-

Posts

914 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by drobinson02199

-

-

[EDIT NOTE: As sometimes happens on this site, the pictures came out in reverse order from what I intended]

I'm stuck at the moment because there aren't enough copper plates in the kit to finish the job -- by about 400. Ages of Sail is sending me more, but in the meantime I'm working around it to the extent I can, which is limited.

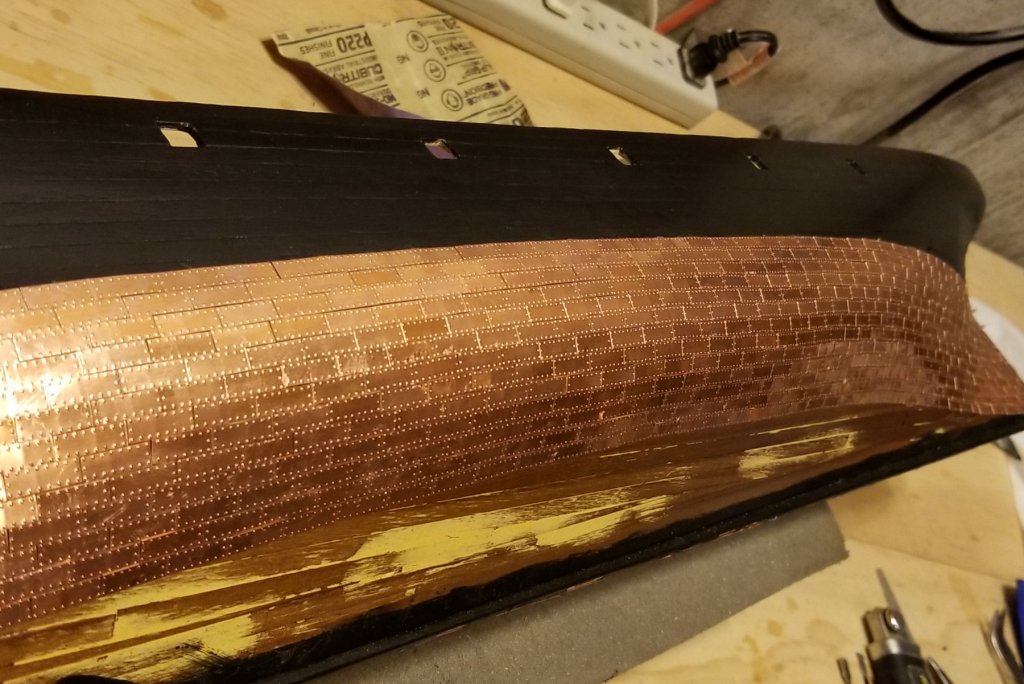

I've mentioned above that I used a different approach to copper each side of the hull. On the first side I started at the keel, then worked up a bit, then went to the waterline, worked down, and then fitted the two together. You can see that in the picture below.

