-

Posts

9,725 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

That sounds like so much fun....Enjoy the day!!!

- 208 replies

-

- kitbashing

- Woodcarving

-

(and 4 more)

Tagged with:

-

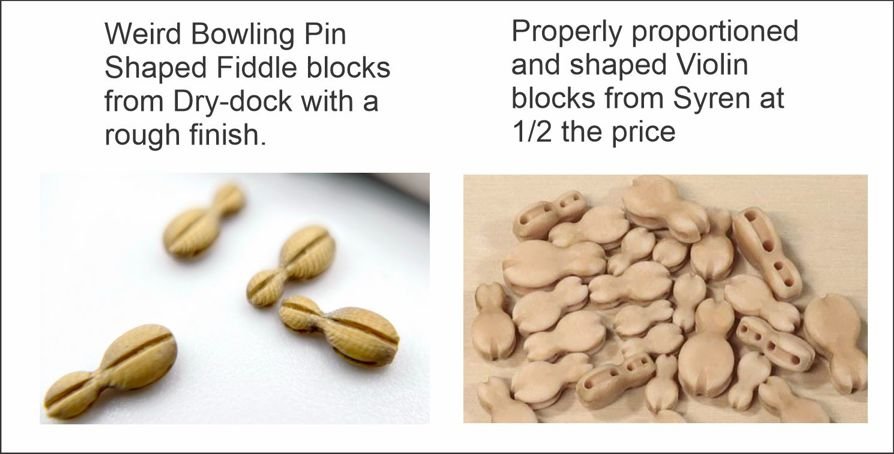

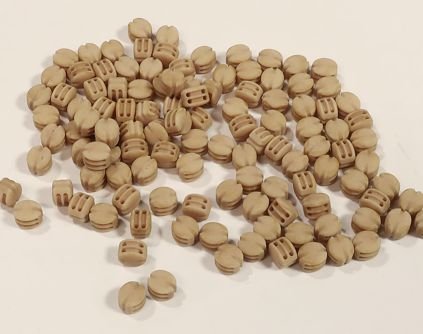

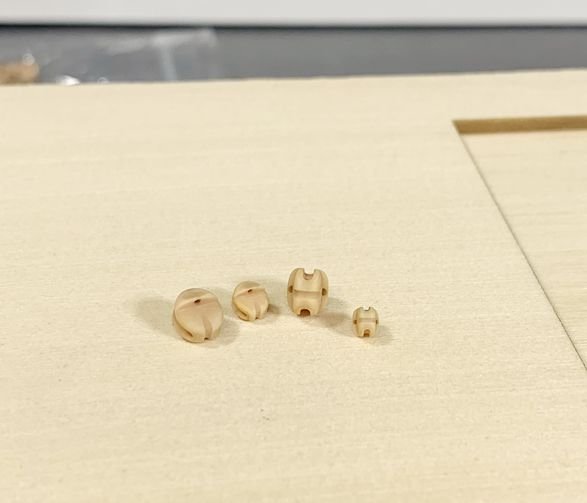

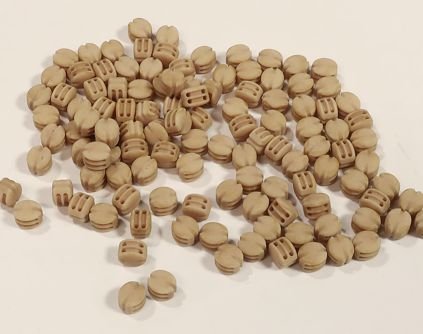

Thank you for saying. Its just too much to continue making them by hand out of real boxwood. This is also much less expensive for you guys and offers more possibilities. For example...clue blocks are now in stock with more sizes tomorrow. Its almost impossible to make these any other way which is why you just dont see them available.

-

Thank You... And by the way guys. These 3D printed blocks are pre-dyed and with a matte finish raw when you get them. They are great right out of the bag. BUT...if you really want to make them pop...and give them an even richer color and real wood finish/appearance...apply a coat of Minwax wipe-on-poly or sanding sealer. You will truly be amazed at how incredible they look. Use a satin finish or Matte finish. That is the real secret!!! Shhh!!! don't tell anyone. Treat them like wood and you will be a believer and convert. As I make each batch of these I apply some WOP to a small number of them and put them in these clear plastic bags. I then toss them on the model and do this as my QC color/texture test to see how well they look like wood and if I can even tell the difference. You guys can be the judge....try it.

-

Nicely done...the fun stuff!!!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This was Noted earlier and in the monograph. Note: Those building from the laser cut parts, there are two frame parts mislabeled on sheet “M”. The two frame parts etched as “Af” are actually supposed to be parts “10a” Please correct these parts on your sheet before you begin building. Only the first 12 kits are mislabeled. You will see two sets of AF parts with one mislabeled. The correct AF parts are on sheet "N".

