-

Posts

10,594 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

Very nice work, and congratulations on your finished model!

- 26 replies

-

- muscongus bay lobster smack

- Model Shipways

-

(and 1 more)

Tagged with:

-

New to ship modelling? But what do you build first?

ccoyle replied to MSW's topic in Wood ship model kits

Based on your photos, I believe I can safely say that you have joined the ranks of those doing the blowing away! -

Tachikawa Ki-9 'Cedar' by Javlin - Nichimo - 1/48 - PLASTIC

ccoyle replied to Javlin's topic in Completed non-ship models

Nice! I have been eyeing this same aircraft in card in 1/33 scale. I'm a sucker for brightly colored biplanes. -

Welcome aboard! Is your kit the old Gertrude Thebaud kit?

-

Your craft knife, commonly referred to as an X-acto knife in the US (though that is a brand name) can accept a variety of blades -- the #11 blade in your picture is the most commonly used type. As you have discovered, #11 blade tips do not hold up well to too much pressure and are thus a poor choice for cutting the tabs in plywood frets. A pin vise is designed to be held in position by an index finger while the barrel is turned with a thumb and middle finger. The bit is held by a collet, which in turn is held in place by tightening the two or three pieces of the barrel (one part of it is threaded to fit into the other part). The collet normally has different-sized openings at either end to accept a wide range of bit sizes. This is harder to explain than to actually do -- play around with the vise for awhile and you'll quickly figure it all out. Cheers!

- 21 replies

-

We also have a card modeling tutorial based on a WW1 torpedoboat -- different, subject but same basic techniques. The guy who wrote it seems to have a rudimentary grasp of the subject.

