-

Posts

3,043 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Looks like you are making progress, should be an attractive model when finished. Just a point to satisfy my curiosity: have you allowed for the camber of the deck? From the photos, especially photo #3, it seems the tops of the bulkheads are at full height for the intended level of the finished deck. If you have not glued them in place yet I suggest you cut the camber before assembly as it will be much easier than trying to do so after they are glued up. The camber will be the same along the whole length of the deck so a simple jig should make quick work of all the bulkheads. Use the curve shown in the stern view. If you have this in hand already, ignore me 🤐. Interesting subject, I will be watching to see the progress of a fellow first-time scratch builder. Bruce

-

I am lucky enough to have Timberline a few miles away. They have lancewood, lime, English lime and Castello on the shelf plus plenty of others. I didn't have the opportunity to discuss their sources in detail but know from the past that they only deal in 'legit' wood. Back to lancewood, thanks Vaddoc, I find the wood database to be compulsive reading 👍. It mentioned good turning properties but in this hobby we all know there is always more to the story. Thanks Bruce

-

I have just impulse-purchased a length of lancewood because I understand it is desirable for masts and spars. Then the questions began to bubble to the surface. (A) Is that correct, it is good for masts and spars? (B) What is the quality that makes it better in that application? (C) Does it have any pros & cons I should know about? My piece was obtained from a luthiers' supplier and I believe is sapwood. The application I have in mind is masts and spars, possibly cap rails? and the masts will have an octagonal section visible. Thanks in advance. Bruce

-

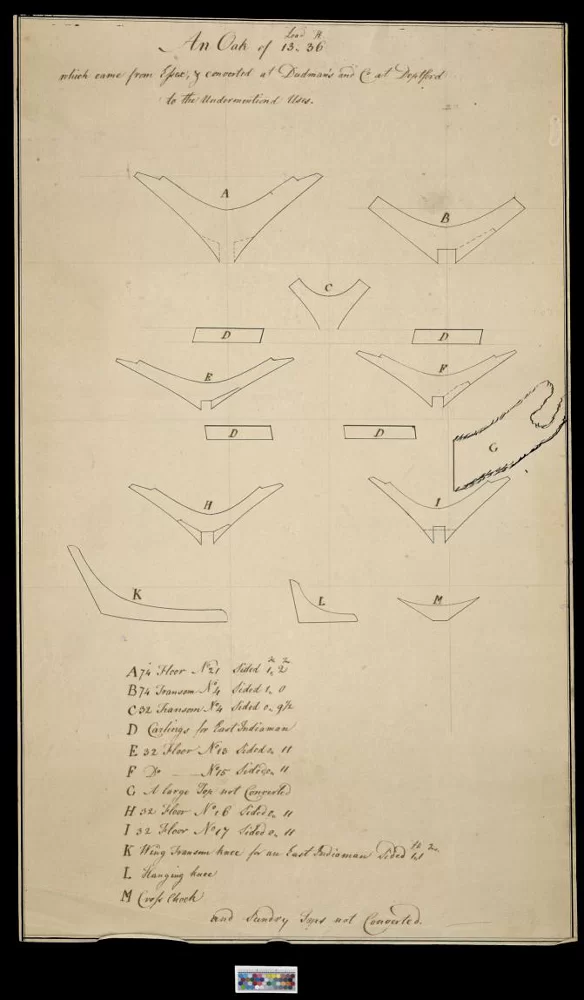

An 18th c record of what pieces were to be made from a piece of oak. This refers to a single piece from 'Load 36' delivered to Dudmans & Co at Deptford for conversion. Sadly there is no date so we can't narrow down which craft might have used these pieces. One of these instructions was produced for each harvested oak and was the contemporary equivalent of a modern work order. They were to be followed strictly. Another example of why the drawing office was always busy!

-

Zac, welcome to MSW from the UK. My advice is to read the advice above, it is all good. I am looking forward to your build logs. FWIW, I can't think of a better reason to get into this hobby than the one you gave: an interest in the history behind the ships. A model shipwright and an amateur historian are heads and tails of the same coin. Ask questions! 👍 Bruce

-

Dutch East India Company Shipbuilding by Wendy van Duivenvoorde Open access document Dutch_East_India_Company_Shipbuilding_Ch.pdf

-

Wayne, ... Good grief, good find, many thanks. 👍 Bruce

- 17 replies

-

- Book

- great britain

-

(and 1 more)

Tagged with:

