-

Posts

344 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikeaidanh

-

Just to amplify Tony's advice to buy in Germany. Do It! The prices in the UK are a rip off. Either SAT Berlin or TBS-Aachen. will see you right. I have bought all but one of my Proxxon tools this way though I do not have either of their saw tables though as I believe the Byrnes saw from the USA to be a better bit of kit, more expensive but better. Good luck with your "tooling up" Mike.

-

WORKSHOP CHAIR

mikeaidanh replied to Cap'n Rat Fink's topic in Modeling tools and Workshop Equipment

Well, I tried lying down to do some work. No good. I fell asleep and when I awoke I could not remember why I was on the floor. I have just realised that I cannot remember when last I had a good idea. I hope they haven't gone for good. Scary! Mike. Ps. sorry for interrupting this serious topic. -

WORKSHOP CHAIR

mikeaidanh replied to Cap'n Rat Fink's topic in Modeling tools and Workshop Equipment

I am considering lying down to work as I will be close to all the bits and pieces that I drop. When I have tried this out I will report back. Mike. -

Hello Dee_Dee, I have been looking at your log as this model is next on my list. I intend building it at 1:12.5 (ish !) and have just had the keel and bulkhead plans enlarged. I have not bought the kit as I want to scratch build. Your experiences with the hull planking have me shaking with anticipation......or perhaps it is fear! I look forward to seeing more of your excellent build. Mike.

-

Proxxon compound table -- Opinions?

mikeaidanh replied to rtropp's topic in Modeling tools and Workshop Equipment

I have been pleased with mine so far. The hand wheels are a little small and, as discussed elsewhere on the Forum, they would benefit from enlargement. I have not needed to do any adjusting yet but it looks likely to be a simple operation. For the price I would say it is a good bit of kit. Mike. -

What camera do you use

mikeaidanh replied to Scholzy's topic in Modeling tools and Workshop Equipment

iPhone 6 for me Dave. I can get in really tight with that. Apple rules! Mike. -

Many thanks to all who commented. That is one of the nicest things about this forum.....and long may it continue. I shall now go away and think about my next, and first scratch, build which should be a Sloup Coquillier a Brittany fishing vessel. Back soon, Mike.

- 28 replies

-

What astonishing detail ! This is an inspirational build. Mike.