-

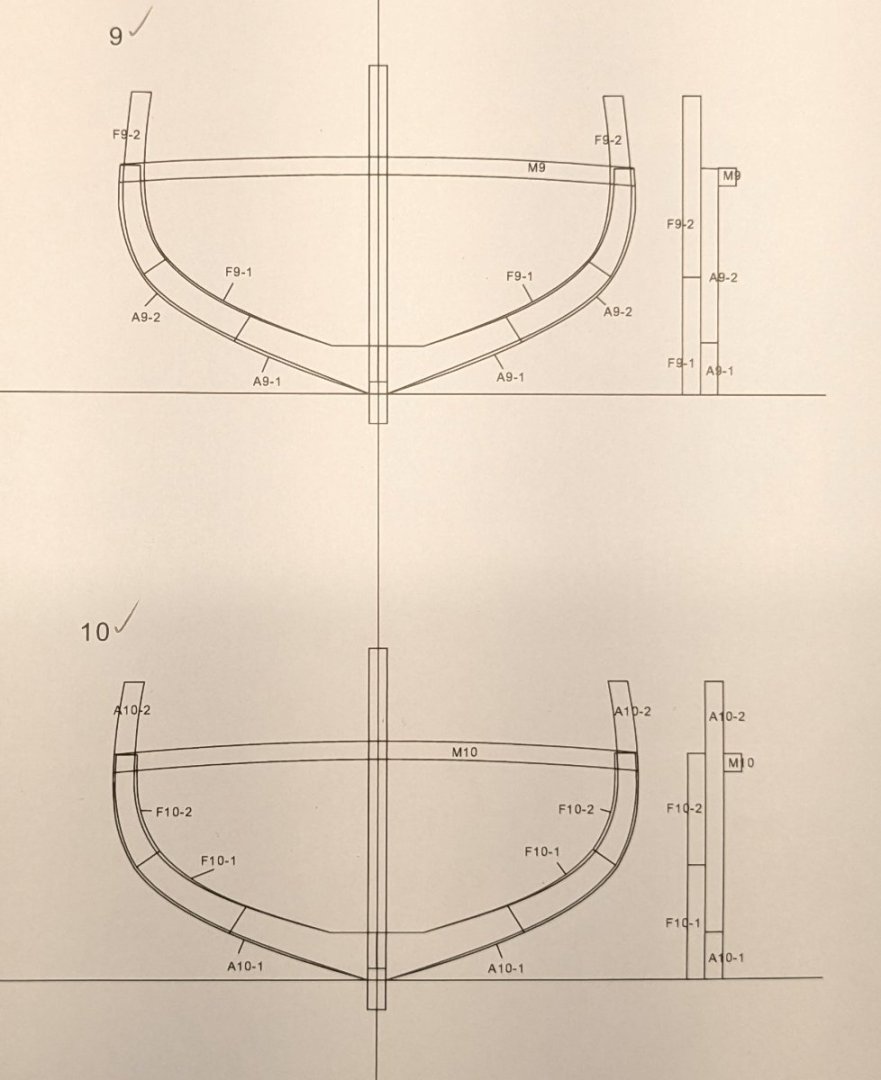

I have a nice little collection of frames going. Like most repetitive tasks, I'm discovering some techniques that make the assembly process go a bit quicker. One thing for potential builders to look out for is that between frames 9 and 10, the transverse beam shifts from spanning the short pair of futtocks to the longer pair. This is due to the positioning of the gun ports. Back to work!

-

HMS Renard 1872 by Draque - 1/24 - POF

ccoyle replied to Draque's topic in - Build logs for subjects built 1851 - 1900

That's a very handsome subject, and not a type that we normally see around here. -

It's a sad compromise made necessary by economic reality. I intend to replace all of the kit-supplied line on my next rigged model.

- 111 replies

-

- Nonsuch 30

- Model Shipways

-

(and 1 more)

Tagged with:

-

Welcome aboard 'Vitus' (not the original, I presume!) and good luck with your project!

