-

Posts

607 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Remcohe

-

-

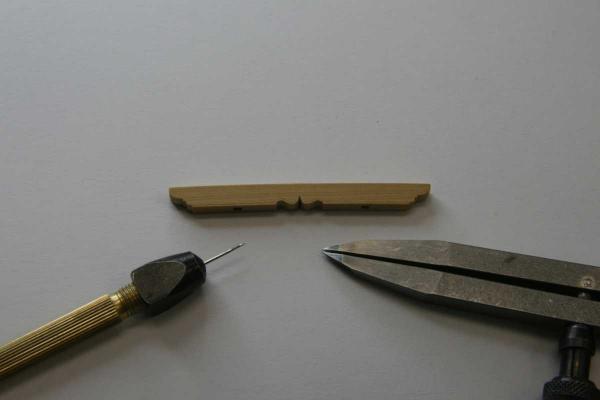

Thats a great picture Greg, to bad Annapolis is not on my route to the office. It's a bit heavy on the details added on the cross piece and bitt's for my liking. So I wasn't planning to do a mold and just make a test on a piece of scrap to see if it could be done. The result is shown here, I did it on the good piece anyway when I found out it worked out

I think more subtile than the Annapolis model and better matching the rest of my KF.

Remco

- Jeronimo, giampieroricci, druxey and 9 others

-

12

12

-

-

Thanks Greg that is really kind of you, but "My Swan was O.K" must be the understatement of the year

I don't know Mark I don't have a copy of Napier, but I take it as a big compliment.

MarkII, yep I cut them by hand, couple of real sharp chisels did the job.

Thnx Christian

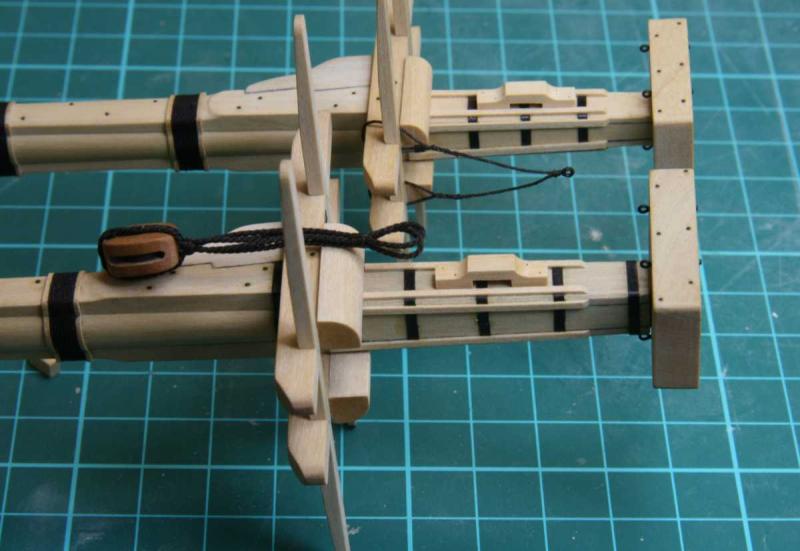

Back to work, the Gallow is morticed/tenoned I wanted to give this a try after seeing Tony making tenons for the deck pillars. My hat is off to you Tony, it's a daunting task...

Remco

-

Really stunning Matt!

-

- fatih79, Jeronimo, Elmer Cornish and 3 others

-

6

6

-

Thanks guys. Yes Carl time really fly's...

