-

Posts

10,594 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

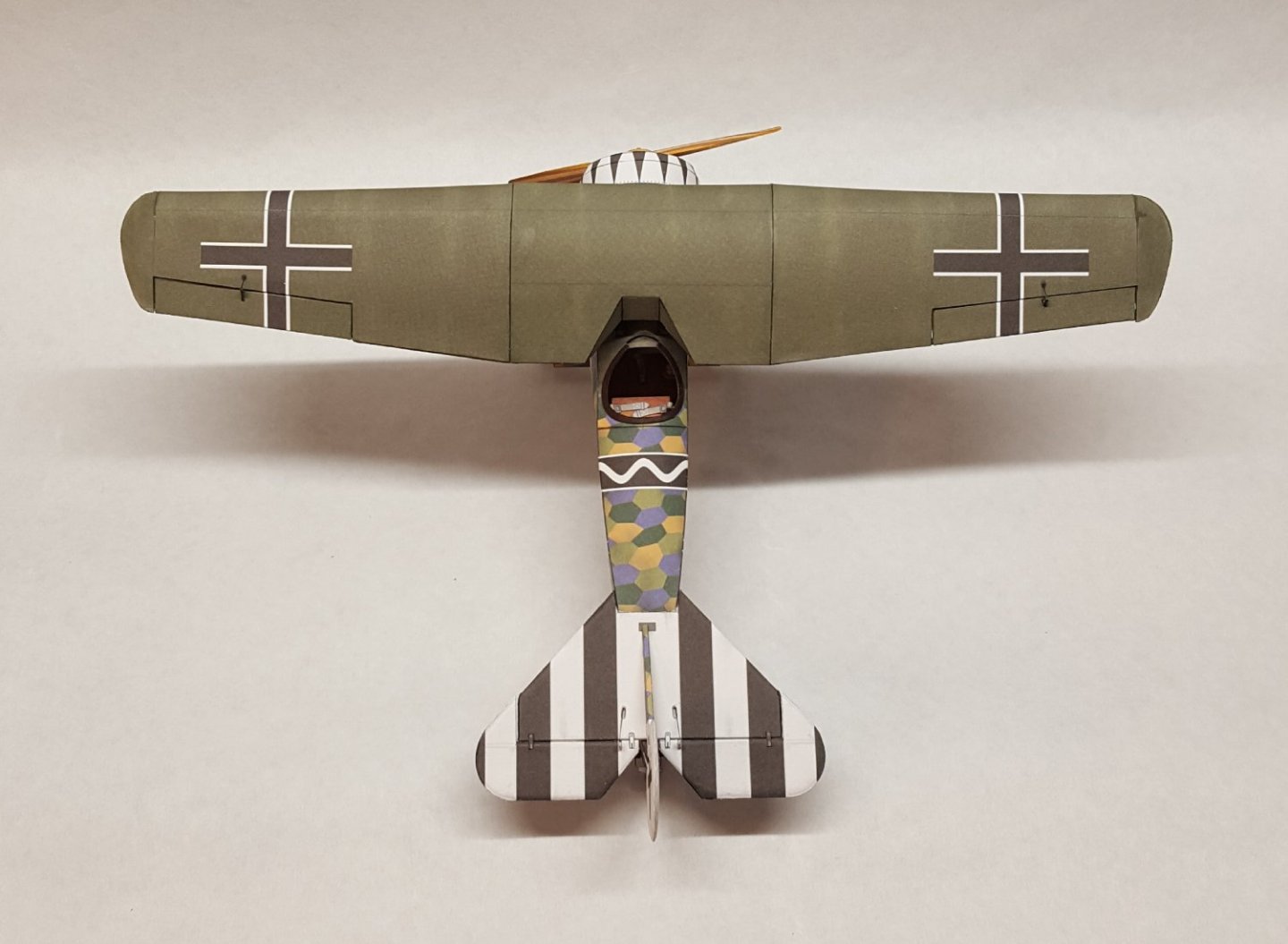

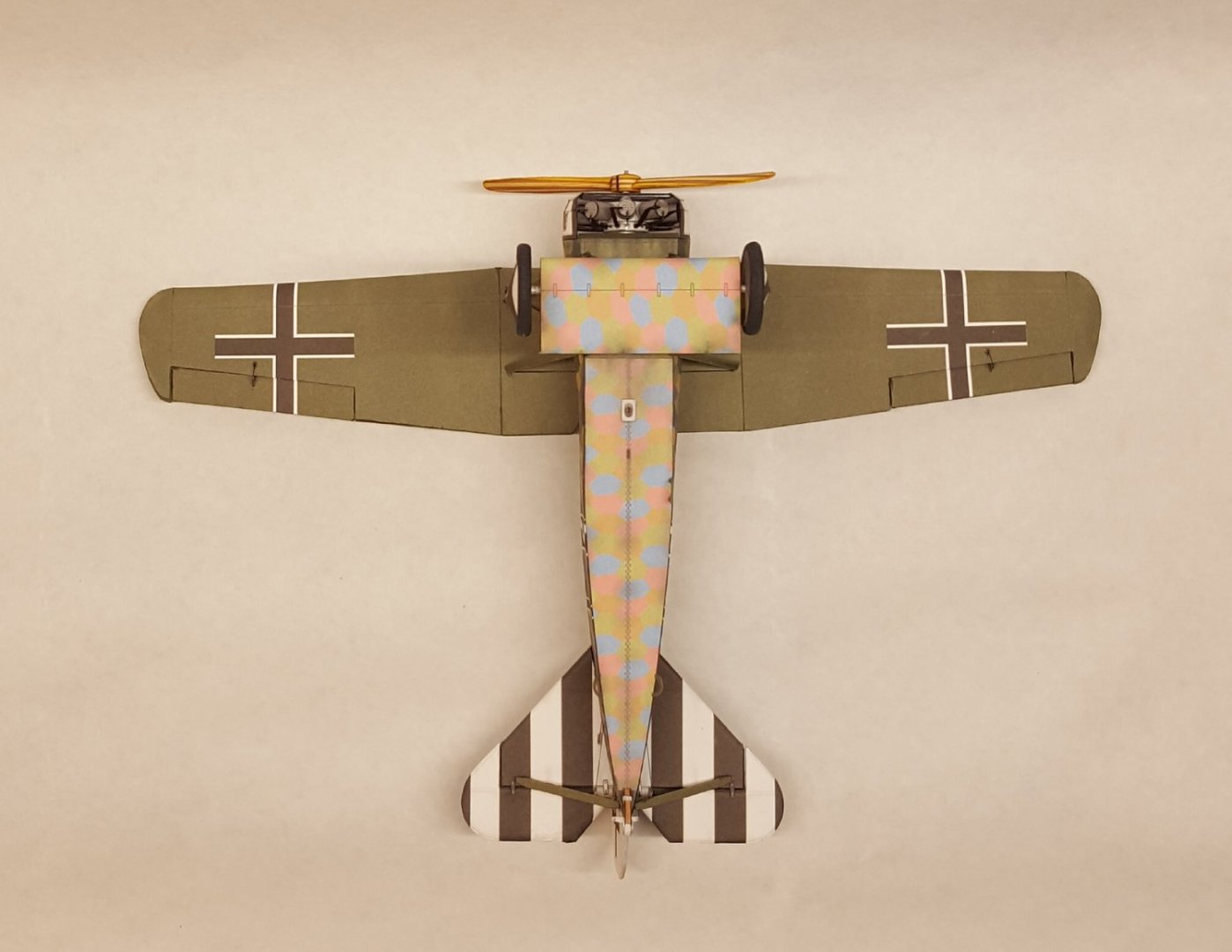

The Big Reveal! Yes, three weeks to the day and she's finished - another fantastic model from Kartonowa Kolekcja. I can't say enough good things about Pawel's designs -- they very nearly fall together by themselves. Anyways, on to the pictures! I noticed as I was posting this next shot that the entry step got knocked askew -- gonna have to fix that. Thanks to everyone who has followed along, liked, and commented. I hope you have enjoyed this quick build, and we'll see you on whatever is next!

