-

Posts

2,213 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GuntherMT

-

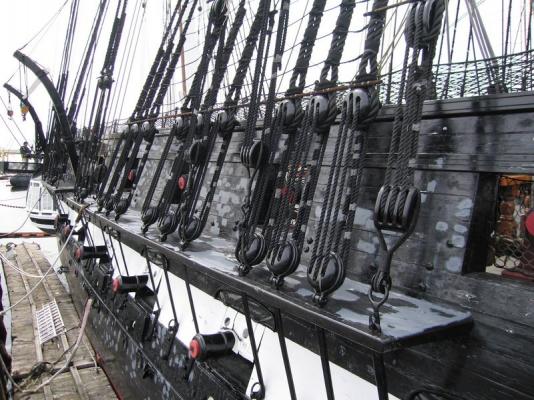

I did the same as Bill - create a 'needle' out of the end of the rope with CA and cutting an angle. I also downsized the rigging line on the deadeyes, as the line there should be quite a bit smaller than the shroud lines. For many of the blocks on the Carmen, even though I used a slightly smaller line than included in the kit, I still used a micro-drill and pin-vise and drilled all of the holes in the blocks larger to take the line as it simply wouldn't fit without this. You may want to consider whether you should be using smaller rope for the deadeyes based on looking at photo's of the real ship as a reference, or just go with what looks right to you. Here is a shot from Google image search of the real ship -

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

The AVS kit includes cast white metal rings, or at least that is what is supplied in mine.

- 31 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

Looking good Dave, nice to see an update here on another AVS.

- 31 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

Interesting technique, gives the deck a very striking appearance. Looking forward to seeing what else you do with this!

- 114 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

If you want sapele, I know that model_ship_builder on ebay (listed in this forum on a place to source wood here in the US) lists Sapele as one of the woods he has in his planking and lumber sets for ships. Here is a link to his ebay store if you are interested - http://www.ebay.com/usr/tallships_model_builder Prices are in the 20-22 dollar range for 60 pieces of whatever size you like (can mix/match woods and sizes) plus shipping. I got some wood from him to test for various things and he shipped quick and sent more than asked for. Hobbymill is great (I have both boxwood and holly on order from Jeff), but his forecast deliveries are now out to January, and for the use you have here, not sure you need his precision and finish.

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

When I got my micro-drills I ordered a set with 5 of each size, just because I knew I'd break or lose them. Nice work on the deck, looks good.

- 114 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

That's a whole bunch of little knots! Looking great!

- 84 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

You guys are trying to make my head big. Thank you for the kind words and feedback. I probably worded my 'failure' wrong. What I was trying to say was that I had a goal in mind for the first planking that I failed to achieve, although I came reasonably close. From the perspective of whether it's good enough to go on, certainly it's not a failure in that sense, as it's more then solid enough as a base for the next layer of planking, and practicing drop planks and stealers is probably a good thing. I actually like the appearance that well-done drop planks and stealers give a hull that's finished well, because as you say Keith, they are quite authentic, it's simply that I was trying to achieve this first layer without them.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

