-

Posts

862 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by aydingocer

-

-

Build day 44: 2 hrs / Total 96 hours

- Finished hull decorations.

- Installed Hull side steps.

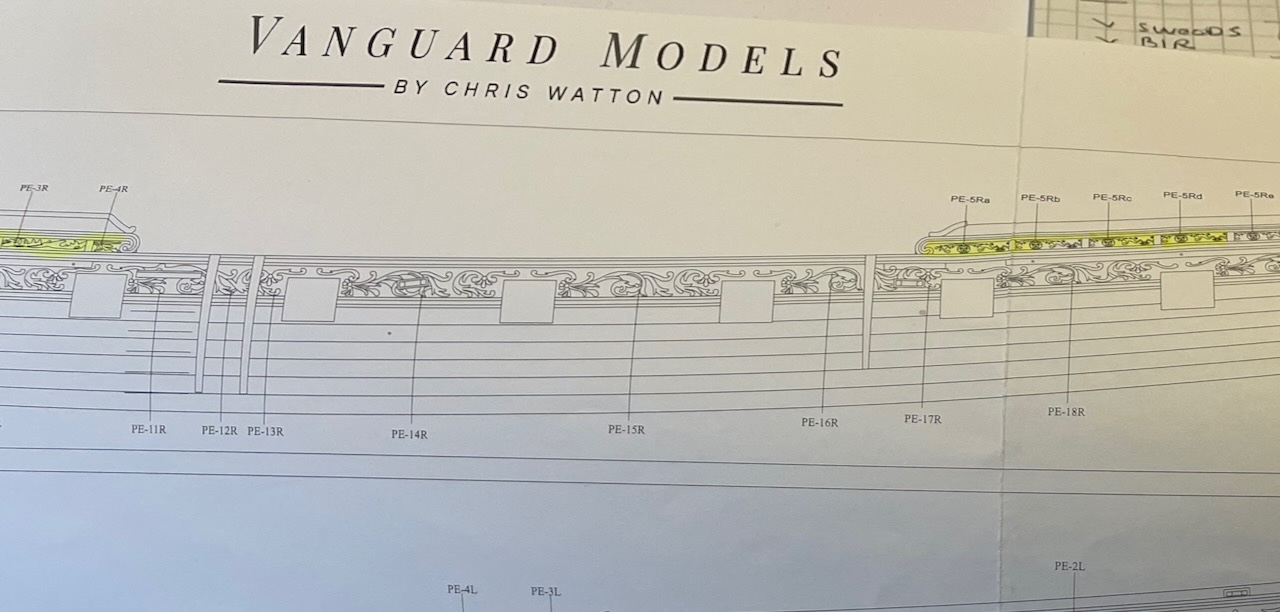

Photos 449-451: Some photos showing the hull decorations. The whole process went rather smoothly. In s few spots I had to trim the PE to fit in place. They were mainly under the channels.

- BobG, mtaylor, Knocklouder and 1 other

-

4

4

-

-

-

-

Build day 43: 3 hrs / Total 94 hours

Continued with

- Quarter deck roof structure

-

Hull decorations

- preparation (prime, paint, seal with varnish)

