-

Posts

898 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by aydingocer

-

-

-

-

-

Build Day 31: 1hr / Total 62 hours

After sanding, one layer of wood filling looks good enough to me. I prefer the wood plank patterns exposing a little under the paint than having a perfectly smooth painted hull. To me it gives a more handmade look than ready made hull. It is a question of taste.

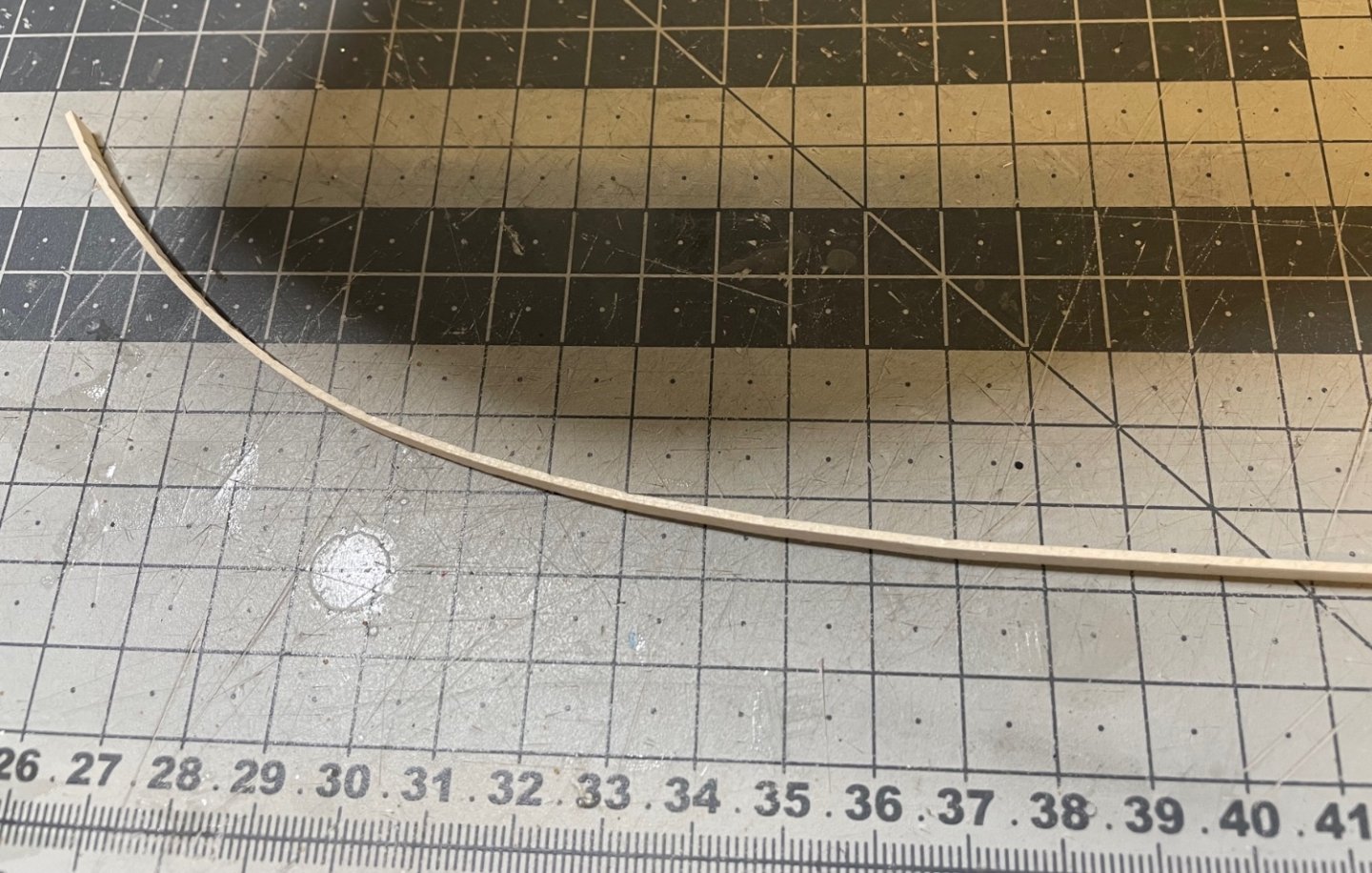

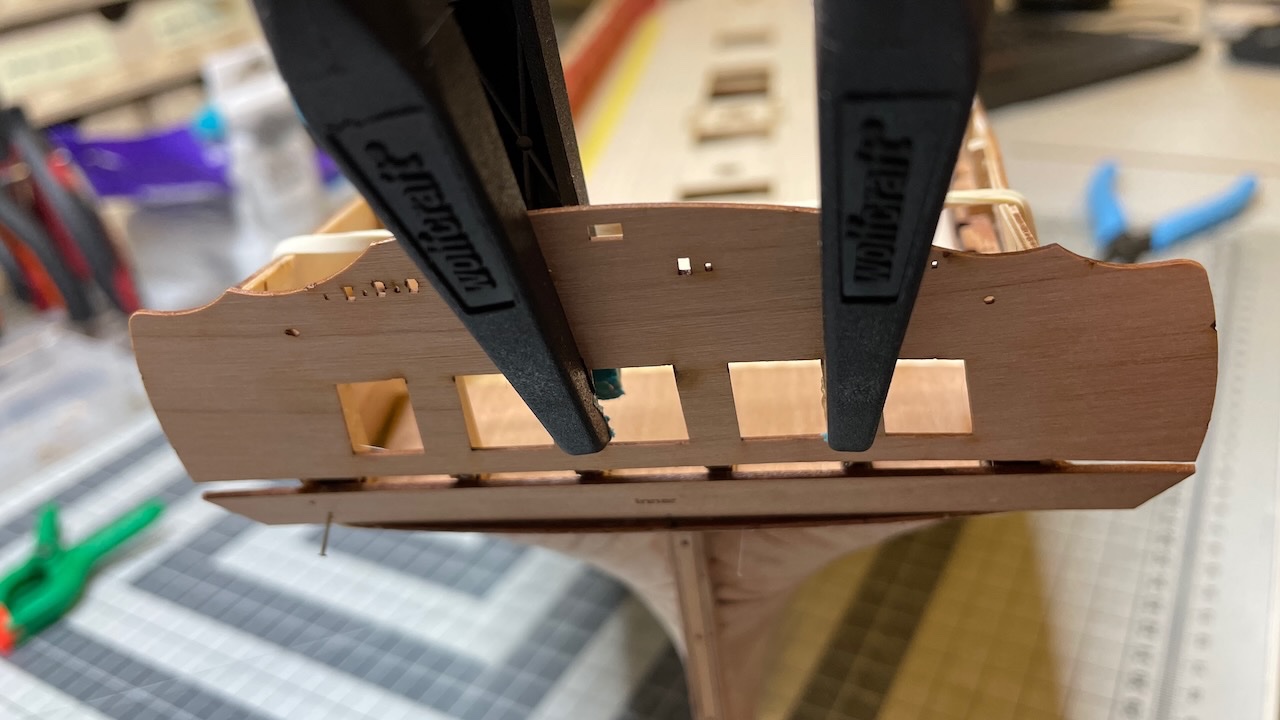

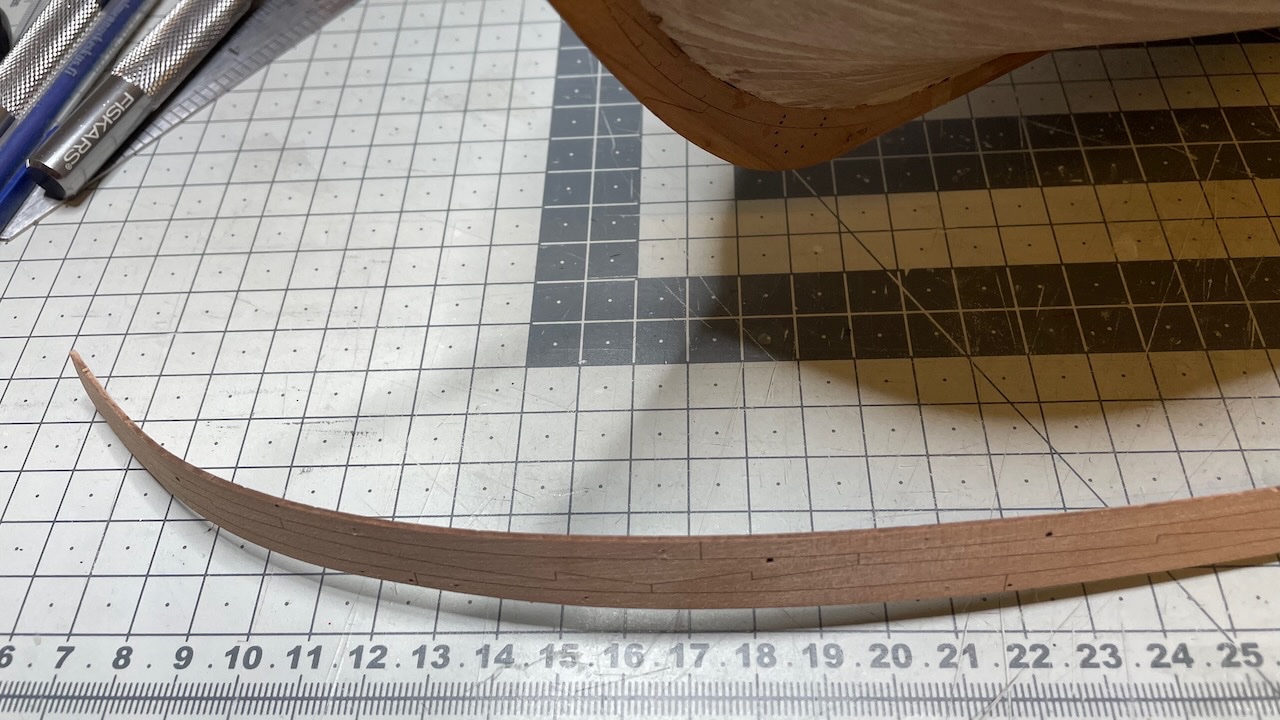

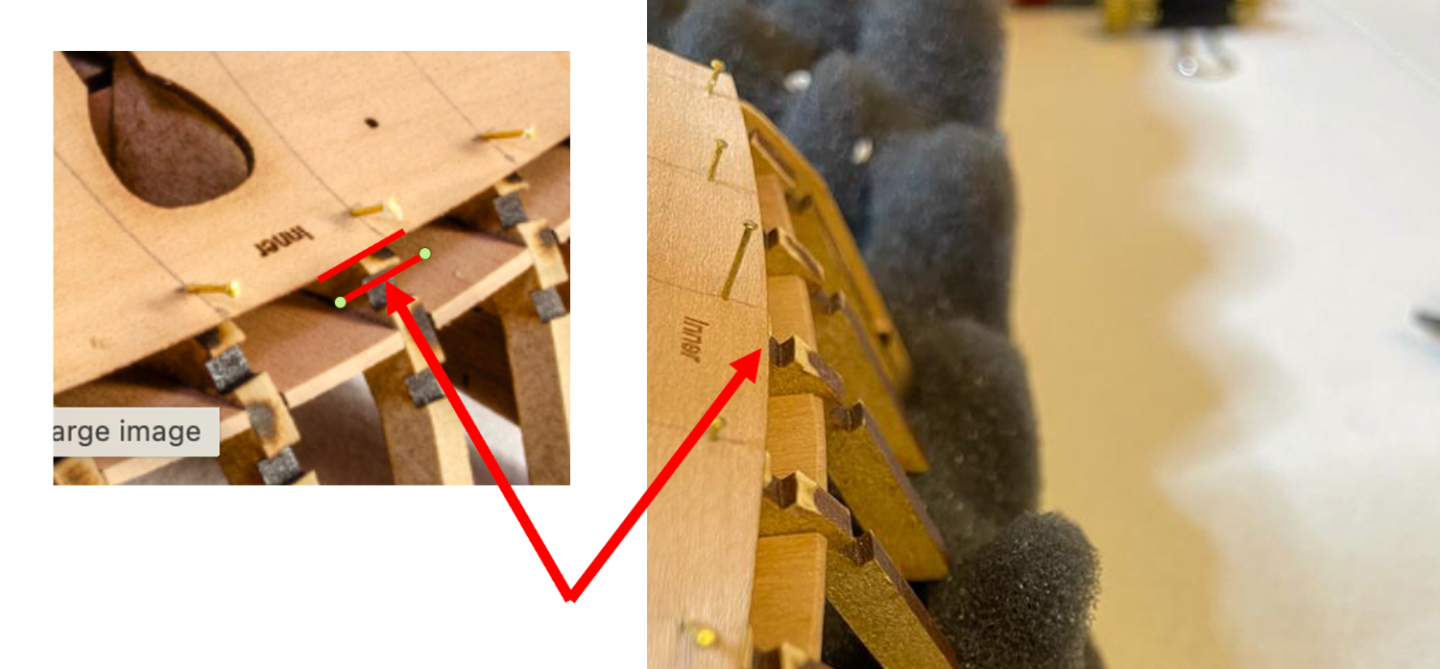

Photos 267-269: Main whale patterns soaked in hot water for 30mins and pinned temporarily in place to dry and get the shape. These are thicker than the parts we did the same procedure earlier (1mm vs 0.8mm) therefore 30 mins is the minimum you should keep them in water. It was enough to soak only the front section where it will bend. Now it will rest at least 24 hours.