- 248 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

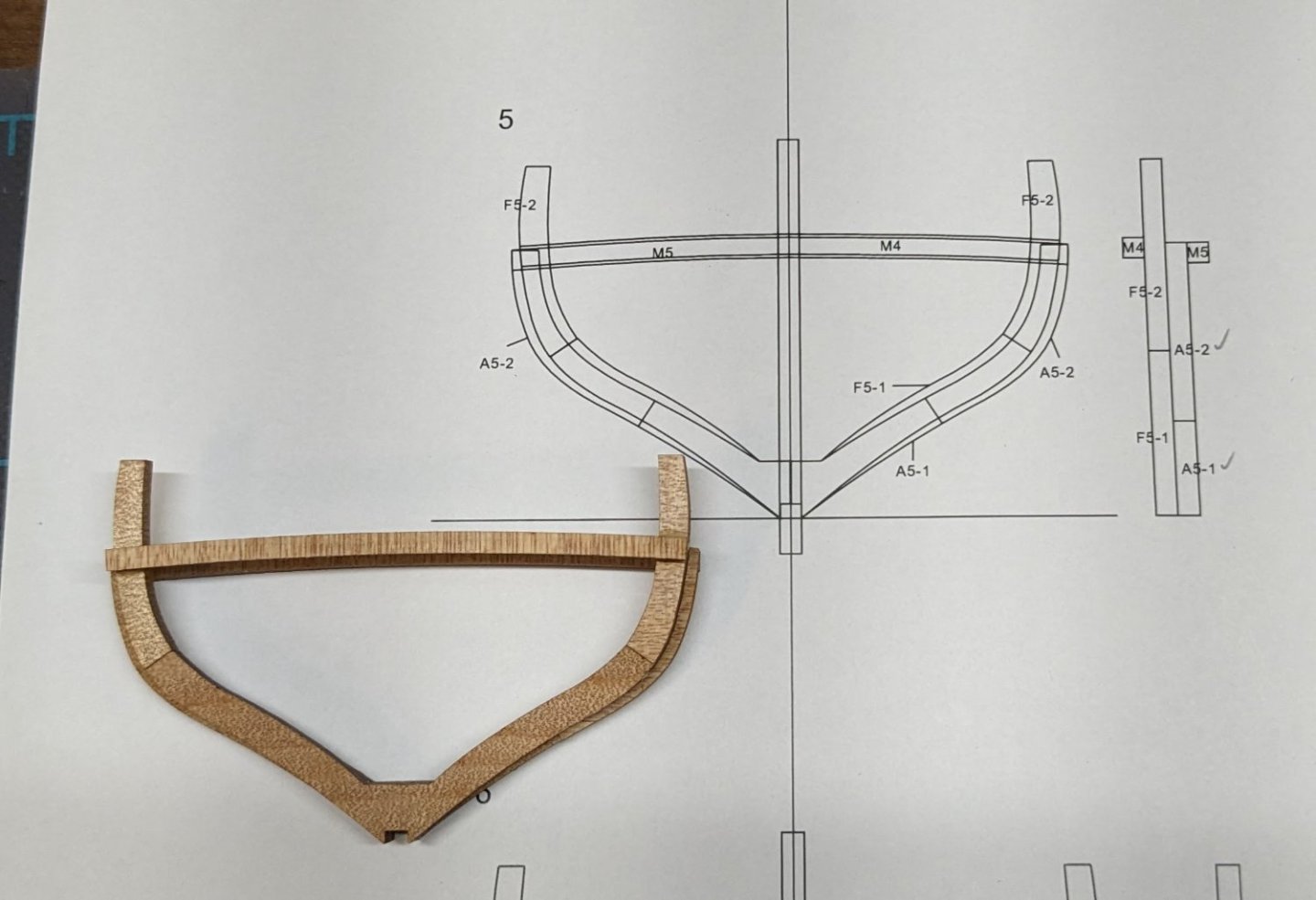

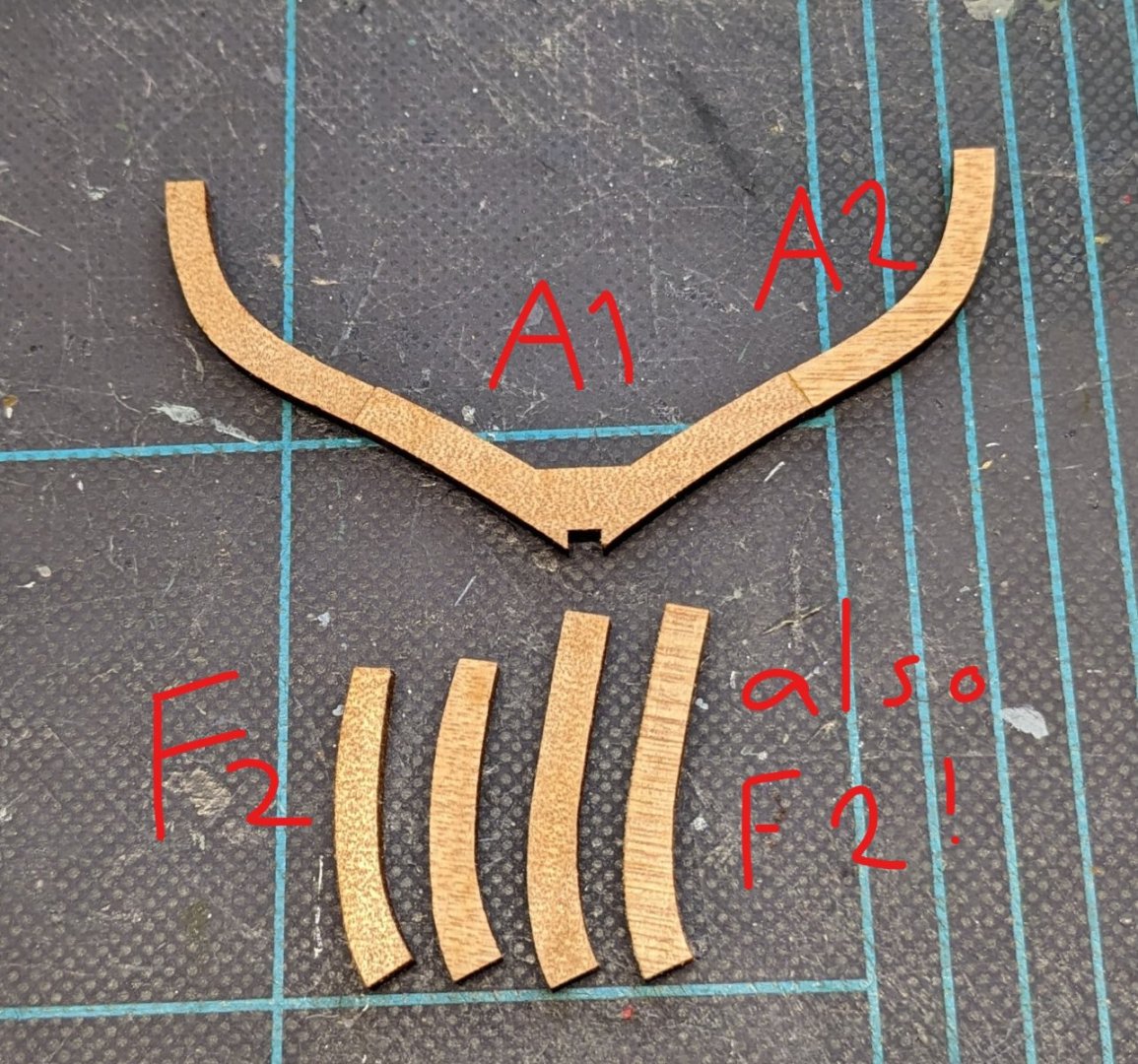

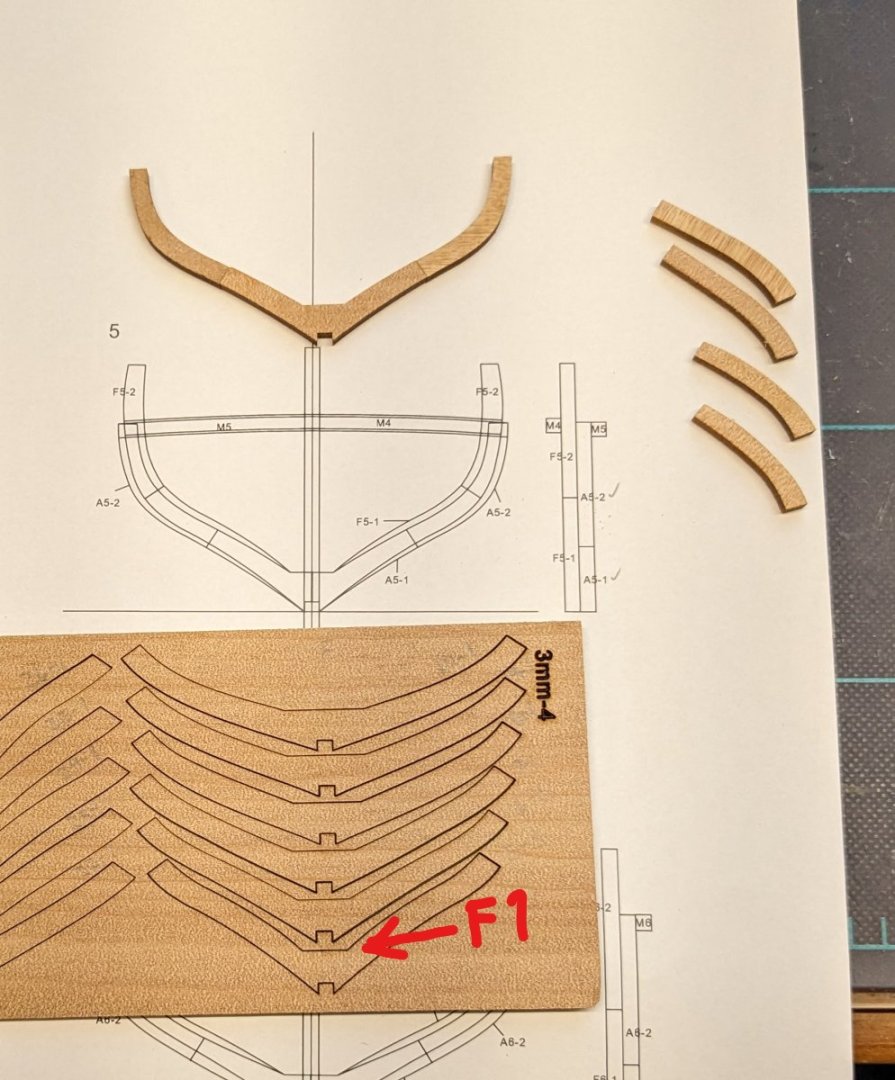

The construction of this kit is proving less straightforward than one might have hoped, as seen in the following set of images. Frame 5 is the first full-width frame. Parts A5-1 and A5-2 (forgive me for forgetting to add the '5' part to all of the labels on the photos!) were easy enough to find on their sheets and assemble, but then we ran into a mystery with parts F5-1 and F5-2. First of all, there are four parts labeled as F5-2 on the parts sheets, but only two are needed, and, as you can see, the pairs of F5-2 parts are not all the same length. No problem, I figured -- one of the two pairs must be F5-1. The shorter F5-2s matched the dimensions on the frame diagram, so I deduced that the longer pair must be F5-1. Except the F5-1s did not match the frame diagram contours at all. After some head-scratching and additional fret searching, I found the real F5-1. It all made sense now. Except . . . now it appears that I have a surplus pair of futtocks (F5-1)?? Mysteries and more mysteries! Back to head-scratching!

