-

Posts

1,824 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tkay11

-

There used to be at least two Ballahoo builds on MSW 1.0 (i.e. before the Great Crash) but their logs disappeared with it and have not been replaced. I had thought either vulcanbomber or bangle was one of the ones who did the build, but a quick search on their names now suggests that my memory is haywire as there is no reference to Ballahoo under their names. I also searched the Internet Archive of MSW 1.0 but there was only one page available for Balahoo under the name cornishxxx (who doesn't seem to be on this rebuilt forum -- so this is by way of saying it looks as though you can't ask an original builder to repost their logs! I think the choice is whether you want to have guidance on your build for the particularities of your kit or whether you are happy to go for general advice. If you like the Ballahoo then you'll get lots of support anyway as you come across problems (most problems with builds are not really specific to a model). If you want the security of seeing how others have built a model, there are one-masted models such as the Chatham, Lady Nelson and Sherbourne which probably are similar in construction and in the same price range (although on this forum there are now no Chathams being built). Others have gone for the Bounty Jolly Boat as a nice first build. Either way, as has been said, you will pick it up fairly quickly with lots of support from people who will be looking out for you. This is a particularly friendly forum from that point of view -- many of the most experienced modellers on this site have often stated that they too at one time have been through the same issues with a first build and are only too eager to help others. The moderators keep a sharp eye out for new builds so that they can do just that. Tony

-

Quiet as far as the forum goes. I've been very busy with supporting a music festival run by my son as well after having returned from a long trip abroad, but I've also been re-thinking how to make blocks as I discovered that my method of attaching hooks to the blocks made the whole unit (block + hook) so large that there was no room for the ropes between blocks! All the same, it's lovely to see your bowsprit, Gregor. Now that you're ahead of me in construction I can learn from you -- so that's a real bonus! Tony (hoping to have something to show by the end of the year!)

- 210 replies

-

- Sherbourne

- Cutter

-

(and 5 more)

Tagged with:

-

Well, thank goodness it's resolved so you can start the new year afresh. You must have been quite frustrated. We're looking forward to the build. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Budget Lathes in UK; Advice please!

tkay11 replied to Phoenix_63's topic in Modeling tools and Workshop Equipment

Nice to know about Amadeal. I hadn't heard of them, and as they're in London that's handy for me. Keep us posted as to how you get on. Tony -

Budget Lathes in UK; Advice please!

tkay11 replied to Phoenix_63's topic in Modeling tools and Workshop Equipment

Have you looked at the ones at ArcEuroTrade? They're at http://www.arceurotrade.co.uk/Catalogue/Machines-Accessories/Lathes. The baby lathe is £255 and has good reviews. You just need to follow the advice when setting it up to check everything's working as best it should. Tony -

Cad Programs

tkay11 replied to michaelpsutton2's topic in CAD and 3D Modelling/Drafting Plans with Software

I'll second that. I also use TurboCad and it really is not expensive. However, I am tinkering with Draftsight out of interest, but it is only 2D. TurboCad allows you to work in 3D as well. Tony -

Cad Programs

tkay11 replied to michaelpsutton2's topic in CAD and 3D Modelling/Drafting Plans with Software

Draftsight is free and runs on PC, Mac or Linux. Tony -

What do you use your mill for ?

tkay11 replied to captainbob's topic in Modeling tools and Workshop Equipment

Just for the interest of those who've been following this topic, I've posted the modifications I made to my Proxxon MB 140 drill stand to make it into a milling machine as well. The link is http://modelshipworld.com/index.php?/topic/4539-how-to-modify-proxxon-mb-140-drill-stand-to-act-as-mill/?p=130660 Tony -

Just for the interest of those who've been following this topic, I've posted the modifications I made to my Proxxon MB 140 drill stand to make it into a milling machine as well. The link is http://modelshipworld.com/index.php?/topic/4539-how-to-modify-proxxon-mb-140-drill-stand-to-act-as-mill/?p=130660 Tony

