-

Posts

1,934 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ronald-V

-

That's is truly a fantastic result! Congratulations!

- 43 replies

-

- Essex

- Model Shipways

-

(and 2 more)

Tagged with:

-

Don´t be to hard on yourself, the figure looks great! We all know how small these things are

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

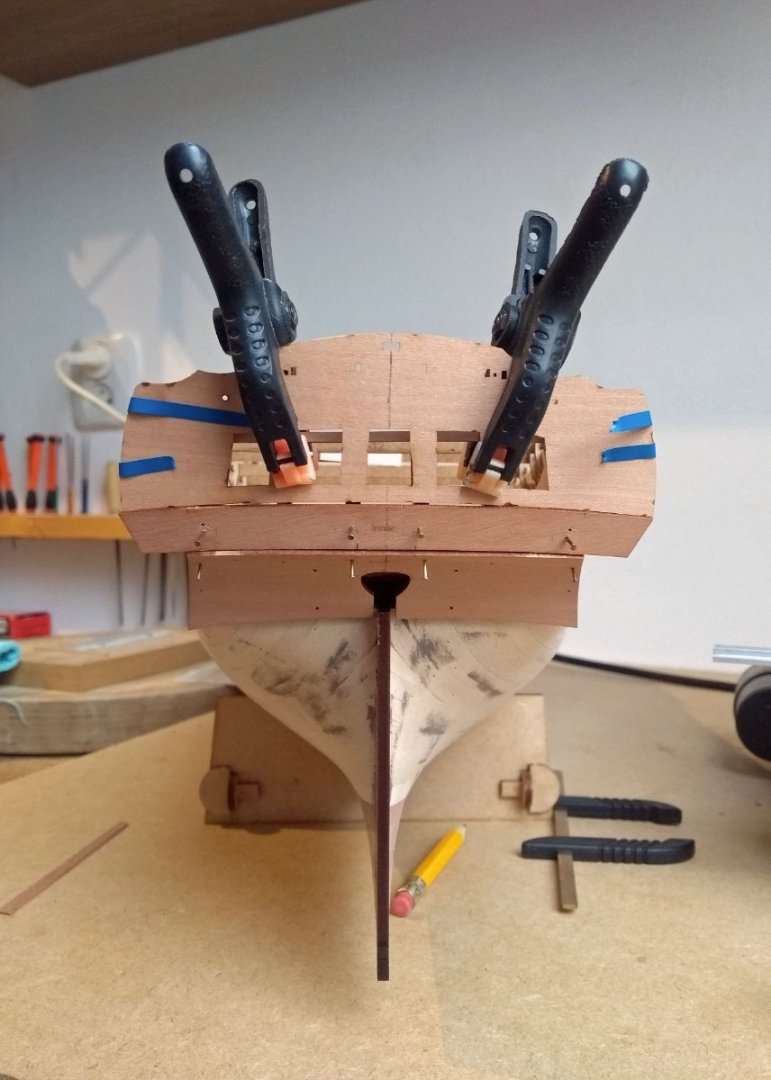

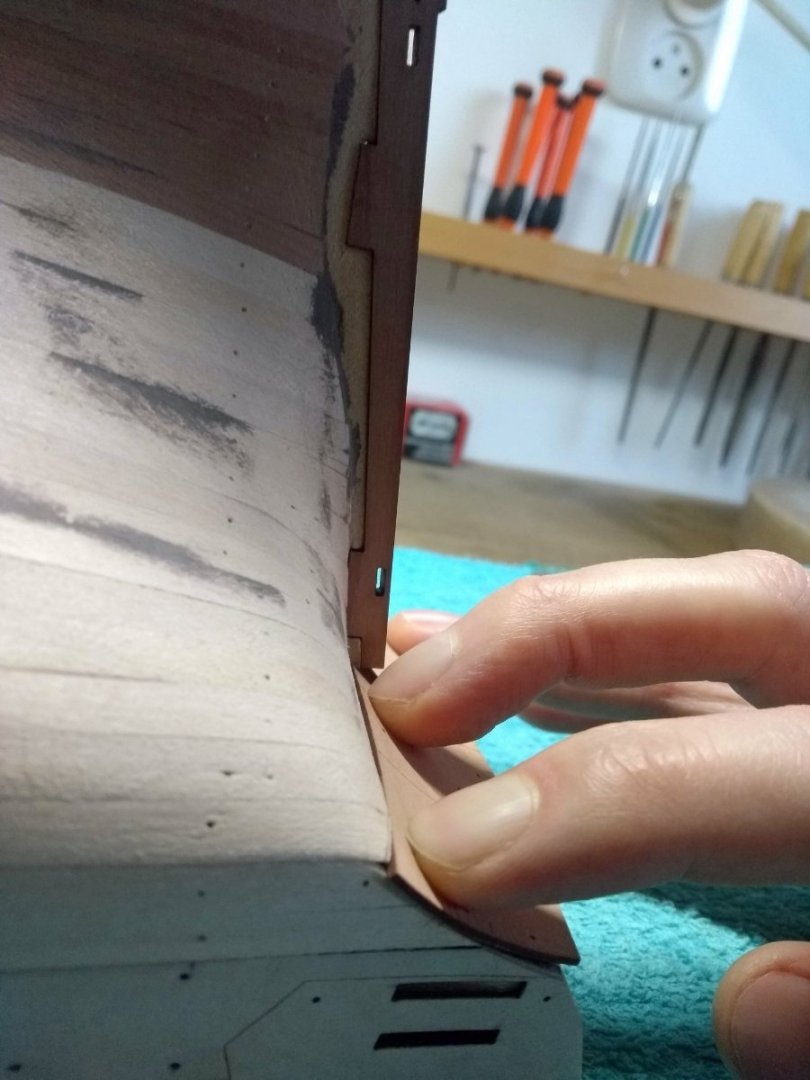

Okay...it's time for me now to place the lower stern counter into the right place, but I have a question...let's see if I can explain it. Blue Ensign did a great job explaining how he tackled it, with temporary pinning the rest of the stern pieces. So you can see if everything lines up. Sounded like a great plan, so I did this too. Need here and there a few little corrections, but in general this looked good and on the correct height (if it's not please let me know ) I asume the first layer of planking needs to be on the same height (thickness) of the lower stern counter. One flows in the same height into the other, without elevation? Well that is what I think it should be but if it's not by design, please let me know. Because as you see in the lower pictures, you see that my first layer of planking is a bit lower than the stern counter. In the outer corners not so, but closer to the stem it is lower. I can put some filler to get it more level with each other.

-

Great result! And like Blue Ensign said...impressive construction speed!

- 233 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks for the suggestion Chris! I'll take it one step at the time...and see where I end

- 96 replies

-

- Sphinx

- Vanguard Models

-

(and 2 more)

Tagged with:

-

Good luck with your Sphinx journey! It's such a lovely kit...I also toyed with the idea of building it without rigging etc. due to space saving. But I also lack the experience to rig a three masted frigate...so i'm going to rig it just for the experience I think...but I have some time to decide it so nothing is set in stone at this point.

- 96 replies

-

- Sphinx

- Vanguard Models

-

(and 2 more)

Tagged with:

-

Congratulations with finishing this stunning ship! Quite a epic journey and wonderful result

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Lovely second layer of planking you did there

- 152 replies

-

- Flirt

- Vanguard Models

-

(and 1 more)

Tagged with:

-

For the Beginner Modeler

Ronald-V replied to kgstakes's topic in Modeling tools and Workshop Equipment

Well a disc sander with adjustable table (like the proxxon one) made my modellers life a lot more enjoyable. It makes it so much more easy. And a Dremel ofcourse...those two are my essentials...for now -

