-

Posts

797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Seventynet

-

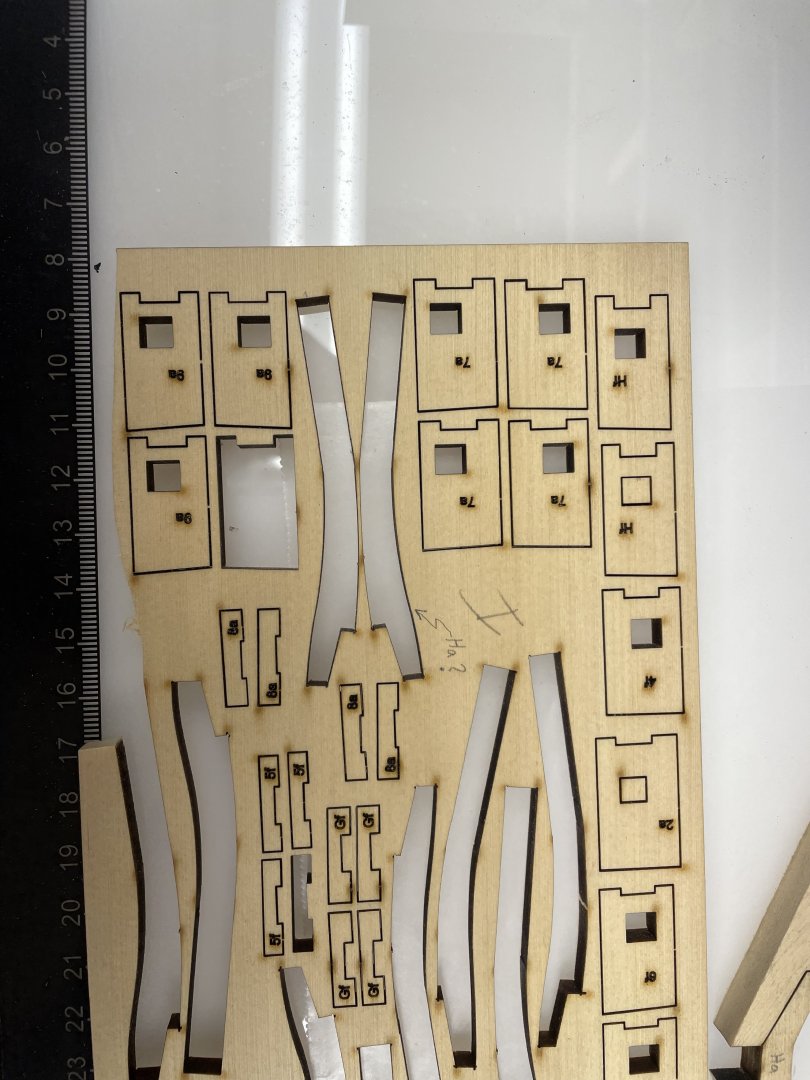

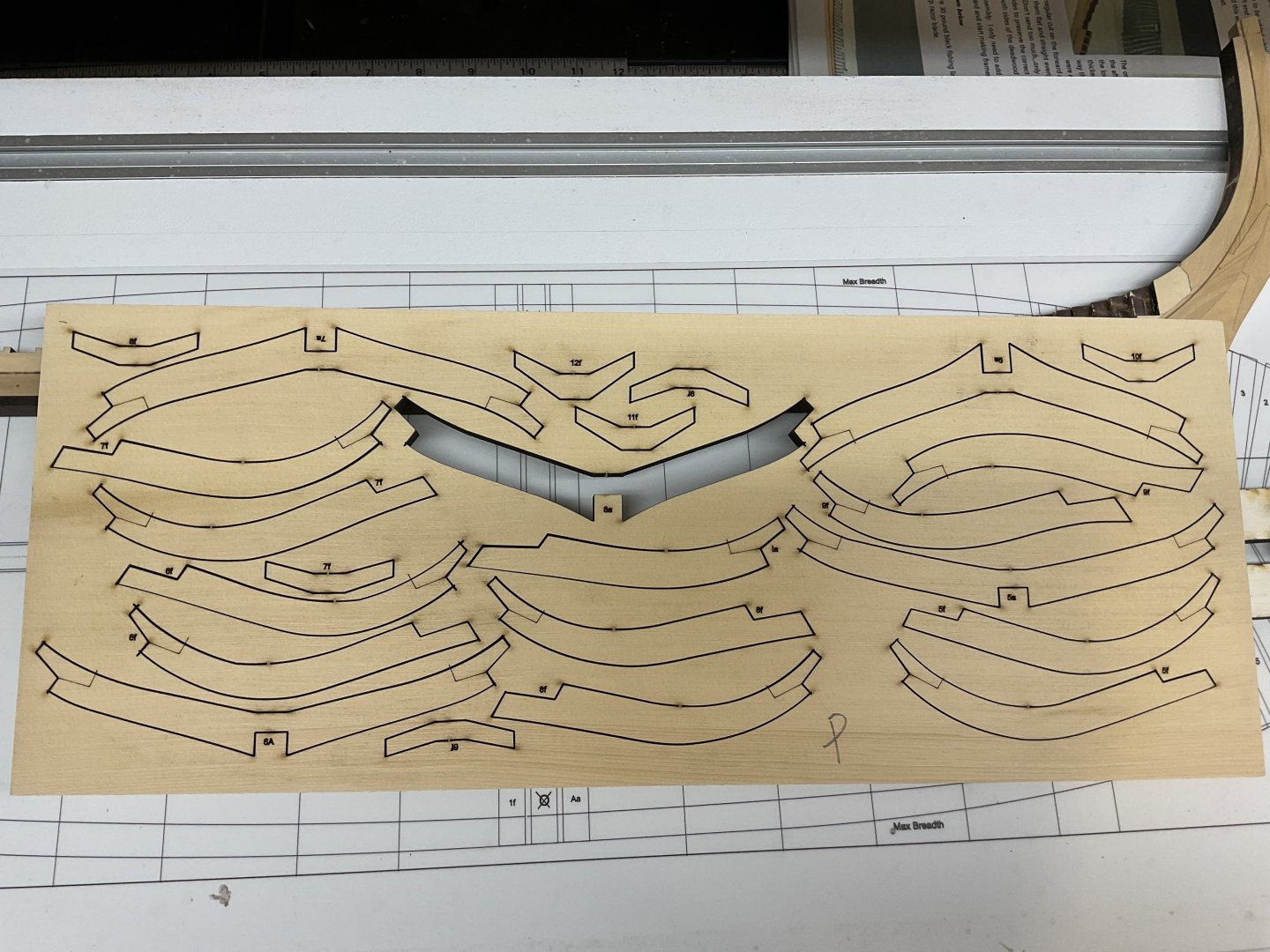

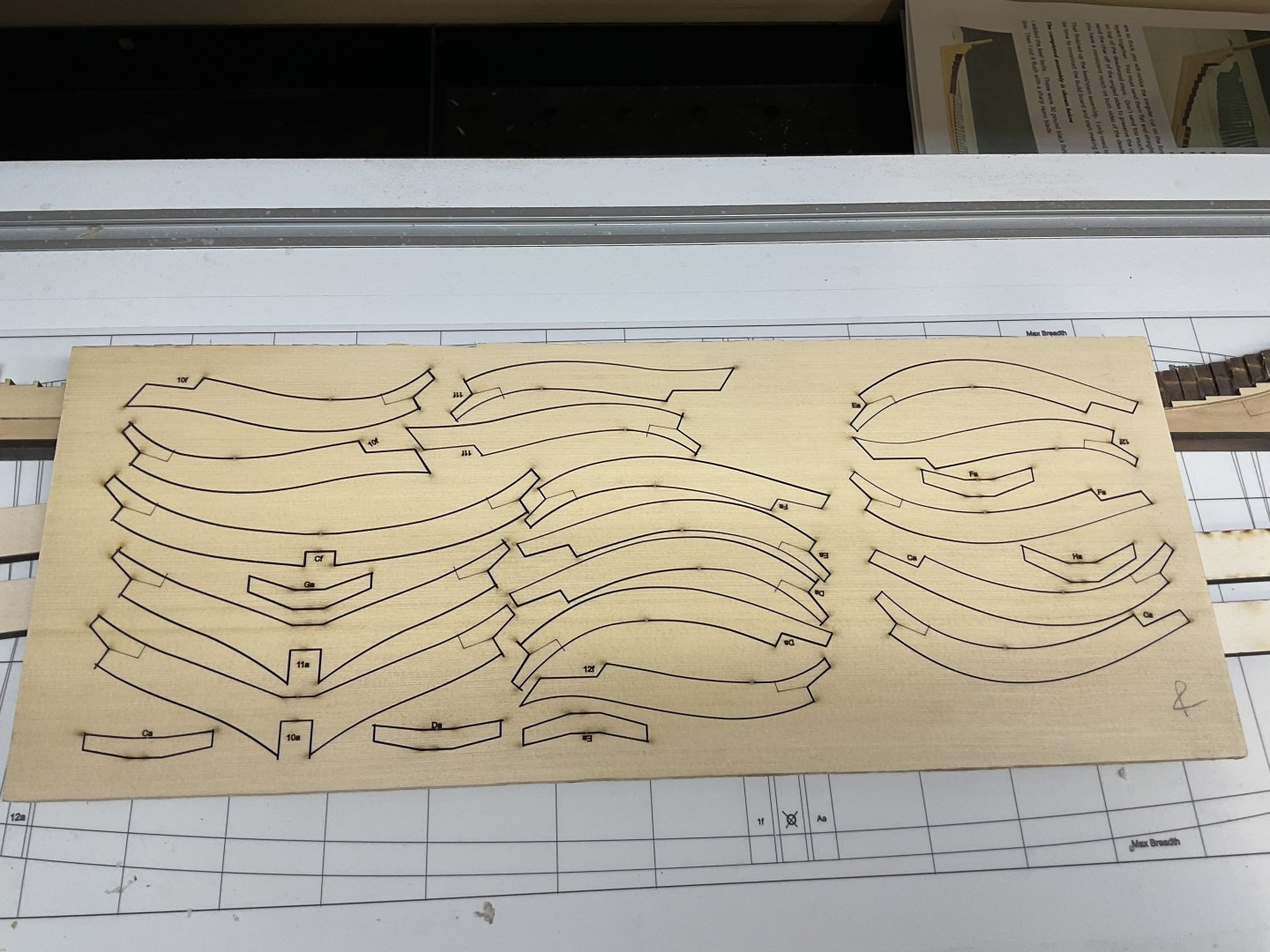

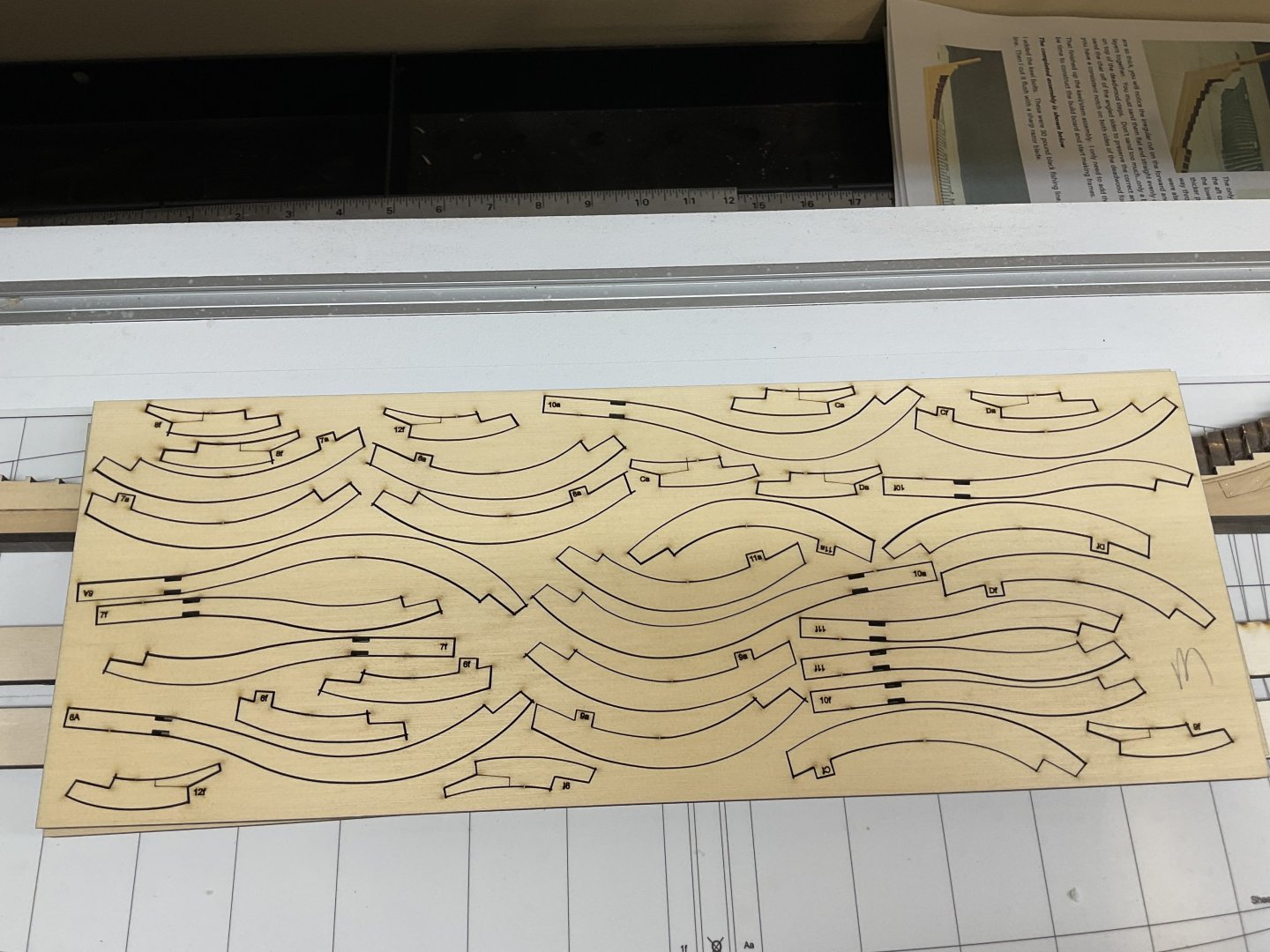

Greetings, Could someone confirm whether the 2 top timbers for Ha are in the template shown below? I have no idea where they have disappeared but if someone could confirm that they are in fact what I have shown I can simply trace and cut new ones. It shouldn’t be too hard to interpolate the notches. You can see that I cut the top timbers out of card and they seem to fit but it is hard to know for sure. If these are not Ha top timbers can you show where they are? Thanks in advance, Ian

-

Hi Paul, I don’t know how I missed this build. What organized, precise work you are doing! I need to take lessons from you on how to do a great build log. Keep it up! Ian