-

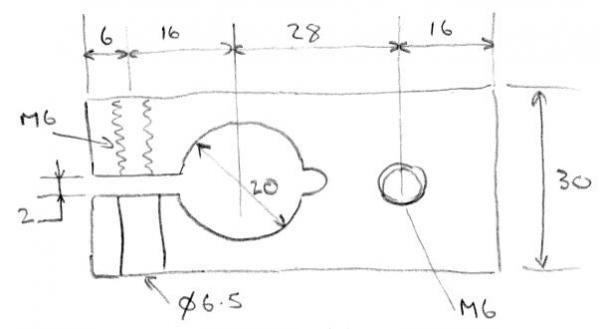

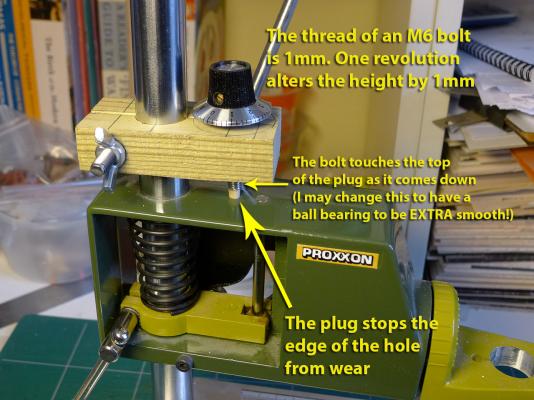

I was thinking about how to modify my Proxxon MB 140 drill stand to have a reasonably accurate vertical feed so I could use it as a mill. So I did a web search on 'Proxxon stand modification' and after several pages of results I came across this modification by a guy called Stu who posted it in a Railway Modellers' forum. I asked him for the details, and he very kindly provided the following plan: He made his block out of Perspex, but I have never worked with Perspex before, so I thought I'd try it with an old piece of pine that was lying around. This wood one works fine and I thought I'd share the results with the forum because there has been such a lot of interest in mills. However, I have ordered a block of 100mm square Perspex to make another one because I have a feeling the screw threads will last longer. The following is a picture of the original stand before modification: The following are the tools I used together with the block of wood ready cut (the very cheap drill stand I used to cut the 20mm and other holes with my large drill is not shown): As you will note, this is not an expensive modification once you have the drill stand, tap wrench and spade bit -- all of which would be useful for many other jobs. There are a couple of changes I made to Stu's original plan: 1. The tightening bolt at the back is not threaded into the block. Instead I drilled a 6mm hole and it closes with a simple wing nut. 2. Rather than driving the 'height' bolt directly on to the top of the stand, I cut off the tip of an old chopstick, put a layer of CA glue on the end to stop it fragmenting when the bolt comes into contact, and use it as a plug in the M5 hole left by the depth stop screw (which is removed when the stand is used as a mill). As you will find out when you try this, the dimensions are not critical. The stand's post is 19.8mm, and because the diameter of the flat bit was 20mm, a good slit is needed in the block to give enough clearance for the sides to flex. 2mm is just fine when you put a 6mm hole across it for the M6 bolt with the wing nut. You'll note that the slit I made on the other side of the hole for the stand looks as though it reaches into the hole for the depth bolt. This is actually the bottom end of the circular saw cut, which is much shallower on the other side of the block. When I make the next one out of Perspex I'll file it out instead. I did also buy a shielded ball bearing for the bamboo plug but it works so well without the ball bearing that I'll leave it out until it proves necessary. In practice it seems accurate. One turn of the knob gives a 1mm change in height because the M6 bolt has a thread spacing of 1mm -- so that suits the knob I bought from Maplin very nicely indeed! I hope this is as useful for others as it has been for me. Once I receive my Perspex block I'll post pictures of that as well. Tony

-

Ship's Launch

tkay11 replied to malcermie's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Alexandru provided a detailed set of pictures of one of his Victory's boats at http://modelshipworld.com/index.php?/topic/1474-34-ft-hms-victory-launch-by-alexandru-scale-148-completed/?p=29512. Tony -

OK, jud, I got it! And I've corrected my previous question in the light of this. Tony

-

Sorry, jud, I'm lost. What's a Smitty? Tony EDIT (after jud's edit): Oh! A smithy! All is clear!

-

Looks like the Unimat (not the old style Unimat but the newer plastic model which is totally unrelated to the old all-metal machines). A quick search will show lots of comments about it if indeed it is the basic Unimat. Most of the comments have been about how limited it is, but of course that is the point. Tony [EDIT: Antony got in before me. I was replying to rtropp's picture just above Antony's post]

-

Great to see you re-posting these, George. Thanks very much -- they really will be a help to the Sherbourne (and other) builders! Tony

- 10 replies

-

- Sherbourne

- Jotika

-

(and 5 more)

Tagged with:

-

What do you use your mill for ?

