-

Posts

675 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by captain_hook

-

-

-

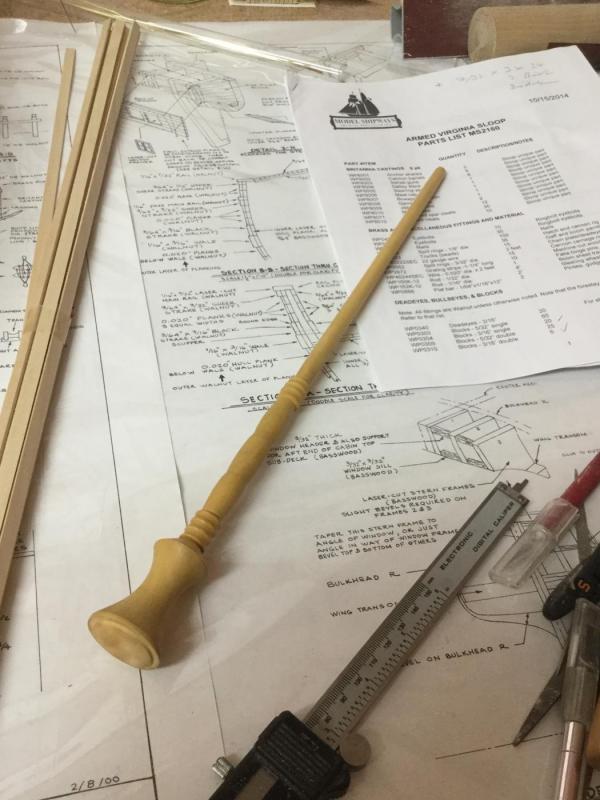

Brian, I followed your suggestion and doubled the filler blocks. My daughter watched Harry Potter first time on TV today. Guess what she asked me to build for her after that....yes, a magic wand. Took me some time to do that, lucky me, had some castello strips left for that. So building will continue tomorrow...

- DocBlake, Blue Pilot, GuntherMT and 5 others

-

8

8

-

-

Installing the filler blocks: I took the distances from the waterway to the lower edge of the gunport filler blocks and sweepport blocks from the plan, cut a rectangle piece of wood from scap that distance long and used it to draw a reference line on the bulkheads with a pencil. Then glued the filler blocks on top of the line. First side is complete...

- zoly99sask, DocBlake, CiscoH and 1 other

-

4

4

-

- zoly99sask, robert952, GuntherMT and 1 other

-

4

4

-

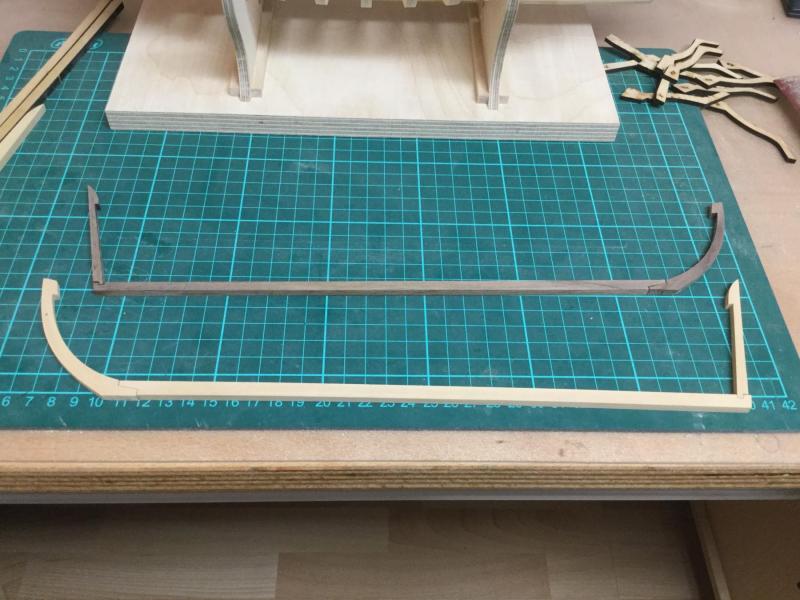

No, just kidding. I cut the parts from boxwood sheet I have in stock. Used the walnut parts as templates.

