-

Posts

3,156 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by trippwj

-

Beautiful work, Bob. Concerning the base for the caboose (Galley stove), according to TFEP - page 224, the following is extracted from the description of the Caboose (Galley stove): "...4 large Screw'd Bolts & nutts for fixing the Hearth to the deck - A Cast Iron additional bottom for the Hearth to Stand upon, instead of Stone Paving, with Bearers under do which gives Water Passage under the Whole by which means the Deck can be always kept Cool & free from danger..."

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Wow, Mobbsie - just plain, simple, jaw bouncing off the table in awe WOW! fantastic job there, sir. Most impressive!

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Congratulations, Anja. I have faith that you shall master the skills and excel at your new posting, and continue to show them that you are a true gem worth keeping! All the best -

-

Yowsa! A ship, me thinks! That's a lot of planking, and looks ok!

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Careful, Augie - I don't want you to knock me off my seat when you fall! Frank - look forward to the update!

- 389 replies

-

- supply

- caldercraft

-

(and 1 more)

Tagged with:

-

Nice looking shop, and your Victory is also shaping up well!

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

Looks good, Sjors. They line up quite well!

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Well, FINALLY!!!! Here are a couple of shots - not sure how well you can tell the difference, but first is a picture of the shrouds on the fore mast. These are with the kit supplied thread. This shows the shrouds on the main mast using thread from Chuck. I used the brown vs the black - think it is a better approximation for this scale. To me, the thread looks better than the kit thread but, more importantly, it is much easier to work with!

-

Nice start on the planking - did you leave any planks for other builders in the Netherlands?????

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

While I have not found (yet) the composition of the pintles and gudgeons in The Essex Papers, they were supplied by Paul Revere who provided the majority of the copper work (plates, bolts &c.) for the Essex. All of the references I could locate indicated he was supplying copper products only, with the iron materials coming from a foundry in Salem. Spikes were provided for 50 cents and 39 cents for rudder braces and pintles.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

I think I have the keel straightened out now - I shaved the holes at the offending bulkheads a bit wider so the dowel was somewhat loose then clamped the beastie with a piece of steel stock on both sides to pressure it straight. There is just a very minor (less than .5mm) curve left now, and I think that will work out as I start planking the hull.

-

Welcome aboard, Lawrence! One thing you can count on with my builds so far - they take a long time, so no problem joining in-progress! Popeye has me beat, both on skill and rapidity of build. Not, however, on the enjoyment factor! This one has been fun so far and a nice distraction from the others! Hope that you can get a good set of plans on the Annie. She would be a very gratifying project for you!

-

Hello, jaxboat. Still working on her a little at a time. Working on frame 10 right now (sanding the bevels). Very much enjoy this one - lot's of space to get creative as I move forward! Interesting about the deck coating - wonder if they used it simply to replicate the original as opposed to going for longevity?

-

We can always count on our dearest friend Sjors - the perfect example of patience!!!! Pffffft

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Superb looking ship, my friend! VERY nice bit of progress!!!

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Sweet! She looks great! Glad you are feeling a bit better. Hope to see ya back to 100% soon! With any luck we'll have a break from snow (24 inches since Thursday) so I can get some building done!

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Dang, Sjors - nice work! Fonzie is looking really statuesque now!!!

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Ahoy, John - Just thought I'd stop by and see how things are going!

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

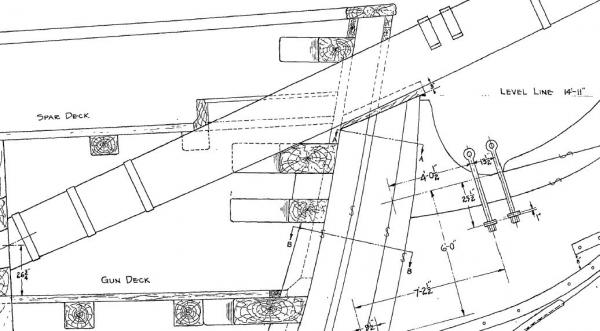

Stan - The light blue line would not necessarily be parallel to the base line as it traces the top surface of the curve of the timbers (I want to say sheer line but not sure it is correct in this instance). There would be a vertical 9as well as lateral) curve to the top lines as you progress from bow to stern - it is evident when you look at the profile. Not sure about the issue in your subsequent post about the fairly flat bottom and fit into the keel. Need to ponder that one!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.