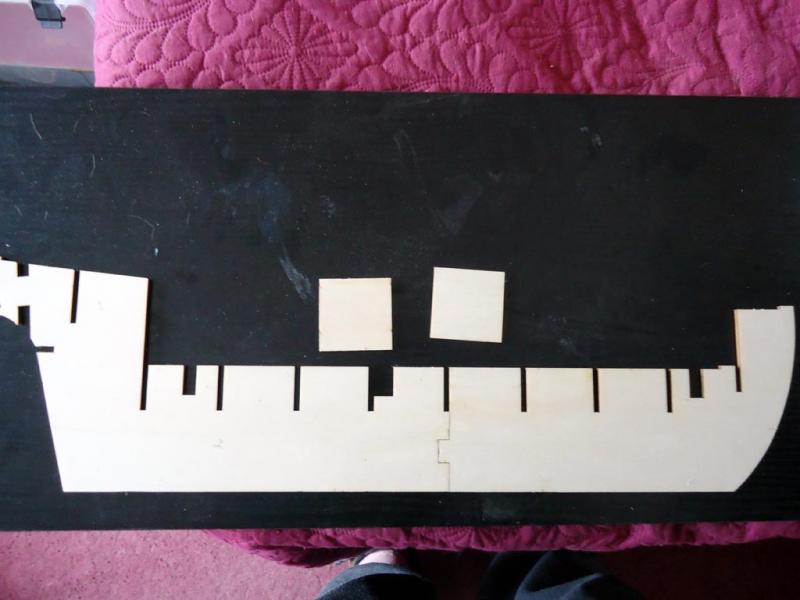

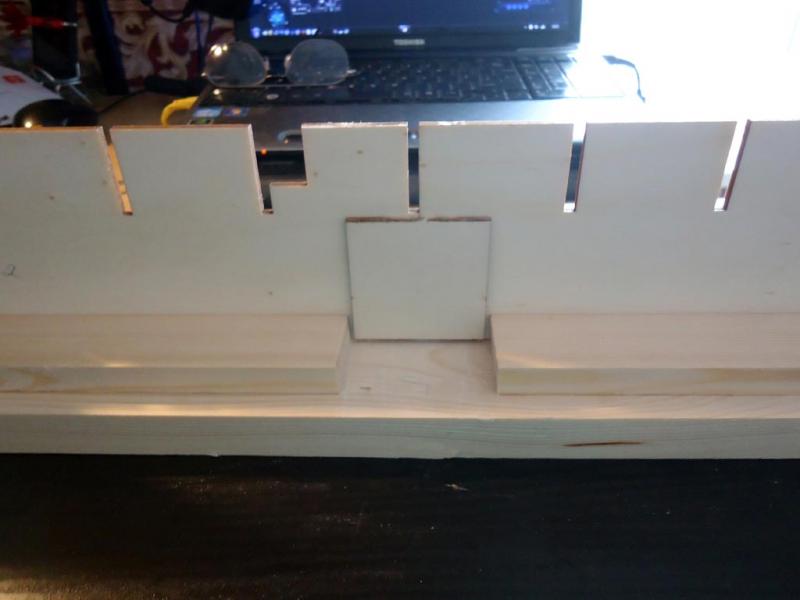

Last part of the slipway build Placed the keel in the slot in the slipway and dry fitted the bulkheads Marked out where the bulkheads cross the slipway Removed keel and cut slots where the bulkhead markings where Replaced the keel and made sure bulkheads sat in the slots cut out for them Checked that the bulkheads were clear of the base of the slipway insuring that they sat all the way down in their slots Long winded way of doing it but by starting with two long strips and then cutting slots in them i know all the pieces are perfectly in line with each other (nothing like piece of mind before continuing)

-

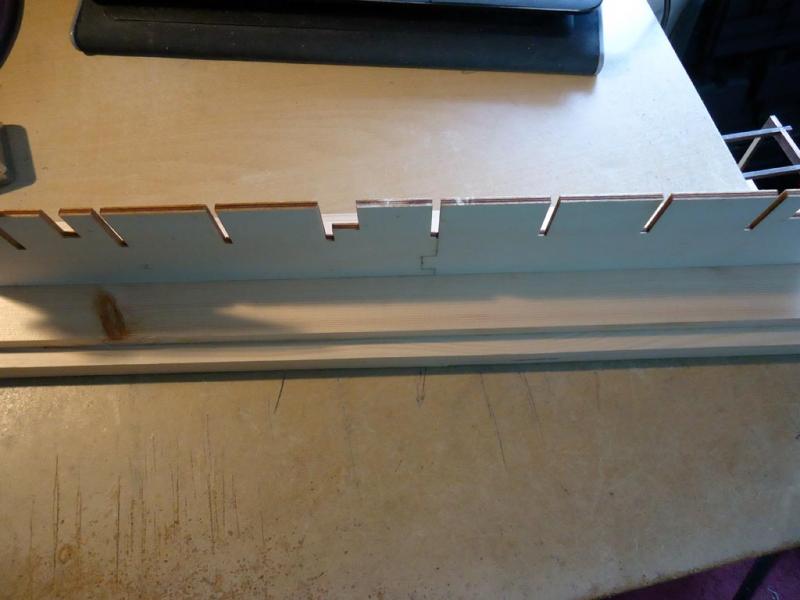

Think it's time to start a new build log As usual first thing is a homemade slipway to keep the keel straight Glue the two halves of the keel together There are two strengthening parts to fit to the joint but not yet Built the slipway first Keel without the strengthening parts fitted Keel now square to the slipway Cut a slot in the slipway to allow the strengthening pieces to be fitted

-

Wow I never realised the kit was so small Makes your work even more impressive

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Ian This one sneaked in under my radar Great little build, nice job As you said a great value for money kit too

- 4 replies

-

- ships boat

- dusek

-

(and 1 more)

Tagged with:

-

Wow it looks bigger in the outside shots :) And i bet that's not all the dog leaves in the grass for you

- 62 replies

-

- batelina

- marisstella

-

(and 1 more)

Tagged with:

-

I look at it this way, building models is a fun pastime and the more time that passes the more fun you must be having

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.