-

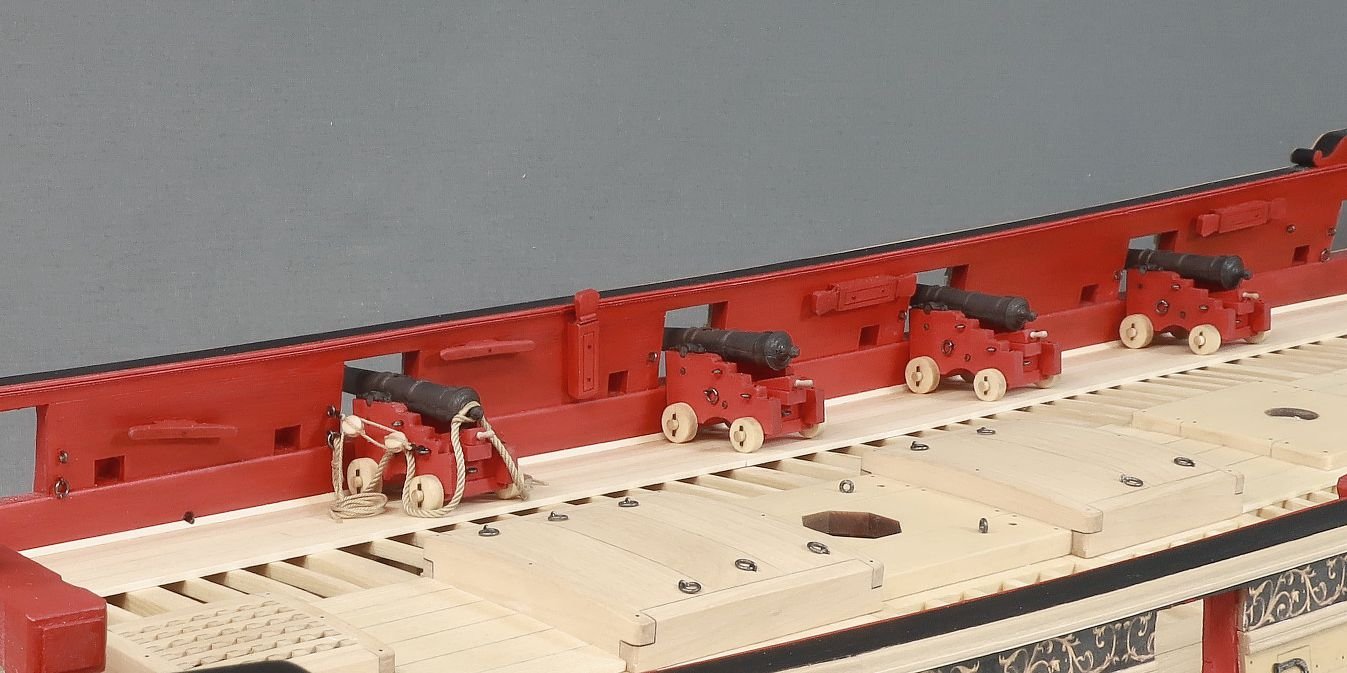

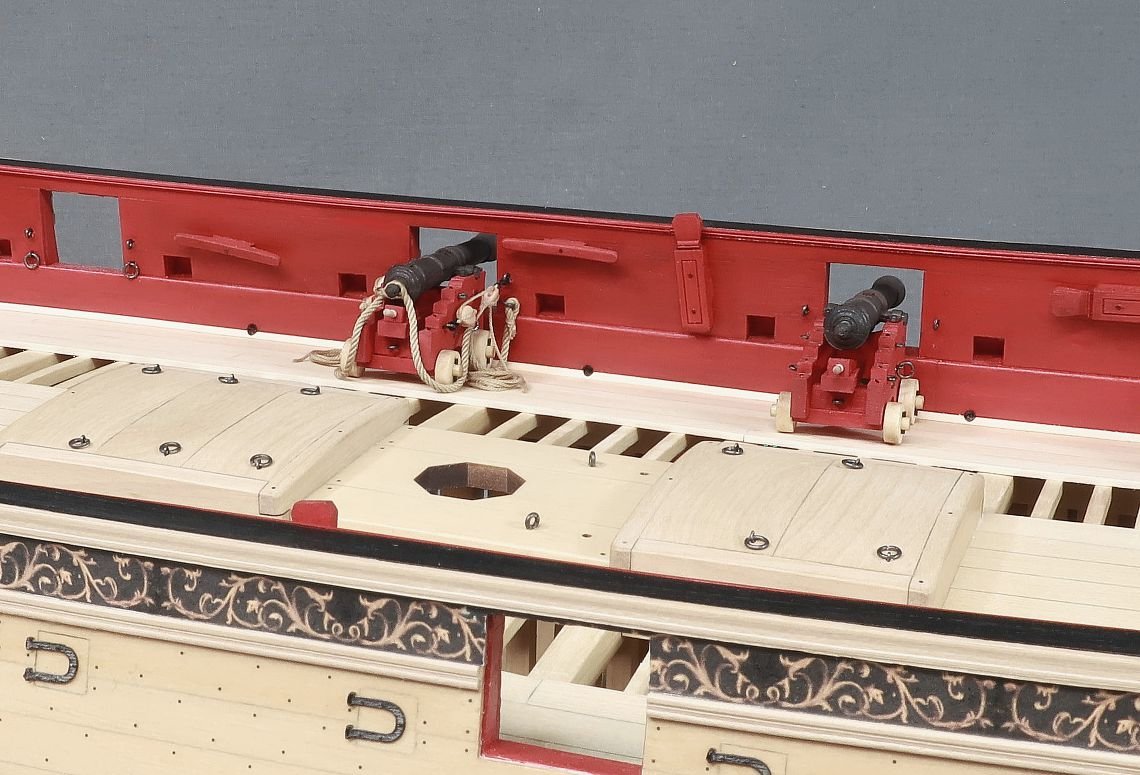

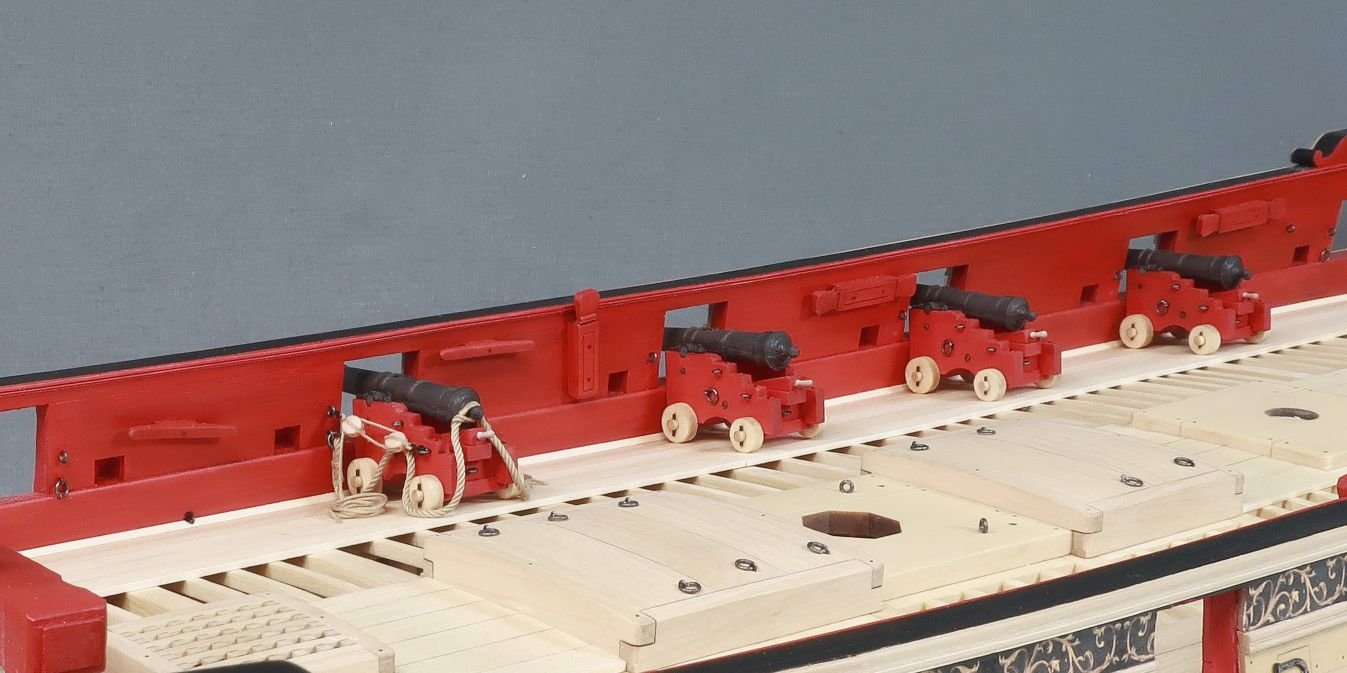

Just singles. The guns were too small for needing doubles. Those were only used on bigger guns. The winnie only used singles on the guns as well. Im not sure where you got the idea that doubles were used. They are only used on the biggest guns. The winnie has 12 pounders which would only have used singles also.