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

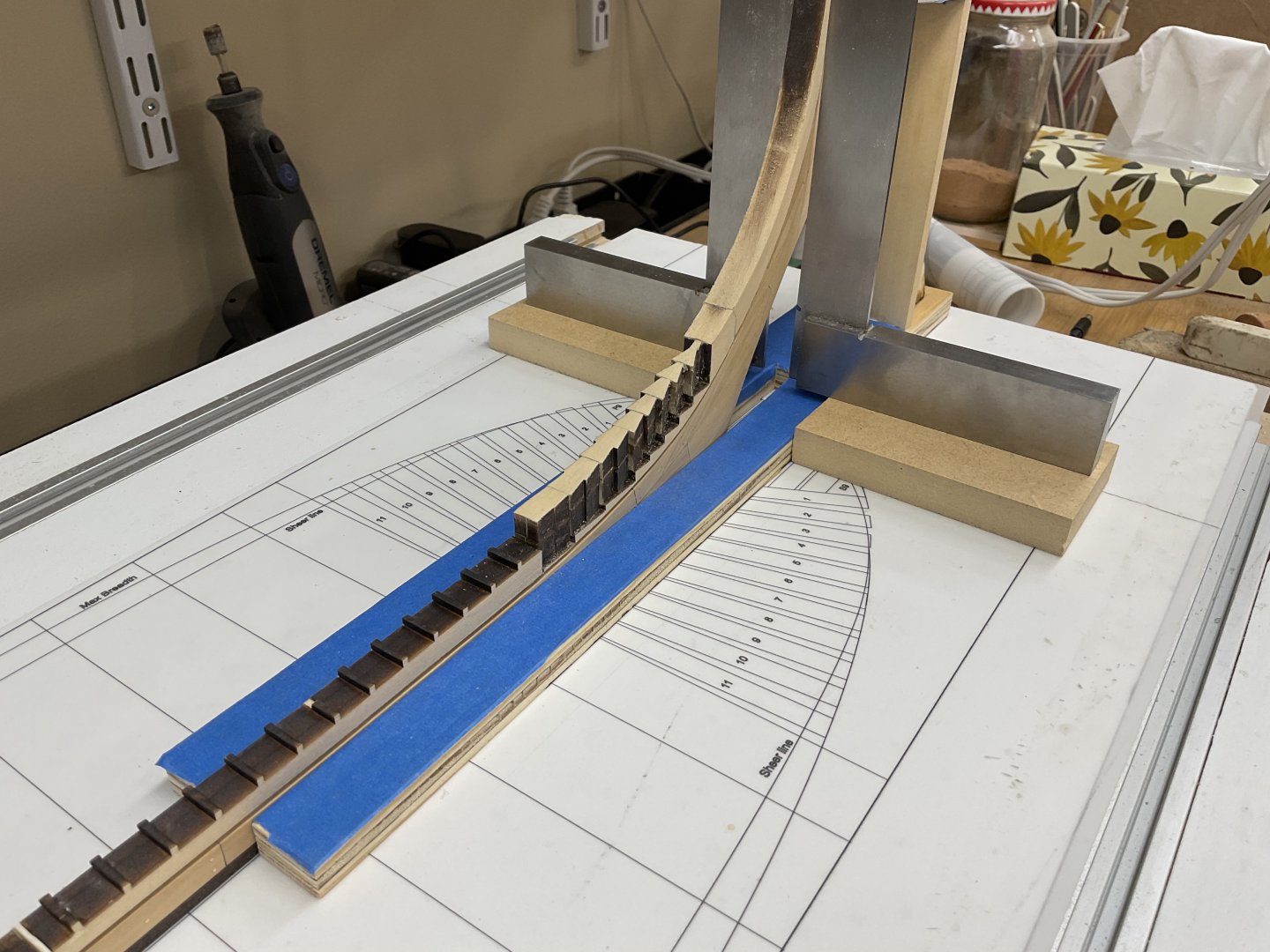

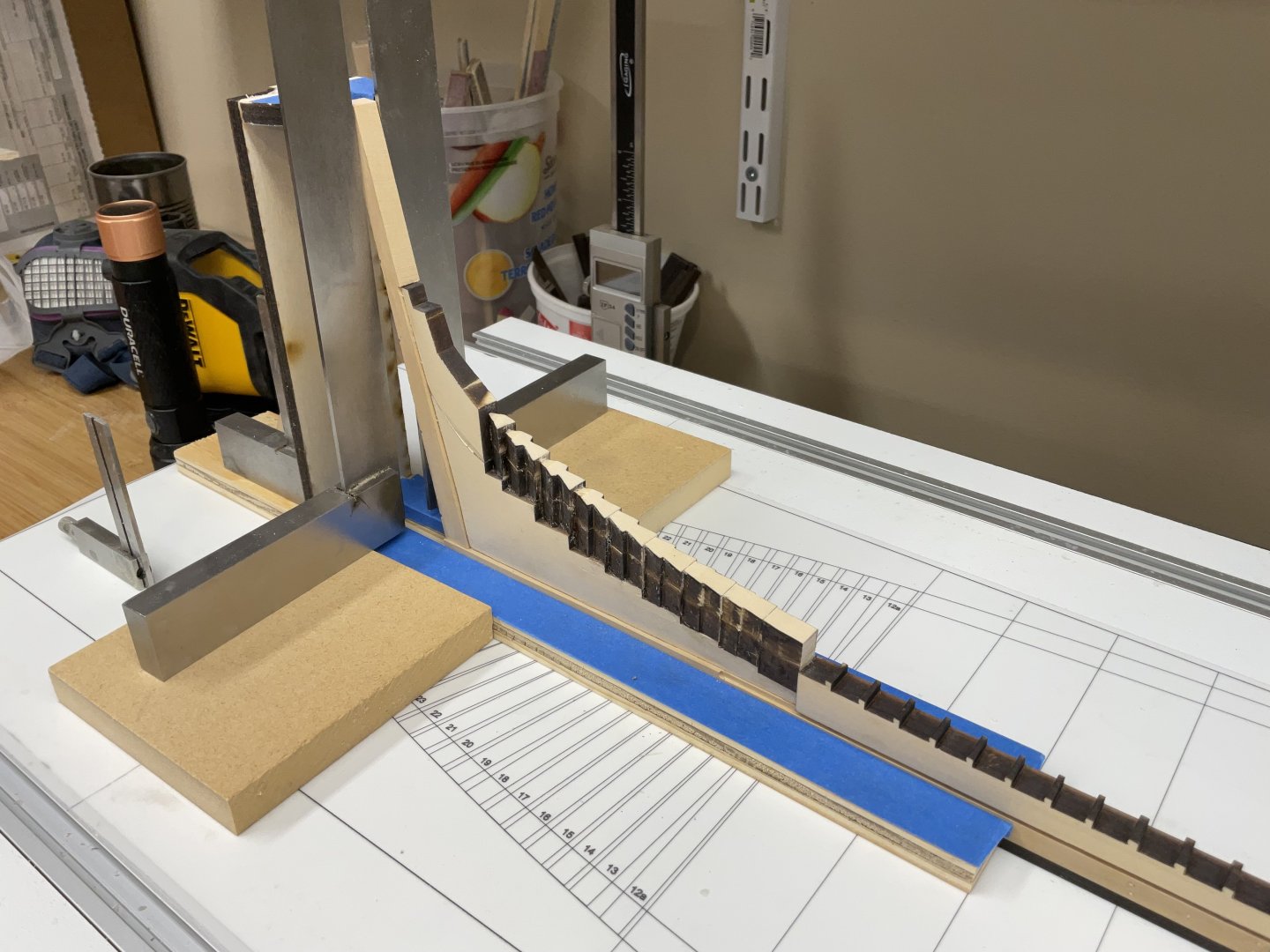

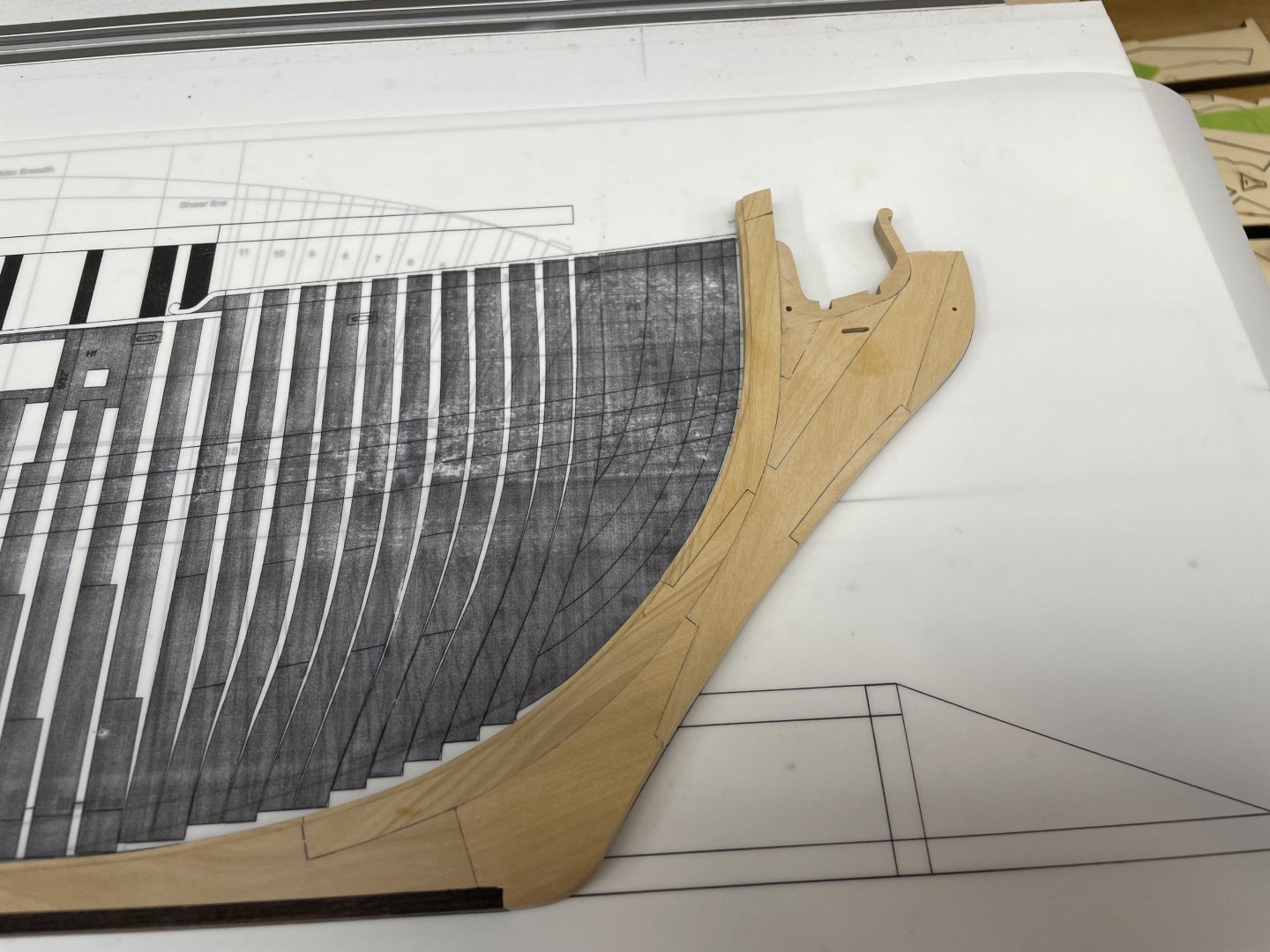

Greetings, Let the real work begin! I am ready to start the frames. I realized that the keel I had made a year ago is slightly thicker than Chuck’s but I think I can get away with a little tapering at the stern when the time comes. The rest of the fittings were straightforward although I had my fair share of screwups. I decided to employ a higher build board jig so that the stern and stem posts were clasped at their tops - though I know that these extensions will get in my way later. I will interchange the lower jigs when the time comes. Cheers, Ian