-

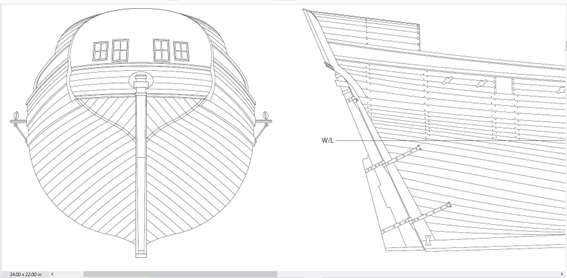

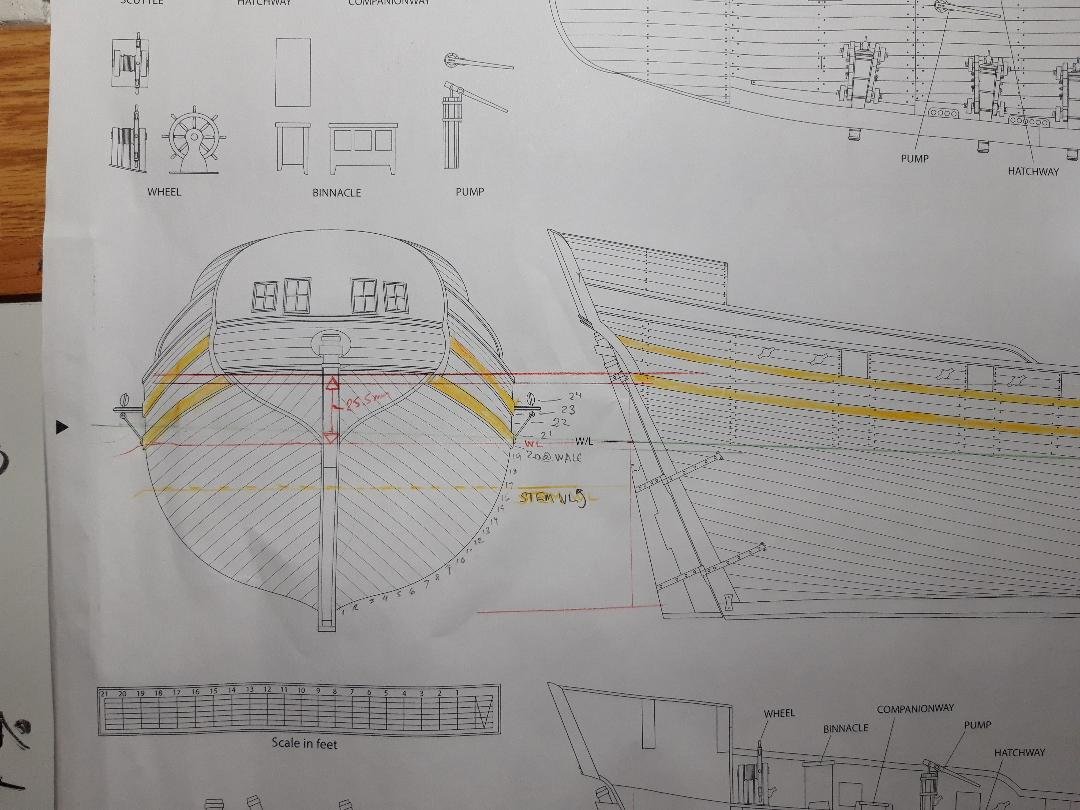

Fairing continues and has exposed a couple of my blind-spots. The filler blocks for the stem seem to be working and there are some ‘different-next-time’ moments but generally the process is sound. The stern has demanded some focus and re-thinking. No matter how much I stared at the assembled hull former and bulkheads I could not believe the planks would be able to run in the neat straight lines indicated on the stern view of the Stuadt plans as drawn. See below, pretty, ain’t they?: There are no fashion pieces illustrated but several different views are included in the plans to locate the pieces that make up the transom. It seems I missed something because I put the lower of the two pieces too low. This wasted a lot of time because of course the run of the planks now did not follow the plans. Doh! (Most of Post# 31 above is given over to me making this piece and then fixing it in what turns out to be the wrong place.) The error is understandable (he says defensively) as the location is shown on the plans but without mention of the fairing needed to all four edges of the piece. I tried to second guess the designer and got it wrong. Hopefully this will be of interest to anyone making their own Mediator. Having found my error, I focused on how to achieve those lovely straight lines of the stern planking. Fortunately, aligning with the lower wale gives a precise point of reference for this. Another view in the plans gives a positive position for the wale in relation to the level of the deck at the waterways so this can be taken from the assembly I have so far. See red lines in picture below. So, the plan is to fit a dummy wale, align the naughty transom piece and work upwards from there. Why upwards? Because the second issue that I encountered, while minor, still is at the stern of the boat and I must view them all together. The back of the ship has an enclosed cabin. One of the defining visual features of Mediator is the seamless transition from hull planking to cabin sides and cleanly into the ‘roof’. This is often associated with Bermuda sloops but was common also along the Eastern American yards at the time. On the model the shape of this cabin is defined by three bulkheads. They slot into the tail end of the main former which also creates the top of the cabin profile. The top profile of all three flow logically but the sides of the middle bulkhead do not extend to full width so I will have to fettle something to give support to the planking. The three bulkheads in the picture are dry fitted. Here is the improvised way I faired these bulkheads with my Foredom. I have come to love my Foredom. Sigh... So none of this is a problem, just stuff to do and enough to convince me to leave permanently attaching the cabin bulkheads, which may have to be modified, until satisfied that the transom and wales are all spot on target. It may be that I am getting ahead of myself but I want to get the lines of that cabin right, and I can’t complete the fairing until the transom is in place, and those junctions affect the cabin, and on and on… In case it sounds like I am grumbling, let me say for the record I am enjoying the whole process. Bruce

