-

Posts

9,725 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

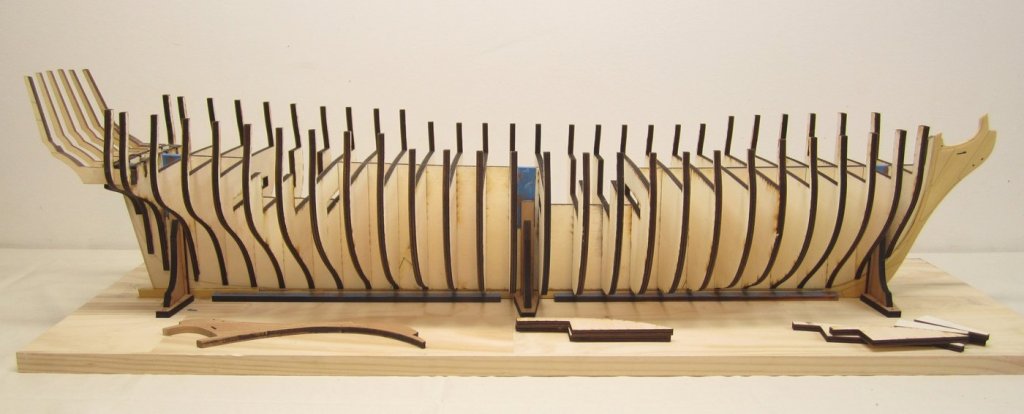

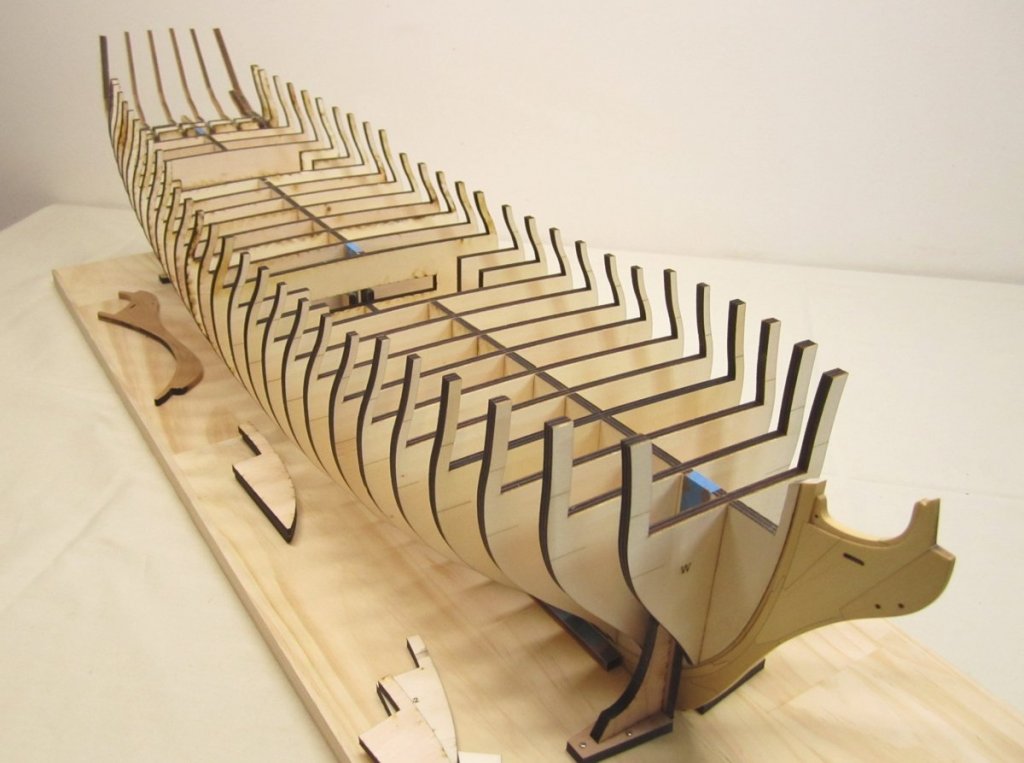

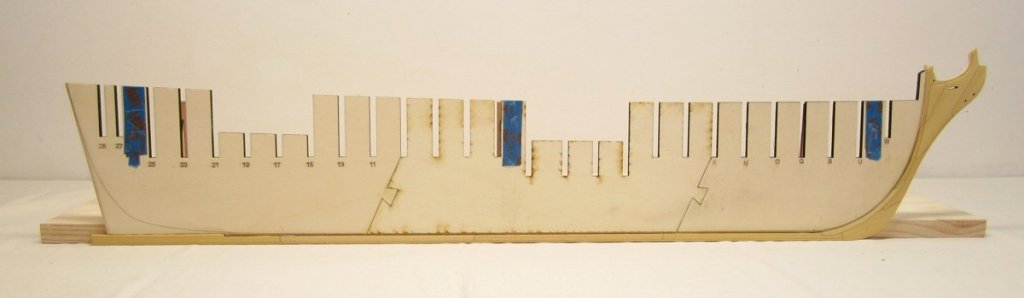

Thanks...I still have to edit it. Its on the list of things to do. Below is a dry fit of the bulkheads and stern frames. All looks good to go for the next step. And just this one time only...I dragged out the old dusty and broken 3/16" scale version of the Winnie for a size comparison. They are lined up at the stern so you can see the difference. What a mess the old model is....full of dust and filthy as well as busted up a bit.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wonderful work....very nice. Just catching up with your progress.

- 59 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

That will be a seperate mini kit because they are easy enough to make on your own for anyone who wants to do so. No sense in forcing people to spend for more than they intend to use. I like to give as many options as possible if it makes it more economical. I would also recommend that everyone buys or makes a set of these because they can be reused for all models at this stage of construction. Its worth the time to make them. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Oh it wont be too long hopefully now that I dont have to wait until the entire project is completed and a book is published and printed. I can release parts of the project as I complete them much like I did for Cheerful. Hopefully the starter package will be released shortly after planking has begun. I have attached the first chapter to give you guys an idea of what the monograph will look like. I am more than happy to answer any questions or embellish any parts of the monograph should more detail be needed. But this will at least give you guys an idea of what I am shooting for. I also wanted to mention again that I have many images of the contemporary model that I will be sharing along the way which I am sure no one has seen yet. Here is one showing the headrails and cheeks....I am getting really excited again to get into the thick of building this model. Chapterone.pdf Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

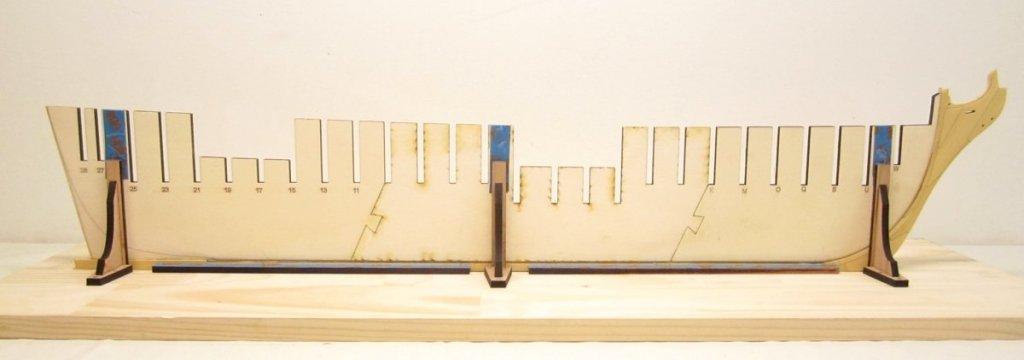