- gluing

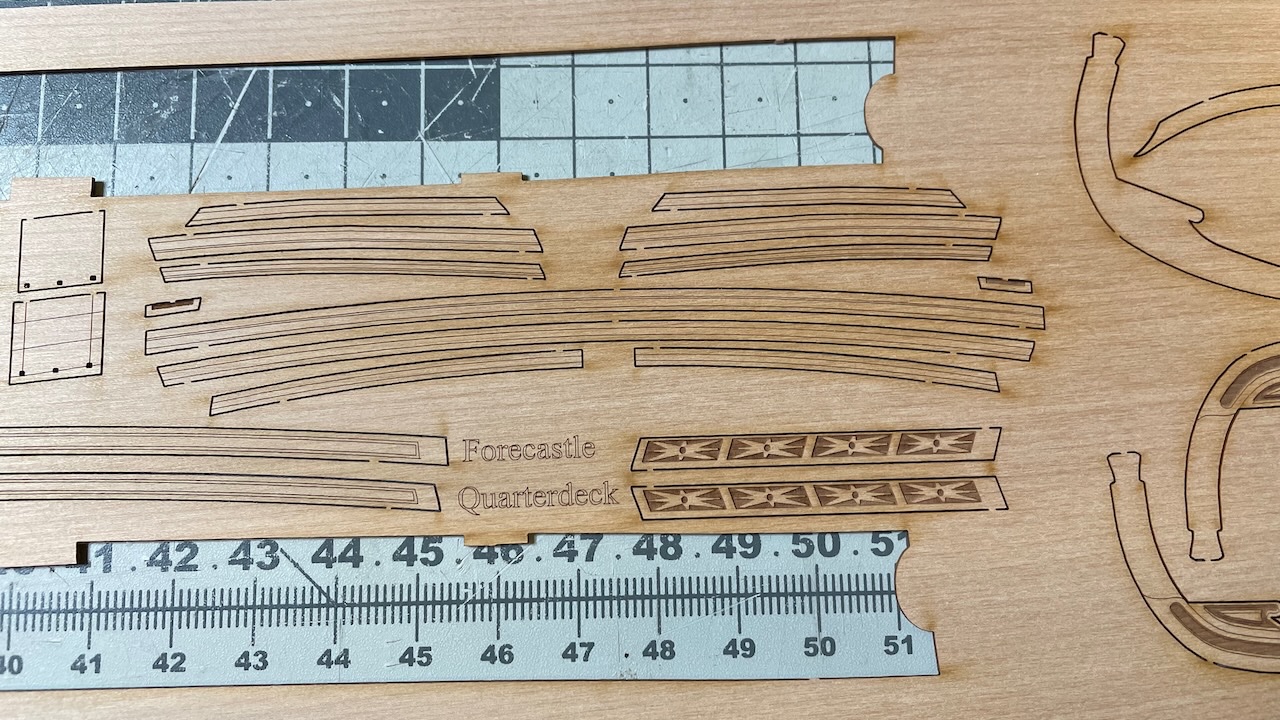

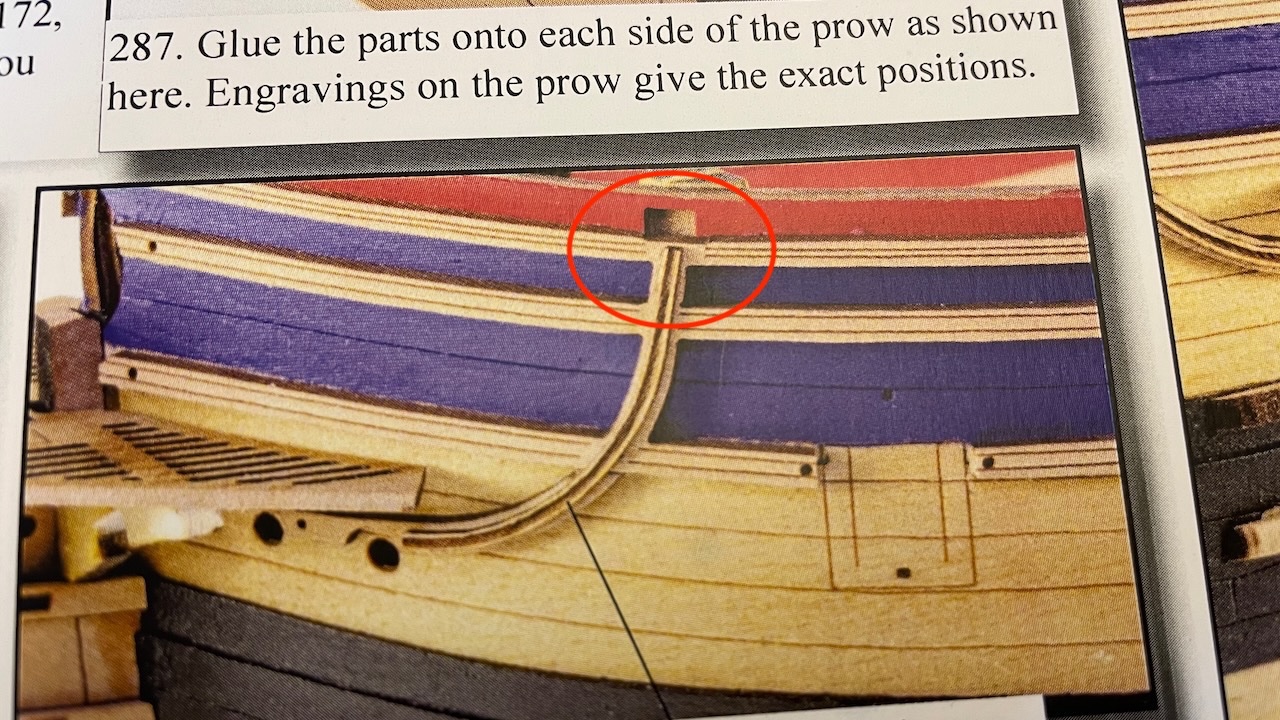

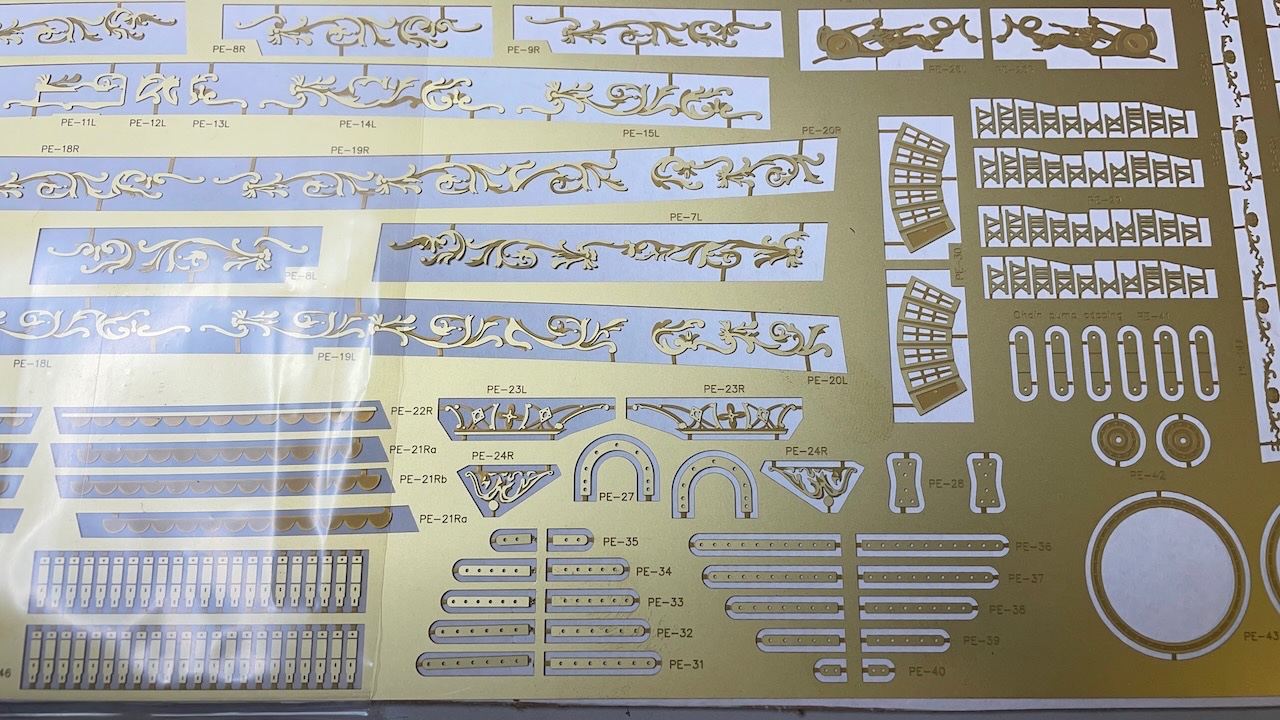

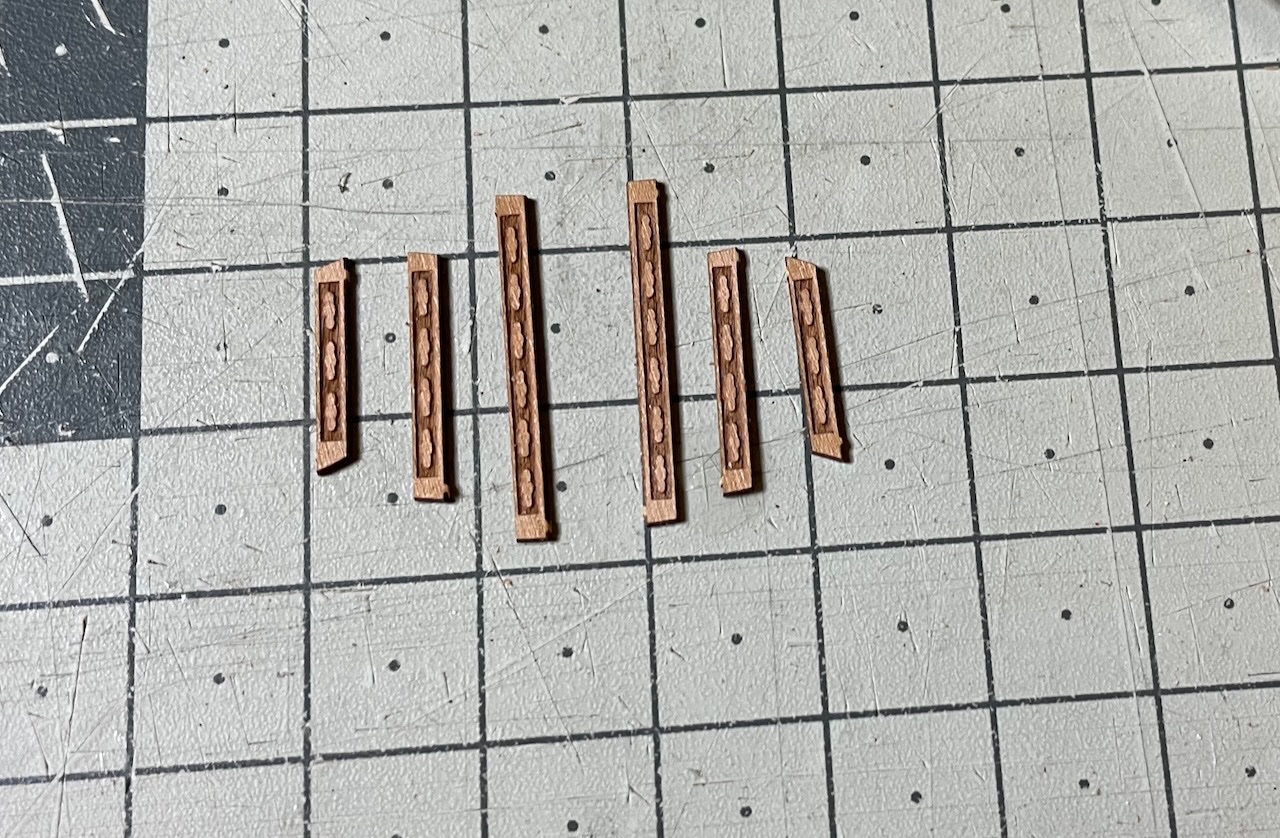

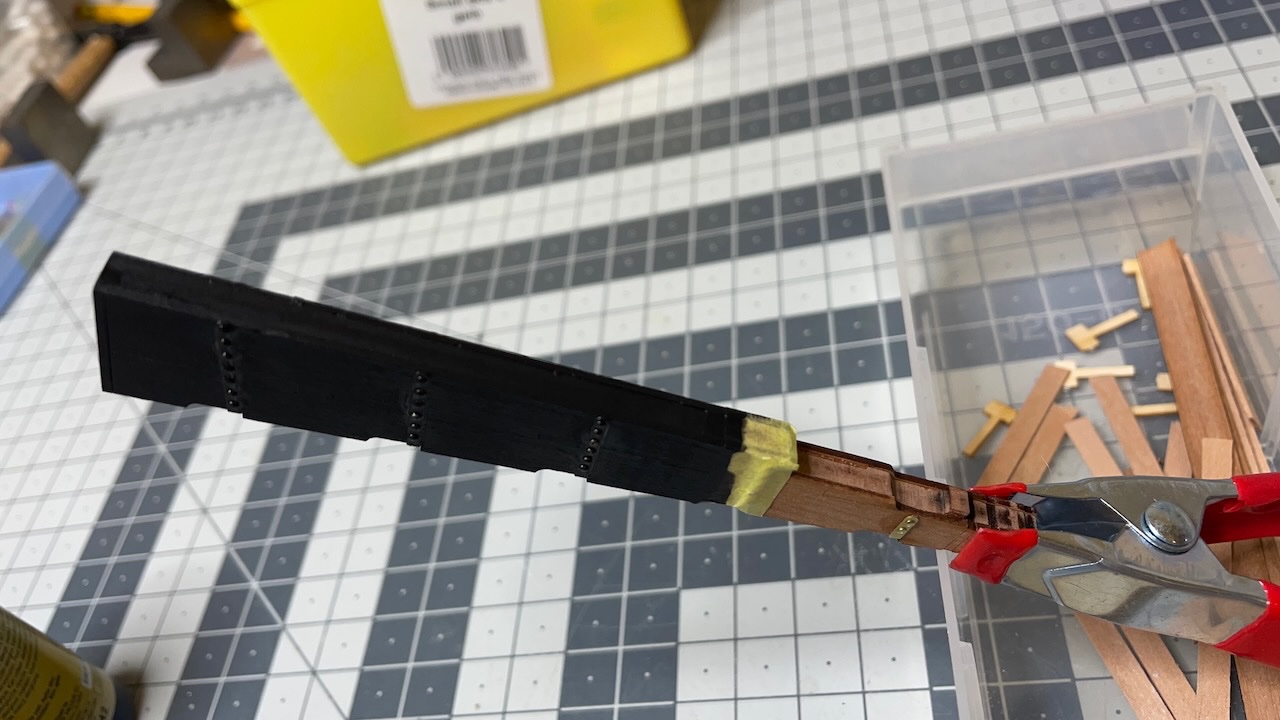

Photo 442: Quarter deck roof tiles, from photo etched sheet. The photo was taken after I had already started fitting the hull decoration, as seen on the right side.

