-

Posts

3,986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

Eberhard. My current thought is white down to the waterline and mahogany below waterline. I can change my mind however as I just need to plank over the ply with a thin mahogany veneer. I may reconsider as I too like to see the beauty of natural wood. Mark - not quite sure where you are referring to? The only hollow that I could feel was the one I filled. I'm going now to have another look.

-

Tony I started with a Billings kit some 30 years ago. I seem to remember building it was fairly "plain sailing" albeit I think the materials supplied were a bit better quality then. Just give it a go, take your time and ask for help. I used to work for BAA at Heathrow - but am now retired. I was one of those people you probably cursed every time Concorde took off.

-

I finished off the transom. I started by covering with paper the part of the former that I wanted to remove later. This was held in place by double sided tape. The transom was covered with two layers 1/32" ply, these were soaked in boiling water and then held over a former with an elastic band until they set in shape. The two layers were then glued in place . The edges were sanded back to match the hull profile. Because of the shallow angle the plywood layers became very obvious and the attachment area for the planks became quite substantial. In preparation for planking I marked up the hull with lines drawn equi-spaced from the deck line (shear strake). Although I don't expect the planking to follow these lines they will be a good guide to keeping the planking equal on the two sides of the hull. I find that this type of hull shape does not lend itself to the usual approach of segmenting the frames into plank widths. This approach works well where the keel and the shear strake follow "rationally flowing" lines. In the case of Germania (and other similar yachts) the keel line is as bent as a dogs hind leg. I suppose I could establish a "rational" line somewhere near the keel hull intersection by laying on a "naturally"bent plank. The only trouble with this approach is that I can create many different "natural" plank lines - basically it comes down to guessing. My preferred approach is to recognise that that the planks at maximum beam will need to be about twice as wide as the planks at the stern. I put the first 2 planks (shear strake) on each side as parallel planks and the start using tapered planks of 2:1 width ratio. As I proceed with planking I adjust the degree of taper occasionally to ease the degree of "un-natural" plank deformation. I think I will christen my approach the "suck it and see method". In preparation for the planking I cut down a 36" x 3" x .75" plank of antique mahogany into 36" x .75" x .225" strips using the carbide tipped blade on the Byrnes saw. I had decided that the final planks would be .225" wide by .055" thick. I had given much consideration to the final planking size and produced versions of .25" x .065" and .2" wide x .055" before settling on the final size. The heftier plank was rejected as too stiff while the smaller plank increased the number of planks without appreciable benefit in terms of flexibility. I slit off the final planks (.225" x .055") using .031" wide slitting saw blade with zero clearance insert. I got 7 or 8 planks out of each 3/4" wide strip. The planks turned out at .055" +/- .002". Because I don't cut planks very often I forget some of the historic learning points. My slitting saw blade was 3" x .031" x 108 teeth. It struggled on the first few planks - the saw slowed, burnt and produced variable widths. I flipped the planks lengthways and side to side without benefit. Finally I mounted a new blade - what a transformation. What appears to be sharp isn't always!!!!

-

Dan - it actually looks pretty complex to me - maybe your concept of complexity is starting to get a bit warped. She is looking very crisp.

- 238 replies

-

- leviathan

- troop ship

-

(and 2 more)

Tagged with:

-

yes Michael - I sometimes get strange ideas in my head - like "filler is cheating". Silly really as its going to be buried under planks. John / Pat - thank you.

-

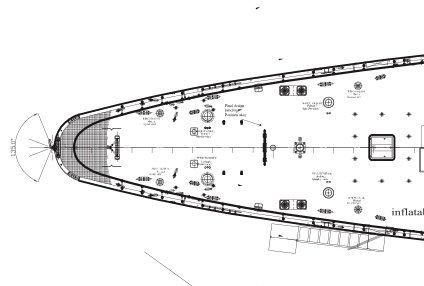

Yes Michael - very much a racer. Druxey / John - thank you. I am now sorting out the hull before I commence planking. As predicted by Eberhard, the infill allowed me to find problems before they manifested themselves as hull irregularities after planking. The issue with the original lines drawing was that in areas of quickly changing curvature insufficient points were available to accurately define the hull shape. Having sanded the balsa infill back to the frames I spent some time running the palms of my hands over the hull to identify discontinuities. All was well with the exception of keel to hull intersection at the rear of the keel. Here there was a definite hollow. Using a straight edge I deduced the the dip covered an area of 6"x3" and was a little over .040" deep at its lowest point. The dip was present on both sides of the keel indicating that the frames were slightly off. I decided to plank over the hollow with .050" x .250" obechi planks and then sand back to remove it. I did the port side first. In the following photo the port side has been done and I have started planking the starboard And here the starboard side is done. You can see that much of the planking has been sanded away. I then spent a little time building up the bow in front of the foremost frame. Once this are was completed I moved on to sort out the transom. The transom on these classic yachts is quite an interesting area. When viewed from directly above or below the stern follows a smooth curve. Whereas the transom itself is curved in one direction while being flat in the other. When I first did a transom I was a bit perplexed as to how the various curves interacted and I only sorted it out by by trial and error. In the next photo I have added the above deck former. This will be removed later and I have inserted a piece of paper to act as separation surface. The line of the transom has been marked on and I have started sanding the above deck former. Some time later the transom form has been achieved. As can be seen the shape turns out to be an "eye" shape which is almost symmetrical about the major and minor axes.

-

Kortes New planking looks good - how did you remove the old planking?

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

ancre La Salamandre by tadheus - 1:24

KeithAug replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Always a joy to visit your build Pawel -

A little more infill work and the then I completed the rough sanding. Still thinking about the bulwarks I added infill blocks at every 3rd frame. I though this would aid securing the bulwark planks while glueing. Obviously they have to be removed once the bulwark is finished and I though one in three a good compromise rather than filling every space. Then it was on with final sanding - this time taking the surface down to the frames with light sanding on the frame edges. The pinky purple sanding dust was a bonus.

-

Hello Sorjs. I built this model nearly 30 years ago and I still have the finished model. It is interesting to see how Billings have value engineered the kit over the years. When I built the kit nearly all the hull was planked - none of the large flat plywood panel sections you have had to deal with. As a consequence of the planking solution the hull profile was much less angular than yours. It is a pity that in the pursuit of profits manufacturers are inclined to cut corners on even the less expensive materials. I cant believe that the cost of a hundred of so obechi planks rather than ply would have made the kit uneconomic. I hope you health is improving.

-

Excellent Patrick - so is it back to boats now you have finished your intergalactic space cruiser?

-

I finished fairing the frames - the bottom of the keel turns out to be unbelievably fine - i think I will correct it to have a small radius curve as part of the planking process. As I decided previously I made a start on infilling between the frames. But first I re-coloured the frames in preparation for further sanding later on. I infilled with medium hardness balsa in a range of thicknesses - 1/4" 3/8" and 1/2". I quite enjoy the process although it is a bit time consuming. I am sanding the balsa to be flush of the frames as I go along. I will finish sand once the infill is complete. \ The sanding dust is getting everywhere.

-

Wefalck Michael gave away your christian name - it is less impersonal than Wefalck. Do you mind if i use it?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.