tkay11 replied to captainbob's topic in Modeling tools and Workshop Equipment

Jigs are always interesting, so a new thread would be great, Nigel! Tony -

Clinkered-blinkered? No! Carveled-marveled. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Eamonn: I think you can buy the plans for some models of the Bounty, depending on which is the kit manufacturer. I know Cornwall Model Boats has plans from the Amati and Sergal kits (links provided) for £15-20. Even if yours is not from one of these manufacturers, you might find that the details are similar enough to be of help. You can even write to manufacturers to obtain the plans directly. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Just one further thought on this point. Many, including myself, see each stage of a build as a model or project in its own right. So there's the planking, then each different type of deck structure (catheads, anchors, windlass, guns, hatches, companionways...), then the rigging, the painting, the sails and so on. Each little bit has its own skills to develop. So to my mind the question is how many of these bits do you want to start to learn with your first kit (I say 'start' as I have a feeling it's an endless process)? Linked to this is how quickly you want to achieve a completed ship build. My own answer is that I am more than happy tinkering away at each little project on the Sherbourne. I am not in the least fussed as to when or if I get 'to the end' -- each of the bits so far has been more than totally absorbing with the research, the planning, the learning of the use of each tool, the making, the mistakes and the re-making. There's a whole range of attitudes to this kind of question amongst the builders on this and other sites. So don't be worried about your own thoughts. Whatever they are they'll generate interest on this site and much pleasure for yourself. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

You can see a few builds of the Swift on this site (including Dirk's completed build!). The rigging appears to be simpler than that for the Sherbourne and there's not so much to put on the deck. Others have also recommended the Bounty's jolly boat, which has several builds as well. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Jan, I've seen about 3 or 4 models of the Sherbourne with clinker planking but not any with wood from the kit. There was a debate on MSW1 about whether a cutter of that date would have been clinker built, but it was as likely to have been so built as not -- so definitely something up to the builder to decide. From what I've seen, although it might be possible to do with the 4mm strips from the kit, a lot of people use thinner strips of wood for the second planking, whether clinker built or carvel built. Sumner has clinker-built his Sherbourne, which you can see at http://modelshipworld.com/index.php?/topic/661-hmc-sherbourne-by-sumner-caldercraft-scale-164-kitbashed-to-1763-nmm-plans-first-wooden-ship-build/?p=106782. He used 4 x 0.5mm strips. I used wider and thinner strips (bought from Cornwall Model Boats) but didn't clinker build, as you will have noted. I suppose the answer is that you try with the wood from the kit first and see what you think. Eamonn: I wouldn't worry too much about confidence-building with another kit. The fact is that many (including myself) have had the Sherbourne as a first build and almost as soon as you start you'll find you're surprising yourself with the fact that you can do it. Try not to be put off by the wonderful skills shown by others with the Sherbourne -- I think they all have had several previous models under their belt and have built their skills as gradually as we all do. The great thing about these wooden models is that mistakes are for the most part rectifiable. Some people have even taken their planking apart and started all over again! Whenever you come up against a problem, search the forum, have a look at builds of other ships, go to the books, and, most important of all, think. I really do recommend Hubert Sicard's website as he does show how to do most of the basics (and not so basics) with ordinary tools -- the only powered one being his mini-drill. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

That's great, Greg. It really is a nice kit and I've been helped greatly by all the expertise here (especially by those who have kit-bashed the Sherbourne) as well as by George Bandurek's 'Super-Detailing the Cutter Sherbourne' (which I bought from Model Dockyard), the Anatomy of the Ship book on the Cutter Alert, and the wonderful hints and tips on Hubert's web site 'Wooden Ship Modeling for Dummies'. We're really flourishing now with the Sherbournes. I noticed you were on MSW1.0 before but can't remember if you had a build going. Looking forward to your new log -- which looks as though it's going to start at around the same time as hollander's. I'm sitting here in Northern Nigeria planning how to re-do the 3-pounder guns when I get back at the end of the month as I now realise I mis-read the plans for them terribly (I thought the sides raked inwards vertically as well as horizontally because I hadn't realised that the drawings in the AOTS Alert were perspective drawings rather than the plans I thought they were!). Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Thanks a lot, hollander. Welcome to the little Sherbourne fleet we are building! It's always great to have another person to contribute to the builds as everyone has a distinctive approach and brings different ideas to this lovely little cutter. I am certainly looking forward to your log when you begin your build, as many others will be, I am sure. You will have noticed how friendly everyone is on the forum, so as you get on with your build you can look forward to lots of helpful comments and support as well as to people responding to the ideas and experience you bring -- from whatever aspect. I notice you say in your other post that you are not so new to modelling, so it will be nice to hear of that experience. It has been said many times on the forum that there's no such thing as a stupid question, so don't be afraid to ask about anything over which you are puzzled. Every builder here has been, at some stage, through the process of learning and even the most experienced tell us frequently that they love this hobby because they continue to learn. If you also want suggestions about books and other sites that we have found helpful, don't forget to ask about these as well -- though it may be that you have already done enough research of your own in this regard. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.