no that is just painters tape. It is used to just make the bulhead former fit tighter within the three brackets. i use painters tape a lot for this purpose because it can easily be removed later. The bformer is nice and snug now.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just a quick update...Alaskan yellow cedar is being used for this model. The new 1/4" scale stem is now assembled onto the bulkhead former. The rabbet strip was added to the bulkhead former first (5/32 x 1/16). After that dried, the Bformer was beveled along the bearding line into the rabbet strip. Then the stem assembly was glued to that. Finally, the individual keel pieces which are laser cut were glued in succession along the bottom of the bulkhead former. To finish it off, the bolts were simulated using 15 pound black mono filament. I assembled some right angle braces that I designed for the build board to keep the false keel from twisting and bending. Now its time to laser cut those bulkheads and add them. To give you a sense of size...the build board is 36" long. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great....I should be catching up to you soon enough. I think the supports will keep your hull ...or any hull for that matter from twisting. Nicely done.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You will certainly change your mind Phil. Although small and inexpensive, the planking of the hull is certainly advanced and will give any model builder a really good challenge. Most beginners dont know what the word spile means and in order to plank this hull they fail to realize the extreme bends and plank shaping required. This is more evident when it comes time to plank inboard. In addition to this, the fragility of the hull and small parts also ramp this kits skill level up to advanced. This type of hull structure needs someone familiar with handling a model with a light touch which is something that requires some experience. Having said that, I will certainly watch and follow along as you build the model, and hope that your progress can help those who start to build their own. It shall be a very interesting progress. Tools are the easy part, since everything is laser cut and if you use the planks supplied....hardly any are required beyond the basic stuff as outlined in the instructions. Oh....I dont know what the eta is...but a 1/2" scale version is in the works from ME. This is what I suggested they do all along. But anyway, that one would make life a lot easier for folks. Might want to wait for that one. Chuck