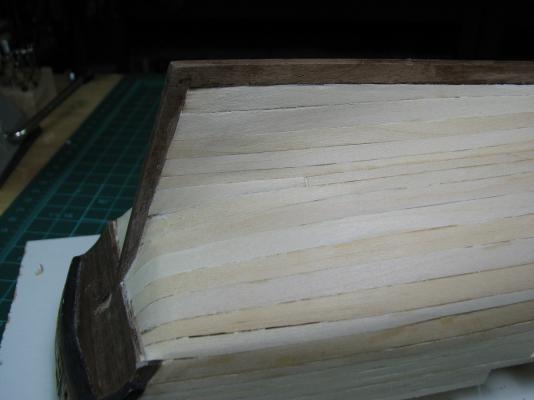

Somebody has to keep my head from expanding to fill the room Alistair! After dinner I couldn't wait until tomorrow, so I moved on to the port side. I did a much better job of keeping the planks aligned on this side, and used no stealers or drop planks at all! I probably should have used a single stealer at the stern, but even there, the only reason I needed one is the gap left because I accidentally trimmed the 2nd to last plank off too narrow - I got too aggressive shaving it and broke the full width off at the stern, and didn't feel like starting over on that plank. I thought I might be able to completely close the gap by using a section of 1/4" plank at the stern to finish, but it came up just short so there is a small triangular gap there, but I don't think it's enough to affect the second planking. Here is the hull with only a single plank gap left, and the 1/4" plank section placed at the stern. The gap that's left is exactly the same width for the entire length (pats self on back). Well, the digital calipers could find variations, but a marked strip was on the same pencil mark for the entire length, so close enough to exact for me! And a bunch of different shots showing the completed first planking, ready to move on to.. whatever is next! Actually, what's next it the Wales, and inner bulkwark planking, black strake, etc., before moving on to the second planking. I'll decide after the second planking whether it gets painted or not, but my plan is to leave it natural below the black strake if I can do a good enough job at the planking.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Slow progress continues on the first planking. I managed to completely mess up my planking plan where the bottom and top planking come together, and didn't figure it out until too late to be able to close it up without using any drop planks or stealers, and ended up having to use both. Not a terrible tragedy, but was completely due to my own lack of proper planning. Another lesson learned. I used a single drop plank at the bow because the planks just weren't working out there and the edge bends were getting too severe as they transitioned to the bow. I did this when the first plank kinked while trying to edge bend it. Rather than just toss the entire plank, I cut it off and added the drop plank to allow me to use a single spiled plank forward from that point for two planks headed aft. It turned out ok in the end, but was a little bit bummed that I had to use it. After that, I ended up using both drop planks and a stealer towards the stern because of how narrow my gap got before it widened out in the stern area. The starboard side first layer is now complete as can be seen above, and while I'm happy with the flow and believe that this will make a great foundation for the second layer, as a 'practice' run it was a bit of a failure, but taught me some lessons about basswood planking. I was being very careful to try to make no gaps, but as can be seen there are numerous noticeable gaps. I believe that I was placing the planks while they were still too wet, and the gaps were formed (mostly) by shrinkage after the planks dried out. There are also a couple planks that have some ugly gaps where I over-trimmed while spiling. If this was the final layer of planking, I would need to fill & sand, meaning I would have to paint the hull. Luckily it's not the final layer, so I can just clean up the edges around the rabbet so that the 2nd layer will tuck into the rabbet properly, and call it good. After I finish the other side of course. The port side is down to the final 3 (or 4) planks remaining (pictured in my last update), we'll see if I can figure out a way to do it without as much patchwork in the form of drop planks and stealers. I think the port side has a better chance of working out, as it's a much more consistent spaced gap left to fill.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Already taken care of Ken, I laid in some single and double blocks of every size all the way down to the tiny 2mm ones (which are just silly small), and had already planned to downsize the cannon rigging blocks based on notes from build logs here. Thanks for bringing it up though, certainly good to know if I hadn't noticed that!

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Check the plans for notes - on the AVS there is a note to use one size of eye-bolts for all the deck things, and to use the other size for all the rigging. My guess is that the Niagra kit only supplies the rings for the rigging, and all the deck eye-bolts are to be made per the instructions on page 21, figure 5-9. As Dale said, it looks like a simple matter of twisting a bit of wire around a drill-bit of the appropriate size to make the eye-bolts. Looking good by the way!

-

I completely forgot to reply to this as discussed a couple weeks ago. Yea, there is quite a difference between the blocks. These are 5/32 doubles: No regrets, although it will be a while before I actually need to use any of these.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Fantastic looking ship, congratulations. I'm sure it will be admired for years to come, wherever you display it.