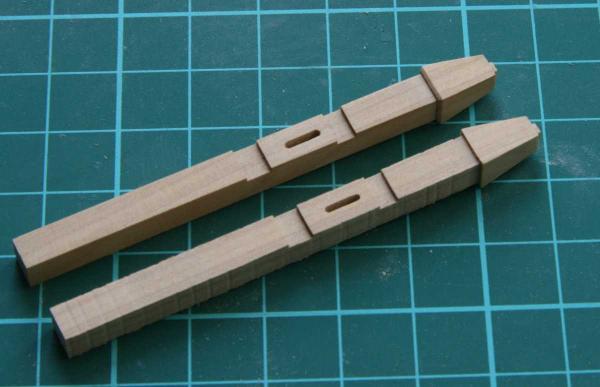

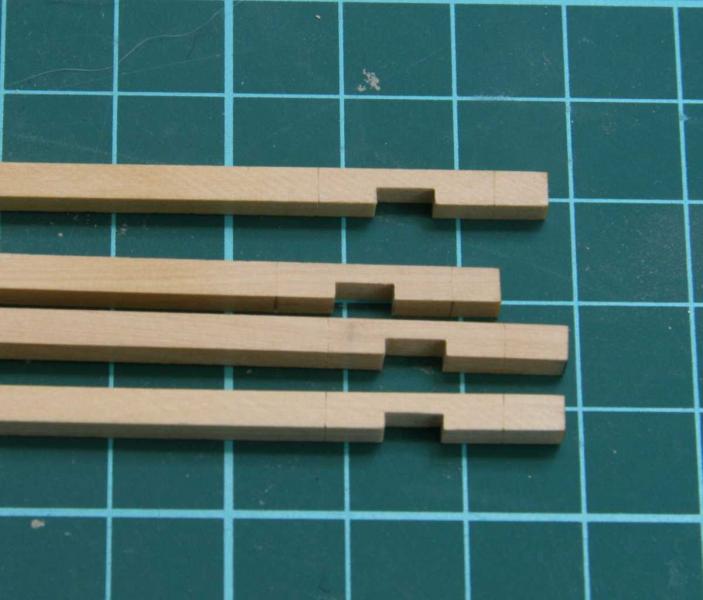

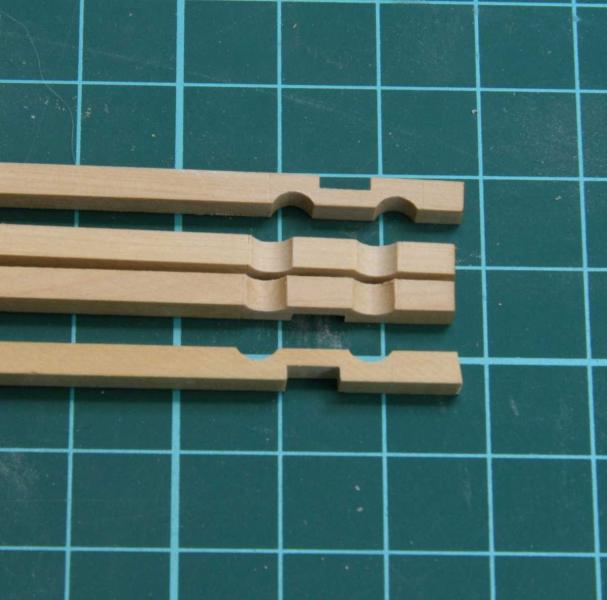

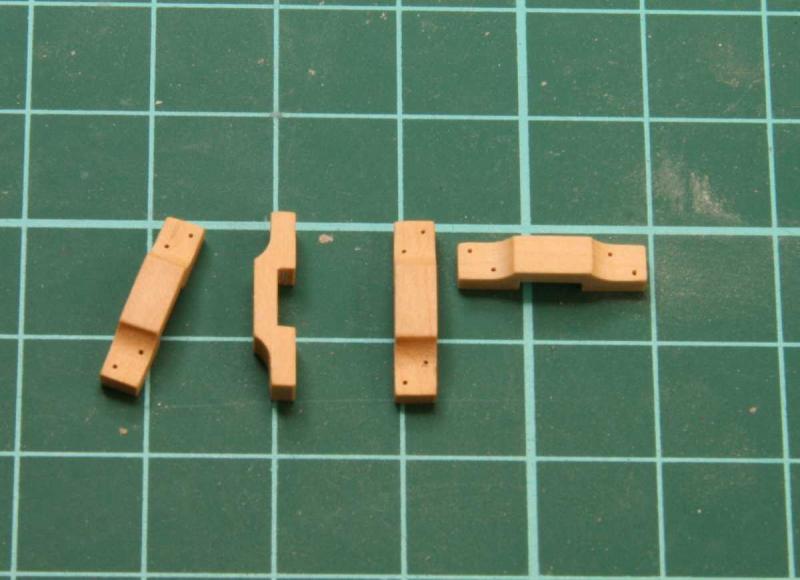

I'm working on the main topsail bitt's. The score's for the deckbeam and cross piece were scored on the table saw as well as several scores to mark the thickness of this piece. The rest was removed using files and sanding sticks. I used a special angled sanding tick to add the small sloped face at the bottom edge of the head.

Here they are test fitted next up is adding the shaves and the cheeks I'm not sure if the bitt's were also bolted to the upper deck beam, I'll will do botls so I can register the bitts with some pins.

Remco

- Jeronimo, Elmer Cornish, butch and 4 others

-

7

7

-

That is a clever way of approaching the gratings. I'll certainly give this a try as my results using the more common way on the table saw were quite poor.

Remco

-

-

Very nice Mark. No rush indeed unless it is to get into the workshop.

Remco

-

Nice pump chain . Are you speechless?

Remco

-

Thanks guys.

