-

Posts

609 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Timmo

-

I’m continually impressed whenever I check in on you build Reg. That’s money well spent in your expert hands and you are also answering questions I’ve been wondering about like the fruitwood gel. Eagerly awaiting more.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice work. The beech looks nice and crisp next to the pear.

- 143 replies

-

Thanks Jerry. That's really helpful. I'm not the first to want to make an Enterprize go then! Ah well. That's a really nice rendition he's got there and very stable in the water. My Harrier still bobs and heels a lot more than I'd like but I can't really ballast her any further as she's a little lower in the water than accurate. By my maths on his comments about frame width his Enterprize might be close in size to mine. Interesting he seems to do well with what appears to be all masts rotating together rather than an independant foremast. He gets some massive rotation angle so that's likely the secret there. Anyways... The sideways servo mounting you mention could be worth me revisiting when I get back to it as I hear what you say about the reduced slack. Harrier's braces work surprisingly well as horizontals with some rudimentary line guides, enough tension on the lines and equal rotation off and onto the drum through even distances to each side of the yard. Plenty to think about there. I suspect I won't catch up to you before Macedonian is on the water and under her own power.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

At the risk of looking like I’m easily distracted, Enterprise has been laid up on the stocks while I devote my time to a new project that’s been on the Wishlist for years. it’ll be a 14.5 ft ply sailing dinghy - an Ilur from French designer François Vivier. Hopefully it’ll look something like this: (pic: c Harlan) my build will be here if anyone’s interested. http://forum.woodenboat.com/showthread.php?267473-An-Ilur-in-NZ I’m looking forward to returning to Enterprise down the track and have picked up some kauri timber for the Ilur that I’ve thought about maybe saving for the planking on Enterprise. We’ll see. I’ll still be checking out MSW in the meantime. good luck all.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