- 425 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

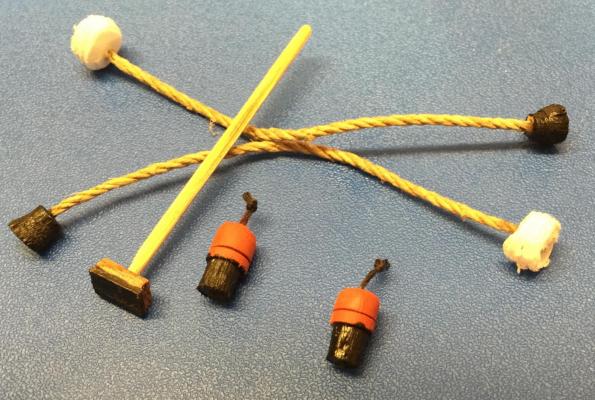

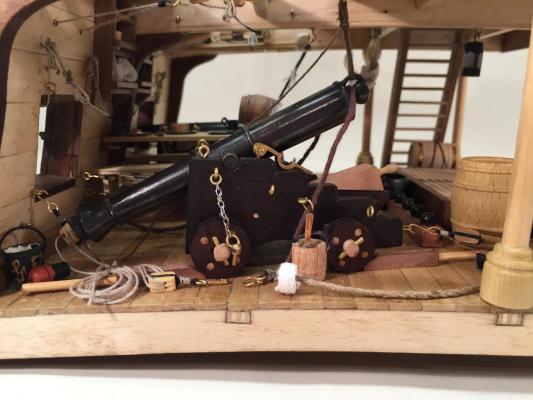

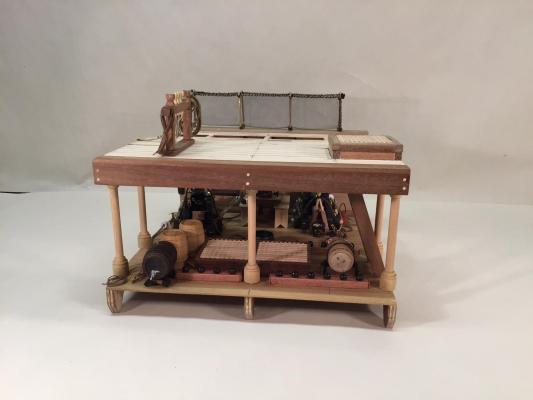

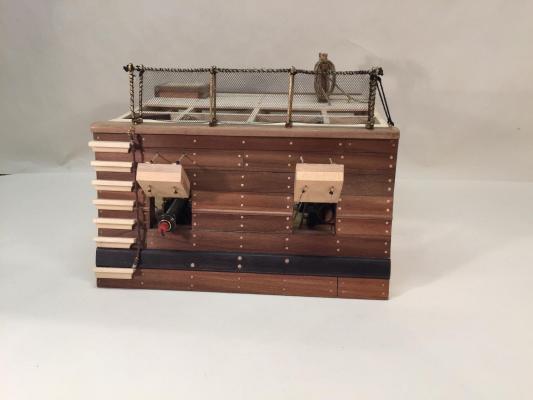

Back again for the final part of this build log. There were an assortment of parts to be made to complete the below deck display and, in no particular order, here they are: Storage racks, Tiiddly table hangers, Table, Water breaker, Plates, knives, cheese, tankard and "square meal" Fire buckets, Hammock, The "tidy" gun showing training levers, fire bucket, cartridge and tackles, Serving tools, Bench with squeeze box, Grease bucket and brush, Tompions, flexible rammers and spongers and a deck broom, The Legend. HMS. Innominate Is carrying out some self maintenance. One of the great guns has been serviced and tidied away with all the serving tools neatly stowed. The gun crew are about to enjoy a meal and, maybe, some music. Meanwhile the second gun is still being worked on. One trunnion strap is open and grease is being applied. There seems to be a problem under the barrel as well as it has been hoisted up to the deckhead and secured whilst work goes on. The training and hauling tackles have been used to position the gun. The training levers are seen acting as wheel chocks; I have no proof that this was done but logically it might have been. Where are the crew? They are in my minds eye. They fade in and out of this representation of a moment in time and, if you concentrate, you will see and hear them as I do. I have greatly enjoyed this model and by using the plans as a guide I think I have achieved an interesting object that, hopefully, my great friend and O'Brian aficionado will enjoy whilst he reads of Jack and his adventures. Mikeaidanh 19/02/15

- 28 replies

-

Can i live without a BYRNES TABLE SAW

mikeaidanh replied to shihawk's topic in Modeling tools and Workshop Equipment

i have used the tilt table to cut the angles on the gun port hatches for my gun deck cross section. The kit solution was to make them up from three laminates and file the bevels. Sod that for a game of soldiers! Mine were made from solid and cut on the Byrnes saw. Thank you Jim. Mike. -

Can i live without a BYRNES TABLE SAW

mikeaidanh replied to shihawk's topic in Modeling tools and Workshop Equipment

Question !. "Can you live without a Byrnes saw" ? Yes. Question 2. "why would you want to"? -

Thank you Boyd. All the parts you need to follow the kit instructions are included. You may find, however, that it is pleasing to add or modify as you go. The cannon barrels for instance did not have eyes for the breaching ropes. These were fashioned from brass wire and glued into holes drilled to take them.The boarding ladder is not part of the kit but I think it adds interesting detail to the model. Similarly the ladder to the upper deck and its hatchway are not part of the kit. I think the builder can pretty much do as they please around the basic structure.Once I get to grips with the below decks details the fun will really start! I suppose, in summary, that these cross section kits are open to more interpretation than those for specific vessels. Mike.