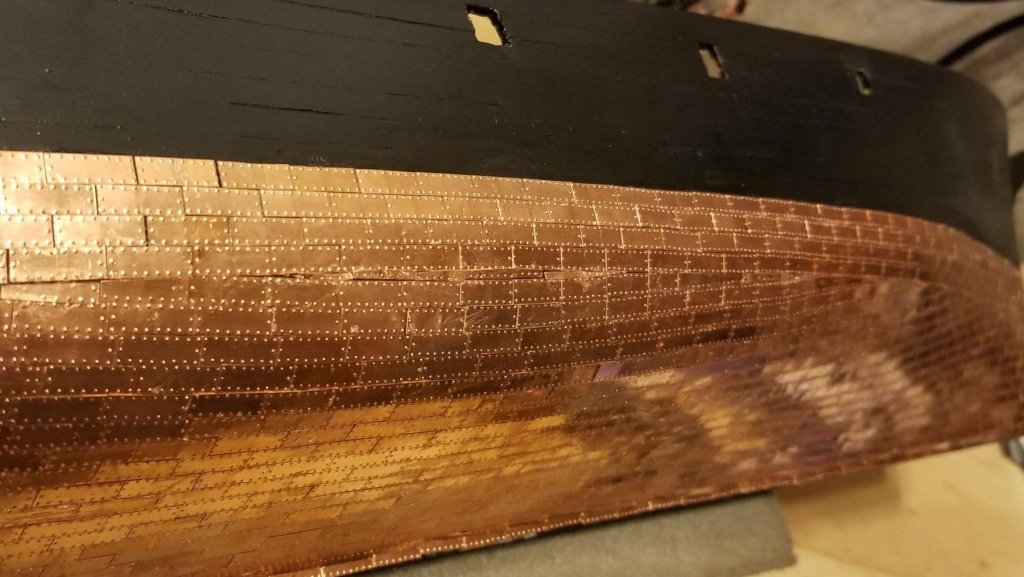

On the second side (the one I plan to display), I started at the waterline and am working down (you can see where I ran out of plates). As the picture shows, it's a much better looking pattern up close.

From 3 feet or more away, the first side looks fine, but the display side looks much better.

Regards,

David

-

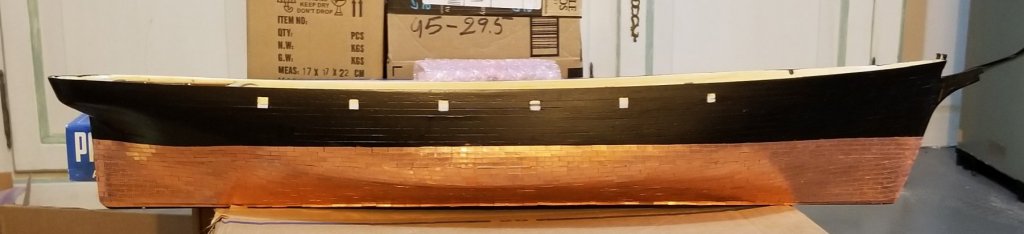

I haven't posted in a while because I've been coppering, coppering, coppering . . .

One side now done -- picture attached. I started on the side I don't plan to display so I could learn from it. Results are fine, but on the other side I think I'll start at the waterline and bring it down to the keel, where the final fitting of odd pieces and shapes will be easier. On this side, I did it where the bottom and top layers met, and it was a LOT of cutting, filing, and fitting.

I'm a bit concerned about my supply of copper plates, but we'll see how that goes. May have to call Ages of Sail for a "make good".

Regards,

David

-

Yes -- as soon as I bring this section over to the bow, I'm going to start on the waterline and work down.

Regards,

David

-

-

HOF:

Thanks -- the YouTube videos were really helpful. He's using very thin plates -- mine are the thicker kit plates so I don't have the same flexibility he does.

Two big things I took out of the videos:

- The idea of end-capping the cutwater, stern and keel. It's given me a new thought on how to do that on my model.

- I'm reflecting on his approach of doing the waterline with a row of plates and then using cut plates in the middle to finish off. I was going to trim plates to fit at the waterline. On reflection, I think his way will work better and so that's what I'll do.

I'm using medium glue all the way, and it's working pretty well. I'll post a shot when I get a bit further along.

Regards,

David

-

-

Here's why I abandoned the tape. I made up a strip of the copper tape and put it above a row of the real plates that I have started at the keel.

It's really hard to get good shots of this because of the way the tape and plates reflect light, but you can see it in these two pics. The pounce wheel does a fair job of making rivet marks at top and bottom, but the divider rivets just don't look right -- AND, the tape is really shiny compared to the copper plates.

Regards,

David

-

Change in direction. I tried my first piece of copper tape, and it just doesn't look right compared to the copper plates supplied with the kit. The impressions made by the pounce wheel are uneven, and the tape is too shiny.

So it's on to individual plates, and I'll probably be at that for a while.