Photo 443 : One of the longer parts. With 0.2mm thickness and even less on the engraved areas, these parts deserve replacing the knife with a new sharp blade before removing.

Photo 444: Gluing in progress.

-

Build day 42: 2 hr / Total 93 hours

Photo 441: All stern decorations in place and with the name plates installed, now my ship is officially SPHINX!

. I will need to rest my eyes for a while after this tiring work. But after all I can confidently say the result was worth it.

. I will need to rest my eyes for a while after this tiring work. But after all I can confidently say the result was worth it.

-

-

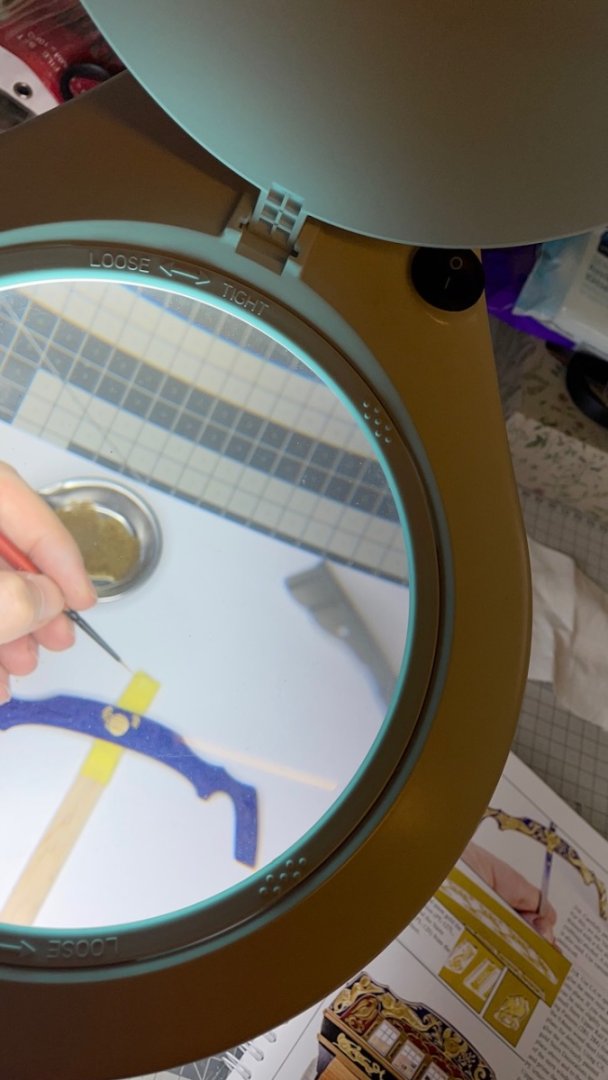

Photo 439: This is the first time ever for me to do such an intricate paint job. I use 3/0 (or 000) paint brush and do it under magnifying table lamp.

Before that, as instructed, I rested the resin stern decoration in very hot (just boiled) water briefly (10-15 seconds) to bend it to follow the stern fascia curve.

Photo 440: Overall I am happy with the result.

-

Build day 41: 1 hr / Total 91 hours

Football World Cup started yesterday and will certainly impact my pace

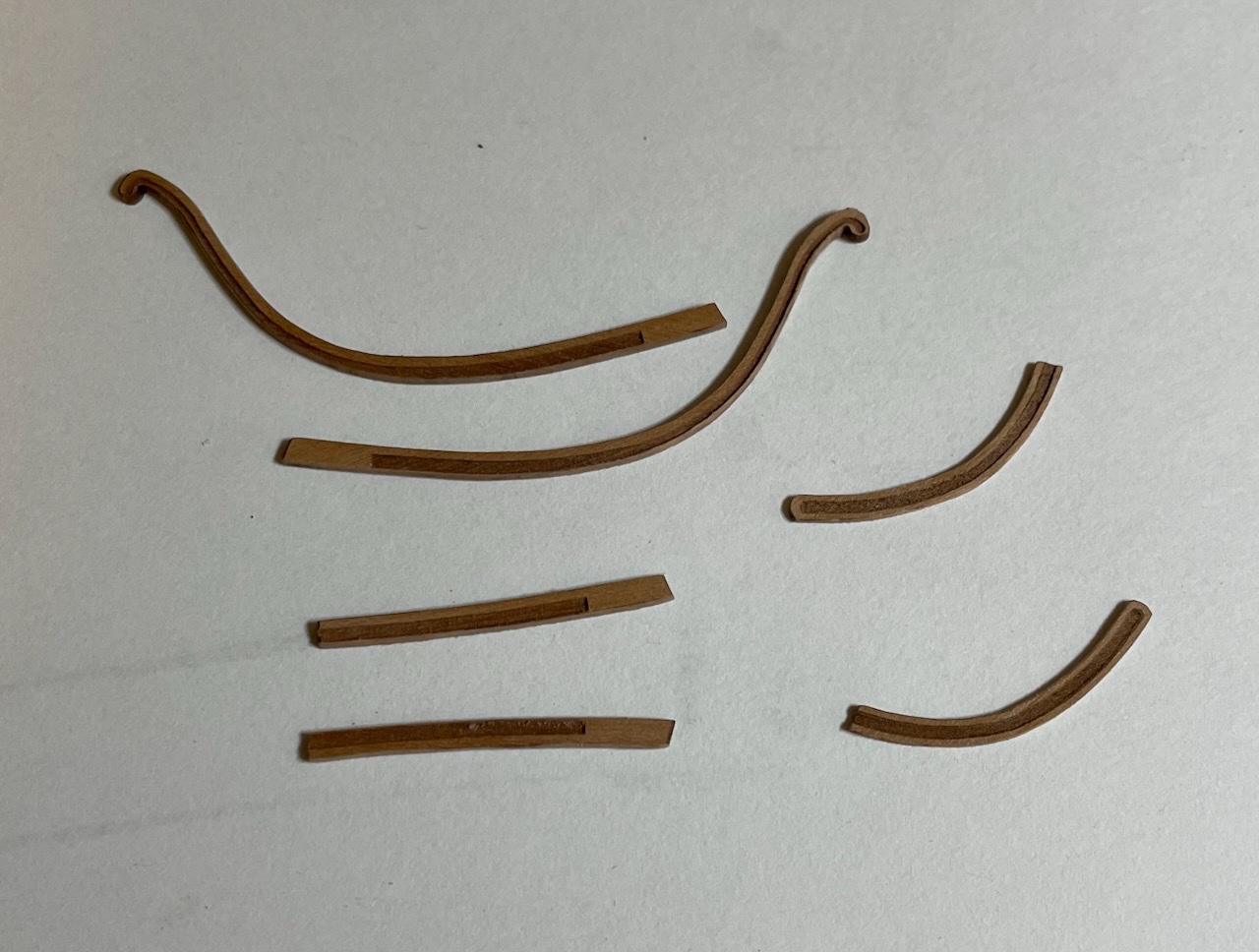

Today I managed to glue the Quarter Gallery Rails, Quarter Gallery Upper Fretwork and paint the Stern Decoration between the games.

Photo 406: Quarter Gallery Rails and Quarter Gallery Upper Fretwork. I haven't taken a photo from the back yet but two rails align nicely with those rails on the stern.

