-

Posts

9,725 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

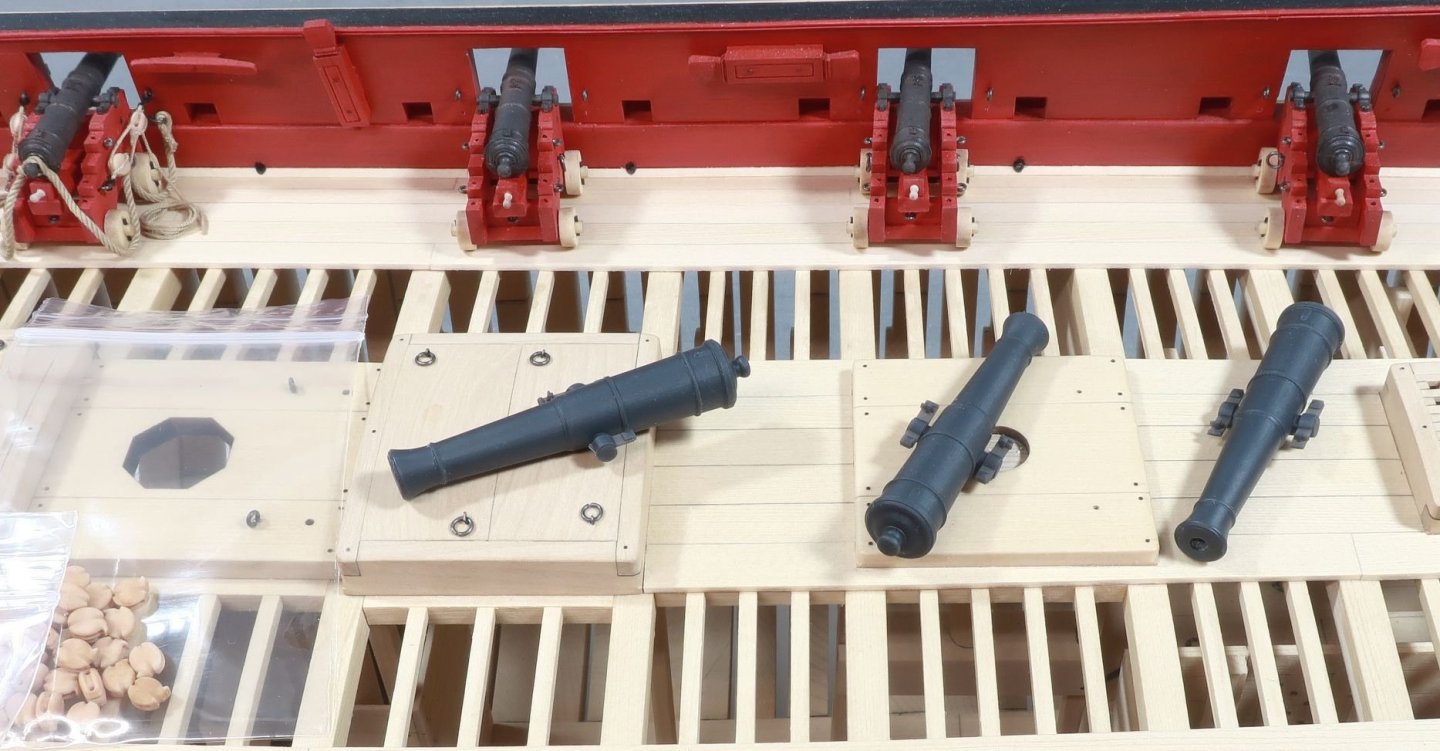

Here is a test print run of an Armstrong Fredrick which Ron (thibaultron) sent me. Its a lovely cannon and prints very nicely. Ron has posted the stl files for these for everyone to print in our 3D printing forum area. I am very thankful to Ron. I will be selling these in my shop with his permission to anyone who does not wish to go down the 3d printing rabbit hole. These are printed in Gray/black resin. They are hard to photograph but hopefully you can see the royal monogram on the barrels and vent hole. The trunnion pin is also extra long so it will fit any carriage. Just snip off the excess and sand it flat. I know you guys sometime buy barrels to fit the carriages supplied by the kits you are building. Just in case.