-

HMS Granado by ir3 - CAF - 1:48 - POF

ccoyle replied to ir3's topic in - Kit build logs for subjects built from 1501 - 1750

No harm in setting it aside for now and coming back to it when you feel better prepared. -

Yup. Gonna need a whole lot more information.

-

Welcome, Andre! Stunning helicopters!

-

Witam, Pitr! You are doing such a lovely job with this model. I realize you are modifying the basic kit, but it still makes me want to give one of the Shipyard models a try someday. Cheers! Robisz cudowną robotę z tym modelem. Zdaję sobie sprawę, że modyfikujesz podstawowy zestaw, ale mimo to mam ochotę kiedyś wypróbować jeden z modeli Shipyard.

-

To tack on to what others have said about this kit, one thing that can be said for Model Shipways kits in general is that they don't engage in hand-holding -- they assume that the builder is bringing a certain amount of skill and knowledge to the party. If you don't know how to do a task like strop a block, for example, Model Expo instructions do not usually tell you how to do it; you will need to consult some outside resources, such as books on 18th century rigging practices. Also, Model Shipways kits have far fewer pre-cut parts than other kits; oftentimes, you are given only the requisite wood materials and are expected to take the dimensions off the plans (proportional dividers are handy for this task). Same goes for things like determining the position of the wales, locating scuppers, etc. -- that information is provided in the plans and is not described in any great detail anywhere. If you don't mind my asking, since you are new here and you say this is your first intermediate kit, what kinds of kits have you finished before this one? Don't be fooled by the word "intermediate" on this kit -- that term is relative. It's certainly intermediate compared to tackling an ornately decorated 17th-century ship of the line, but it still has plenty of elements (e.g. guns, three masts, square-rigged) that a modeler may find very challenging, and it is certainly more challenging than other types of models that have less of those elements and are therefore more intermediate-friendly, such as a brigs, cutters, or schooners. Your answer to this question may suggest that a simpler model would be better suited to your current skill level. Kind regards,