-

Photo 403: Stern Wing Transom Rails – Left & Right, the Stern Lower Counter Rail and the Stern Upper Counter Rail. (the 4 parts in the middle of the photo)

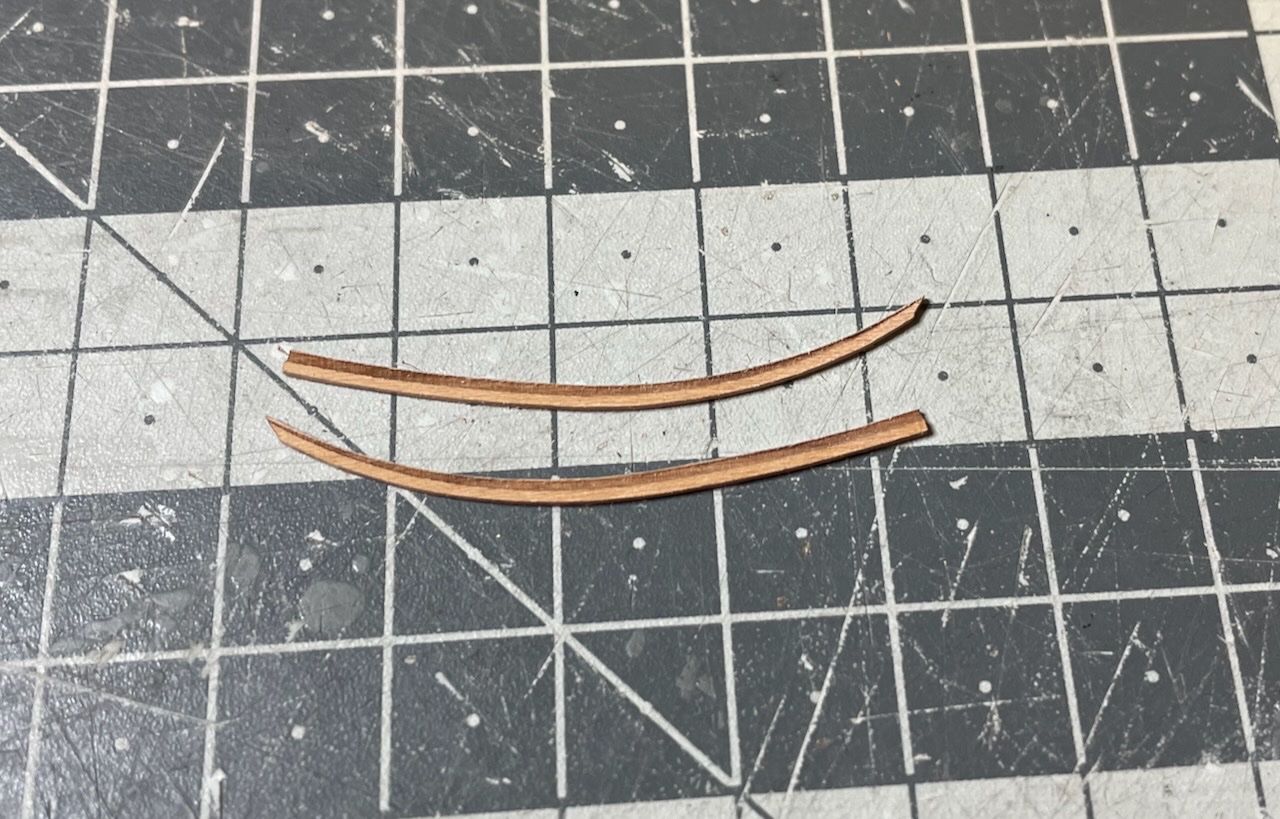

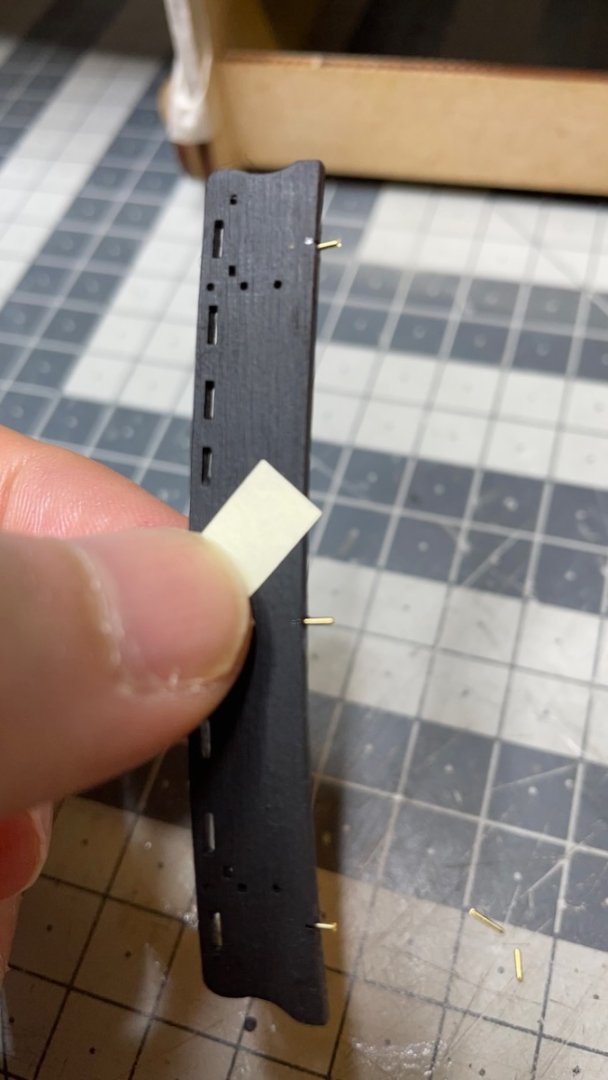

Photos 404-405: I have a slight gap between the stren facia and the the black part. This is from when I was installing the inner pieces. Normally it should not be there. But anyway, now is the time to take care of that gap. I copied the contour of the upper counter rail where I had removed the part from the sheet and used a scrap part from 0.6mm wood to make a filler strip. With painting it to black, it is difficult to notice it, looks quite good.

With the gap:

Gap filled with custom strip:

- ccoyle, Oldsalt1950, mtaylor and 1 other

-

4

4

-

-

Build day 40: 4hrs / Total 90 hours

I am logging two days' work today. This is build day 40.

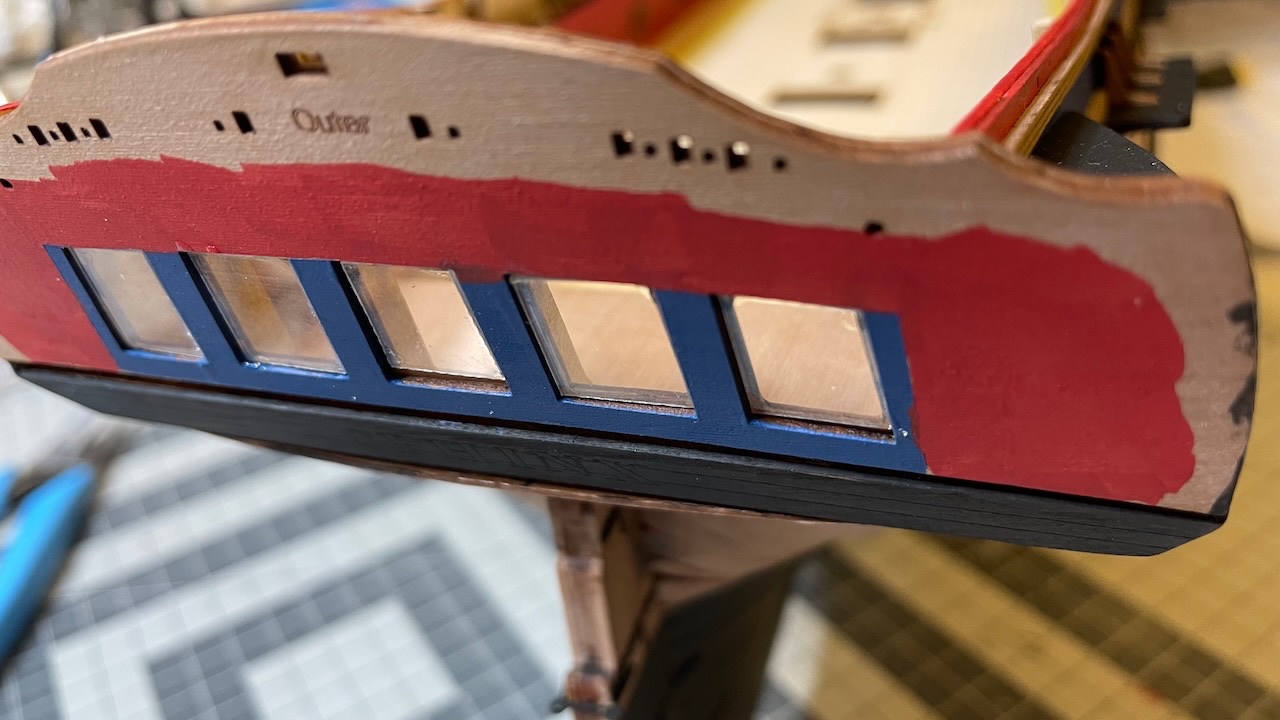

More stern work. Instructions recommend to use acrylic transparent varnish for gluing the window glasses (made of PVC) and for the frames instead of CA glue, to prevent fogging of the PVC windows. However I tried with scrap piece of PVC a tiny amount of CA only on the corners and didn't experience any fogging, therefore I decided to use CA. Note that use a pecision glue nozzle, which allows me to apply the glue in really small amounts.