-

Thank you so much!!! I know this is a tough decision for folks...to abandon wood and take the plunge. But they look pretty good to me. I am glad you like them. And you cant beat that price!! I am using them on my Speedwell. I wouldnt sell them if I didnt feel comfortable using them on my own models. I test rigged one of the guns with them.

-

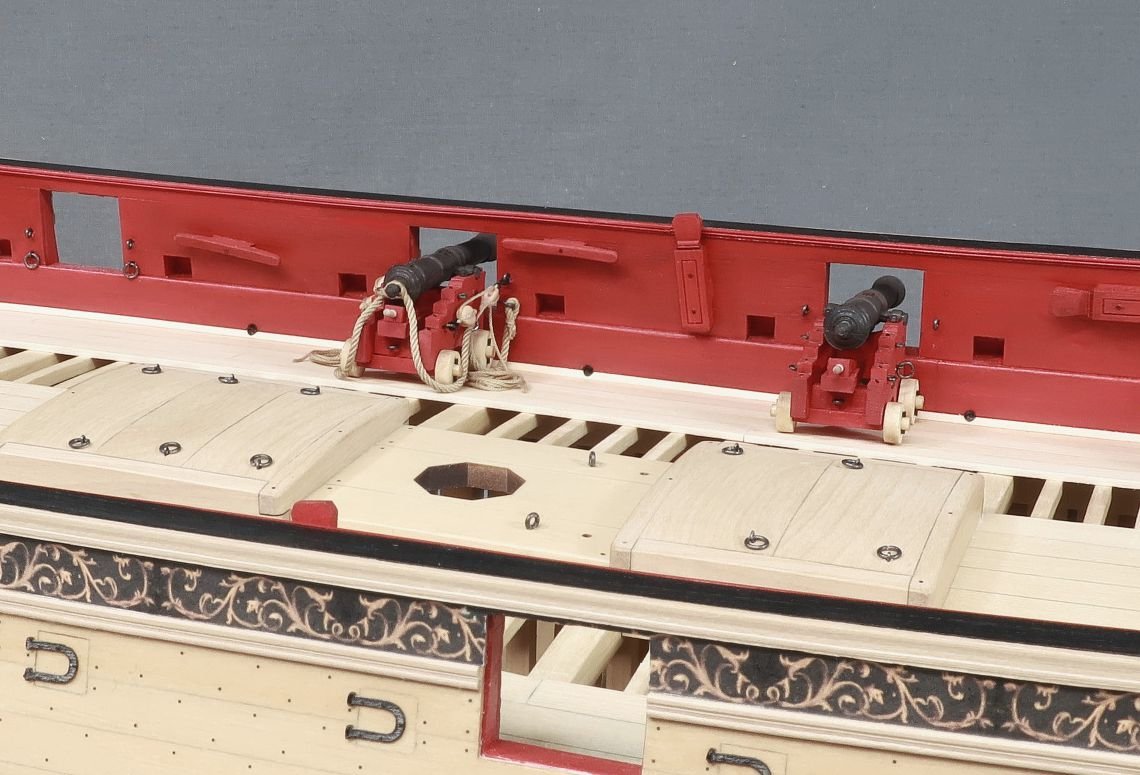

I took a break today from making blocks and rope to test rig one of my guns. I think it all worked out well enough. It had been many many years since I rigged any guns. I think Cheerful was the last time I did this. Anyway...I went with a 5" single block (5/32") for the tackles with .018 tan rigging. For the Breach line I went with .055 tan rope. I also used my acrylic rigging hooks for the tackle but I did make the ring bolts from 24 gauge black wire. I really wanted to establish the length for the breach line in this test so you guys would know how long to make them. The Breech line was 6" long end-to-end. I rigged it just like I did on Cheerful and Confederacy. These details will be spelled out in a step by step once I rig the other seven. This was just the first test run. My goal was to make the guns look like they have some very natural and properly hanging ropes. I am not sure if I pulled it off but I am happy with the results. The next 7 guns should get better...as I get used to rigging and rope-work again. And yes...rigging the guns is optional but this time I decided to take the plunge. Chuck

-

Most single and double blocks are now in stock. I still have some bigger sizes to make but I have most of the popular sizes done. Just $4.75 per package. https://syrenshipmodelcompany.com/boxwood-rigging-blocks.php Triple blocks will follow really soon. Probably this weekend as I wrap up singles and doubles. Chuck

-

Singles are now starting to be added as "in stock" in my online store. Doubles will follow early next week. I think you guys will really, really like the price. So much cheaper than nearly $9 per package for cnc blocks. I hope this makes for an affordable option and they are really terrific looking blocks. I hope you guys give them a try. I am going for a slightly darker "English Boxwood" color on these as I know most dont like the very light blocks on a model. I hope you will be pleased.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.