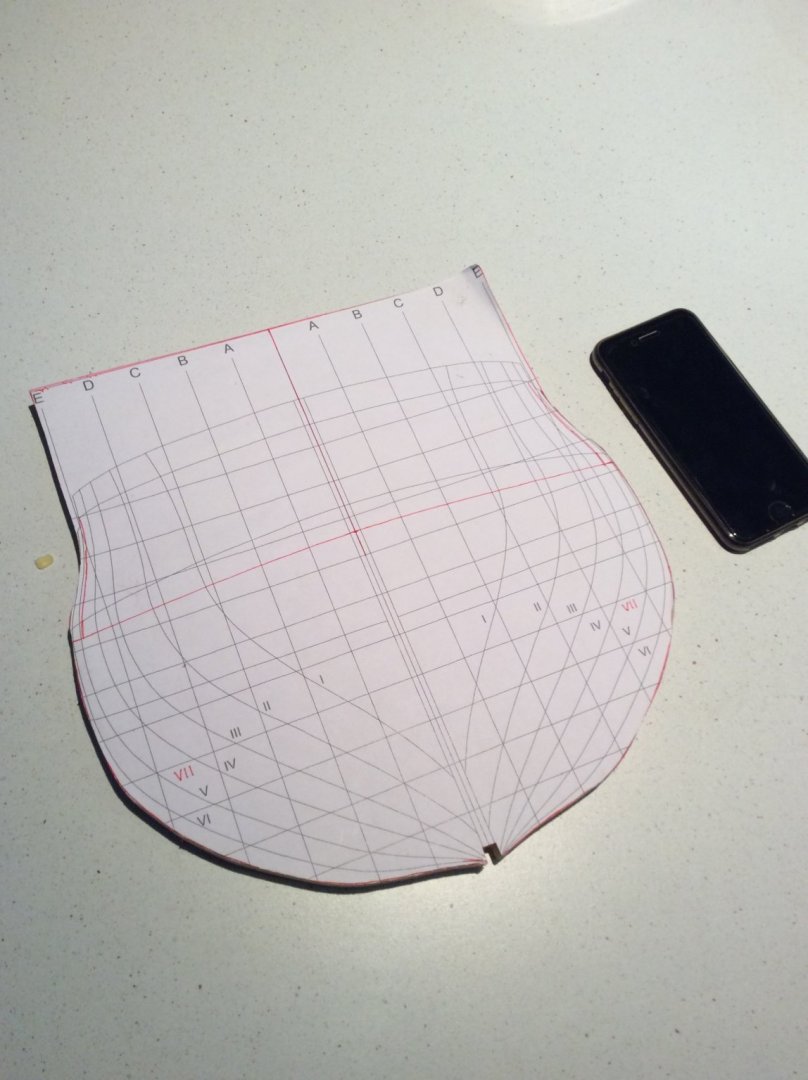

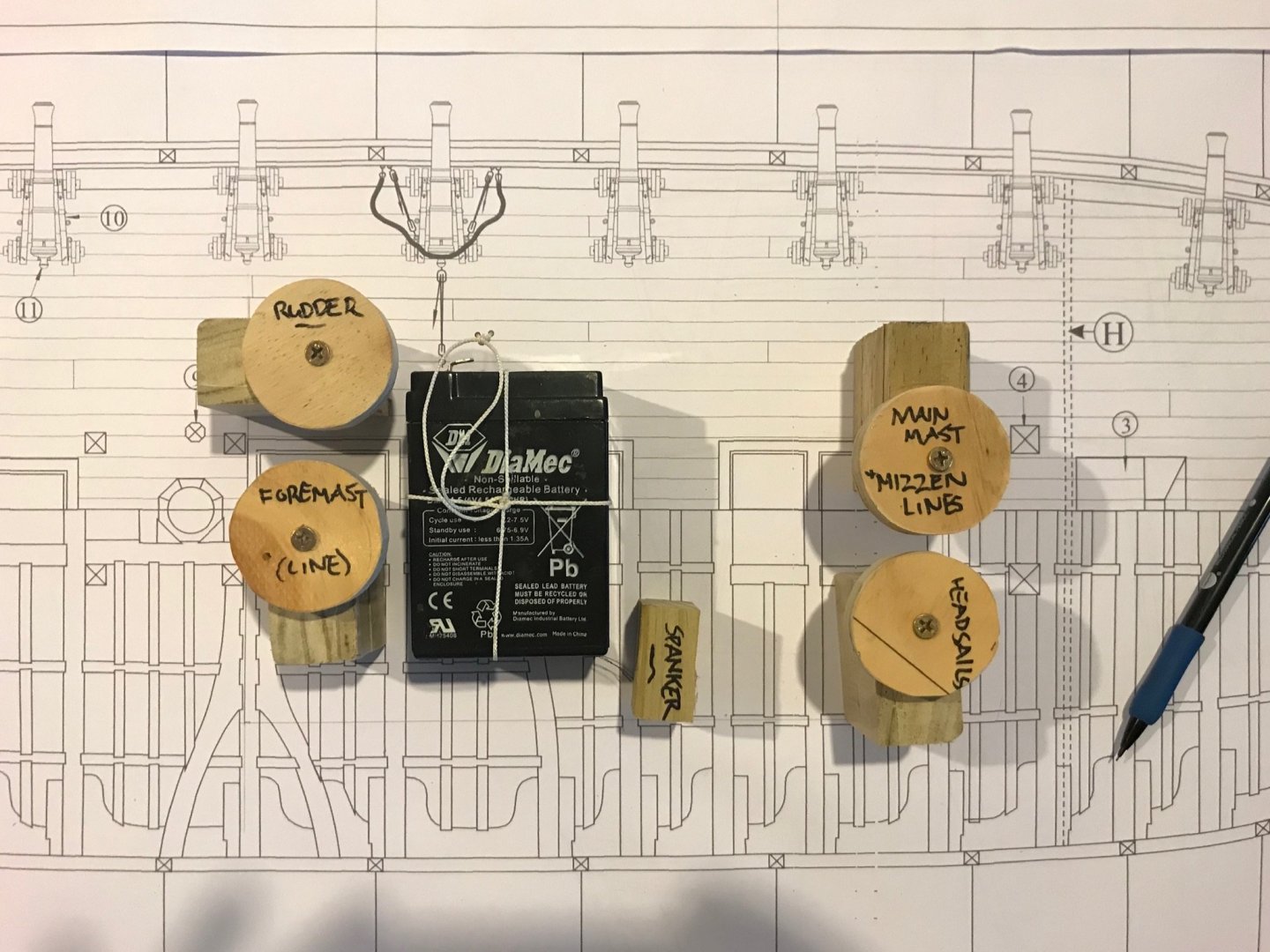

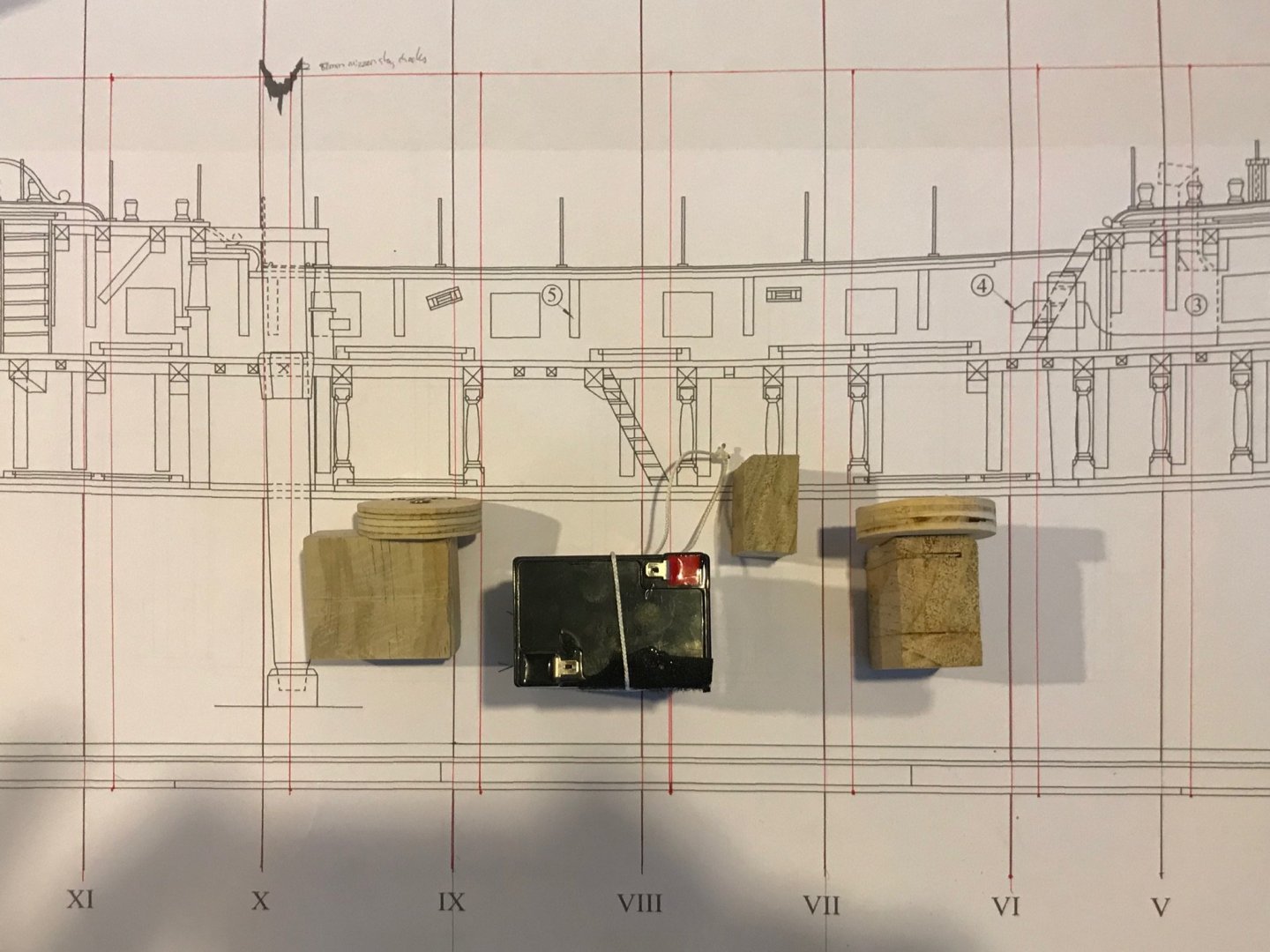

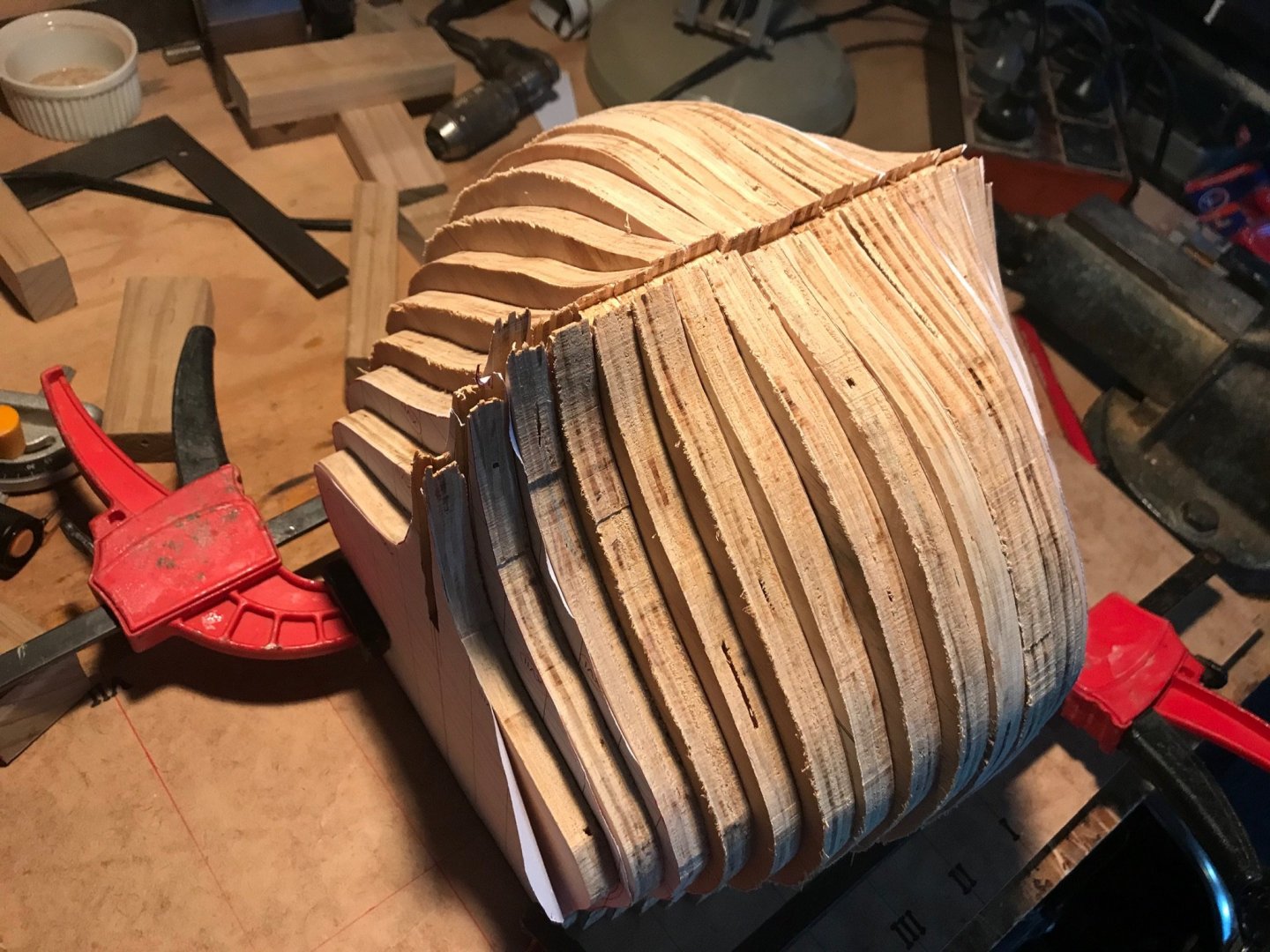

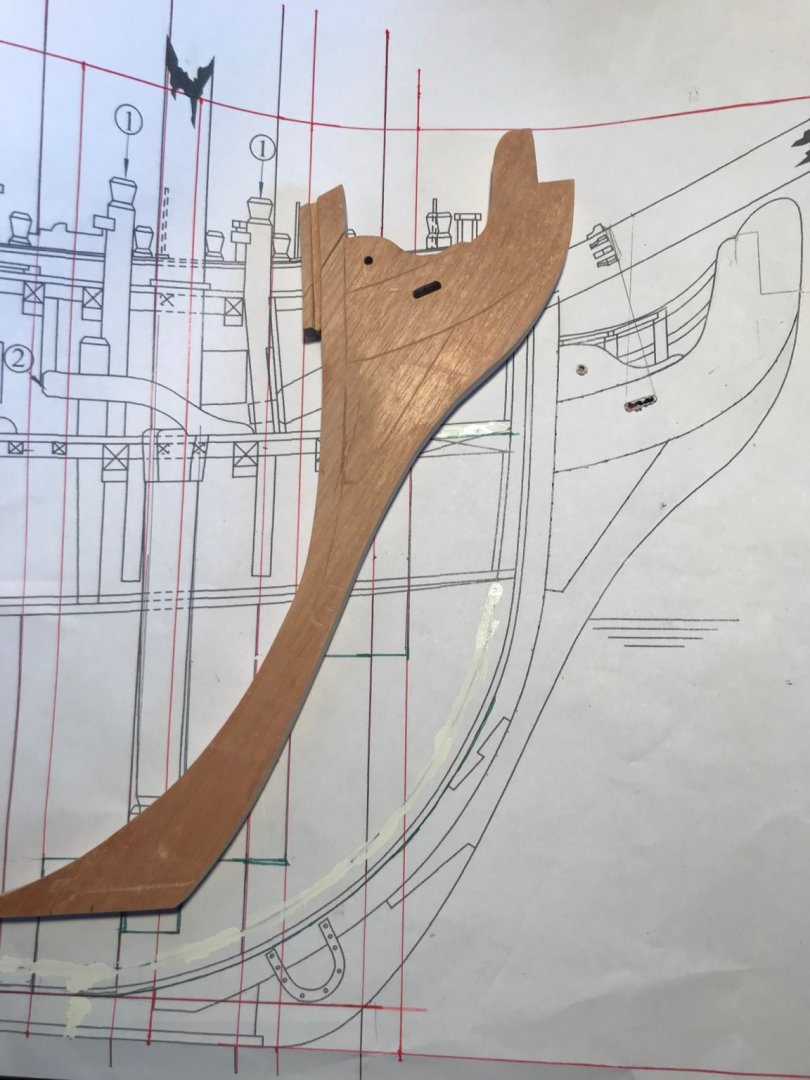

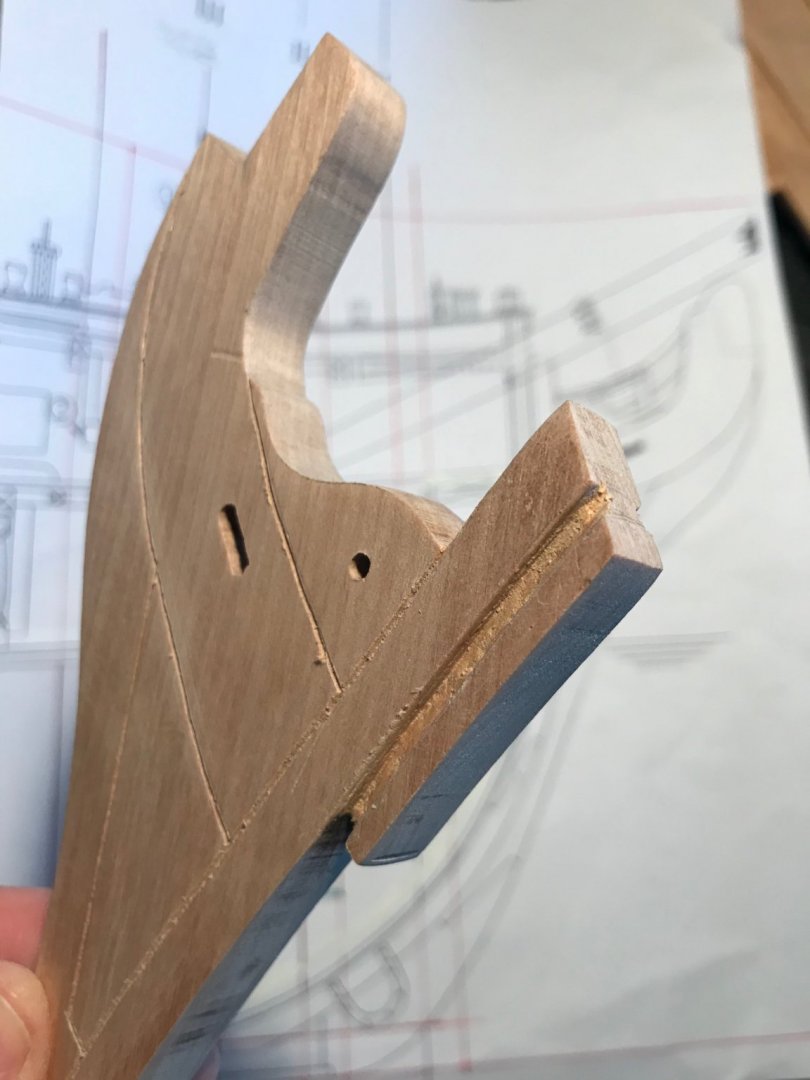

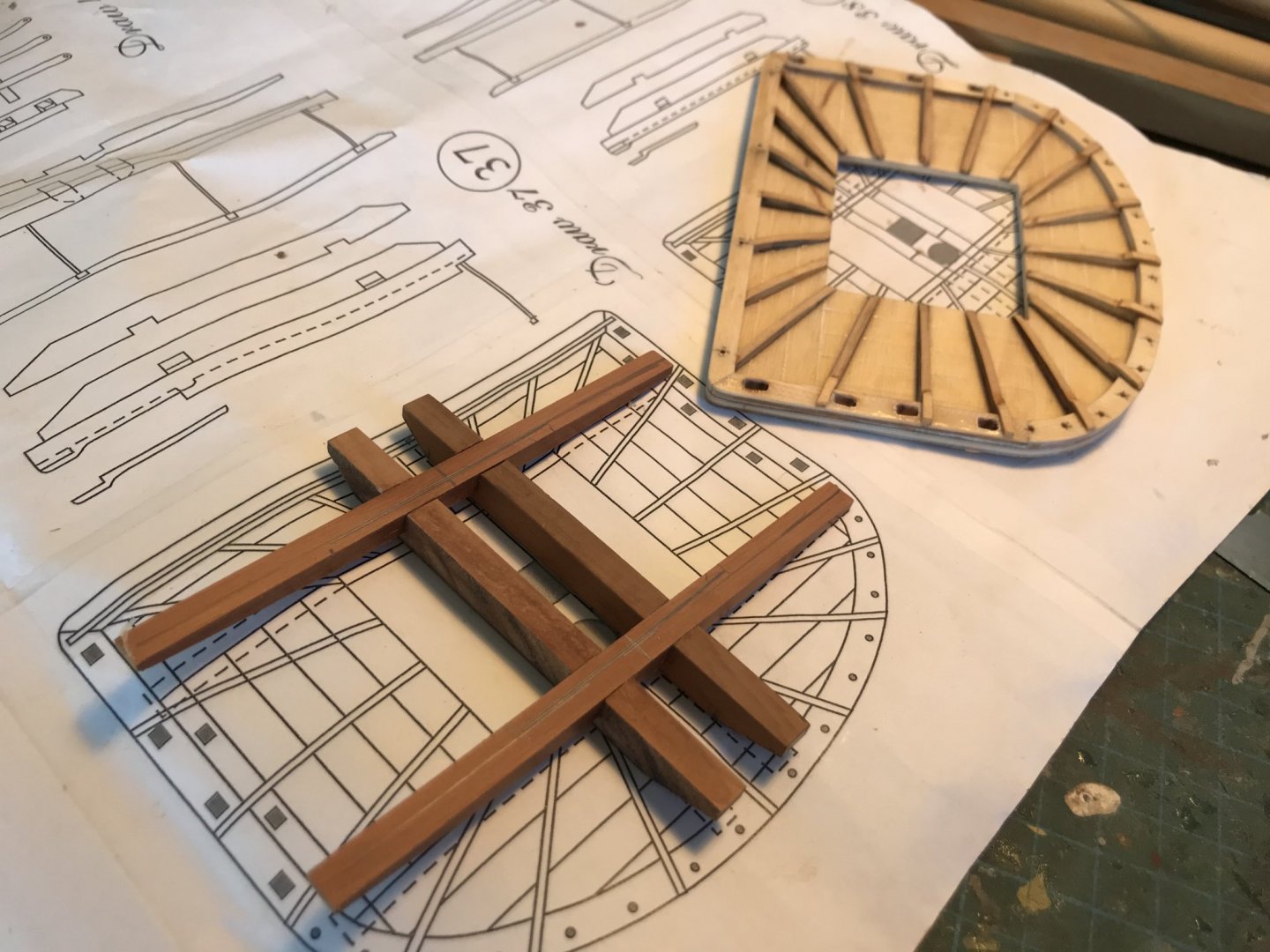

Work has moved to the hull. The frames have been drawn up and cut out. These are still solid at present but will have the middle cut out to leave a hollow frame. This will contain the cambered gun deck line. On Harrier I did the same but ended up replacing them with stronger timber deck beams, especially around the hatches. I might do the same here but having the floor leave on ply is helpful for showing the level. the deck is shown marked in red above. It’s about 5mm below the actual level to account for the 3mm false deck and then planking on top of that. Here are the frames stacked up. Fitting in the RC gear has been a big consideration of the build. there is more internal space than harrier but the added complexity of a quarterdeck and also gun deck that needs to be pierced to make it accessible. While spreading the servos out is possible it would also mean more hatches for access with the difficulty of getting through two decks. Some wooden servo blanks were made This is also gives an idea of what controls Enterprise will have. All are drum style sail winches with the exception of the spanker, which is a simple arm, as per Harrier. That worked well so I’m not going to change it up now. There will be a single large access hatch the size of the centre of the gun deck from just fore of the mainmast to just short of the main bitts. this means fewer holes in the hull and less waterproofing trouble. Most of the control lines travel up the main and foremast so are within easy reach. The exceptions are the lines for the spanker and rudder, which will run through pre installed guide eyelets or pulleys below deck and be accessible at a stretch with tools. Harrier’s rudder has surprisingly needed no maintenance to date so I’m hoping for the same with Enterprise, but at worst the removal of one rear servo should allow plenty of room to get an arm in. The stem and keel have been has been cut. A bearding line was continued up the stem for planks to slot into. Also joint lines were scribed in. This is largely one piece of timber, with just a 10mm extension epoxied on. It’s very strong and will get more so once planking and other parts tie it together. Recent work has involved cutting and test fitting the stern timbers for the gallery etc. that’s where things really get complex.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

go on then, another one... The ominous torpedo ballast keel is visible when in the pool, unlike local lakes etc. I'm interested to see whether Enterprise's greater hull capacity and bouyancy will allow a bit more internal ballast and something that will be less yacht-like underneath her.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