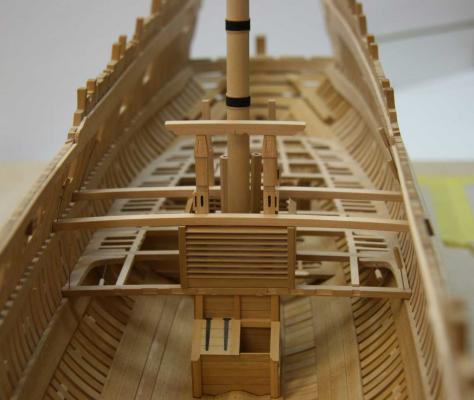

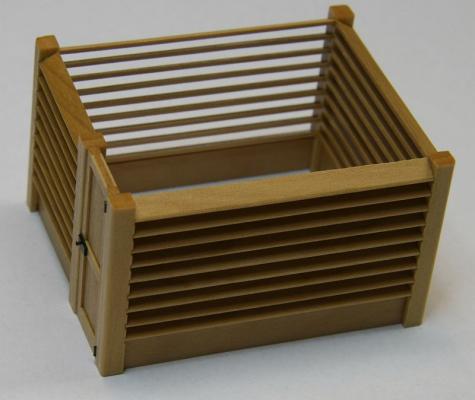

Now is also the time to dryfit the upper well. I had made this one two years ago.

Actually it didn't fit and some modification was necessarily, it was slightly to high but this was good as I also had forgotten to take the chamber of the deckbeams into account when I made the well. Removing wood is easier than adding

Now it looks like this.

I also made another set of hanging knees, nasty bits to make... I still need to get back into the flow of making beam, knee and ledges parts

Remco

-

I guess I tuned in a little late for this build. You certainly go the whole nine yards when you say scratch building. You're even milling your own wood, something I don't dare even if I had the space and the budget to get the tools...... You're off on a very promising start.

Remco

-

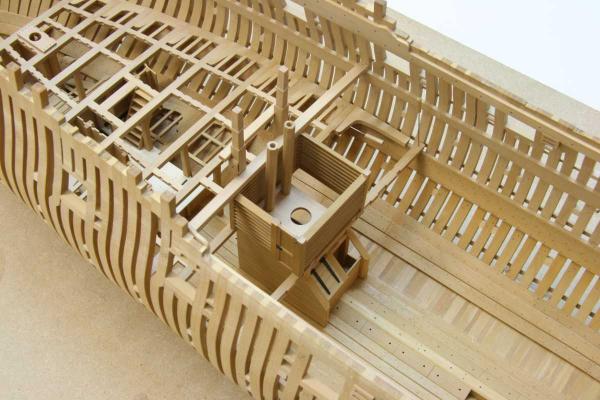

Thanks guys. Sure Bob, although I haven't found a safe place yet. .. Piet, the beams are cut on a scroll saw and sanded using a simple jig. I still have some pictures somewhere in my archive. Of course the mortices are hand cut

That said, I had to take out the lathe to make the mast wedge. I used French Box which is a real treat to turn on a lathe.

The mast step is hold in place with wedges

Everything was dry fitted, this is becoming a cramped part of the ship and this is even without the cisterns

The holes in the mast partner are cut using chisels and files

Remco

- cookster, Jeronimo, aviaamator and 9 others

-

12

12

-

You've done some great lofting there Piet. She'll be a very impressive model at this scale.

I'm glad I could help you out with a small part of the research, I now how much it means to you to build the O19.

Remco

-

Thanks guys. Druxey, the cleats aren't fixed yet, I'll first make the lashings, but this needs to wait until the stays are in place. Probably some years from now........I'll make the cleats for the foremast a little smaller, I found them a bit on the large side too. As the masts are now finished to a point I'm going to store them it's time to return to the hull. Remember I started making the mast so I could position the mast partners. What a fun few months of deviation from the path this has been, can't wait to return to the mast. Maybe as a side project somewhere down the road.