- chris watton, DonSangria, mtaylor and 2 others

-

5

5

-

- CiscoH, Glenn-UK, CaptnBirdseye and 2 others

-

5

5

-

- Knocklouder, BobG and mtaylor

-

3

3

-

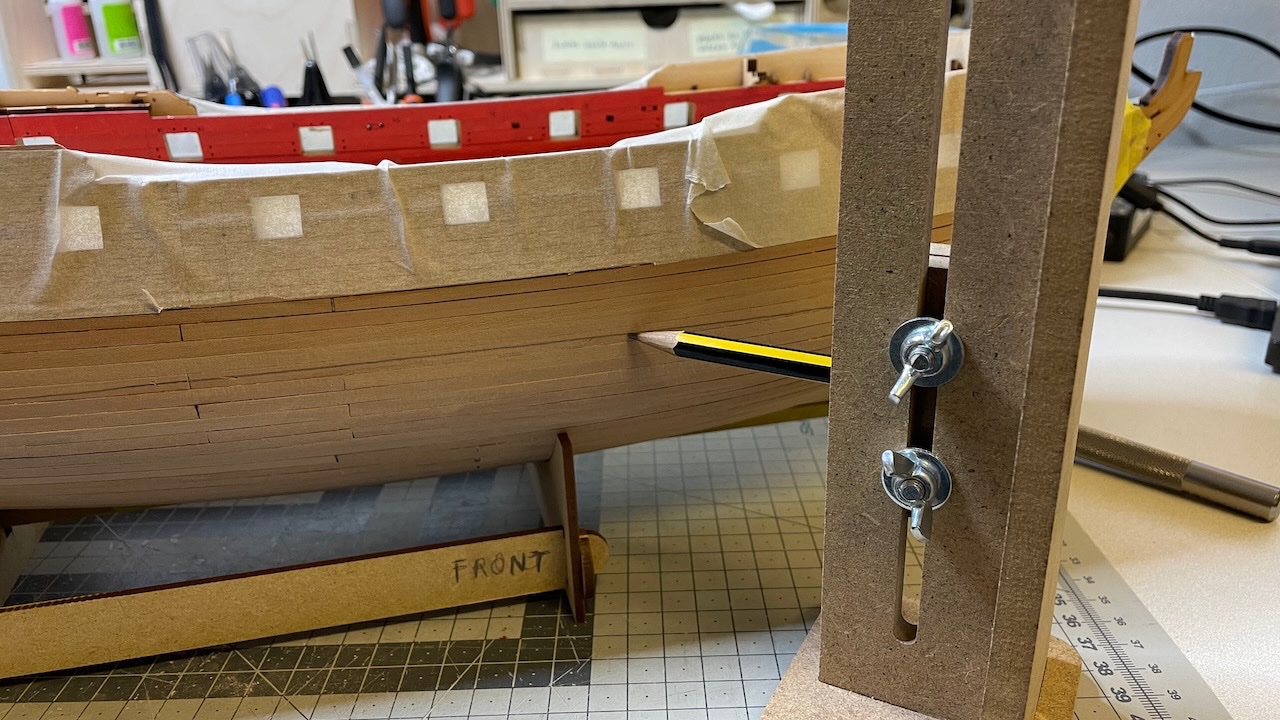

BUILD DAYS 27-30: 14hrs / Total 60 hours

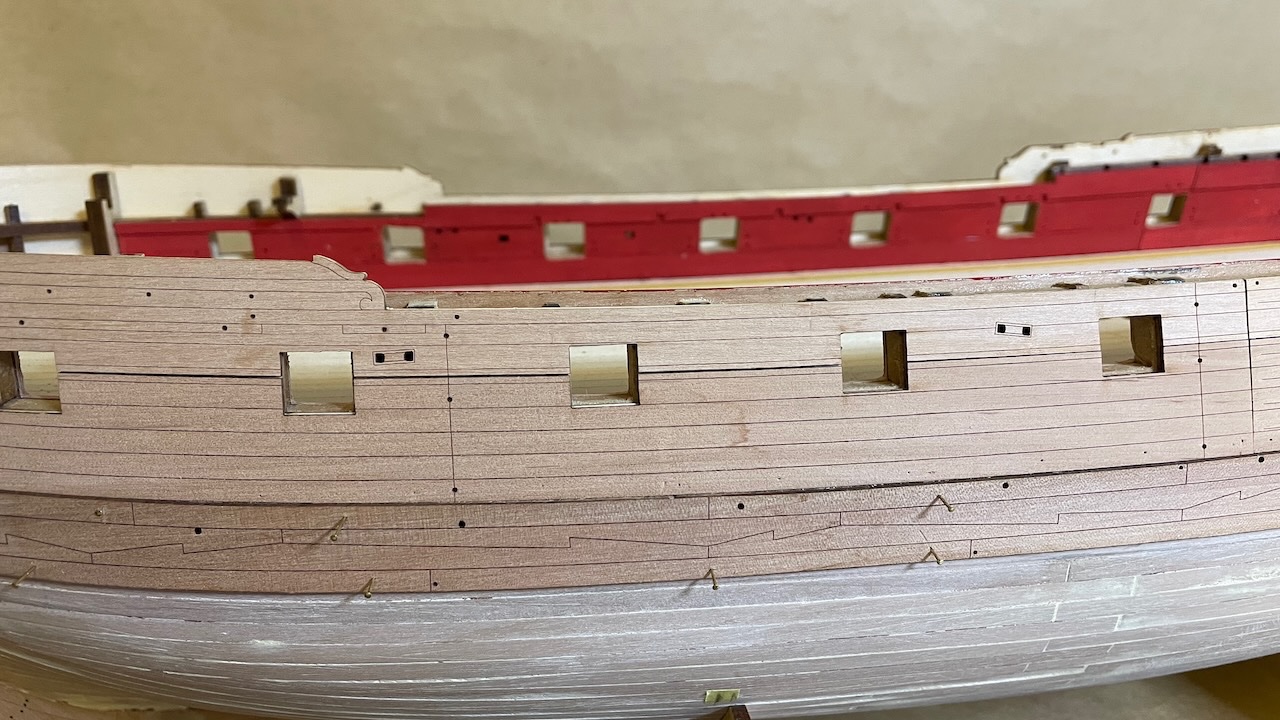