-

You could but nobody will see it. The molding strip will run along that seam and will be obscured or even covered. Lovely work.

- 103 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

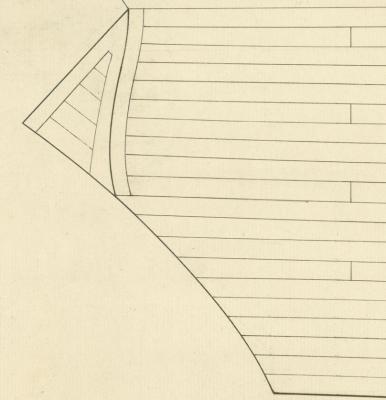

Dont plank cheerful like that....very different square tuck. Mine follows the original draft to the letter....you are doing a great job on her so far. Here is the square tuck from cheerful's original draft for the external planking. Cant get anymore correct than this!!!

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

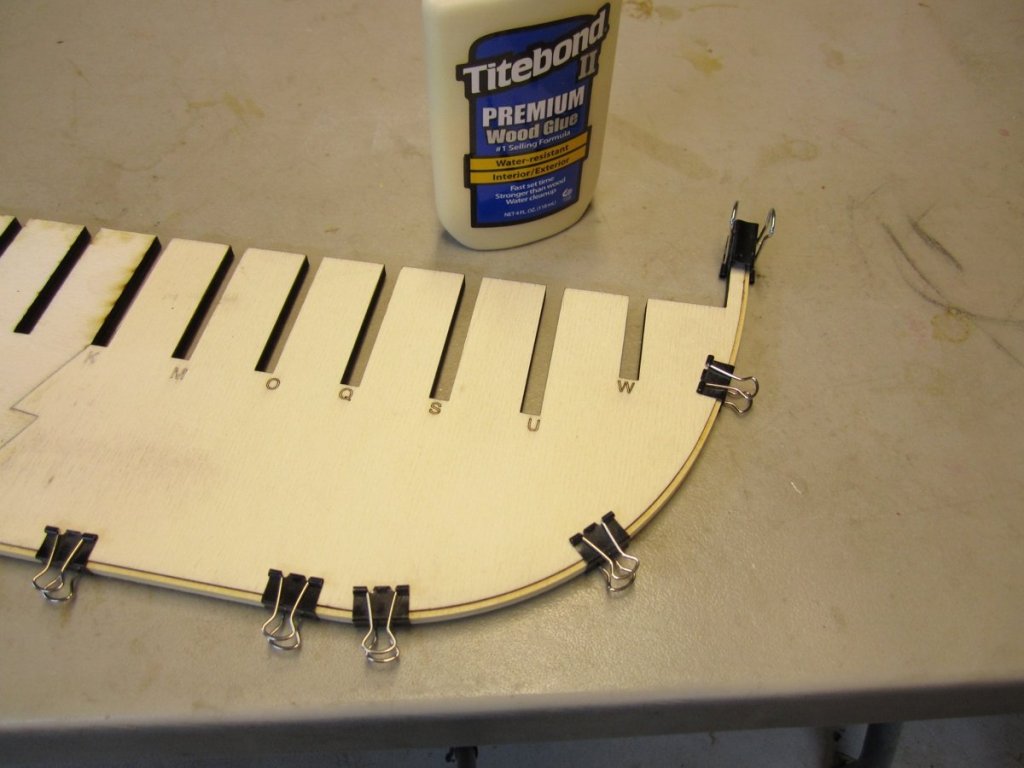

I actually waited til I had the flag staff so I could make sure it was straight when gluing it in. Thank goodness it takes a while for Titebond to cure which allows you to move the flag around while its in the step so you can get it straight.