-

Bob, I've somehow managed to miss this log before now, luckily Keith posted a link here in my log for your excellent planking techniques, so now I've spent the time to go through this entire log. Your workmanship is simply amazing to see, and the entire process has made this small little boat really a beautiful work. Thank you for posting such excellent photo's and descriptions of your work.

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Thanks Alistair and Lawrence, Also thanks to the other folks for the likes. Today I made some progress with the planking, and I also have been repainting the stern fashion pieces. I sanded them down since I was unhappy with how rough the black paint looked, and then I re-primed with thinned primer, sanded with 320 grit, primed again, sanded with 320 grit, then added a coat of thinned black and sanded once more. After that I added about 6 or 7 coats of very thin (think - more of a wash than paint) black. I did this over the last few days of course, and I actually did the first two primer coats before leaving on my trip. Much happier with the smoothness of the black painted area now, although I still need to fill the gaps around the windows at some point. The planking is progressing reasonably well, even if I'm not 100% happy with everything about it, it is after all going to be covered up later. I really need to get better at trimming the pieces to size, as whichever end I finish with isn't getting trimmed to the right size very well. I've got the garboard plank on the other side, but none of the other lower planking there. Last day of my short little vacation is tomorrow, so maybe I'll finish up the first planking layer.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

If there were only two rings, then they were no doubt not for this purpose. I expect there would be somewhere around a dozen hoops on each mast for the two main sails. My AVS kit has 12 hoops for a single mast (just counted them). So for your kit with two masts I expect there would be somewhere between 22 to 26 hoops provided if they are included. You should be able to find some reference to 'mast hoops' in the instructions or plans to clarify them for you.

-

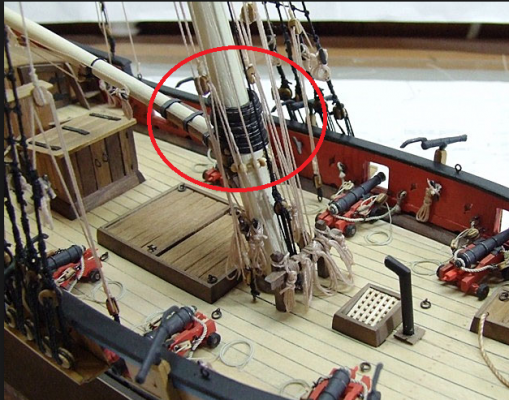

Not familiar with this kit, but if you need to put rings on the masts that the sails would be connected to, you should have done that before assembling the top sections of the masts. You could use some sort of split ring, but if you want to use solid rings, you should look at disassembling the masts to add them now, as later on after you've added a lot more things, you'll remove the option to put the correct style of rings on. I did this on the Carmen, my first build, and it doesn't have the rings because of this. This is from a Google search of a different model, but shows the rings I'm talking about: I didn't find out about these rings until the rigging was complete and I was almost done, so I did not include them, but wish I'd known earlier so that I could have added them to the model. You should consider reading ahead in your instructions and checking out the later plan sheets that show the rigging, and see if you have these in your kit, and then decide if the effort of removing the top masts is worth it for you to add them in.

-

That's called the 'bowsprit', although the individual parts all have names too. The thickest piece, closest to the hull is the 'bowsprit'. The second somewhat thinner piece is the 'jib boom'. If there was a third section, it would be the 'flying jib boom'. I think the wooden bit that holds the bowsprit and the jib boom together is the 'dolphin striker' or 'martingale'. I think it depends on the era of the ship which it is. I think those are correct, maybe someone else can correct me if I've named any of them wrong.

-

Vossy, You can add as many pictures to a post as you like, just keep adding them on the bottom. You can also insert the pictures anywhere in your post that you want, just position the cursor where you want the picture prior to clicking on the 'add to post' button. Looks like you've made a good start!

-

I've been amazed at all the parts people on here use manila folder type paper for Rich, it's been a real eye opener, and I'm sure I'll be using some of that technique myself before too long. The mast looks great.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.