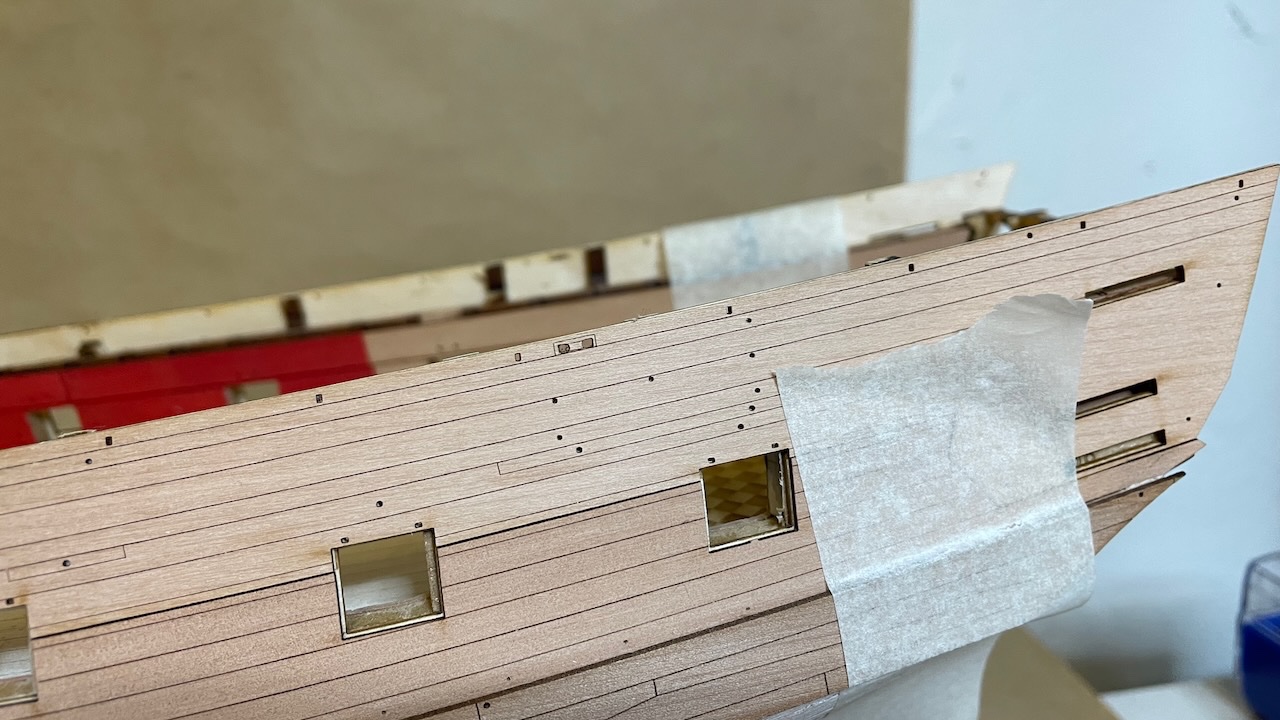

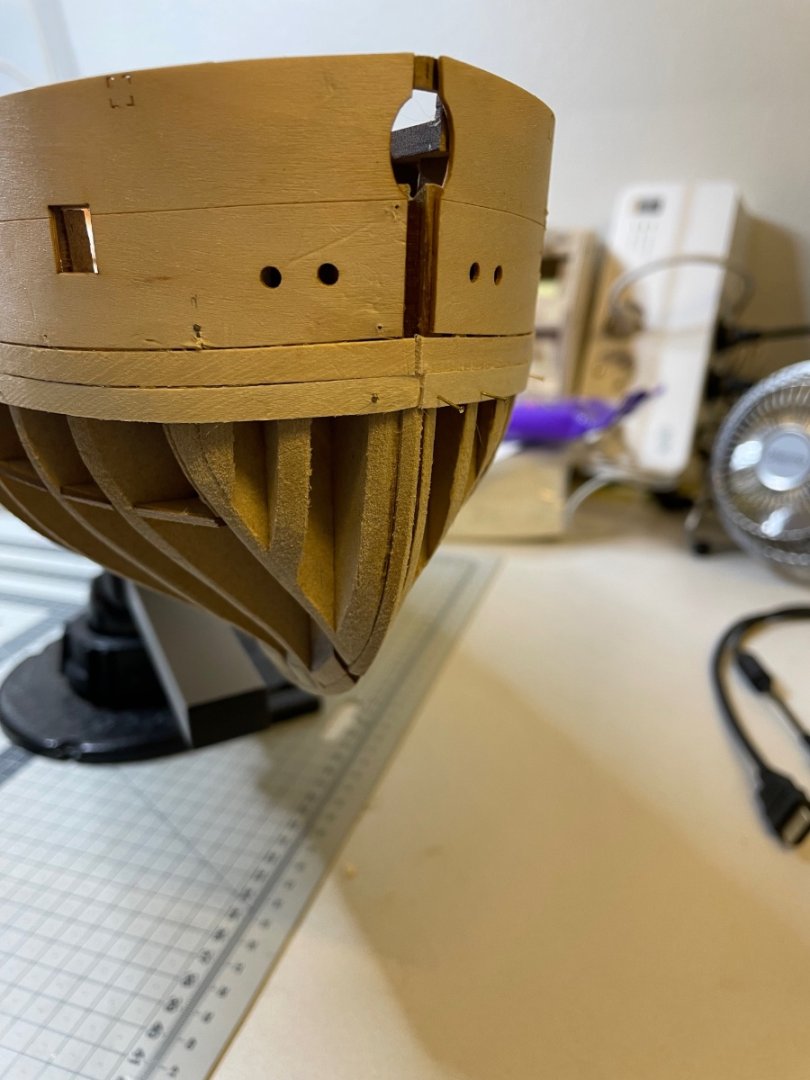

Photo 260: 2nd planking is finished. Now the hull is ready for preparing to remove the jigs and its parts before sanding.I used UHU Hart glue and spots of super glue for securing quickly at the ends.