Last update this year I suppose The hull is now sanded smooth and the little cracks/deeper lying planks etc. are filled. Ready for the next step I guess. I will test fit the prow/keel and sternpost patterns to see if it fits right, and maybe there are spots that need a little extra sanding (places around the tabs that are connected to the prow and keel). Also need to test fit the lower counter ofcourse. I think I also need to check if the upper hull side patterns are flush with the gunports inside. I haven't done that yet, but also didn't see it mentioned in the manual. Would be a good moment for that.

-

And be aware....when you are at the part of glueing it in place....don't put glue on the deck, but only at the false deck below. Because the PVA will moisture the wood causing it to swell a bit. This resulted in that the deck didn't fit anymore because I couldn't get it fast enough onto the false deck, and as a consequence...the deck became fixated in this swelled up size due to the glue that dryed. So I messed this up a bit Totally my own fault due to the inexperience working with thin sheets of wood. So maybe I can warn others to not make these mistakes

-

American Revenue Cutter – Seahorse – 1:72 – Card Kit

Ronald-V replied to Jsk's topic in REVIEWS: Model kits

Looks like a fun project! Will be interesting to see how you tackle it. And nice review/story -

Yes Sphinx is a good alternative, but not sure how experienced you are. I'm building it now and it's a real joy. Your criteria of decent instructions and materials are met with this kit. I can't judge how difficult it is because i'm not that far into the build yet, and i'm considering myself a experienced beginner. But knowing the designer and prototype builder are here on the forum, that gave me enough confidence for trying to tackle this kit

-

Finally closed! Took a bit longer then expected because I was quite sick last week with a flu and fever, but feeling good now so I could do the last planks. I used some 1mm pear that I had lying around, because I had run out of the lime wood. Not because Chris didn't supply enough, but because I redid such large areas. This gave me the change to get a bit familiar with pear wood and how it behaves, so maybe that gives me a bit of an advantage for the final layer. I couldn't get the first layer exactly as I wanted, without mistakes and knowing exactly what I did, but I have learned a lot! So hoping that I learned enough to get a decent second layer that I could be happy about and leave it unpainted. Otherwise there is always the option to paint it white if it's not too great Now first some sanding and filling here and there to get a nice smooth base for the second layer.

-

Congratulations! That´s a real beauty!

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welkom! And nice model you have there

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.