-

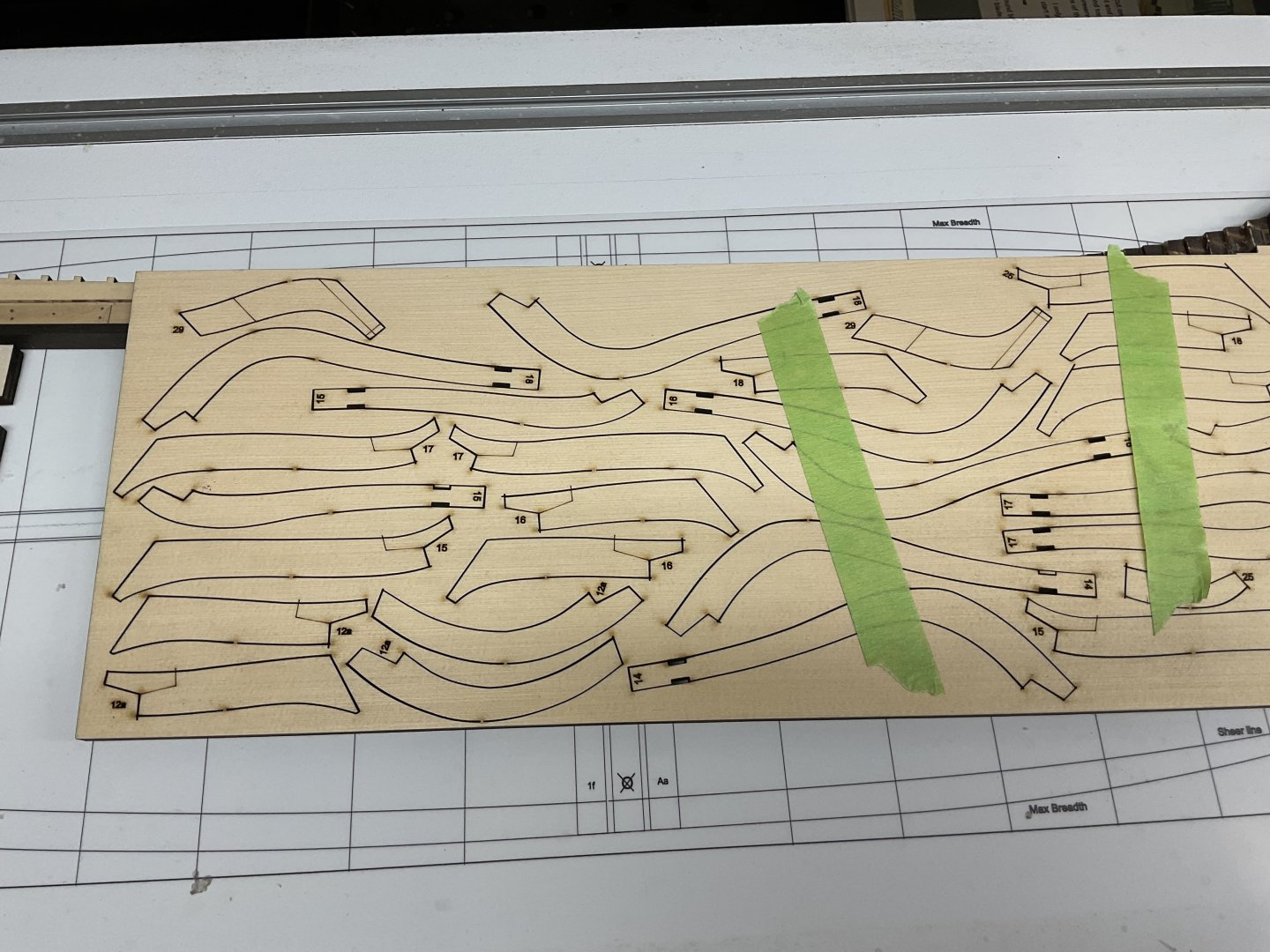

Hi all, Here is my slightly modified version of Chuck’s Speedwell based on Greg and David’s plan. Over a year ago I had planned on upscaling David’s drawings to the same scale as Chuck’s and proceeded to build the keel assembly. After I made some headway I got wrapped up building a CNC mill and learning how to program it. A year flew by as I watched Chuck’s genius in putting together his kit. I could not resist the temptation and decided that I would go the kit way instead, except for using the boxwood (Castello) keel I had already gotten a good start on. Although Chuck’s version of David’s drawings (scaled up) are very similar, they are not identical. However, the keel assembly is close enough (I hope 🫣). I used a router to make the rabbet. The false keel is ebony. I have used a Mylar copy glued onto my building board. Cheers, Ian

-

I puzzled over this for a long time as well but for the life of me I can’t remember what the solution was. I am away from home until next week and will get back to you when I have a look at my model and plans. Hopefully David will lend his guidance before that. You are doing a great job so far. Best, Ian

- 92 replies

-

Beautiful job, Doc! I greatly enjoyed watching this progress. Ian

- 143 replies

-

Paul, just a beautiful job. You should be very happy with the result. Can I ask what’s next? Ian

- 72 replies

-

- Glad Tidings

- Model Shipways

-

(and 1 more)

Tagged with:

-

Beautiful work! I enjoyed following your progress. Thanks for sharing. Ian

- 475 replies

-

Thank you, Bob! Every time I visit my daughter’s place and see the model displayed I think it has to be one of my favourite builds. Ian

- 107 replies

-

- brazzera

- marisstella

-

(and 1 more)

Tagged with:

-

Very, very well done, Bob. Congratulations you should be very proud. Ian

- 111 replies

-

- Nonsuch 30

- Model Shipways

-

(and 1 more)

Tagged with:

-

Absolutely masterful job, Greg and beautiful carvings David! I look forward to building this and hope I can come anywhere close to this. This build log and your books will certainly be a massive help. Ian

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.