- robert952, GuntherMT and Ryland Craze

-

3

3

-

-

- robert952, Ryland Craze and GuntherMT

-

3

3

-

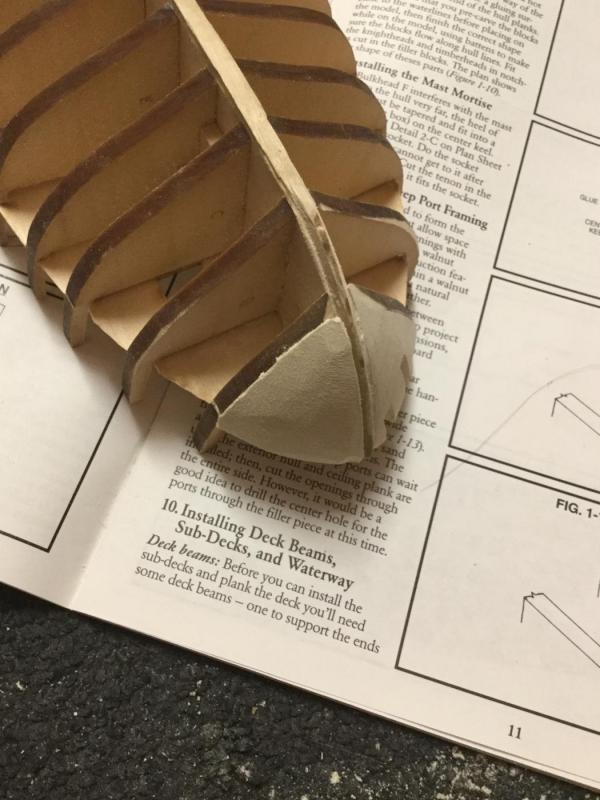

Thank you and everyone for the likes. Yes, the connection seems to be solid, but I may add a (toothpick) pin for each head later before bevelling the bulkheads. Still have to add a lot of filler parts for gun- and sweepports. It is curious. When I built the sherbourne and ballahoo, I was able to start first planking very soon. Only adding the bulkheads and some filler blocks to the false keel, bevelling the bulkheads and I was ready to begin first planking. The AVS require al ot more of preparation and attention before beginning the planking. That is surely a nice lesson of patience for me to learn. :-)