-

I hope to have them in the future. Ron has sent me an Armstron Fredrick cannon stl he made and I will be printing those very soon. I am very grateful for that. Once those are done maybe another type of cannon or yes even a carronade. And if Ron has other files I would be thrilled to print those too should he want to pass them along. But all this does take time. Slowly but surely. I also have ships wheels ready to go and some other things. So lots of goodies yet to come. Chuck

-

I agree with you. But 2mm blocks like these sell like crazy. I dont get it but then again I model at a larger scale. Smaller will be tough. I may call it a win and stop at 2mm becuse they are a pain to make actually. If one drops off the supports and in the VAT of the printer I have to break down the machine and clean it all. That happens a lot with these tiny pieces because you cant use heavy or many supports. That would ruin the look of the blocks. So I may just say 2mm is small enough but you know me. I may just try it once to see if I can do it. It is truly amazing though. Even with a macro photos you cant see any layer lines or that rough surface you guys are probably familiar with. Even made out of wood and cnc they look kind of rough at this size. But these look pretty pristine if you can rig them.

-

I am all done with the different blocks and am fully stocked. So I am now going back and trying to make the tiny stuff that a lot of folks need. These are tricky and to make make them correctly proportioned and looking real even tougher. Anyway these are true 2mm single blocks. I measured my old wooden 2mm blocks and they were probably 2.2mm long. The stuff from Coastline and Dry-duck are even larger. These should be available really soon. Probably today. Doubles and triples to follow. Now can I make them even smaller? I really dont know. But I am willing to try for those who like to build the small models. Take out a peny and look at how big the date is. That is how small these blocks are. The holes are clear and the details crisp. Now how do you strop and rig them. Thats up to you small scale model builders to figure out. Just use the correct scale rope. Tiny stuff. Fly tie stuff for sure. Chuck

-

Such a nice looking model. You are really doing a fine job. I will be following along.

- 102 replies

-

- ancre

- La Mahonesa

-

(and 1 more)

Tagged with:

-

Eventually yes...but life has a funny way of taking turns. Work will be continuous of course but on what all depends on what is going on. For example...I have the Hudson River sloop to get done first as it will be for a museum on the Hudson River. But Speedwell must be finished first and of course....and turning to 3D printing because making from wood by hand or CNC is too time consuming and expensive these days. Things just seem to come up and change the schedule. Chuck

-

Well Done...yes its a challenge. But as you said, all of those other kits really dont do this area of the ship justice. That can clearly be seen with your Winnie. Well worth the effort. I suspect you wont be looking at other headrails on future kits you build the same way again.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Still on a short break from blocks. But I will be back on them this weekend if all goes to plan. This week I am working on a side project while also helping my son move out to his new place. I am officially an "empty-nester" now. So nice although I hear they always come back for one reason or another. Anyway, this project involves learning to make some cannon with the 3d printer. Not difficult by any stretch but there is still a learning curve. How to set the supports and what angles for the cannon are best for the optimal surface quality etc. So after many tests using a wide variety of resins and mixing colors...I have settled on how I will proceed. So all in all a very worthwhile several days as I will be making cannon available that I will be making in house. These tests are of a French style cannon after Boudriot. I am quite sure folks will eventually have a need for these as well as the typical English Fredrick and Armstrong cannon as well. Here are the results...for color and texture. These are 2.15" long and 12 pounders at 1:48 scale and a larger caliber. Earlier test with capsquare which seemed like a good idea but they are just too thin and prone to breakage among other things. So these will be printed separately. Experiments are fun!!! But you can see the quality and surface ultimately achieved along with the scale difference on my Speedwell. They are a little difficult to photograph but they are not pitch black and a stark black but a very dark gray/black.

-

Thanks... Taking a break from the blocks...but not for too long. I am not sure if the resin will be strong enough but it was worth a test. They are absolutely fine for me but I know how some folks really pull their rigging tight. Too tight. They are about as strong as boxwood however...but of course not as strong as brass. But they look fantastic. Properly proportioned and sized. These are 3/8" long or 18" at 1/4" scale. Which is properly scaled.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.