-

Posts

1,735 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by flying_dutchman2

-

It is a great investment. So many plans and so many possible builds. If you have an interest in 17th Century Dutch Ships. Purchase the book and the plans. Marcus

-

Wayne, Thanks for the link. Nicolaes Witsen and Shipbuilding in the Dutch Golden Age. I have this book and it is an excellent read. The plans of the Pinas are also available in the book 17th century Dutch merchant ships by Hoving. http://modelshipworld.com/index.php/topic/8853-17th-century-dutch-merchant-ships/ Marc

-

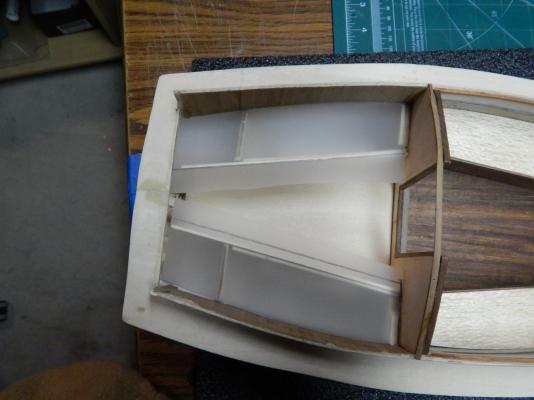

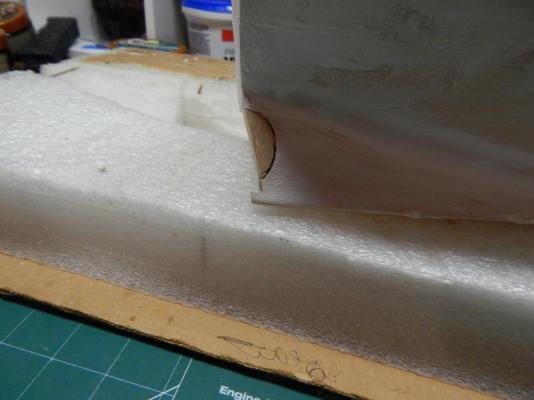

2 - The pilot house does not have a 'U' shaped bench, but has two separate ones. This is the way the kit has it The following is what is re-created for the model to look like the actual boat. Vellum template Took out the back partition and glued in the pilot house. The benches laid in. Next the stern combing, finish all the vertical planking and sand the whole thing. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

After looking at some new pictures from the boat, I noticed there are two major differences. 1 - The front of the cabin is not 'round' but 'squarish'. Re-create like the real boat.

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

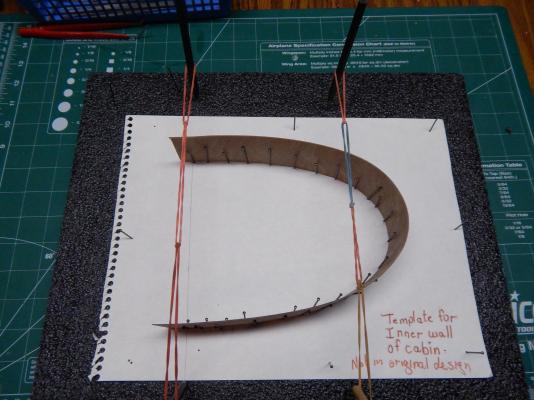

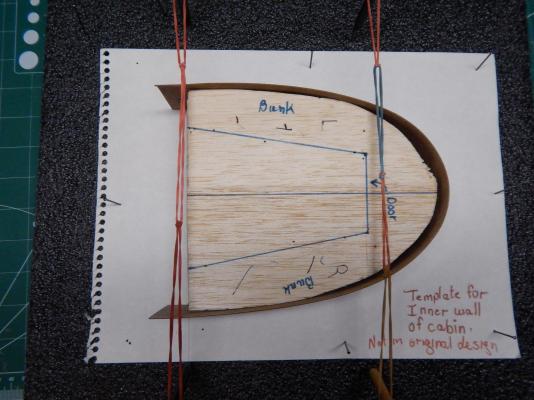

I took apart our 46" old Samsung TV and salvaged this vellum material out of it. Thick and thin sheets. I used them as tracing material. The thick sheets hold there form with numerous touching.

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

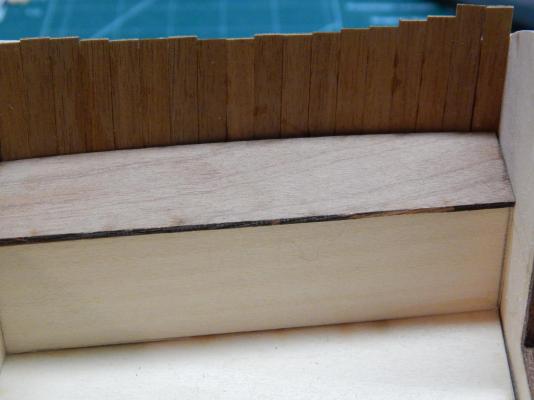

Finished up the cabin Planked the outside combing with basswood strips. Planked the inside of the pilot house with mahogany strips. Completed

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

This model is getting better and better. The molds and the way you do it is new to me and I love what you create with that. Also, I like the coin you used as size comparison. One Gulden? (WOW, cool beans) For the modelers that don't know what that coin looks like it is roughly the same size as a quarter. Marc

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

I want to try this. What is the formula for salt dough? Does it hold together when you create something? Does it really have the consistency of dough? Marcus

-

Many Dutch ships from the yachts (Utrecht, Rotterdam, Amsterdam) to the ship of the line (Seven Provincien, Vlissingen, Bleidorp, Prins Willem, etc). Marc