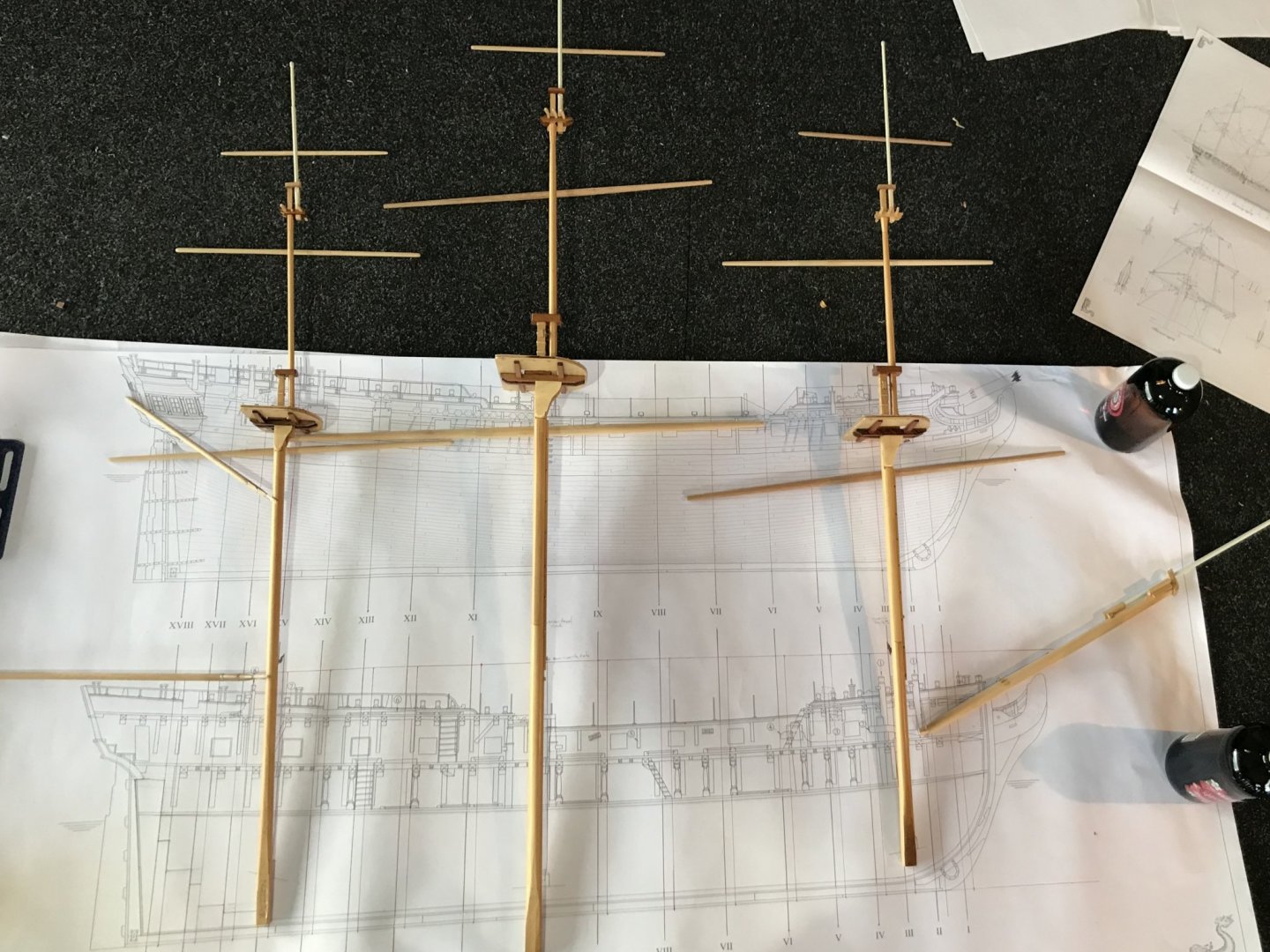

With not much else to do outside working from home hours, and even during a few of those hours in quiet times.... lots of sticks have been made. The mainyard at bottom is 630mm long and 13.5mm wide. It was getting a little tricky eaking out the limited floorboard timber stocks on somthing this size without nail holes and knots. On Harrier I used fibreglass rod for the t'gallant yards for durability but they don't seem to have needed it so these are all timber. Some of the smaller ones have been left slightly overscale, more for the fact that they'll need to take a brass pin through the centre down the track and Harrier has taught me that on large items like masts and yards, slightly larger scale for the sake of functionality is almost impossible to see once it's on the water. Sling and other cleats have been added. The jaws of the driver boom and gaff are fibreglassed ply as per the fighting tops with lead foil 'iron' bands. There's also the first of the ship's many sheaves in the end of the driver boom. This is a little turned brass item from RB Models of Poland. There's quite a few left over from Harrier. Here's Enterprise with her sticks... Given the extremities of the masts and the jib boom are fibreglass they needed to be painted to match the varnished timber of the masts. They were sprayed an off-white colour called 'lace' and some yellow ochre oil paints with a little flat white humbrol was mixed up and brushed on lengthways, allowing brushstrokes and a little of the undercoat showing through to roughly resemble a subtle wood grain. Here's the result with the fibreglass jib boom at top and the wooden bowsprit it's mounted on. It's a little brighter than the timber but I'm fairly happy with it. The undeside of the jib boom has a hole to take a small brass rod sitting up through the heel it rests on. As the stay will pull the tip upwards in the other direction physics should keep it in place on the ship and allow it to be unshipped and telescoped down for transport. Top gallant mast (fibreglass) and wooden topmast under the crosstrees... The masts have been varnished (satin) and the tops and other black parts painted. After using some satin black from a spray can which looked awful and blotchy I finally did the right thing and airbrushed them. The greater control gave a far tidier finish. There's a little shading in there on the fighting tops. The wolding and mast bands have been added to the main and foremasts. This was quite tricky, mainly due to the cane bands used. This was left over from the seats of my canoe and the first bands were stripped off after appearing overscale. Subsequent ones involve the cane split down to a smaller width, which is laborious but looks better. I'm glad I did the masts first as I consider them the unsexy part of the ship that I'd be inclined to rush and avoid adding detail to if I tackled them at the other end of the build. The rope is from a dark brown polyester upholstery thread by Gutermamn turned on my homemade ropewalk which was the very first thing built for Enterprise. If the rope didn't look right there wasn't much point proceeding so that's a hurdle that was worth clearing. I should have just enough rope left for the lighter gauge rope woldings on the mizzen which will be done before I can get out of lockdown. I've just got to add a couple of sheaves to the foremast masthead for the jib stays and they'll be largely finished but as I've run out of epoxy, that'll have to wait too. Here they are (top to bottom: fore, main, mizzen) with a smallish schnauzer, who happened to be passing, for scale... Once the mizzen is finished, it'll be on to drawing up and cutting out the plywood frames for the hull and getting the building board sorted. Three dimensions await! In the meantime, Harrier got a brief outing to test some ballasting and small sail alterations. She's in the landlocked sea that is our newly installed swimming pool. It was dropped in and made barely operational just before lockdown about 6 weeks ago and has been sitting in the otherwise destroyed backyard amid temporary fencing and mud, awaiting the return of the workers since. On the plus side it'll be so much easier trialling Enterprise now the admiralty has seen fit to install this bespoke testing tank so near the shipyard.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

My two cents: I prefer muted natural colours or only a small amount of colour. I know many were likely painted with quite bold colours but it’s like Greek sculptures- even though they were originally quite colourful a modern audience expects them to be plain white marble because that the aesthetic we expect after seeing them only like that in museums. I like the plain lion with maybe some subtle shading to deepen tones. But remember it’s your ship!