Photo 398: Started to install windows and frames.

Photos 399-400: At this stage you also paint the stern to its colors.

Photo 401: Stern window frames also in place.

-

Photo 397: Last task of the day is to paint the deck window frames. For these I used Vallejo primer, followed by Admiralty acrylic white and finished with Vallejo Model Air white. Model Air, with its thin consistency, provides a more smooth finish on tiny surfaces like these frames.

-

-

-

Build day 39: 3hrs / Total 86 hours

Photo 335 : Bow Cheeks and Hawse Bolsters. These are going to be painted in black therefore no need to remove the laser chars.

Photo 336: Bow cheeks in place. Before installing the Hawse Bolsters, you'll need to enlarge the two hawse holes to around 4mm diameter. Currently they are around 2mm diameter. I wonder why they were not laser cut to the correct diameter at first place. Maybe because you'll need to open up the wood behind it anyway. In the photo you see the hole on the left has been opened up, while the one on the right is in original size.

Photo 391: I used this blade for this work.

-

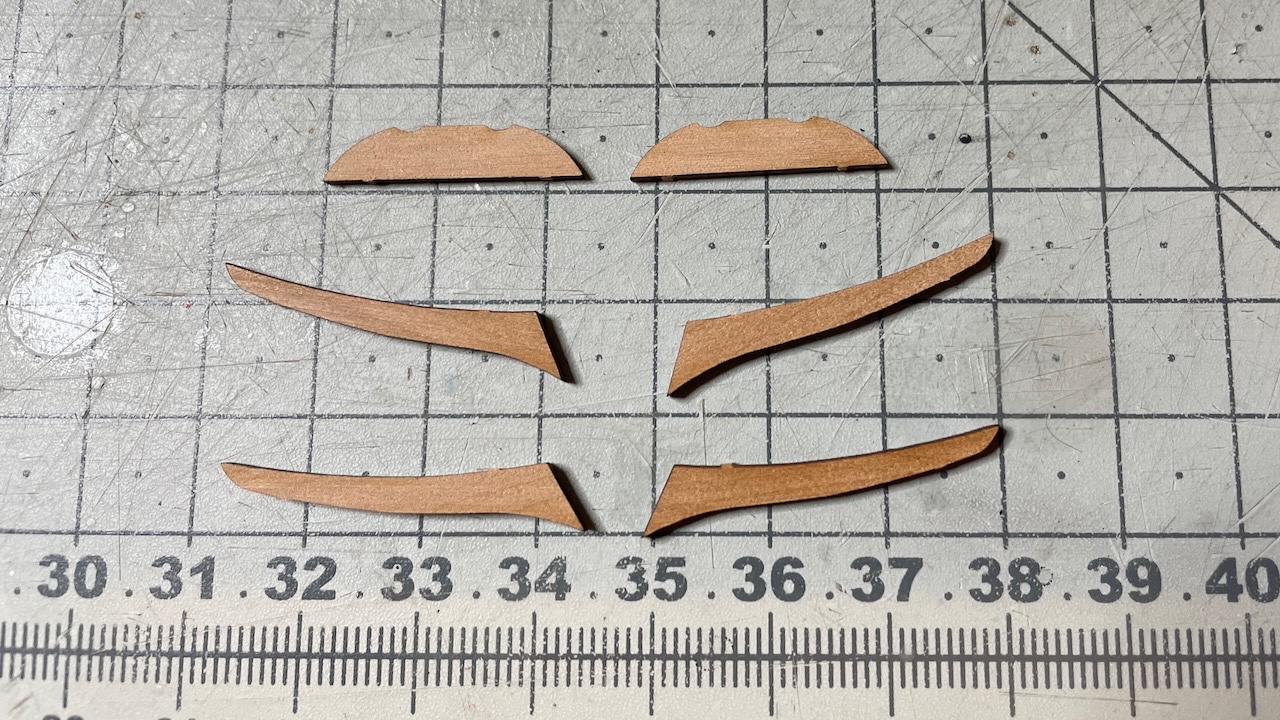

Photo 332: Next, Bow Hair Brackets, Bow Lower Rail and "Ekeing Mouldinf Patterns". Took about half an hour to remove the laser char carefully from the edges. I used 400 grit sandpaper for this.

Photos 333-334: In the first photo below, see the Ekeing pattern, ending at the lower rail, while in the instructions (second photo) it goes all the way to the upper rail. I wonder if this is something changed since the prototype. There is also one pair of them in spare, should I cut from the spare part and amend it to the upper end so that it looks the same as in the instructions? Any suggestions?