-

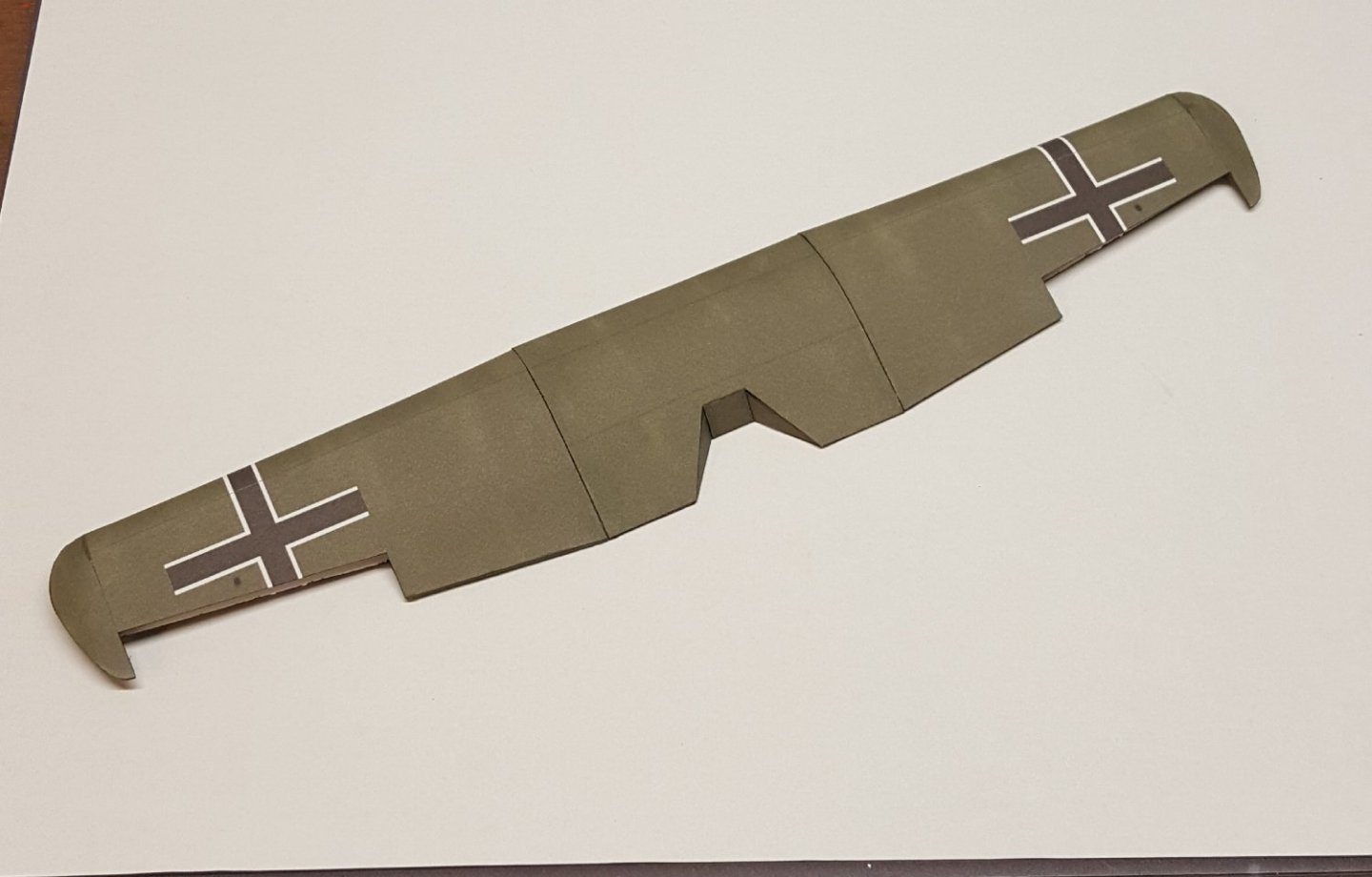

Moving quickly along . . . The wing was finished off by the addition of ailerons and control horns with their cables. Struts were made by wrapping the paper parts around 0.020" steel rod, then glued to the fuselage. Finally, the wing was mounted, bringing the model to its present state. For future reference, I should note that some of the struts, both for wings and for undercarriage, appear to have been misnumbered when compared to the diagrams, but a careful study of the diagrams reveals their correct placement on the model. Cheers!

-

Welcome aboard! Dedicated shrimpers are rare in kit form, as are modern workboats in general, at least if you are looking for US examples. Several kits for European/UK boats do exist, though these tend to portray older, sort of 'classic' boats. What kind of vessel did you have in mind?

-

Slipping in from Massachusetts and Minnesota

ccoyle replied to Janelle's topic in New member Introductions

Garlic and apples -- an interesting combination. Welcome aboard! -

Aha, another cardist (see signature)! Welcome aboard!

-

That's a very handsome model, Jeff. Well done!

- 23 replies

-

- Herreshoff 12 1/2

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

An outstanding finished product -- well done!

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Please be advised that the plans produced by that "Japanese guy" constitute an unlicensed reproduction that he is not legally entitled to distribute and thus violate our site's intellectual property rules. I'm not familiar with the other set you mention, but the same rules apply if his work is an exact BP likeness.

-

The plans should be available from BlueJacket Shipcrafters, since they make a kit of the Notman.

-

You can send Kurt a private message here in the forum. His username is kurtvd19.

-

Hi. Sorry to hear about your husband. I have removed your email address to protect you from spam bots. Interested members may contact you by private message. To ensure that this is a genuine offer, please post some photos and descriptions of your husband's materials. Also, you might be interested in donating the materials to a local club. It's a not-uncommon practice, and clubs typically auction off the donations to raise funds. There is a local club that meets in Portland -- you can find their contact information by clicking this link, then scrolling down to the Oregon clubs. Kind regards, Chris

-

The tackles on the 1/64 scale 4-pounders for my Sherbourne required 2 mm blocks -- they were tiny, and definitely a challenge to work with.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.