-

Posts

7,755 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CDW

-

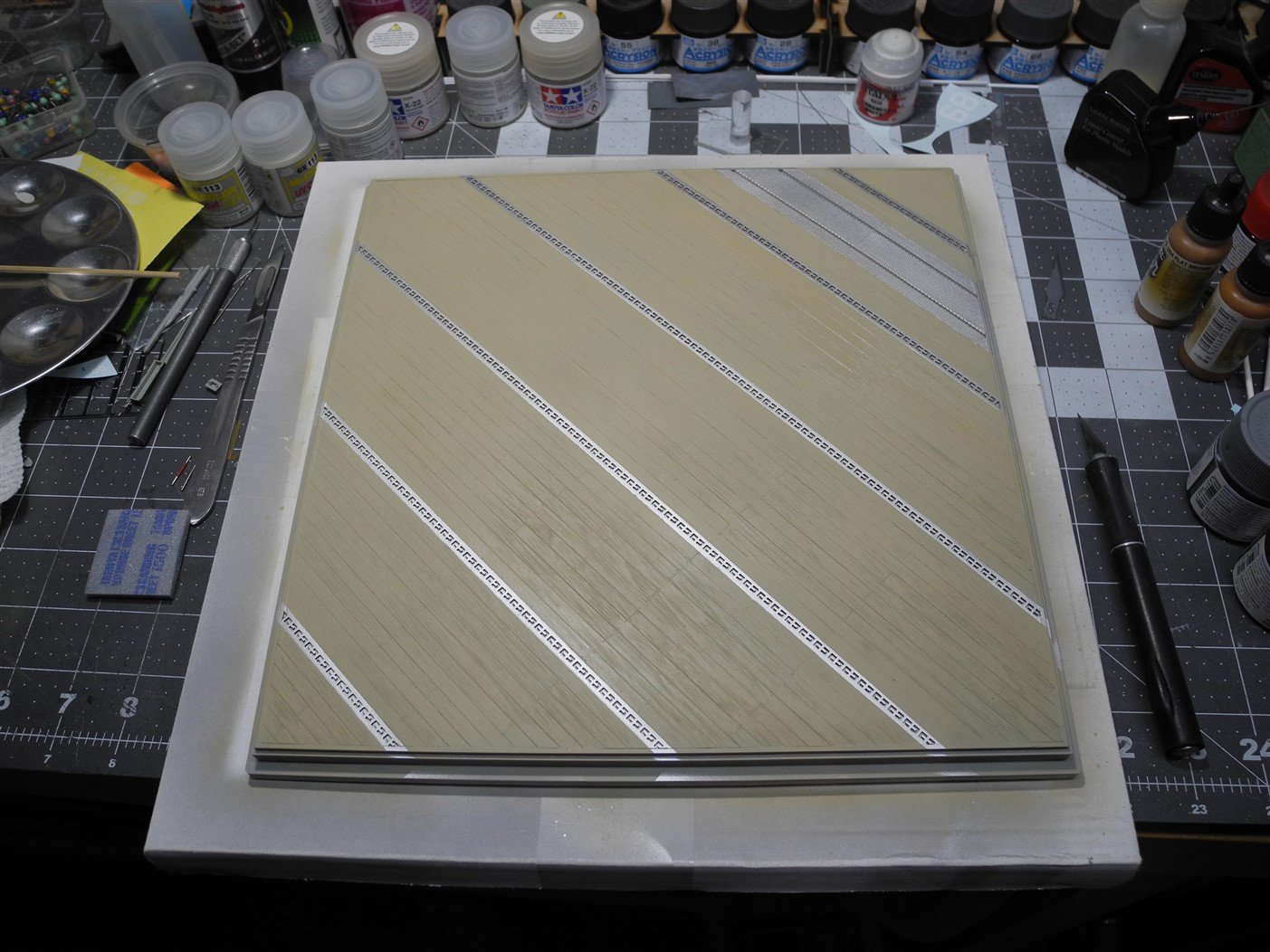

I'm debating whether to use the hairspray technique for the deck chafing or possibly to use a "windex" technique I saw on the net. It seems to me the windex method might give a more authentic look than the hairspray method which is a chipping look. I really want it to look chafed or scratched rather than chipped.