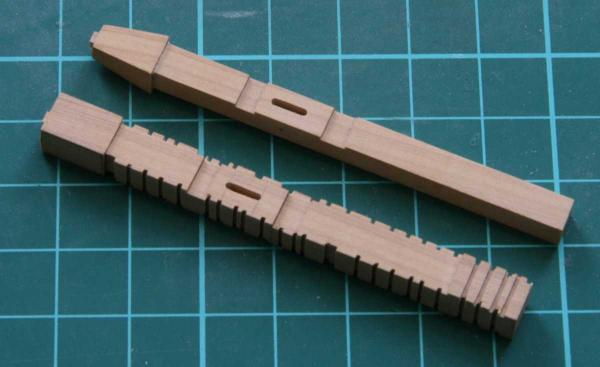

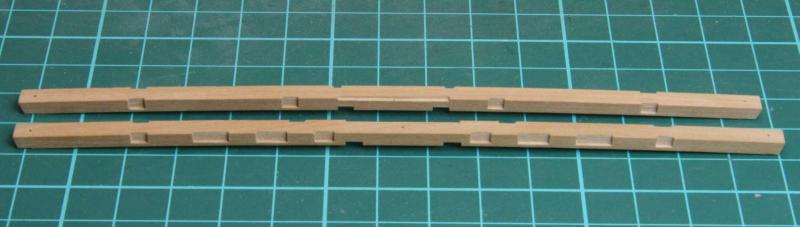

Now it's back to deck building. Plenty of challenges here to like this beam with all the mortices.....

Remco

- druxey, archjofo, Wishmaster and 5 others

-

8

8

-

Hi Bob, I think you'll find yourself quite at home on the dark side,

Remco

-

Piet, great to see you've started the log of you fathers O19. Your family has been part of a sad chapter of our history, I'm glad you are still her here to share it with us and that you're now able to make this special tribute to your father.

Remco

- bp1535, avsjerome2003 and edmay

-

3

3

-

Thanks all! Greg the squares are 1 cm so a bit larger than you thought.

Time to make the cleats that will support the blocks from the mast. For one second I thought of setting up the mill but decided to make the cleats by hand. Glad I did, it's fun to do and there is something about cutting wood with a well honed chisel. A couple of files did the rest.

I made the cleats for both the fore and the main mast the same size, not sure if this is correct.

Remco

- fatih79, Mirabell61, archjofo and 8 others

-

11

11

-

-

Thank you Karl.

Thanks Mark, it's just a line for positioning. I have to make a special cleat and rope to attach the blocks to the tops. You'll see.

Mark II, here's the how to. I used this link to understand how it works: http://www.animatedknots.com/spliceshort/index.php?Categ=splicing&LogoImage=LogoGrog.jpg&Website=www.animatedknots.com

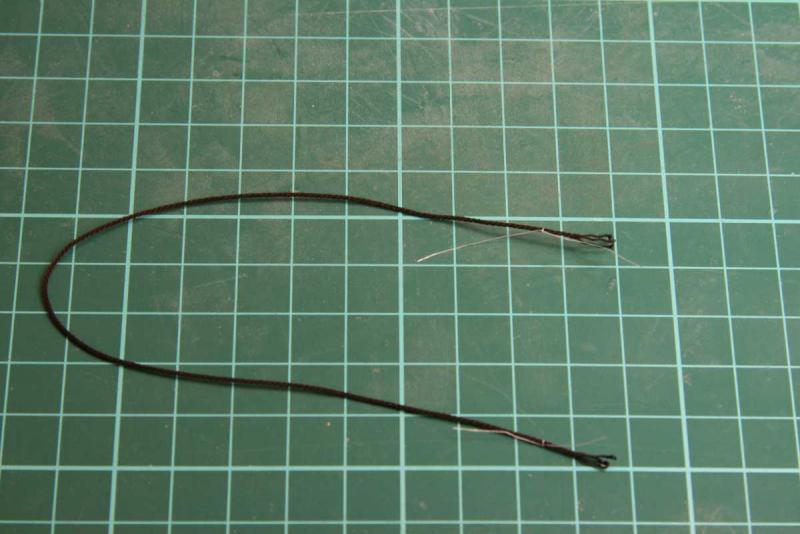

First the length I need is laid out and tied off at both ends. The tips of the ropes are dipped in CA to prevent from unraveling