-

Nice fish! At the risk of getting off topic... Here's a voyage of mine with a tiny trout (thrown back) on one of the hydro lakes north of Taupo.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

Just found your build nzreg and pleased to see a Winchelsea in 'un zed'. It's coming along really nicely and that planking looks great. I've been very tempted to start one myself, especially since Chuck changed tack and made it a group project. However, I'd better make use of the plans I've already got and finish what I've started... Good luck with the build.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks. I try to catch them closer to home but am not always successful!

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

thanks Joe. It's nice to be back in the smaller scale (even though it's 1/36) shipyard.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

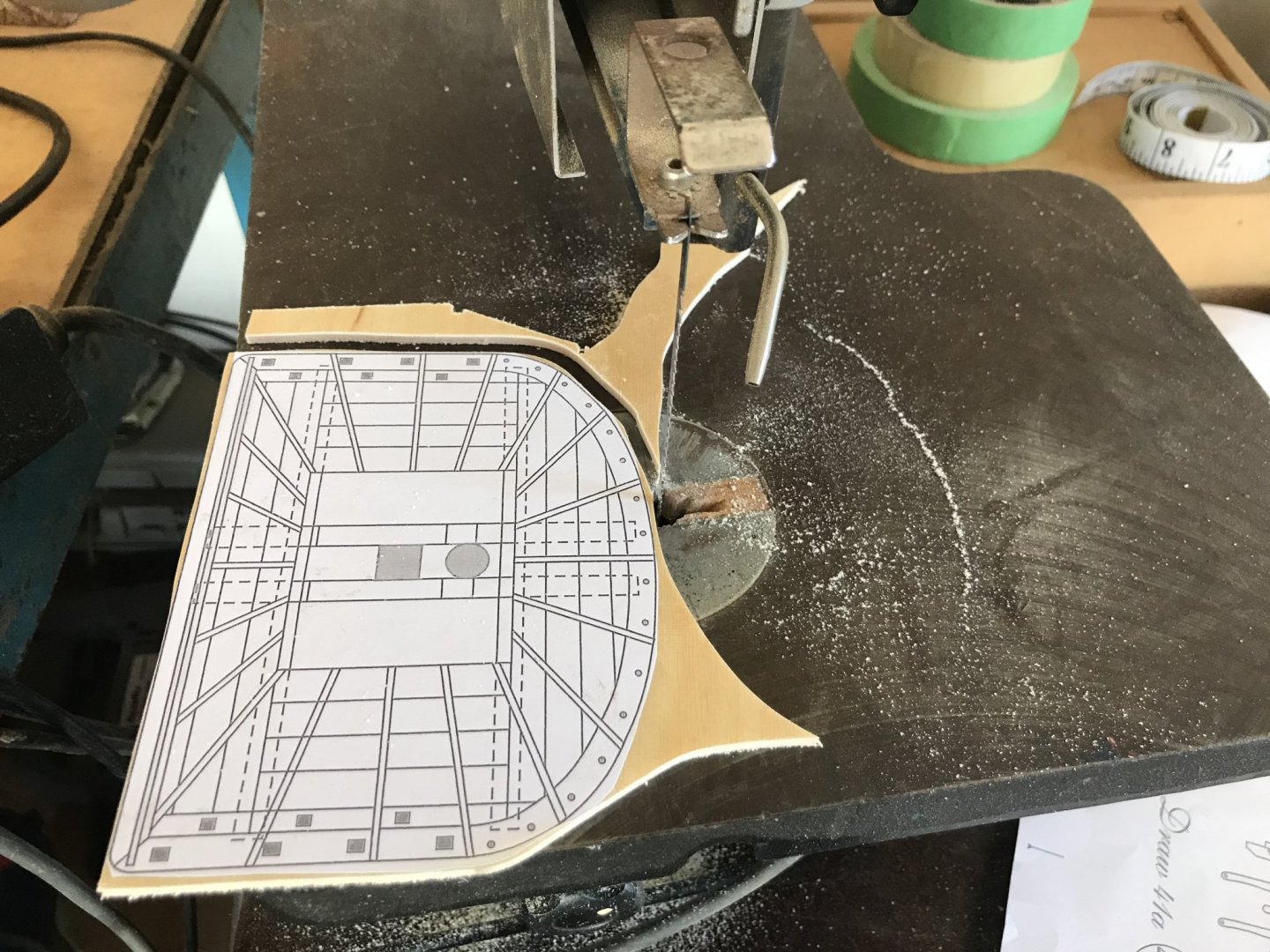

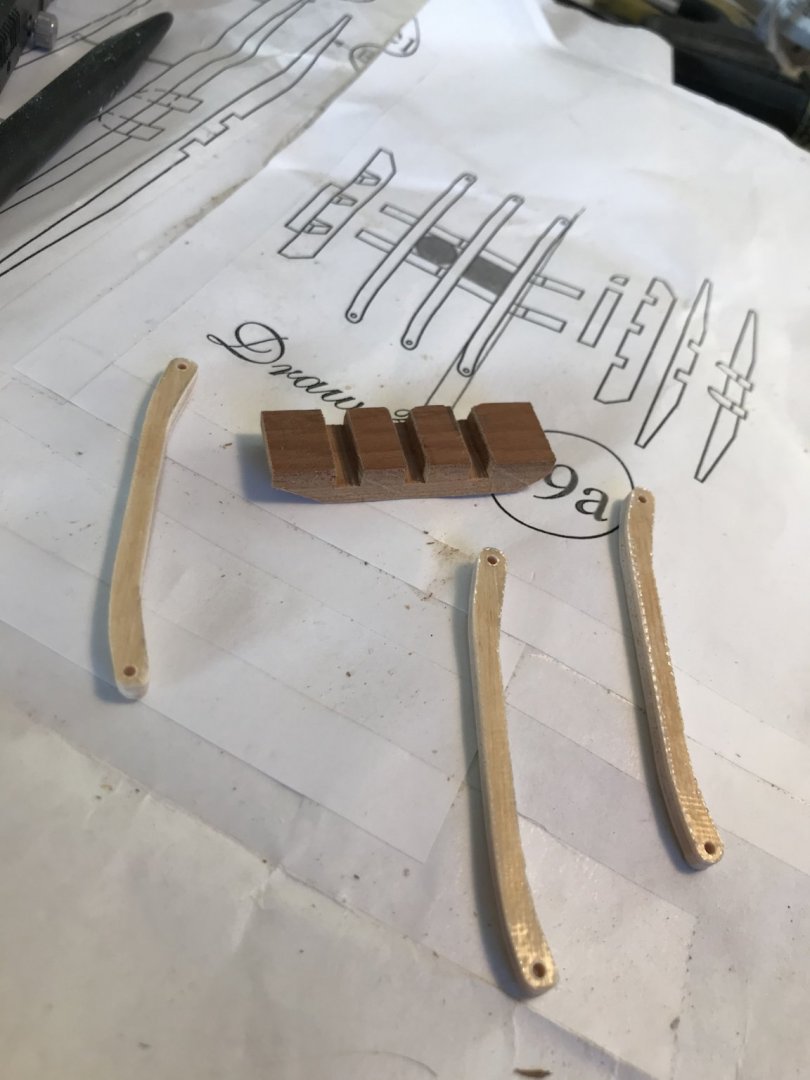

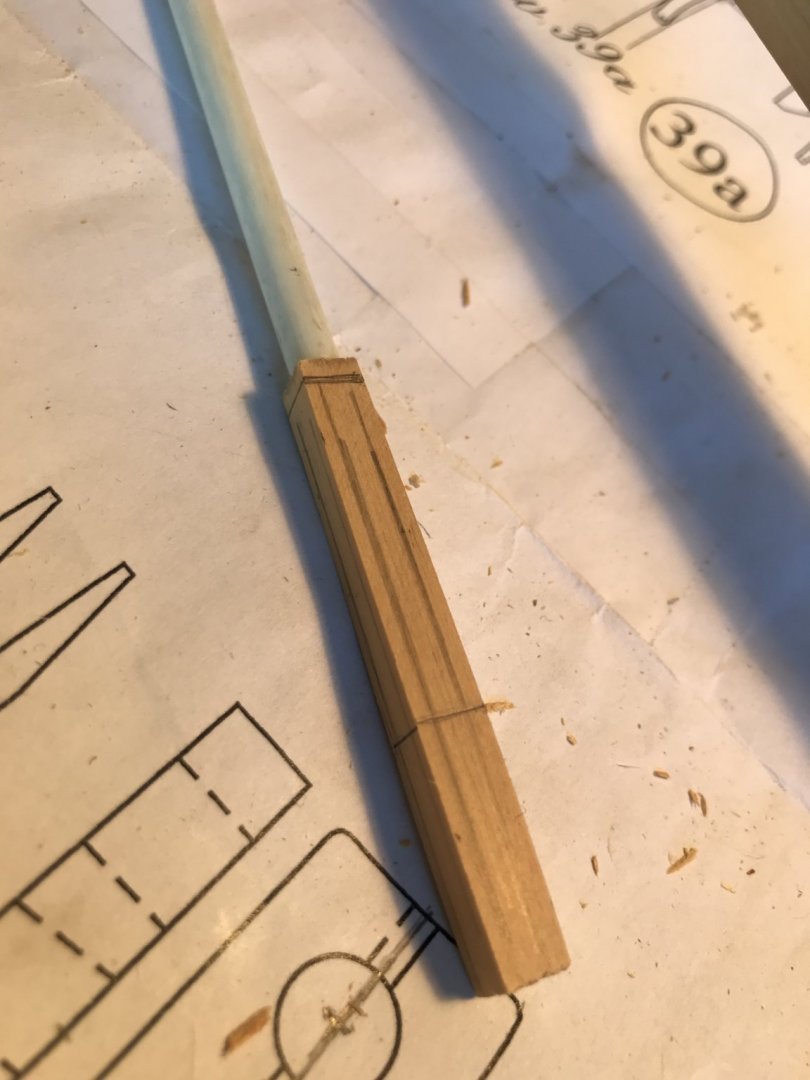

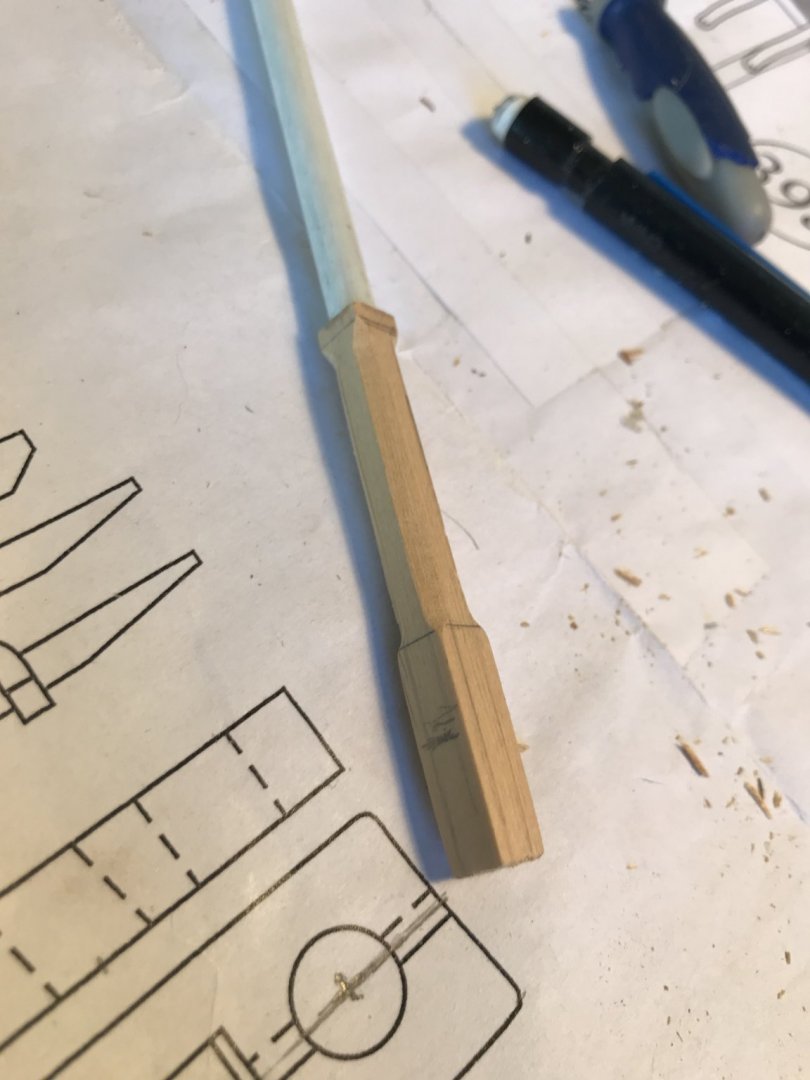

With the country now in lockdown due to coronavirus I'm pretty limited on what materails I've got to hand. Given this project might be started and then put away for a bit if circumstances dictate, I started on the masts as they they are easy to store and are little projects in their own right. Square battens for the masts were cut to size from floorboard stock, ranging from about 15mm for the lower main to 9-10mm for the mizzen and smaller again for the topmast sections. This might sound small for a model facing the stresses of actually sailing but, like the original ships, there is strength is in the timber but it's multiplied immensely by the rigging as shrouds and stays make Harrier's masts surprisingly strong for a ship that scale. The battens were marked up from the plans and shaped into square stock with the table saw for the mast heads and octagonal sections with the help of a very useful online spar gauge and block plane and razor blade. The sides were either taken down to 16-sided with the plane or sanded from there depending on the size. The simple Proxxon lathe with a bed extension was useful for some shaping by hand with sandpaper. tis is the main topmast. Note the rising octagonal section near the head. The main and fore lower masts are 'made' masts featuring seperate pieces from front and side. These have iron hoops and also woldings around them with some going under the fore bolster. Slots were cut in these for the hoops to slip through later. The bolster itself was steamed over a pan of water and tied to the mast with cable ties overnight to give it a concave shape before it was stuck on the next day. The fighting top platforms are made from a small 3mm hobby ply board that was fibreglassed on either side as there will be a few thin but structurally important parts needing this material. Between building model ships I've knocked up a wooden canoe and kayak and the glassing skills have come in handy. Copies of the patterns were glued to the ply and cut out with a scroll saw. The edges, including the curved front on the mast, fore and mizzen tops were cut form the same material. The tops had board lines scribed on. It's a little detail but something I did on Harrier. It wasn't particularly visible there as I used a straight satin black paint but I'm looking at adding a little weathering, including drybrushing of the black areas on Enterprise that should make details like this pop a little more. Below is a finished top with battens and rim added and holes cut for the futtock plates and also the little holes on the front edge for the crowsfeet rigging, something the Cruiser class brigs like Harrier didn't feature. Also below is one of the trestletrees, made from interlocking pieces of darker timber. The slots for the joints on