- Ryland Craze, robert952 and zoly99sask

-

3

3

-

- zoly99sask, Ryland Craze, GuntherMT and 1 other

-

4

4

-

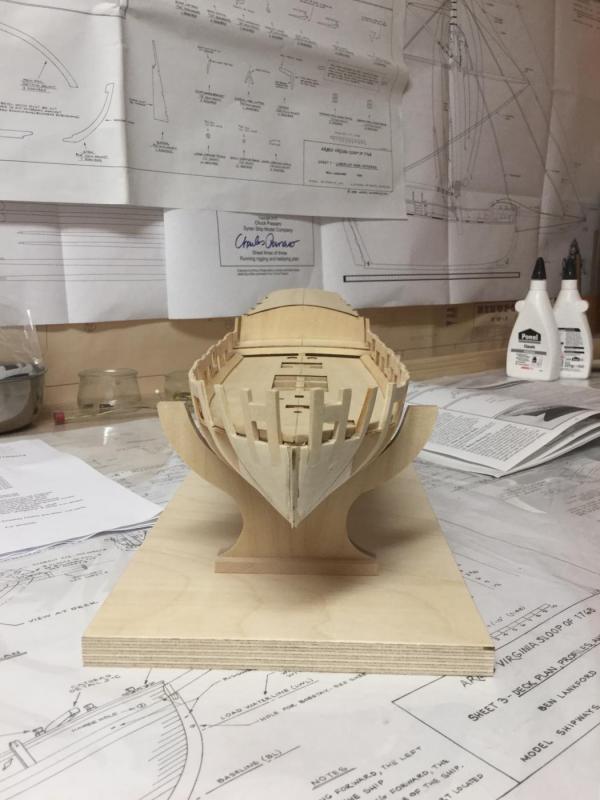

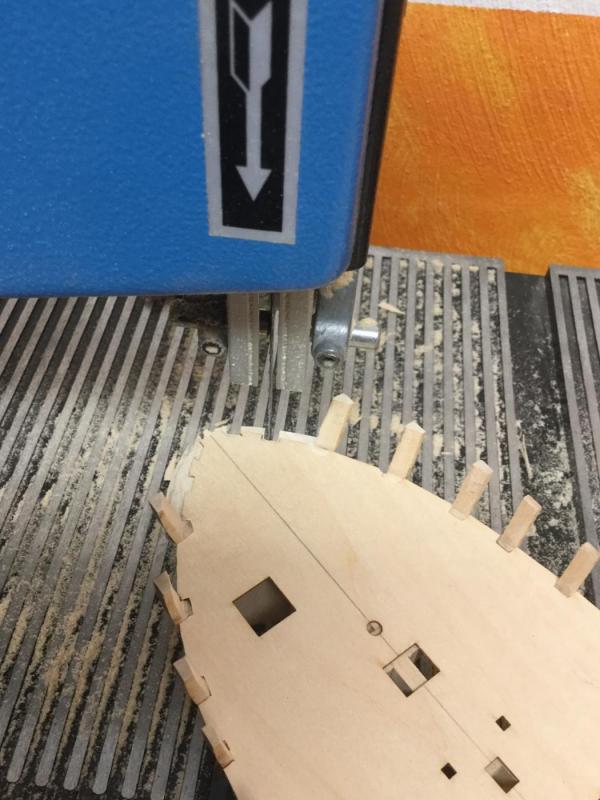

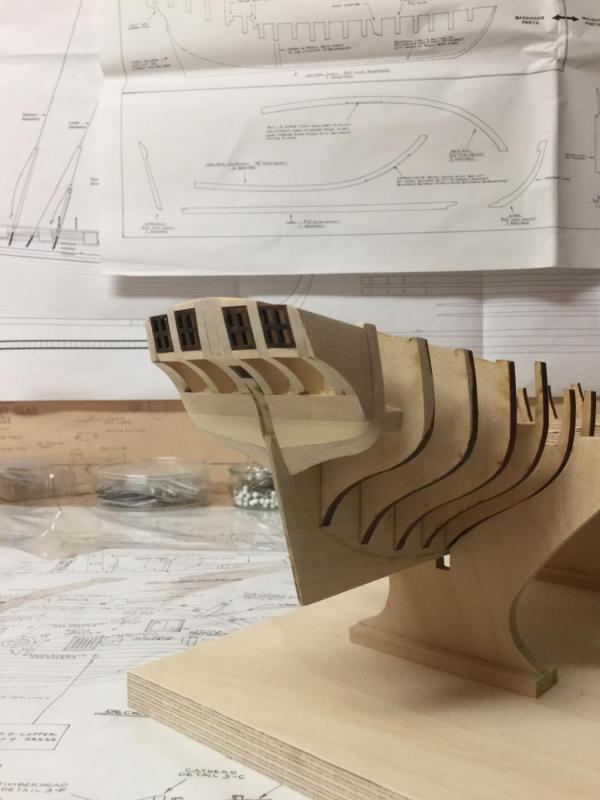

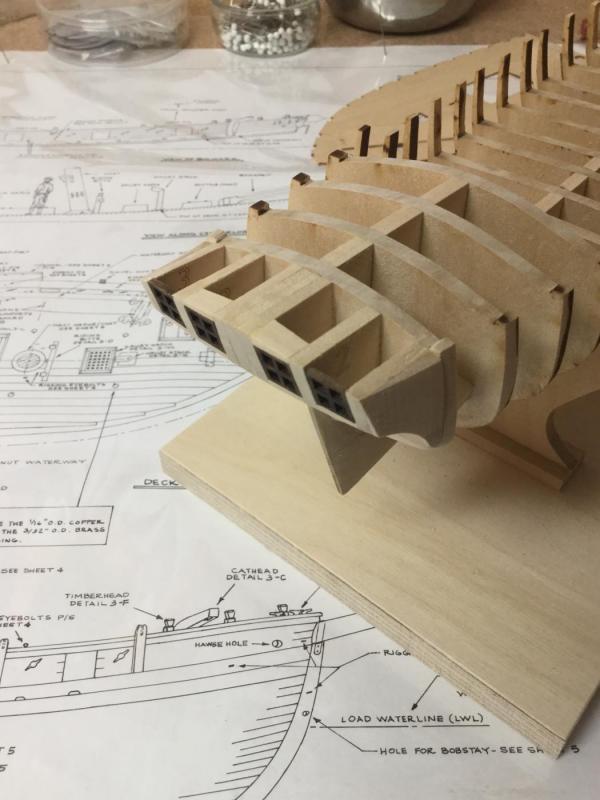

To install the timberheads and knightheads I first sanded the bow fillers roughly to shape. Then used my scrollsaw to cut the notches for both of them. The model had to stand upright on the platform to ensure vertical notches. For the timberhead pieces I used the scrapwood that held the bulkheads earlier and draw a piece close to the bulkhead outline. Cut that with my scrollsaw, sanded it to shape and installed it into the previous cut notch. I will give it its final shape when it comes to bevelling the bulkheads. Only three more to go...

- GuntherMT, zoly99sask, DocBlake and 1 other

-

4

4

-

- gerty, zoly99sask, Ryland Craze and 2 others

-

5

5

-