- 120 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very nice....and yes that is the exact reason I added extras. Same is true for the decorative panels.....you should be almost ready to add those too. You are moving along relatively quickly which is good. I see a Pegasus Cross Section Rusty beta test in the works for you!!!

- 120 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you very much guys. This is a fun project but it will no doubt be an advanced kit. But so far ....so good. Chuck

- 130 replies

-

I did reach a milestone of sorts. I have completed all seven frames in phase one. The frames will be built and installed in three phases to make it easier to manage. Phase one has seven frames. Once the frames are all done and dry fit in the keel, you can start adding the port framing. The port framing is tricky but manageable. You will be removing the frames quite a bit to tweak them and the slots for the port sills so you can get a good fit. Same is true for the sweep port framing. Once you have the port framing dry fit nicely, then we can glue all the frames in this phase permanently to the keel. Then glue the port framing in too!!! I havent glued it together yet....but that is the next step. What you see in the photo are all the frames and port sills simply dry fit port and starboard. I will glue it all together after the Connecticut show. Then the frames can be faired outboard...and the alignment tabs you see on the inboard side removed as well...but I get ahead of myself. Then its onto phase two and another seven frames done exactly the same way.

- 130 replies

-

Thanks!!! I never posted how I am going to handle the shifted or bent frames. This is how it will be done. Its basically the same as the traditional frame you saw already where you flip over the pieces for a better fit. BUT....the top timbers are 1/4" thick vs 3/16" thick like the other parts of the frame. You can see the components below. After making so many of these I have found that it is best to glue the two pieces for each side of the frame together first. Note how the top timbers (2-C) are thicker. Once the tightbond is dried, I dont sand any of the char off yet. But I did remove the alignment tabs to make shaping the shifted top timber easier. Then I glue some specially prepared templates to the outside edge of the frame showing the bend as shown above. I used rubber cement but anything low tack will work. Then its just a matter of shaping to match the template. I used a sharp #11 blade to just shave away the majority of the wood that needed to be removed. Then I used some 220 grit sandpaper to finish it off nicely. Once done you can remove the template as seen below. Then its just like any other frame where you glue these two parts to the other frame sections.

- 130 replies

-

That looks very very good. One thing you can do that I recommend is to spray the painted surface with dull coat or a matte fixative. Dont spray a heavy coat but several light coats from afar. This really evens out the painting and you wont see any brush strokes at all. It works a treat!!! And you dont have to worry about getting any on the unpainted cherry. It works there as well.

- 120 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This is a poll of just registered members. Only members can vote. The most logical place for it is in the kit build log area and that is why it is there. This is the largest collection of build logs on any ship model site. The knowledge and expertise shared is quite valuable and it is something we want to encourage people to sign up for in order to see and take advantage of.

-

Its looking excellent so far. Well done!!

- 103 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Actually scale means nothing and the measurements are what you need. It depends on what size you need for the ship you are working on. If you are building a frigate at 1:64 scale and your frigate carried 12 pounders then my 1 29/64" barrels are fine. If you are building a larger ship that carried 42 pounders then my larger size would be better. What are you building? What scale.....and what size guns did she carry? You can also download the drawing from my site (cannon page) and compare them to your plan to see if they match as well. Chuck

-

I have been swamped with trying to rebuild my inventory before the Connecticut show. But yes I have made some progress but nothing really new. I basically have caught up to where I was on the earlier version. This is where I am at right now. The good news is that I have completed the set up in shop for some serious model building after the show. I am ready to go and have set up an area to take better pictures.....hopefully. Right now everything is kind of thrown onto the same table....as you can see.

- 130 replies

-

looks very good so far. Well done

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks very good Mike. Dont forget to bring it on Saturday to my shop. I will have bulkhead formers laser cut by then.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This is just in the states Mike...I have no idea what is happening in Europe but I am actually looking to buy bulk from Europe soon as the prices do seem to be stable there. Also it is very very tough to find 12/4 stock boxwood in the states now and it is plentiful in Europe. There is just the shipping and taxes to contend with. Gilmer on the west coast of the US for example only has 8/4 boxwood and its priced at $40 per board foot now as opposed to $24 per board foot just last year. Its a bit of a ripp-off. I have been led to believe by those suppliers that it is because of the increased tax placed on all lumber imported into the US by these companies. But who knows why....could just be greed. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.