this were cut on the Byrnes table saw. It's no exageration to say this project would be impossible without that tool. Once epoxied to the top, the trestletree makes it a very strong structure. It has to be as I've found with Harrier that these take a lot of weight and wear. It's easiest to grab the ship from under the two tops when dong a straight lift from above (not ideal for the back) into or out of the water and also when erecting the masts by pushing through the topmast from underneath against the downward force of the shrouds. Here's an example of that with Harrier... Thumb on the front of the top pushing down as a finger pushes the topmast up from underneath as the other hand slots in the brass pin that acts as the mast fid. After the tops, the mastheads were detailed with iron bands made from cane leftover from a canoe seat. This will be painted so should be protection enough from it splitting etc. Here you can see these added and a marked up topmast being tried for size before being shaped. The crosstrees for each mast where made from ply for the cross pieces and timber for the supprts. Here are the supports as one piece with notches for the crossmembers cut. Many of these twin parts are easier to make as a simgle piece which can then be cut down the centre, ensuring symetry and squareness. The crosstrees on Harrier were made overscale for strength but after some use they don't seem to be at risk of breaking. The spreaders or crossmembers that hold the topgallant shrouds don't actually have vertical stress on them from the shrouds like I expected when they were made so the Enterprise parts are closer to scale size. Hopefully that's not a move to be regretted. Below you can see the weave of the fibreglass on the cut face before it's sanded. Here's a look at a topmast with a temporary shroud. The topgallant masts are getting down to 5mm diameter and below and as they are only supported by shrouds for half their lengths are way too fragile for timber. The Harrier has fibreglass rods painted to look like wood for these pieces and it's been well worth it as extremities like the t'gallant masts and jib boom are the first to come into contact with obstacles when transporting and even setting up the ship at the lakeside. I have broken a fibreglass rod upper mast on Harrier after a few stupid knocks but it was one that was already weakened by having a brass rod through it for rigging purposes and was easily fixed with epoxy as it was the uppermost section that carries no yard and is really just cosmetic. The lower t'gallant masts have an octagonal and square section where it meets the crosstrees etc below. To replicate this a square section of timber was drilled out and the rod inserted. This was then marked up: And shaped with a blade and files... The top fibreglass section was turned on the lathe with sandpaper and a blade. I only had enough rod leftover from Harrier to make the main t'gallant mast so the rest, including the jib boom, will have to wait until after lockdown. Here's the trio of masts completed minus t'gallants where shortages in the shipyard dictate and without wolding etc which will be added after varnishing the timber.. The mainmast stands about 1.3m tall from the keel. It telescopes down as shown for transport with brass pins for fids holding the masts in place when rigged. The bowsprit was shaped as per the masts but by hand as it is not symetrical in section. The heel was marked and cut with a handsaw and blade. The head of the bowsprit has a square section from which the bees are attached. A rebate was cut with a blade for these to sit in and their supports underneath cut to shape. Square sheave holes for the foremast stays were cut before glueing. That's progress to date. Next up it's the yards.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