Thank you very much, Brian. I missed that on the plan (maybe I should look on the plan more often). I refitted the stern frames, added blocks and transom and the window sills. Then I spend an hour sanding everything to shape. Dry-fitted the windows last. The outer windows leave nearly no space for the upper window sills so I have to add them later after glueing the cabin top sub deck or reduce the lower sills a little. Next: Adding bow filler blocks..

- Ryland Craze, GuntherMT, Sea Hoss and 1 other

-

4

4

-

- zoly99sask, GuntherMT, DocBlake and 1 other

-

4

4

-

-

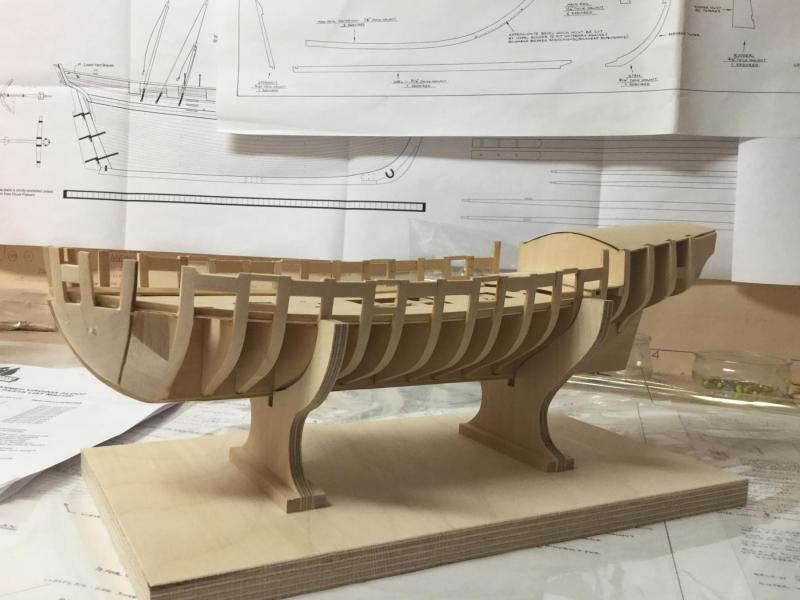

I added the mast mortise and sanded all bulkheads flush with the false keel, so the false deck will fit on properly later. Next: Adding filler blocks and stern wing transom... Due to the curvature of the deck I made myself a tool, consisting of three layers of spruce, watered, bend to curved shape and glued. Then some sanding paper is attached with double adhesive tape, so the tool can be used again after the sanding paper is no longer of use.