- mtaylor, DonSangria and BobG

-

3

3

-

BUILD DAY 26: 1 hour / Total 46 hours

Photo 259: Continued planking with two rows of pre-cut pear planks and one row of pear strips.

- ccoyle, DonSangria, James H and 3 others

-

6

6

-

BUILD DAY 25: 1 hour / Total 45 hours

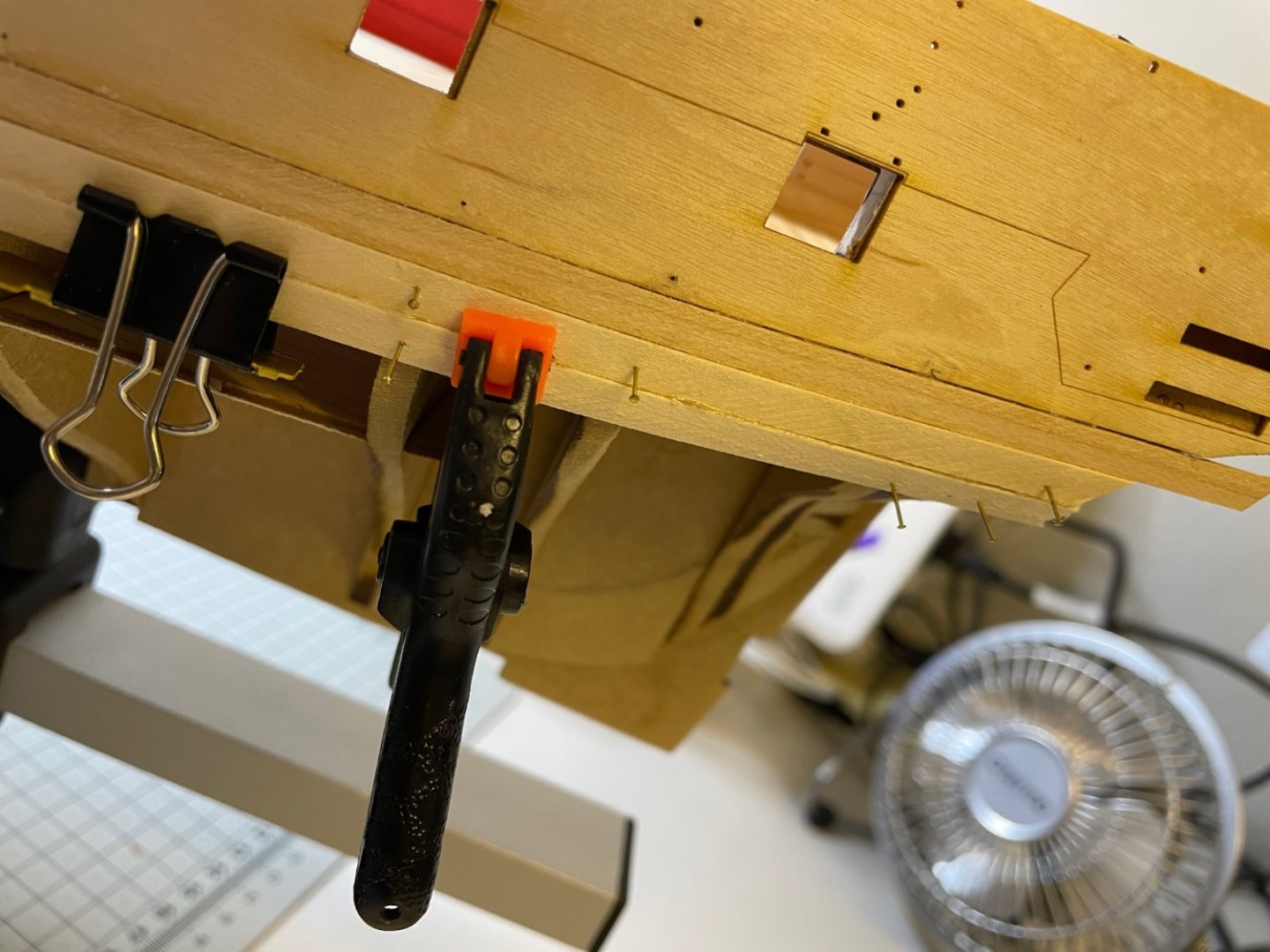

-----Photo 255-258:

Aft Outer Planking Patterns (271, 273),

Front lower Outer Planking Patterns (305, 307),

Rear lower Outer Planking Patterns (306, 308)

are also now glued in place, after soaking and bending where necessary.