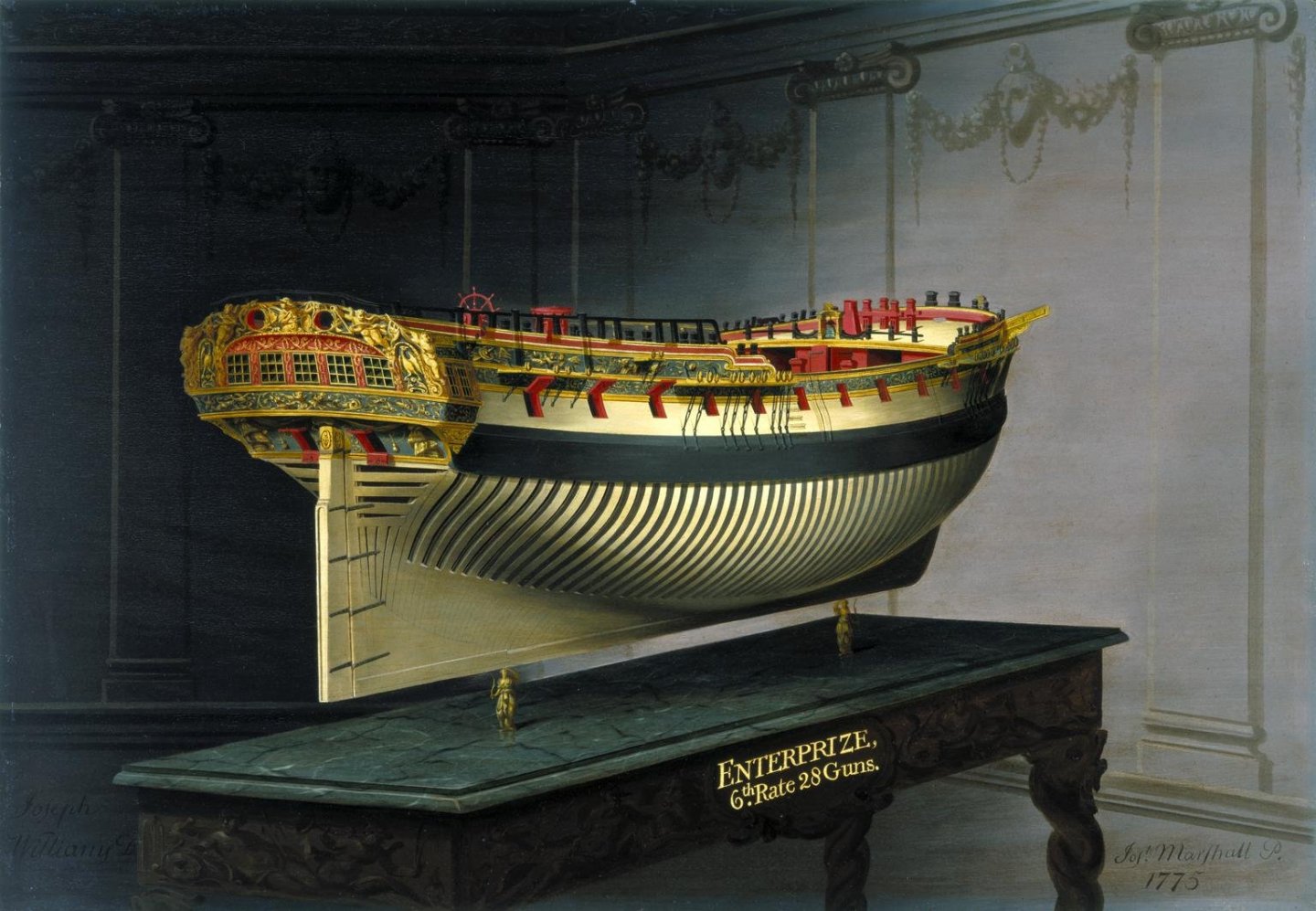

Like Harrier, Enterprise will be built on the cheap to a certain degree, using largely the same materials. Most timber, and certainly the visible bits will be matai. This is a moderately hard new Zealand native that was once abundant and used for everything from framing to floorboards up until the about the 70s. With most stands of native trees now protected this isn't milled on any commercial scale that I'm aware of but there's plenty of it available as old floorboards at the demo yarn. Some of it is even already dressed, which will be good for planking but for the larger pieces like masts etc, I'm milling down floorboards with my full sized table saw before using the Byrnes table saw to finish them. Even with the tongue and groove and nail holes you can still get reasonable sized pieces from a board. Most pieces I'm using are about NZ$6-8 a metre - that's about US$3-4. If I can do a clean enough build the idea is to leave the ship with plenty of 'bright work' or natural timber hull and other details above the waterline as per contemporary models and the Marshall paintings. Matai is a striking timber that alternates between a gentle honey colour remiscient of aged boxwood and a deep brown. Here's an example on some flooring in my friend's 60s era home. It's easy enough to pick out the boards with more blond wood than not.