- 43 replies

-

- mediator

- first build

-

(and 1 more)

Tagged with:

-

Welcome to MSW from the UK, I look forward to seeing your work. Regards, Bruce

-

Hello Kevin, I'm glad you asked and will start things off. I have the Foredom SR with flexishaft and 6mm key-type chuck. It is one of the standard entry-level packages with foot control. I thought I would wait to see which other end-pieces were right for me and so far I don't think I will be ordering any more. The 6mm chuck is good even with .8mm drill bits. I keep the chuck key in a spring clip beside the work space and (so far) have not suffered for lack of quick-release handpiece. Perhaps if I ever get into some serious detail carving with a need to constantly change burrs that will change but not yet. One thing I now know for certain is that, at least for me, the foot controller is a must. It gives me an extra hand to wrangle those fiddly little bits. BTW, the business end of the standard SR handpiece has parallel sides and works well in a clamp. I am not sure this is the case with the QR handpiece. I made a clamp-on worktable from wood scraps in about half an hour that works fine and gives me a small work surface for offering pieces up to the drum/burr/router bit. I had something similar for my Dremel but the foot speed control and high speed of the Foredom makes this the better tool for that job. EDIT: Forgot to say that one lesson learned was that the tool is not hanging where I originally imagined. It is also hanging quite successfully on an improvised bit of stiff electrical cable that lets me make adjustments when I am leaning over the workbench or the Foredom is clamped in place. Not sure how that will work with one of the purpose made hangers. The limiting factor can be the distance from the tool to the foot controller. HTH, will be watching for the input from others with their own tweaks. Bruce

-

Yes, I remember that. Good story.

-

The IJN had some a/c carrying subs at the outbreak such as I-15, I-16 etc and then developed the mamoth I-400 class later. I think it was I-15 that successfully attacked the US west coast. Both classes are available as kits, sorry I'm not up to date but there are 1/700 waterline kits, also I know Nichimo did them in 1/200 scale years ago. HTH Bruce

-

Caution! Thread drift strikes again! George, you have rattled my cage. Ouch. I have a piece of old Bermudian cedar which is not pink at all: now I wonder if it really is 'old Bermudian Cedar'. Can you just confirm that you are saying the deck of the model in your picture is old Bermudian Cedar, i.e. pre-1950 cutting, not a more recent harvest? BTW, that model looks nice.

-

Chris, I can’t offer a definitive answer to what orders were given, and when, but there are a few anecdotes in the ADM (Admiralty) records in The National Archives UK to keep the subject lively: 7 February, 1772 - Commissioner Frederick Rogers, Plymouth advises their Lordships at the Admiralty that they should ‘… inform what price is allowed the contractor for painting the names and ornamenting the compartments in ships' sterns.’ ADM 106/1216/96 - 11 February, 1772 – The Plymouth Officers advise their Lords at the Admiralty that ‘the contractor for painter's work here has not been paid for painting the ships names and compartments in their sterns and opine he deserves 6s. (6 shillings) for each ship’ ADM 106/1215/31 - 26 October, 1772 - The Plymouth Officers ordered Thomas Winsloe of Tiverton to write the names of several ships on the stern. They requested from the Admiralty for him to be paid at the rate of 6 shillings for each ship, the price they thought it is worth. ADM 106/1217/208 - 21 July 1773 - Portsmouth Officers report that they have asked ‘… Phillip Avery, the Painter ... the reason the name of the Albion was not written on her stern, when she was last painted at Spithead. They inform us that on their application to the Captain (rear-admiral Hon. Samuel Barrington) for doing it, he told them it was unnecessary as the name was carved and supported by the claws of the Lyon in her Head.’ ADM 106/1220/266 - And then 18 April 1778, Commissioner Proby of Chatham acknowledges ‘Receipt of warrants to rub the names out of the sterns of the Victory and Formidable, …’ ADM 106/1244/116 So here we have at least one captain saying ‘No, not on my ship’. HTH, Bruce

-

And a warm welcome to MSW from the UK. 👍

-

Polaris by JDillon - OcCre

bruce d replied to JDillon's topic in - Kit build logs for subjects built from 1801 - 1850

Looking good, Joe. BTW, ignore my advice in the other thread about Cornwall Model Boats, I see you have already found them. 👍 -

Joe, I hear you. The good news is that it is unlikely you will be the first to encounter an issue with a particular material or kit so ... ask and find out how someone here has already found an answer. Besides our MSW sponsors there are other places that support the UK model-habit such as Cornwall Model Boats ( Cornwall Model Boats - Static display and radio control model boat kits including period wooden model ships.Model Ship fittings, Caldercraft Boats ) to name but one. They stock Occre kits. HTH Bruce

-

Double sided tape works well for this. If you are using a slitting saw blade it's probably best to raise it higher than normal practice and use a slow feed rate. To release the brass from the sacrificial wood without distortion can be a problem, I soaked the whole assembly for a day or so in white spirits to loosen the bond. Plywood may fall apart after this which is the best result.

- 1,124 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.