- DonSangria, JeffT, ct mike and 2 others

-

5

5

-

- CaptnBirdseye, James H, mtaylor and 1 other

-

4

4

-

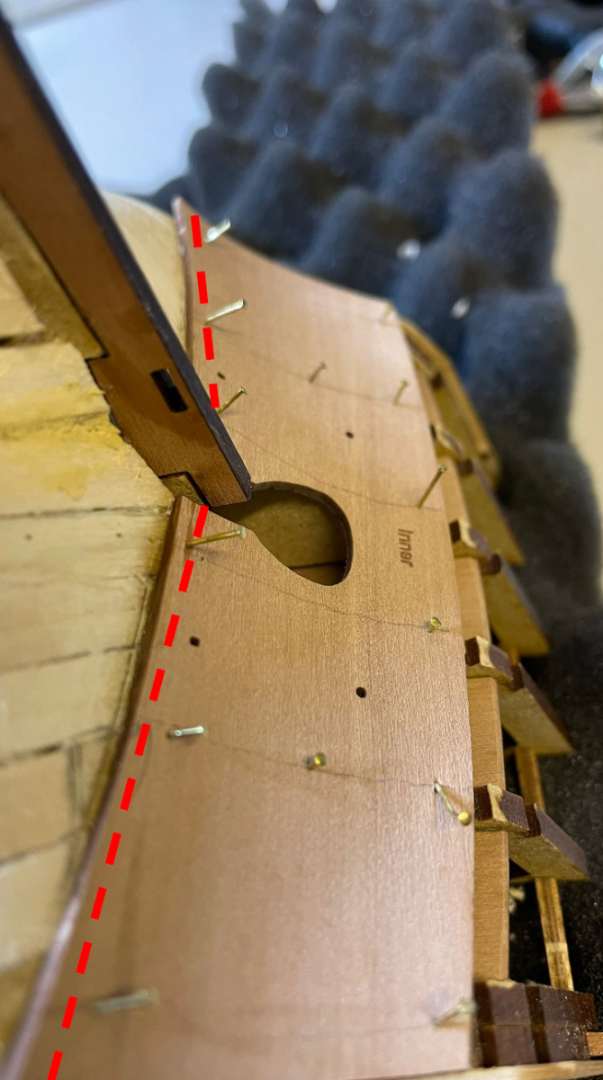

Photo 251: Fore outer planking patterns. Soaked in hot water and clamped in position, waiting to dry... this time completely, I promise 🤣!

- hollowneck, mtaylor and CiscoH

-

3

3

-

- mtaylor and hollowneck

-

2

2

-

-

6 minutes ago, James H said:

Ah, and if that piece is still damp, it won't have shrunken back to its proper size. Pear swells a LOT, so you need to make sure it's bone dry.

That's most probably the case. It is the first time I am working with pear and I have to admit it was not perfectly dry. I have left my workshop room for the day now and I'll see tomorrow how much it shrank. Luckily after all it will stay under the upper counter so I am hoping there is room for correction.

- hollowneck and mtaylor

-

2

2

-

1 hour ago, James H said:

Jesus where did I go wrong?