Regards,

David

-

Have now painted the upper part of the hull black. I brushed on the paint vs. spraying. If I spray, I get spray mist all over my workroom (even with major plastic dropcloths) and have to be super careful not to track it into the house. Just a mess. I have a small exhaust fan mounted high, and maybe I'll get motivated and buy some flexible ducting to bring the exhaust down to the spray area I use. But I used a foam brush here and it worked fine.

Time to start coppering. I'm going to see if I can make copper tape work. Stay tuned.

Regards,

David

- GrandpaPhil, tasmanian, gieb8688 and 3 others

-

6

6

-

So here's my plan for painting. I don't want to paint the lower part of the hull, because I've read that paint can be a poor surface for coppering. So as shown in the pics below, I have put pins in the hull just about 1mm below the waterline. I'll leave them in and paint down to them only.

Then when I copper the hull, I'll come up to them and use the holes as a guide for the last copper row, which will cover the holes.

Anyhow, that's the idea and we'll see how it works.

Regards,

David

-

-

Harry:

By "facimilie" for the ports, do you mean the port covers? If so, yes, there are brass ones with tabs.

What happened when you didn't anneal them? Did they snap off?

I've realized that this will be along build -- but that's OK.

Regards,

David

-

Harry:

Yes, the brass bulwarks would have been a help as I have to be really really careful. No need for template as I can take spacing and measurements from the drawing, but just need to be really careful when cutting them out.

The ports don't hit any of the bulwark extensions, so no sequence issue there.

And yes, those strips are rubbing strakes. So much for my nautical vocabulary. 🥴

Regards,

David

-

I've finished the second planking now and have applied 3 coats of varnish, but . . .

The instructions puzzle me, because they call for finish painting of the hull, coppering, and applying decorative wood strips to the outside before cutting the ports and sanding the inside bulwarks. That seems to me to be a prescription for messing up the hull work. So I haven't done the final sand on the varnish or painting or coppering yet, and as you can see I'm cutting the ports now. Tough to get those square and lined up with each other.

Then I'll remove the ribs and sand the inside bulwarks, and THEN I'll paint it and copper it. I'm only going to paint down to just below the waterline, so that the coppering (for which my plan is to use tape) will have a better surface to adhere to.

One of you who has done the Cutty Sark before will likely tell me that I've made a serious sequence error, but it doesn't seem like it. Just another "look ahead" lesson.

Regards,

David

- GrandpaPhil, vossy, tasmanian and 2 others

-

5

5

-

I really appreciate the recent comments of appreciation -- but something odd must have happened on the website to create a notification, because I finished this ship last September.

Nevertheless, thanks all!

Regards,

David

- Martin W and GrandpaPhil

-

2

2

-

-

Hof:

My kit has the flat rail stanchions, and I think I'll live with those.

Are the brass bulwarks specific to the Cutty Sark? Mantua has an extensive UK site (I think it's a distributor, but a lot of fittings) and the bulwarks aren't there. in the fittings section or the Cutty accessories. Thanks for the Mantua email -- I'll think about getting those.

Yes, I am going to copper the hull, but after doing some research and reading about plates popping off, I am going to go with copper tape, onto which I will emboss rivets with a pounce wheel. I think it should make the coppering go a bit faster.

Regards,

David

-

-

Chris:

I don't use display cases. I have them on track-mounted shelving in my office, which allows me to adjust shelf height as I go. When I run out of space, I'm going to put up shelves in my workroom and move my least attractive models there.

Right now in my office, I have six on one wall with room for probably four more, three on another wall with room for possibly two more, and another wall where I could get 4-5. The Titanic is mounted over my flatscreen TV.