-

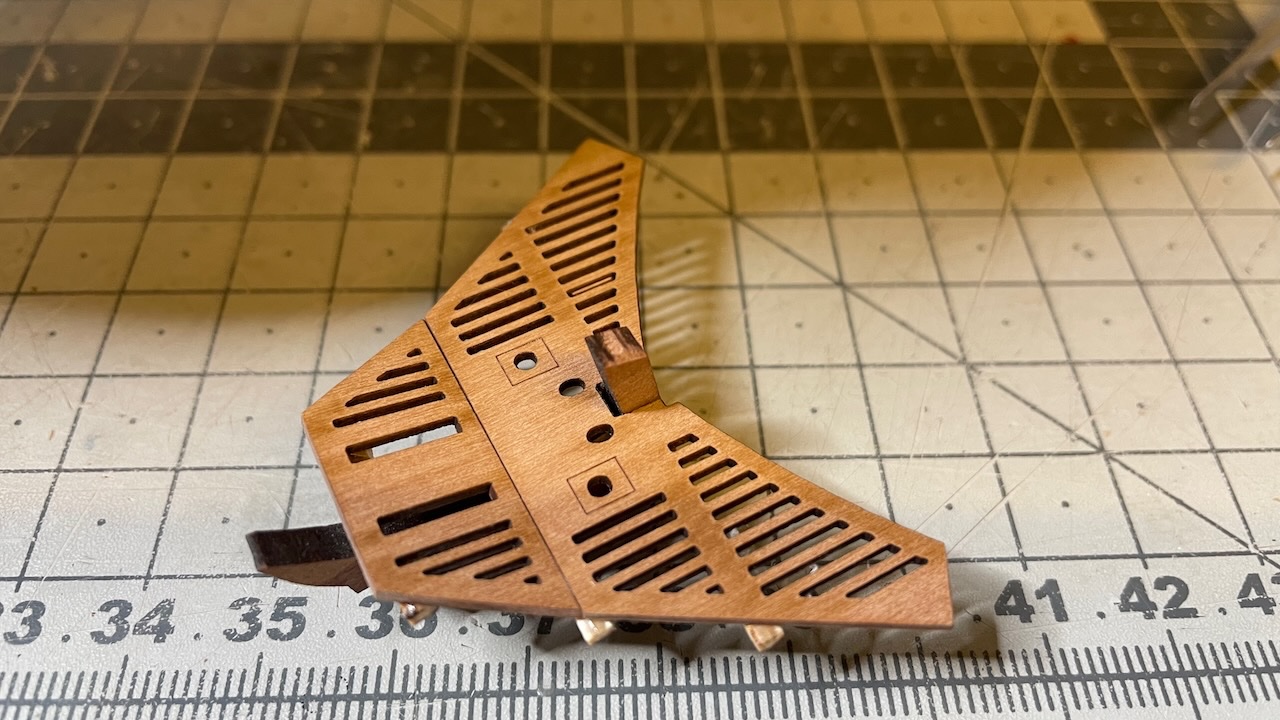

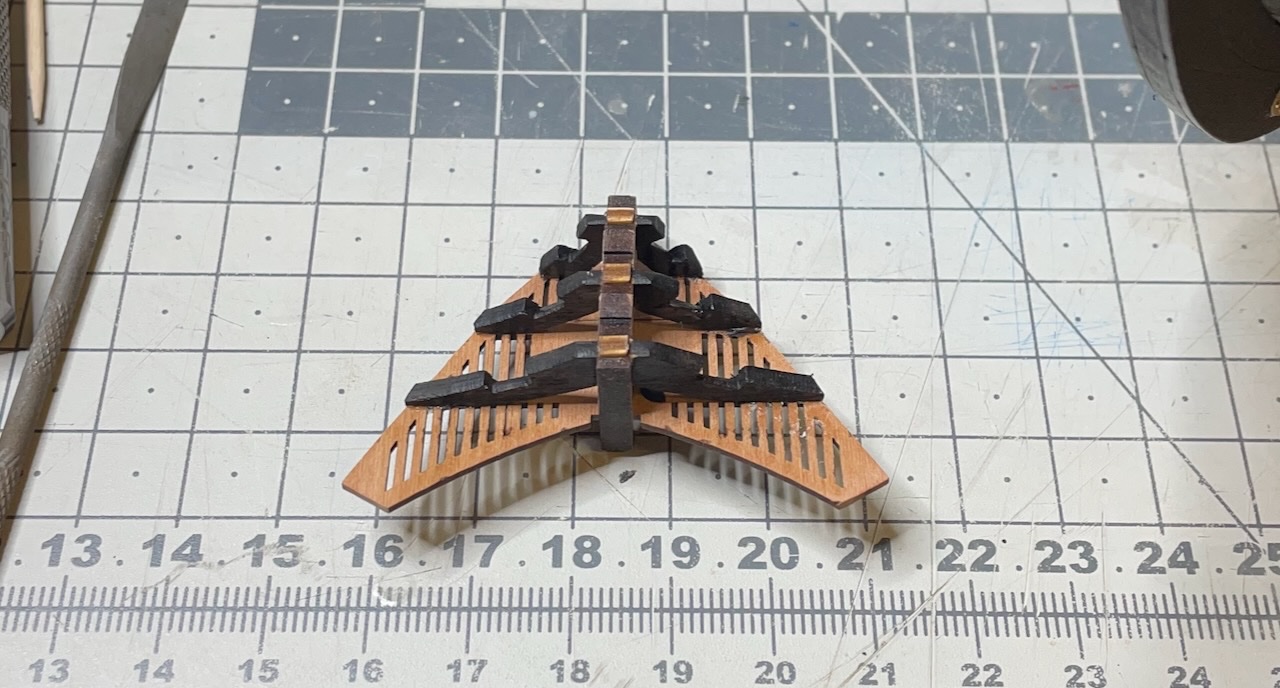

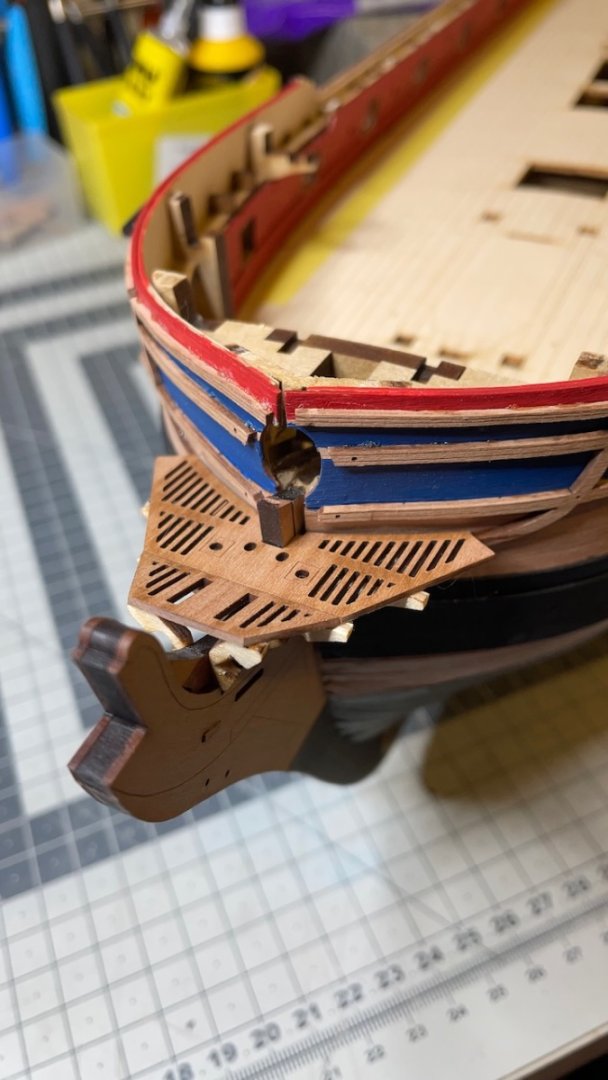

Photo 326: Parts for the bow section. The wings (on the right side) take some bevelling from several areas.

Photo 327: Wings fitted to the "Gammoning knee"

Photo 328: Dry fit to adjust the bow gratings

Photo 329: Bow gratings glued in place. Note the wing ends visible from the sides. They will be filed flush with the grating.

Photo 330: Wings painted in black

Photo 331: Grating in place. I managed to break the inner piece while inserting the structure back in its place, hence the crack line in the middle. Not a big deal.

-

Build day 38: 5hrs / Total 83 hours

Today's activity:

- Fore-, main- and mizzen channels,

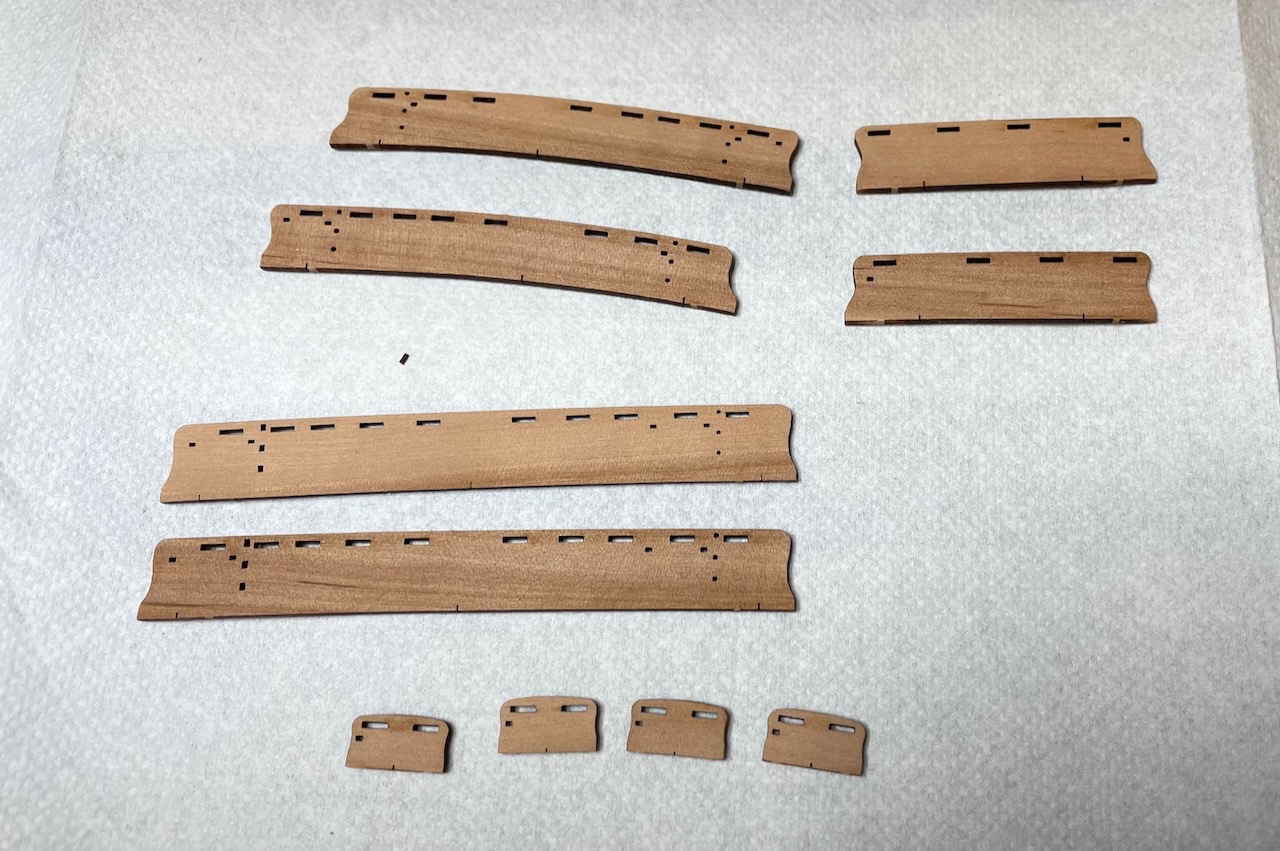

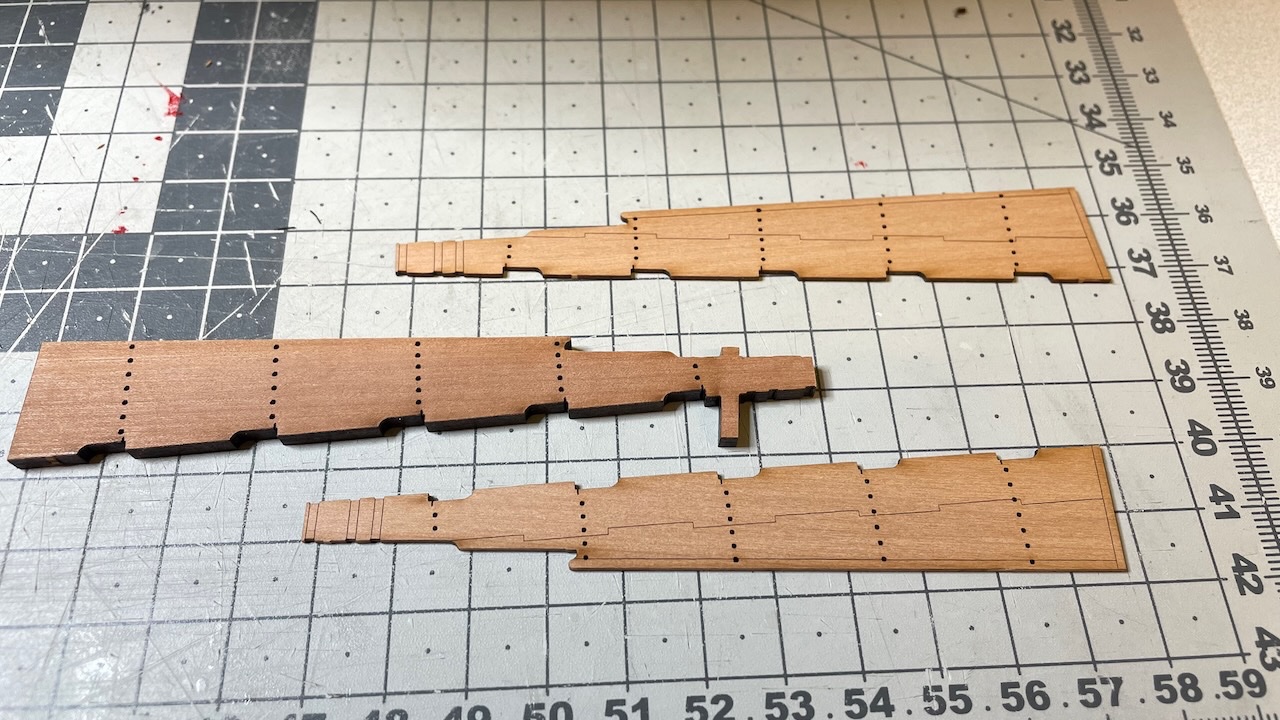

- Bow area gratings.Photo 320: Channel parts removed from sheet and sealed with matte varnish

Photo 321: You drill holes on the side from spots marked with laser. In these holes we insert the nail cut-off leftovers from earlier stage.

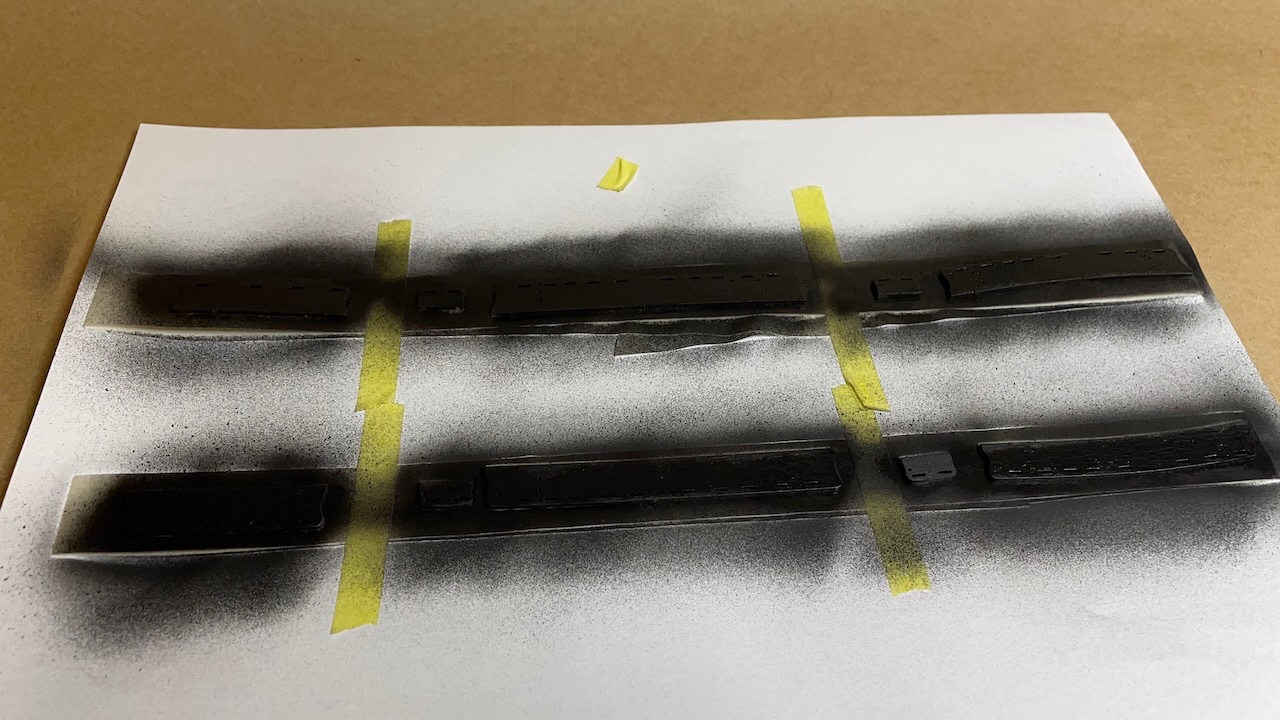

Photo 322: Parts painted in black using airbrush.

Photo 323: Pin cut-offs inserted. They will help install the channels precisely in place by fitting into the ready holes on the hull.

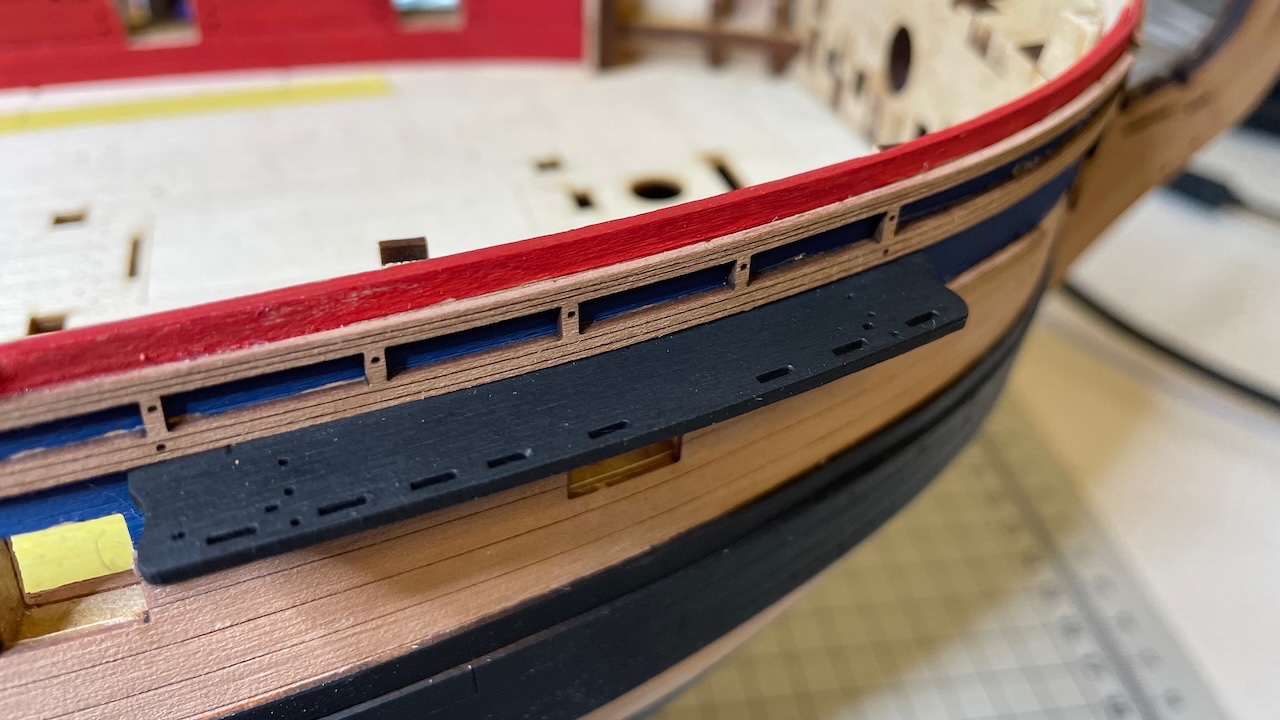

Photo 324: First channel in place.

Photos 325: All channels installed including the so called "Channel knee parts" (those L shaped parts resting on the rails and the channels)

-

Build day 37: 2hrs / Total 78 hours

Rudder ready and installed in place. Also glued the horseshoe and fishplates in their places. I don't have a copper color so I chose a Vallejo Old Gold which was available in my paint box. It is a bit more on the red spectrum and looks good enough for copper on small surfaces such as these ones.