-

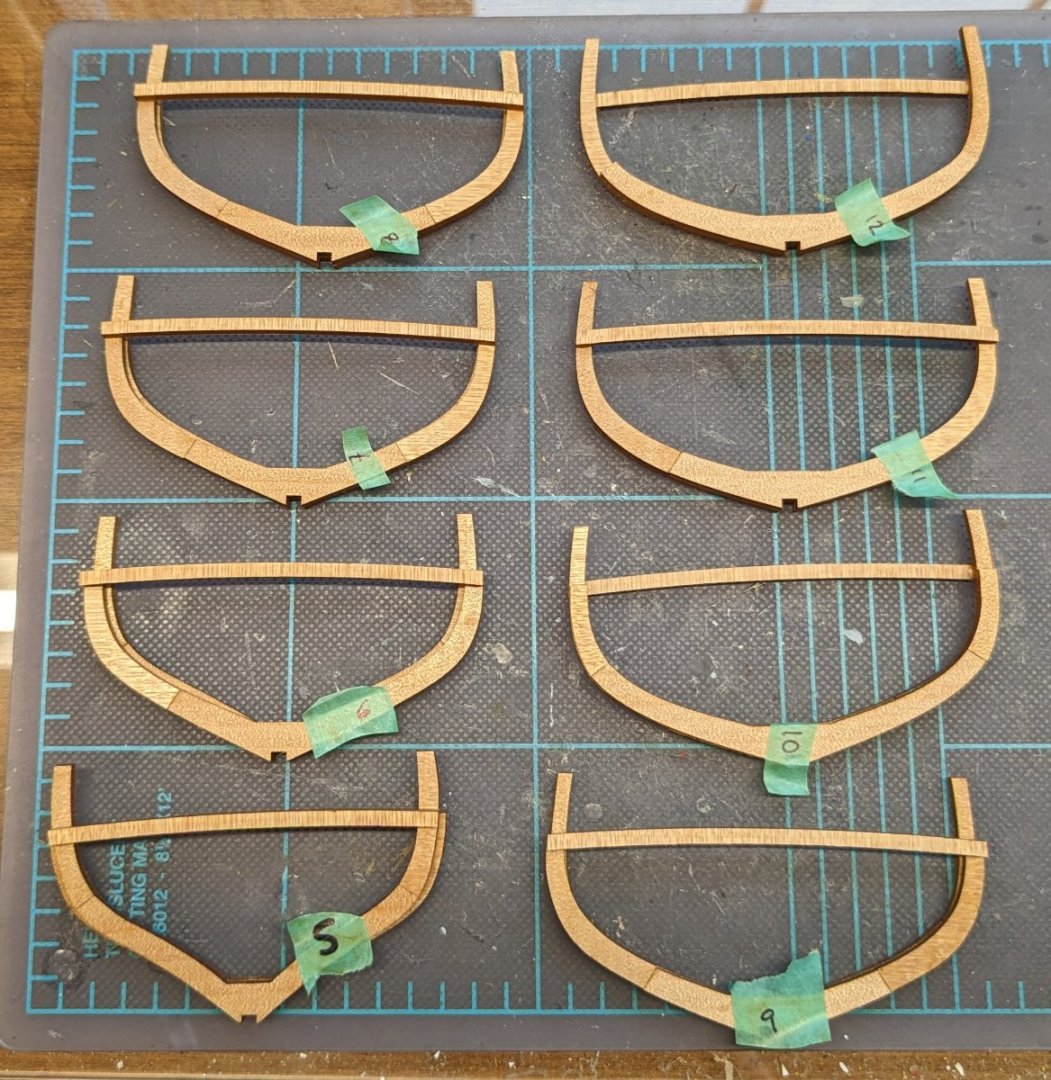

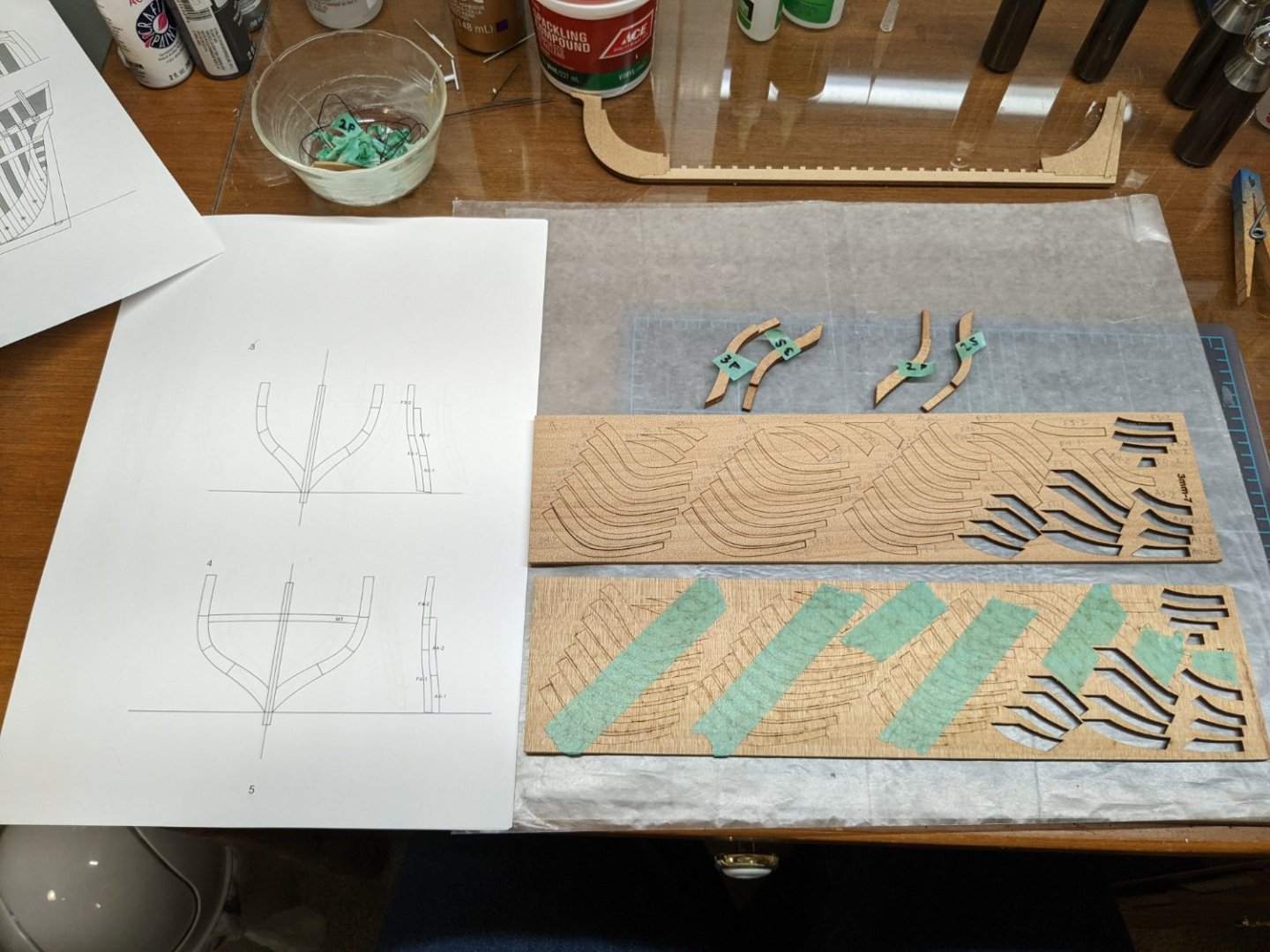

Here's a quick update. Each cant frame is made of four pieces. The laser-cut parts have no tabs and literally drop right out of their frets, which is why the manufacturer has taped the back side of each fret. It would obviously be foolhardy to remove the tape all at one go; instead, I remove only as much as is needed to release each part. There are 31 frame stations along the hull, so as I complete each frame, I use some leftover tape to label it with its station number and, for cant frames, which side it goes on. This process worked well until I got to cant frames #4 and discovered that two of the futtocks for these frames are missing (the same part for each side). I checked all of the frets three times and then checked the parts sheet drawings as well. Yep -- that part # somehow did not get included. I'm going to have to make replacement parts from some scrap material. I think that Mr. Dremel Tool and I will be able to make short work of this task, but it is mildly annoying when one discovers that a kit is missing some parts.

-

Coincidentally, our family also has a Bean (it rhymes with her given name, Kathleen), although I'm probably the only one who calls her that with any regularity. Ironically, her dog is also named Maisy.

-

Greetings from North Carolina

ccoyle replied to PostCaptainAubrey's topic in New member Introductions

Welcome aboard from your neighbor to the south!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.