-

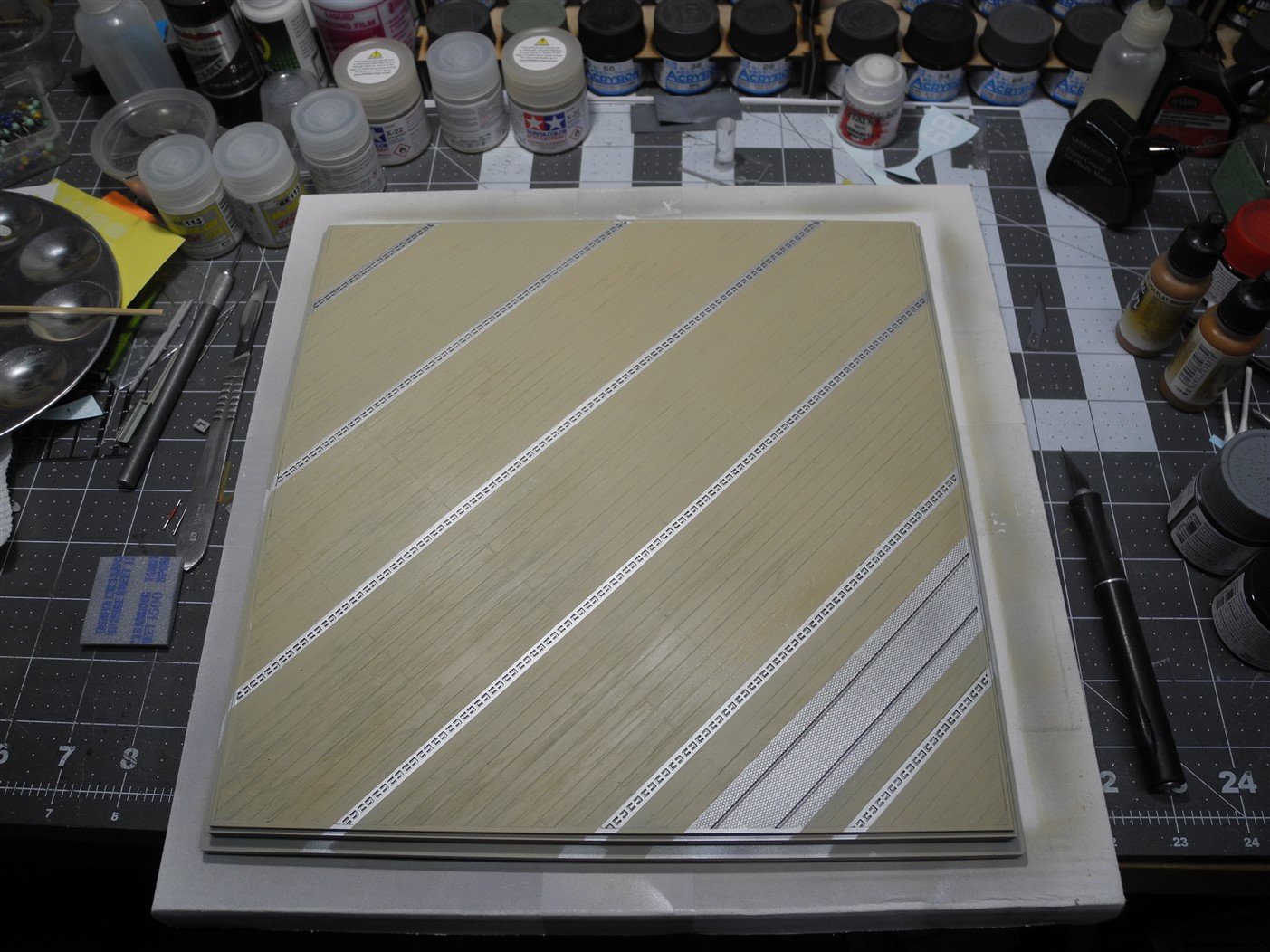

Here, the deck has been painted in a teak color, the deck drains painted in a steel color, then everything covered with a good coat of dull varnish. After the varnish has had a full day to dry, will apply hairspray then cover it all with a deck blue. Some chipping and abrasions will be made to simulate wear and tear on the deck, exposing small portions of the teak and steel colors.