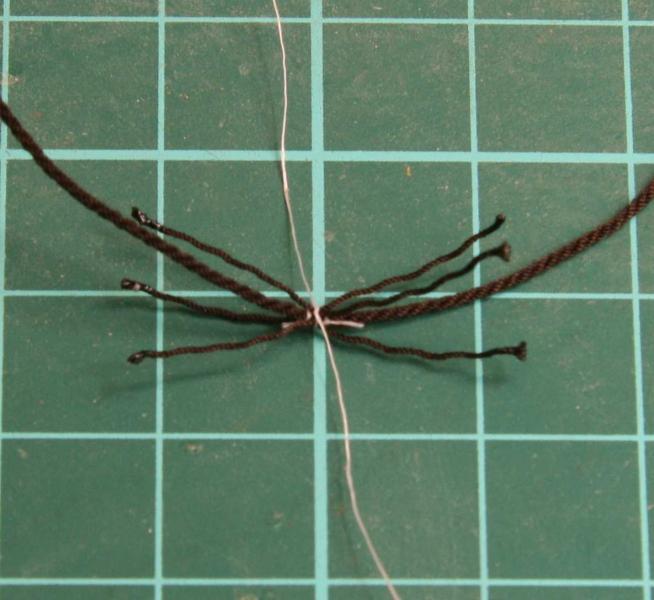

The ends are brought together and tied again

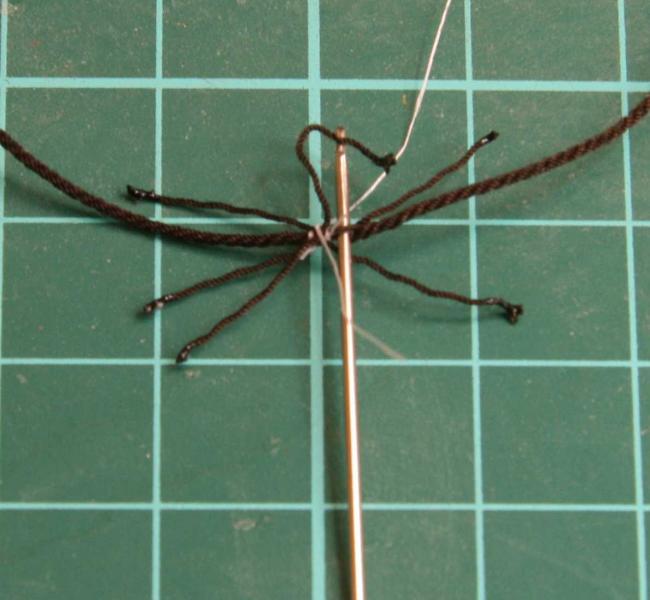

Then the lines are spliced using a needle, it took some time to understand how this works as its quite confusing

I opened the eye of the needle so I can insert the rope easily

The finished splice

The loop is glued to the block

And then seized at both ends

The result

Remco

-

Thanks all.

So the metal work is blackened and installed and it's time to do some rope work. Believe it or not it took me one whole evening to understand the text in TFFM how the block should be stropped and how the rope needed to be spliced. But I got it and spliced the rope properly tying the individual ropes with small fly tying rope to prevent them to unravel. This worked better than a spot of glue as the glue wears of pretty quickly once you start splicing the rope. The blocks are BIG compared to the mast. Nothing refined about it just hardware made to do a job.

Remco

- archjofo, Mirabell61, Elmer Cornish and 4 others

-

7

7

-

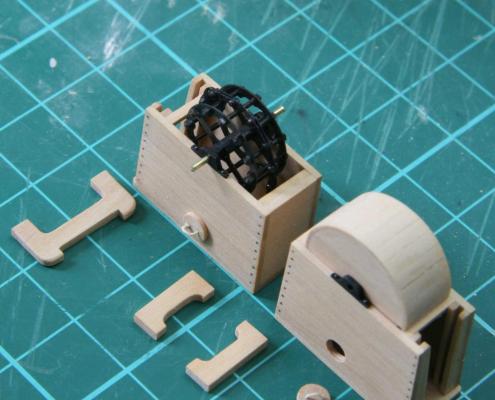

Thanks guys. Progress is a little slow, making the blocks hasn't got me over the block yet.. I'm not mass producing the blocks other than the method described in TFFM vol 4. I've seen how Chuck does it, clever but whenever possible I like to avoid powered tools. Cutting by hand is more satisfying and I'm not on any deadline to get things finished. And doing a repetitive task helps to clear my mind, that's what the hobby is for.

That said I had to turn the shaves on my lathe

I found making bigger blocks harder than the small ones, getting them the same shape and size was necessary as it really shows.

Remco

ps Pat, you can always come over and scavenge my scrapbox

- the learner, paulsutcliffe, PeteB and 5 others

-

8

8

-

Nice shooting board Mark, it reminds me of your inclined sanding board. How do you clamp parts on the board? I'll also see an other nice idea, a bench dog adapted to hold a lamp, neat

I'm sure you'll find new sources of energy to get back to Bellona.

Remco

-

Very nice Erik, once you understand how to make them, it's not as hard as it looks

Remco

HMS Naiad 1797 by EdT - FINISHED - 1:60 - 38-gun frigate

in - Build logs for subjects built 1751 - 1800

Posted

You could try an instrument maker. I got a banana box full of cut offs from a flute maker. I should have taken a picture of all the pieces he had in his stock to turn flutes from. That's was one to admire..... He got his from France from an old castle garden, he told me there is still plenty of box to go around...

Remco