-

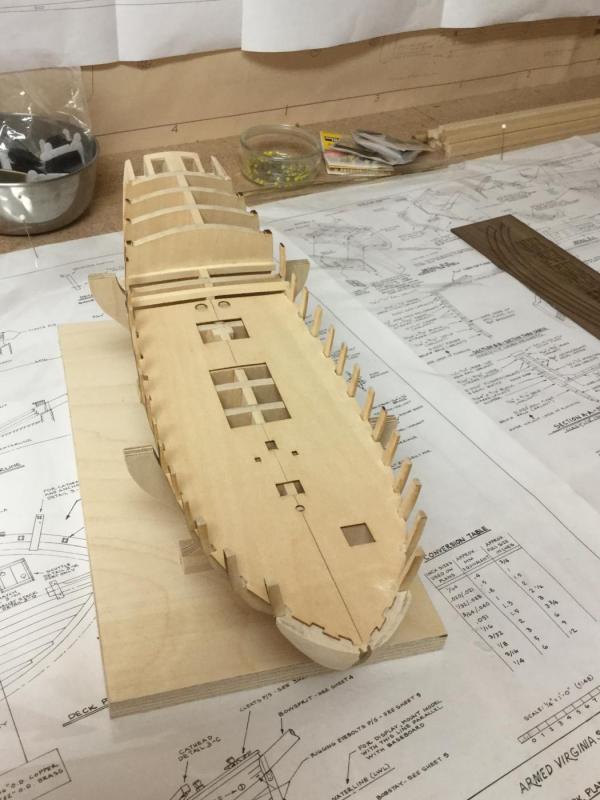

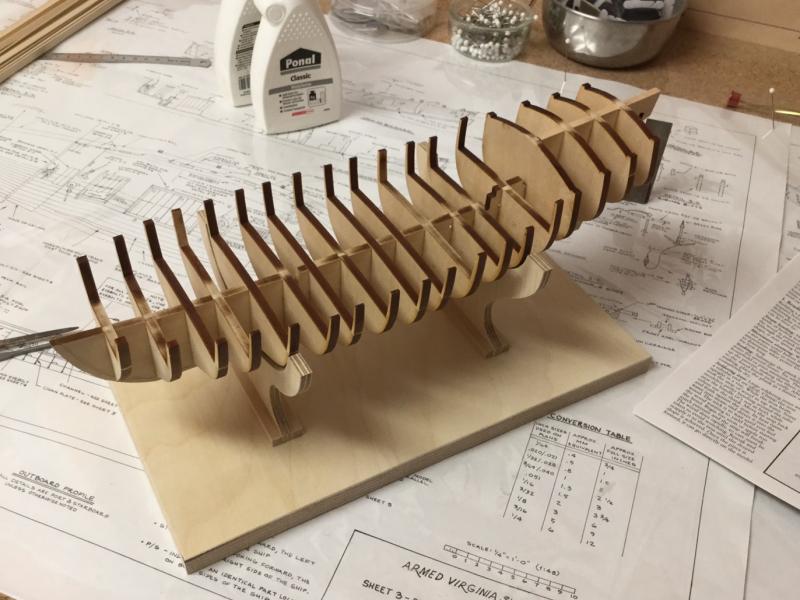

I started to make some replacement keel parts out of boxwood. The kit supplied walnut parts are not bad, but I find boxwood much better to work with. It is much easier to paint, holds edges very well and doesn't have the tendency to split especially when it comes to planking. And in my opinion dark walnut makes shipmodels often look like old furnitures. And it is good practice for future scratchbuilding too. I decide to add the keel parts later as I did with the sherbourne before and to glue the bulkheads in place first. The AVS kit is designed with a lot of bulkheads to install, that should make planking much easier in comparison to the sherboune. The Caldercraft sherboune and also the ballahoo which I did before are labelled as beginner kits but both have only a few bulkheads so I ended up spending as much time for the first planking, filler and sanding as for the second planking. Maybe a lot of people starting this hobby will soon get frustrated with planking because of this and never build another model. So good kit-design is surely a nessesary thing to avoid frustration and to provide motivation for the long time usually spend to build even a kit.

- DocBlake, Ryland Craze and zoly99sask

-

3

3

-

Hello everyone,

this is my third kit build and my first build-log. I wanted to build the excellent cheerful semi-scratch cutter designed by Chuck Passaro next but decided to build this one first cause it was a gift from my wife last christmas and she keeps asking me when I will begin building it. So construction has begun with little one-year delay. The kit itself seems to be of good quality but I may replace some wood with boxwood and some cast-parts. First thing I did was to build a rack to put the model on during the construction. Then I carefully released the bulkheads to dry-fit on the keel.

- GuntherMT, zoly99sask, DocBlake and 1 other

-

4

4

-

Looking very nice, good work.

-

-

-

-

-

Young America 1853 by EdT - FINISHED - extreme clipper

in - Build logs for subjects built 1851 - 1900

Posted

You've done a wonderful work here so far. Can't wait to see more progress.