-

SBD-3 Dauntless 1:48 Hasegawa - Edwardkenway-FINISHED

CDW replied to Edwardkenway's topic in Non-ship/categorised builds

Shep Paine helped sell a lot of Monogram kits with the diorama/detailing instructions that came in their kits in the 70's. Made a huge impression on me. -

Bell UH-1H Huey By lmagna - Dragon - 1/35 - PLASTIC

CDW replied to lmagna's topic in Non-ship/categorised builds

Did you watch it to the end? It's heartbreaking really. Makes me in awe of the resilience of the US Marine. -

Bell UH-1H Huey By lmagna - Dragon - 1/35 - PLASTIC

CDW replied to lmagna's topic in Non-ship/categorised builds

This is the story of Al White, USMC. I can assure you, his story is not only captivating but authentic in a special way. -

B-25 Mitchell "Meet Miss Runyon" by Javlin-HK-1/32

CDW replied to Javlin's topic in Non-ship/categorised builds

Hoping nothing but the best for you Kevin. Make a speedy and full recovery then get back in here and dazzle us with a great finish on this model. Be well, brother. -

Eureka 1:32 WWII USN Aircraft Carrier Deck Pictured here is the Eureka 1:32 scale USN carrier deck kit. The deck is manufactured in Poland and sold by various shops in the USA. I found mine on Ebay. Very reasonably priced. The main deck is cast of lightweight resin. My copy looks perfect, no pinholes, no blemishes whatsoever. It comes with a pre made frame that fits around the resin carrier deck. It also comes with a braided wire to simulate the arrester wire. In my photos, I have first painted the deck with Mr Color 1000 primer/filler. Next will paint the deck in an acrylic teak color, apply chipping materials before covering it all with a deck blue. The chipping will reveal the teak deck boards beneath the blue. The deck drains will be painted in a steel color. Deck striping in a light gray. Will use a wood tone paint for the frame.

-

Thanks for the comments gentlemen. Much appreciated. Thanks for the comments... I have no experience with 1:72 scale, but I believe there are several different manufacturers of the Avenger in that scale. In 1:48 scale, I am aware of three manufacturers. There is the venerable, old, Revell Monogram kit, the Accurate Miniatures kit (in several different versions), and (I believe) a Hobby Boss version. Of these three, I have experience with the Monogram and Accurate Miniatures kits. The Monogram kit is a very old tool, but is proportionally a good scale model. It has raised details and toy-like working features but I have seen some outstanding scale models built from this kit. The Accurate Miniatures kit is very good. Recessed panel lines and a much more modern tool than Monogram. Unfortunately, the manufacturer is out of business but there are other companies (Italeri?) who have packaged the model for sale. It came in several different versions. The Hobby Boss kit is the newest tool of the three, but I have no experience with it at all. Last, in 1:32 scale there is only Trumpeter. It comes in several different versions. Many modelers the world over called it the best 1:32 scale plastic aircraft model ever produced when it came out in 2005.

-

Many moons ago, I was a swamper for dozers working in the mountains doing gas and oil pipelines. Because of mud and clay sticking to the tracks, would have to clean and adjust the tracks daily, sometimes multiple times a day. Otherwise, the tracks would jump right off the drive sprockets. I'm certain military tracked vehicles would need the same kind of regular maintenance, which is why I believe they went to wheels/tires on some of these newer combat vehicles. Of course extremely heavy vehicles such as M-1's need the tracks to spread out the extreme weight of the vehicle over a larger surface area.

-

They did stop importing to the USA when they were Gunze. Once they became Mr. Hobby, imports to the USA resumed. Not sure of all the details of what happened and why, but it could be they had to reformulate to pass certain hazardous designations by the USA. I could be wrong on this, I'm not really sure and have only heard tales that I'm repeating here.

-

B-25 Mitchell "Meet Miss Runyon" by Javlin-HK-1/32

CDW replied to Javlin's topic in Non-ship/categorised builds

And it's often the case that sourcing the right materials is as much or more of a challenge than building it. -

I've been hoarding the 1:350 Roma and a few detail sets. Your Heavy Cruiser Zara is tempting me to build the Roma. Whether it's automobiles, ships, or even aircraft, (not to mention the beautiful women) the Italians make some sexy looking things.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)