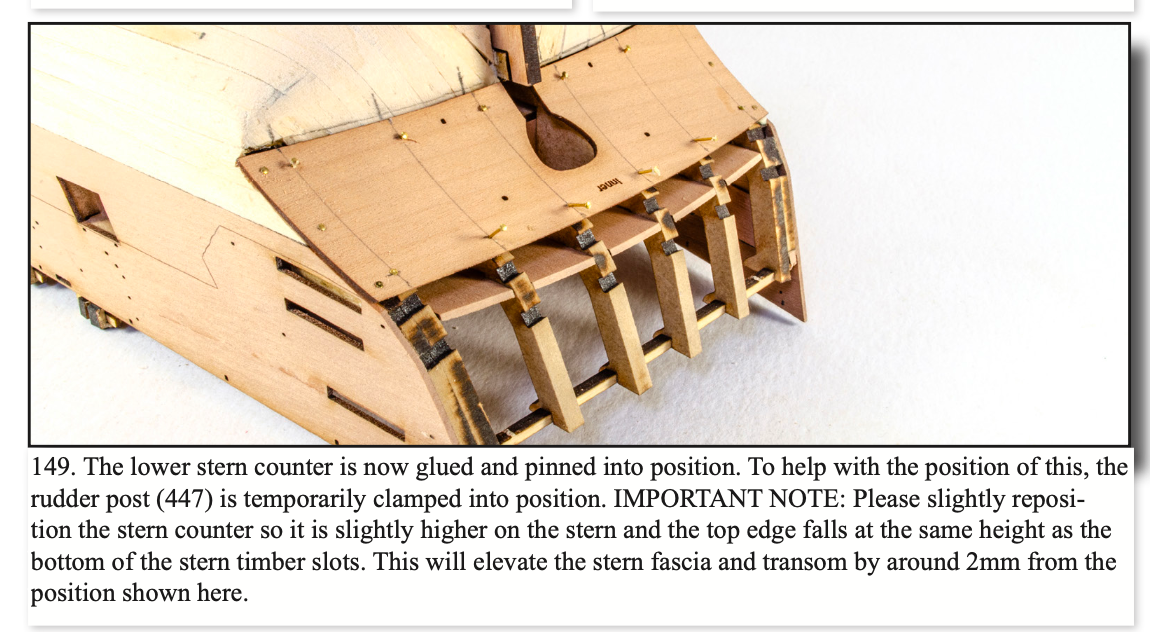

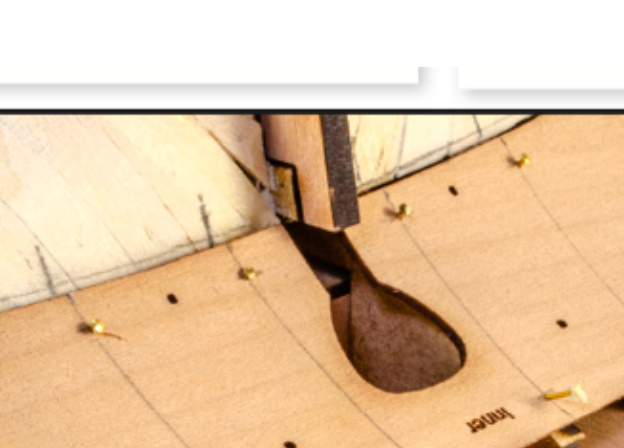

Here is a photo from another angle (mine is on the right). I was focusing on getting the top edge of the inner stern counter at the same height as the bottom of the stern timber slots and didn't really watch what's going on at the rudder post side (lower side). So, in yours it is about 2mm below the bottom of the timber slots, and therefore I raised it 2 mm making it at the same level as the bottom of the timber slots.

But I can't explain why it it goes below the rudder post level on the other edge. Maybe I shall just trim the stern counter from the lower edge and make it level with the rudder post. It is very firmly glued in place now, I could do more harm trying to remove and reposition it. After that I could try to rectify the situation when installing the outer counter pattern.

- hollowneck and mtaylor

-

2

2

-

Photo 195-197: Inner stern counter in place, repositioned slightly higher than the photo in the manual as instructed. You see also prow-, keel- and rudder patterns installed.

- mtaylor, CiscoH and hollowneck

-

3

3

-

- hollowneck, CiscoH and mtaylor

-

3

3

-

-

BUILD DAY 22: 3 hours / Total 42 hours.

Today was about sanding first planking and installing stern counter, and prow- keel- and rudder patterns.

Photo 189: First I used these scrapers to level the planks as much as possible as well as get rid of any hard glue particles. The various contours make it easy to scrape nicely.

Photo 190: Now the surface looks more ready for sanding.

-

BUILD DAYS 15-21: 15 hours / Total: 39 hours

Photos 187-188: First layer of planking is now complete. I have logged roughly 7 build days and a total 15 hours for the whole first planking.Sanding work and small fillings (if I find necessary) is next.

As I was not careful and had oversanded the bow component earlier, I adjusted the bow curve by sanding it to fit the curvature of the Prow Pattern (#445). In the second photo, you can see it has a nice dry fit. I am satisfied with it at the moment, as there will still be the second planking, which will give further chance to cover any remaining imperfections.

- CiscoH, mtaylor and chris watton

-

3

3

-

23 hours ago, James H said:

I would never imagine there would be cannons right inside the command and control room with all the furniture and neat floor and stuff. Did they really fire them? Amazing.

-

- Mr Whippy, Ryland Craze, mtaylor and 2 others

-

5

5

-

As autumn comes, busy times at work and in general with life, I can rarely find any time to continue with planking. But still, first planking is proceeding.

Since this task goes rather scattered with sometimes only one hour in a day and nothing several weeks, it does not make much sense to count build days and hours at this point. So, I will make a total estimate of time it took to complete the first planking, when it is complete. As I wrote earlier it takes about half an hour to complete one row of stripes on both sides, hence, the total time will be roughly (number of plank rows) / 2 hours

Here are some photos to show the progress. Overall no surprise, going pretty much like in the instruction manual. You'll notice the planking on the bow not as it is supposed to be. This is because I had screwed up the bow structure by oversanding it, if you read my earlier posts. Right now I make it so that the strips meet in the bow. I will then sand them to the shape to fit the Prow Outer Patterns.

Photos 180-182:

- chris watton, DonSangria, Mr Whippy and 4 others

-

7

7

-

BUILD DAY 14: 2 hours / Total: 24 hours

Back to build after 2 weeks of vacation in Kusadasi, Turkey at the Aegean Sea coast.

The first 3 rows of planking went just like in the instructions, quite straightforward with no need of tapering. So far it takes about half an hour to plank one strip per side (i.e. 2 strips). I am sure with my speed it will take longer than this in the coming planks where I will need to do the tapering.

Photo 178: This was the only bending I had to do for the first 3 rows.

Photos 179-180: Overall the strips contact the bulkheads quite nicely. I applied nail only in some locations.

HMS Sphinx 1775 by aydingocer - Vanguard Models - 1:64 - Revision #2

in - Kit build logs for subjects built from 1751 - 1800

Posted

Photos 277-278: Masking and painting with airbrush.