Photos 318-319: Rudder, fishplate and horseshoe

- DonSangria, BobG, ccoyle and 1 other

-

4

4

-

-

-

-

Rudder construction.

Photo 308: Removed 3 rudder pieces. The central piece is thicker, while the two outer pieces with engraved patterns are thinner.

Photo 309: Glued together carefully ensuring that the pinholes align.

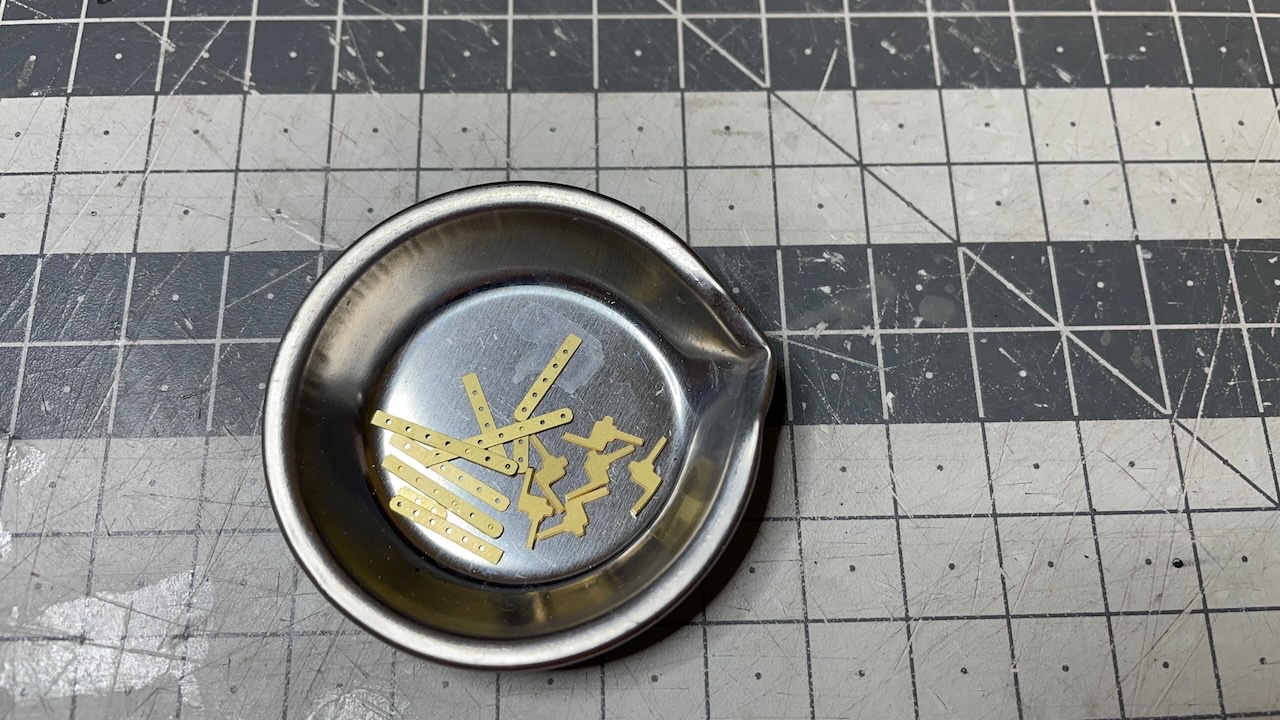

Photo 310: First photo ethced work of this construction. Very delicate parts. We need PE-31 to P-35 for rudder.

HMS Sphinx 1775 by aydingocer - Vanguard Models - 1:64 - Revision #2

in - Kit build logs for subjects built from 1751 - 1800

Posted

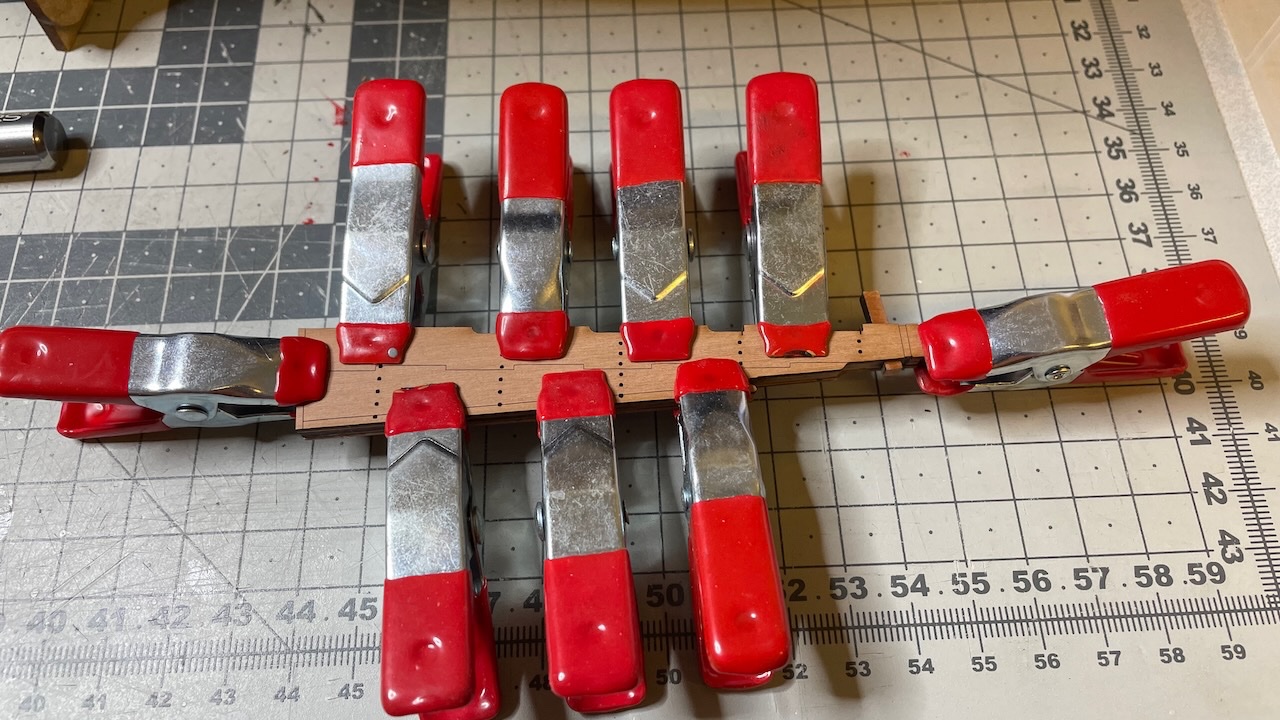

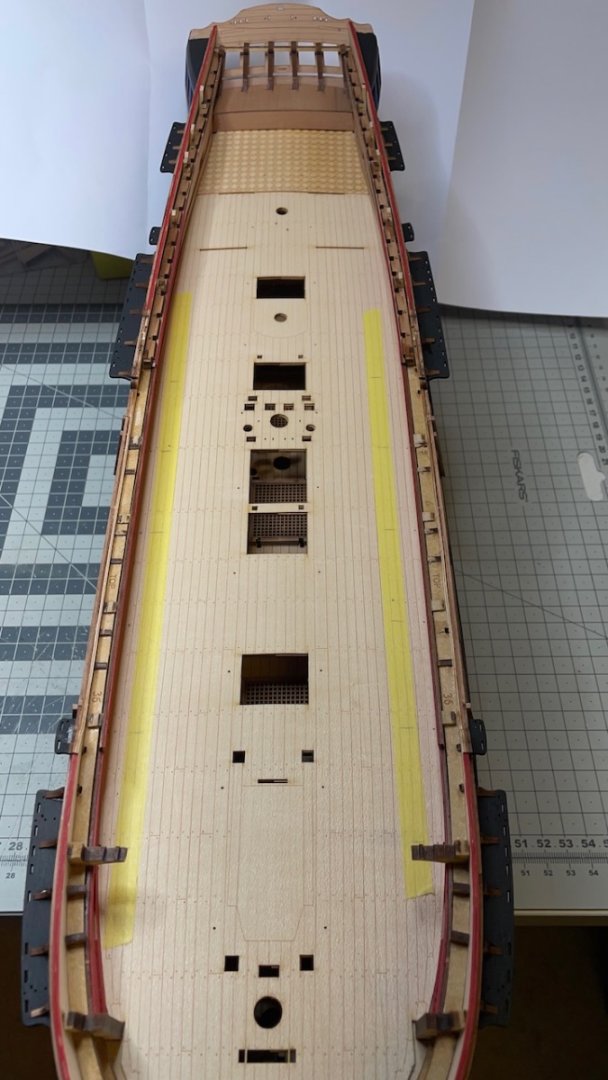

Photos 452-455: Hull side steps prepared, glued and painted. It is essential to refer to the plan sheet for accurate and correct positioning of these.