- 28 replies

-

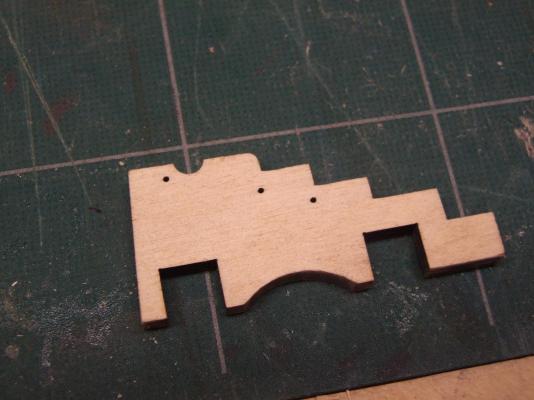

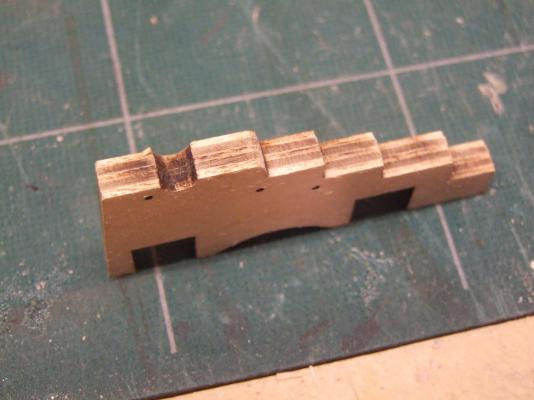

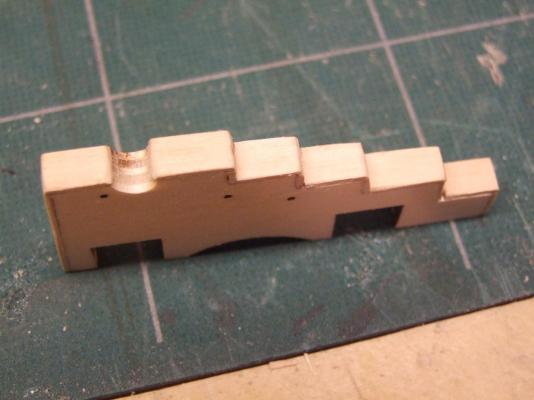

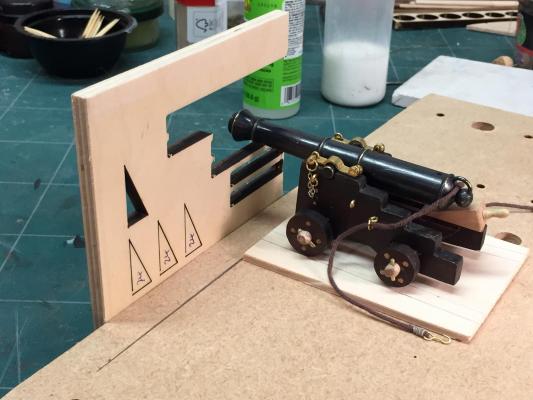

Back again. The next task is to build the two great guns. Some of the kit parts are of plywood and whilst the grain on the faces is ok, being quite fine, the laminate edges look all wrong. At first I was going to cut new parts but then I realised that may not be a one off situation so i decided to experiment with facing the edges with thin slips. The images below show the outcome and although not perfect they will suffice. I think with more care I could have produced a better outcome and I believe this technique has some merit. The gun barrels need to be black and I tried both Humbrol Steel and Gunmetal Metalcoat and settled for the latter. On top of this I rubbed on grate blacking before polishing to a dull sheen. The barrels are not yet finished as I intend replacing them when the build is complete. The next image shows all the parts for one cannon. And the next image shows the two cannon fully assembled and with their shot garlands. Here I am determine the correct distance from the gun port before fitting the cannon with screws through from below into each of the wheels. The next image shows one cannon and its tackles in its final position. The second cannon will need to wait until all the other fitting out is completed as access below deck is tight. More later.

- 28 replies

-

Jack, Your log has been a very good read. Thank you. This model has now been placed on my "must do" list partly at my ancestors insistence!. I just hope there is enough time left for this, and all the others, before my exit date! Mike.

-

For UK readers, The thin rip guide featured in this thread is available in the UK from Axminster Tools who list it as the Axminster thin rip guide! It sells for £21.96 Mike.

-

Proxxon Micro MBS 240/E Band Saw Review

mikeaidanh replied to Blue Ensign's topic in Modeling tools and Workshop Equipment

B.E. I am glad to see you promoting TBS-AAchen. They are the dogs nuts in my humble opinion. Good saw too. I love mine. Mike. -

Thanks Mobbsie, I have been away for a few days but will shortly get back to stage two, the great guns. More anon, Mike.

- 28 replies

-

Thanks Mark, I will try adding that idea as well. The Drum Sanding Committee may defy all logic and design the perfect system......or maybe not! Mike.

-

Hello Markus, Sorry for the delay in replying to your question but I have been away in an area with little or no phone and broadband coverage. Bliss! The dust extraction on my sanding rig is fairly good though not perfect. Lots of dust does get pulled passed the tool but not all of it. I have never used this set up on ply thicker than 12mm so the height problem does not exist. The possibility of limiting the amount of dust escaping was there so I took it. It may be worth adding a half shell at the back of the tool, also extracted, to catch the dust that spins off from the tool. Yes, I like that and I will add it. Mike.

-

Further to Antony's post. I have used various sizes of sander drums mounted as shown in the following image for shaping plywood sections The various size drums are matched to their own table which is square to the drum axis. The tables can be easily removed and replaced. The base of the unit is attached to a vacuum dust extractor. I have not used this set up for model work...yet. Mike.

-

Leaving it. No point going any further. Mike.

-

drill press/mill decision

mikeaidanh replied to peewee's topic in Modeling tools and Workshop Equipment

Nigel, I like your approach. As you probably know there are some heavy duty double sided tapes available these days so it may not be necessary to look beyond them for a fix and this would allow reversion to the original state if a particular job required full clearance. Mike.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.