Regards,

David

-

Henrik:

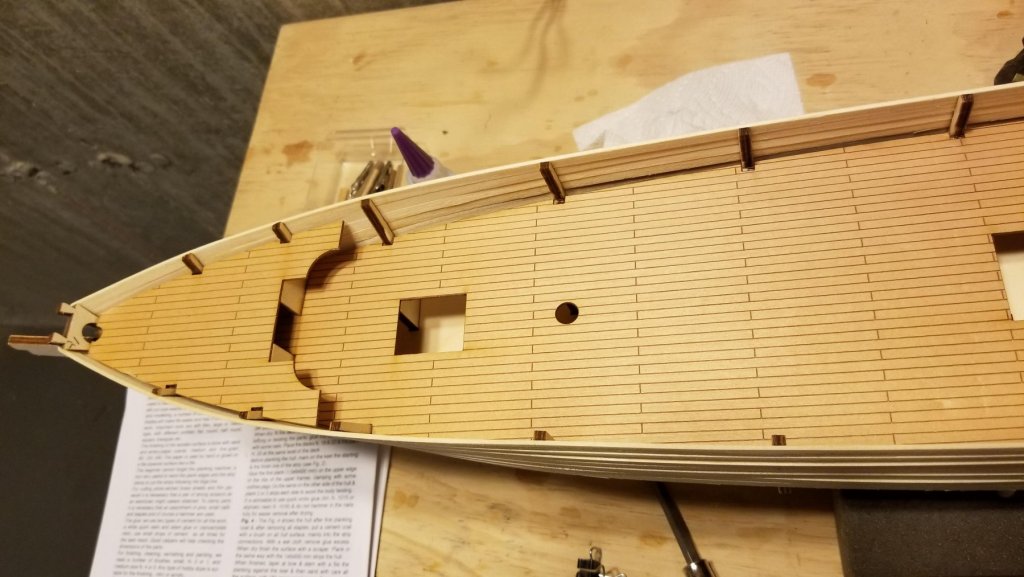

You're right -- the deck pattern is printed on the deck plywood (see picture below).

And it's not a stupid question. When I first saw the decks, I thought "oh, maybe I don't have to plank them." But then I looked ahead and yes, you do have to plank them. So I'm not sure why Mantua did this, but I suppose it's a good guide to get an even deck pattern.

Regards,

David

- coxswain, tasmanian, petervisser and 2 others

-

5

5

-

A progress report on the first planking. Going very smoothly so far. Using my steamer at the stern. Pictures below. I'm making slow progress as I am gluing the planks in segments to be sure of a good fit, and I'm letting the glue dry for each segment.

One thing I noticed reading ahead is that the frame ribs will all be removed above the decks. If you look at the picture of the deck, the bulkhead that will be left is very long, and I was concerned about its integrity. So I glued the planks not only to the frames, but to each other along the entire edge. I was only going to do the edge gluing for the portion above the deck, but have continued further it as it seems to produce a smoother hull.

This is the first time I've done the edge gluing, and I'll now always do it, but I'm curious if it's actually a standard first planking technique and I'm just catching up. Do others of you do that as "standard"?

Regards,

David

- Vladimir_Wairoa, hof00, Henke and 6 others

-

9

9

-

Hull structure completed, frames tapered and ready for first planking. Picture attached.

This is my first Mantua kit. The materials quality appears to be very good -- the frames and keel went together perfectly. The instructions and plans sort of skim things at a high level, however, so I'm glad this wasn't my first (or even my third) kit. Lots of interpretation and prior experience judgment needed.

Regards,

David

- GrandpaPhil, vossy, coxswain and 2 others

-

5

5

-

Thanks, HOF. I found them online and ordered both the general and rigging plans.

Regards,

David

-

Hof:

Not aware of "Campbell's Plans". What are they and how would I get them?

Thanks for the heads up. I have just started -- one of my planned steps is to look for previous build logs to see what people had to work through.

Regards,

David

Cutty Sark by drobinson02199 - FINISHED - Mantua/Sergal - Scale 1:78

in - Kit build logs for subjects built from 1851 - 1900

Posted

While I'm waiting for the rest of the copper plates to arrive from Ages of Sail, I'm doing what I can to move forward. Here are the planked decks.

I can do the next steps involving more deck finishing, but don't want to do the port covers or the white hull strips until I finish the coppering, because they will mar/bend when I lay the ship on its side.

Regards,

David