-

Thanks for the suggestion, David, I will check this out. Hope you are doing well. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Below is the LCD from an HP printer that died. I took it apart to see what it is made off and found the mirror. Very thin and it pretty much fits in the cabin. The mirror is on the far left. Dry fitted everything. This is what it would look like if you look into the cabin. One needs to use a flashlight for better viewing. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

I re-did the cabin / combing with 1/32" birch ply (wonderful wood to work with)and put one window each instead of two according to the kit. Bending the wood to fit the final shape This is the cabin wall that goes below deck. Same wood and thickness as the combing. My sisters boat has no screw on the boat, they have a small outboard motor. So I am covering this part with balsa, spackle, sand and paint. I am redoing the rudder as well. I have sanded the final spackle coat on the boat and spray painted a very light coat of clear on the hull to protect the hull from scratches. In between the kitchen remodeling I am going to start with putting the cabin together and I found a weave thin mirror for the back part of the cabin. It came from a LCD display from an HP printer I scavenged for parts. Will show that in the next installment. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

New mini-mill... CNC and impressive

flying_dutchman2 replied to mtaylor's topic in Modeling tools and Workshop Equipment

WOW, way cool. Time to sell everything that is not nailed down in my house on eBay. If I didn't make enough money on that, take out a small loan, get it and make wooden clocks, sell those to pay off the loan. OR Just wait a couple of years and get it. It will be affordable. Overkill? Probably..... how about 3D printing? In a couple of years this will be all automated with lots of extra's and add-ons. Then we will all be Professional CAD/CAM designers and when all the drawings are done, hit the button, and the following day we have all the parts for the ship. Sand and glue and voila....... you have a model. "Look honey, I just finished the Santísima Trinidad and I only started six months ago". " Next in line will be the Victory which will take me about three months". "Then the armed launch which should take no more than a week or two". "Then I will sell all these models and buy my next CNC machine with X amount of axels". Just think, the market will be flooded with crappy models from Asian countries. Marcus -

I am a bit stuck as I cannot find the paint that looks similar to the real boat. I can do an undercoat but a top coat..... I was mixing different acrylic colors, but that didn't look right ort I am not doing it correctly. I need to read up on "Painting modelships 101". I paint with a brush, no airbrushing.+ My sister sent me a list of the paints and a link to the site where they got the paint. I now have to look similar colors in smaller quantities. http://stright-mackay.com/ Pettit Easypoxy paints on page 431. The topsides are Semi-Gloss White Deck is Sandtone Sides of the cabin are Grand Banks Beige. Bottom anti-fouling Aquagard - a qt of red would do it. Cockpit deck and cabin sole are generic battleship gray. The woodwork is Sikkens Cetol Marine ( Stright doesn't have it, but Home Depot might. If not, we could get it through Hamilton Marine in Searsport, Maine Silica Sand should be added to paint on surfaces where people will walk, for grit - roughens the surface. I will research this and if anyone has any suggestions I would appreciate it very much. Thanks Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Piet; Thanks for the instructions. Only one problem. I am planning to put the boat in a display case which means there will be wires and batteries. There is another solution. I am going to cut a piece of mirror to the dimensions so it fits towards the bow in the cabin. I will leave the cabin door open. Once the boat is in a case, you can use a flashlight and shine it in the cabin and the mirror will reflect the interior. I am going to use the lights setup for something else. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

David, I used the wood filler which is more like Elmer's glue mixed with saw dust to get the large uneven areas. Once very dry the hull gets a good sanding. There still some small unevenness in between the planking and there I use the spackle. I have just sanded that and it is now very smooth (Pictures will follow). I used this method (sawdust/glue and spackle) on an RC boat years ago it I liked the way it looked. But then again maybe it is overkill. Now I need to look at the paint list my sister gave me and see if I can get this in lesser volume compared to the amount for the real boat. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

There is nothing better than raw, young, fresh, caught a few hours ago from the sea herring (Dutch - haring) with a touch of finely cut white onions. Every 2 years when I visit my mother in Amsterdam the first thing I do the next day is go to the local fish shop in her area and have a few of these. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Piet, Please give me some idea about how to do the lights in the cabin. Where do I buy these lights. How are they powered? How is it wired? Outside the boat? Bob Filipowsky (from our club) used a mirror opposite of the cabin entrance and when you point a flash light into it. You can then see the interior. It is no problem with the acrylic in the case. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Ian, You are welcome and the better details I can show the better I can show others how I am building this boat. Marc

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Ed; When building the Naiad are there any descriptions on how to build the masts, sails and rigging or would this be another volume? Personally, I believe that a sailing ship without masts, sails and rigging is not a Sailing ship. I do like the admiralty models that people built and I see on display in naval museums as well. As you mentioned about the YA, that there will be rigging, will there be sails as well? For me that would be an impressive ship to build and I would purchase that volume. Marcus

-

Druxey; There is nothing better than raw, young, fresh, caught a few hours ago from the sea herring (Dutch - haring) with a touch of finely cut white onions. Every 2 years when I visit my mother in Amsterdam the first thing I do the next day is go to the local fish shop in her area and have a few of these. Marcus

-

Here I mix Elmer's white glue with fine sawdust. There are some areas on the hull that are very thin (due to sanding) so I spread this mixture out on these areas and once dry it is solid and very hard. Then I give it a good sanding and because the Catboat will be painted you will not be seeing much of that. After all the rough sanding I now put on a layer of vinyl spackling. It does not shrink, can be painted, easy to apply. Marcus

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.