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

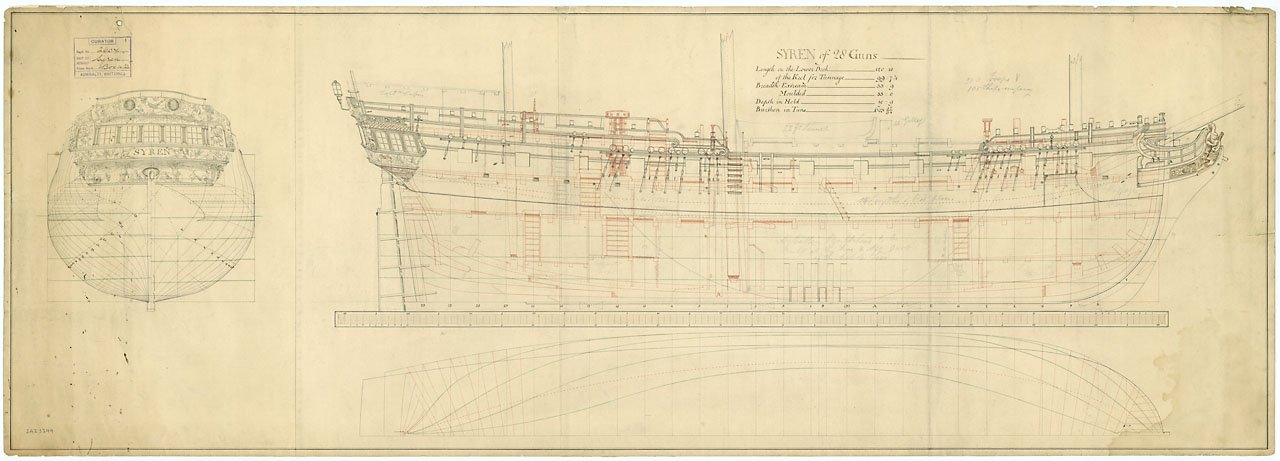

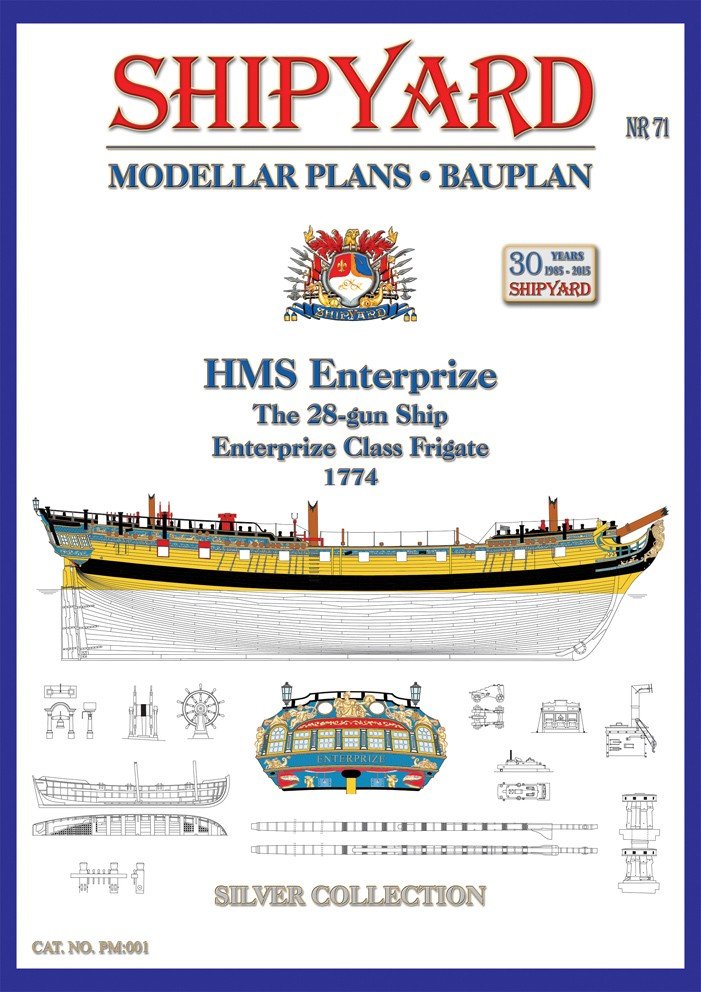

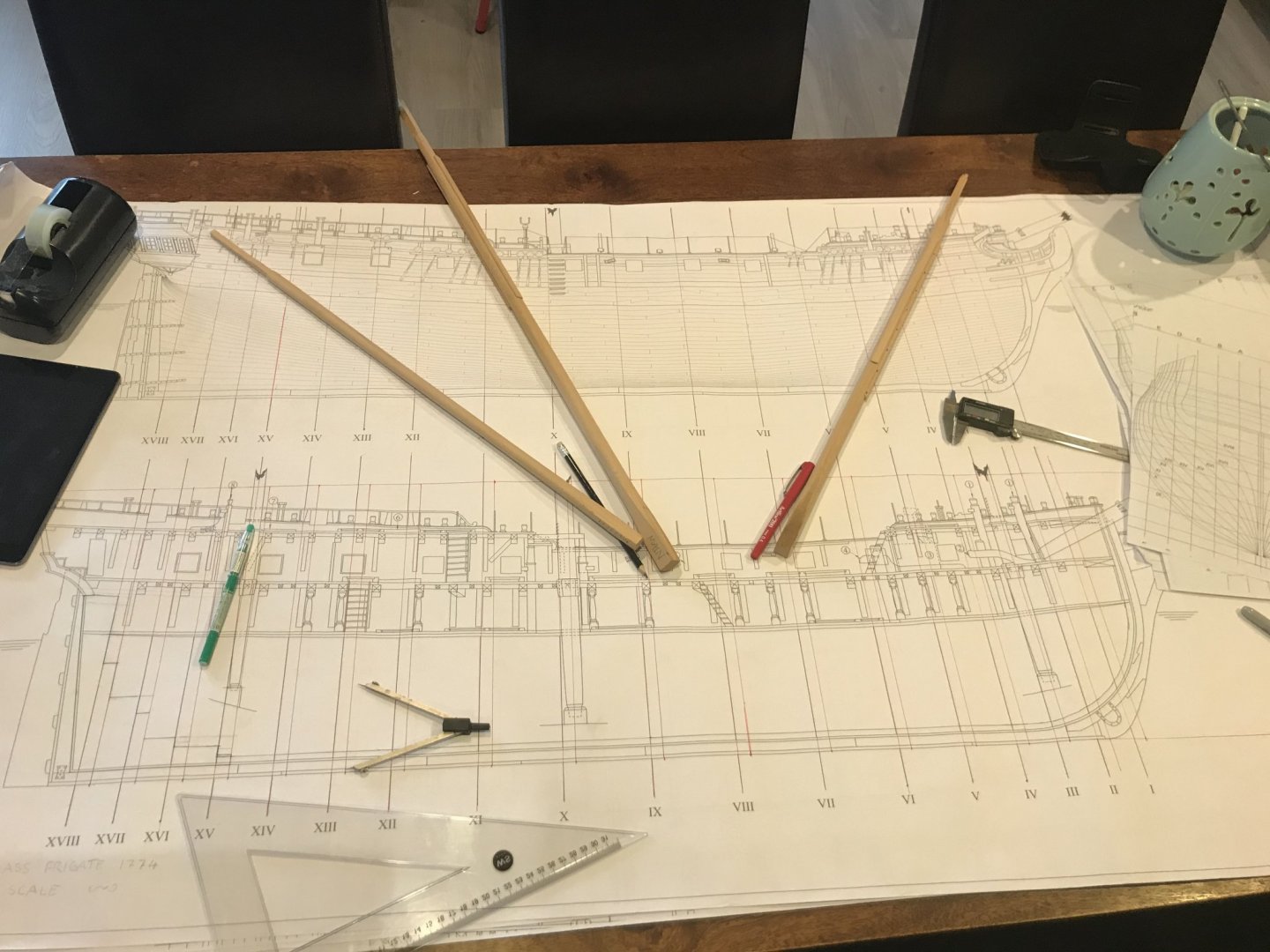

I finished my first RC scratch built square rigger HMS Harrier a couple of years back and although I'm very happy with the result always considered her something of a practice run for the command that everyone wants - a frigate. Check out Harrier in action on video. With the current pandemic making the full sized sailing dinghy I was hoping to start this year look just that - hopeful - there's no time like the present to start the frigate. She's relatively cheap, being cobbled up from old floor boards and ply with the only realtively expensive bits being servos. She'll be easy to break into storeable stages if the world comes to rights and the financial situation lets me build a real boat, and also a bit of a challenge that should take at least a couple of years. So, which frigate? I love the the Artois class like HMS Diana as per the fine examples built by the likes of Jason and Barbossa on MSW but as a 38 gun vessel it's 146ft on the gun deck and getting quite large for transport at a 1.2m hull in 1/36 scale. Also, while the rest ofthe Anatomy of the Ship book is very detailed, the lines needed to reproduce a hull shape in my copy are not very detailed. The Enterprise class is a bit smaller at 120ft with all the attributes of a frigate and has the advantage of being repesented in some detailed orignal ship plans in Greenwhich's National Martime Museum; There are some very colourful contemporary paintings done by Jospeh Marshall as part of a series of ship models to stoke Geroge III's interest in the navy; He dubbed the ship Enterprize, interchanging the Z with an S as was common at the time but most records of the time and modern scholarship have her as Enterprise. The clincher is a very detailed set of plans from Polish model company Shipyard, which also does smaller scale card models of Enterprise and her sister ship Cleopatra. The Shipyard plans cover everything from hull and deck layouts through fitout including guns, boats, masts and spars in a variety of scales ranging from 24,72, 96,192 etc depending on size. The bit where it falls down are the carvings and decorations, which appear speculative at best and include a lion figurehead more suitable for a ship of the early 1700s. The idea for this build is to try to combine the best of the modern plans for a fairly accurate sailing model, with the contemporary plans and paintings to give the full bling of a Georgian vessel. While it's a little uncertain whether a vessel in service would have carried full freizework and decoration, I've always wanted to try my hand at it and the goal is something that looks like a contemporary ship model that can be sailed. As such, the ship will be one of the class, and generally correct for the period but with some speculation on decoration depending which vessel I end up depicting. GIven the diverse sources it'll be a model of a painting of a ship model, so I think that'll give me a bit of latitude. We'll see how close I get to the goal of a big 1770s Navy Board model you can drop in the lake. A little about the Enterprise class: A sixth rate Designed by John WIlliams in 1770, the first five of this class were ordered for the Falklands Islands emergency. Fox, Syren, Surprise and Enterprise and Acteon were launched from the early 1770s through to 1775. Another 15 vessels followed in 76-78 and another seven in 82-83 with solid quarter deck bulkheads. They saw service during the Revolutionary War, with many Enterprises active on the American station against US privateers, at the relief of Gibralter, in the Mediterranean, Caribbean, including at the battle of the Saintes, around the North Sea and French coasts and even the battle of Cuddalore in the Indian Ocean. They were active ships, with losses to weather and enemy action that reflected this, although some limped through as troop ships or on harbour duty until late in the Napoleonic wars. Length on gundeck: 120ft Breadth: 33ft 9 inches Crew: 200 Initial armament: Upper deck: 24 x 9lbers, Quarter deck: 4x3lbers. By 1780 the quarter deck armament was 4x6lbers plus 4 18lb carronades and another two on the forecastle. Making a start The shipyard plans were scaled up to 1/36 scale and details like framing station lines, fixtures for the ballast keel, ply deadwood, rough places for servos and battery and other details drawn in. The plans have station molds indicated, which were expanded to show the 12mm ply that will be used for framing. Some initial work on the masts is visible below. More on that in the next post. The Enterprise hull is roughly 1m on the deck, slightly bigger than Harrier at 80cm and has a much greater internal volume, which should hopefully make some of the fitout easier, although there are issues around internal access with a quarterdeck as well as the main deck. Rough overall length with bowsprit should be 1.6-1.7m, with the masts standing about that tall from the keel, although they will collapse for transport. It should fit in the family wagon, if not it'll have to go in my camping trailer, although my wife is asking where it'll fit in the garage already containing a car, canoe, kayak, the Harrier, kids' bikes, clothesline and my workbench and tools...

- 28 replies

-

- frigate

- enterprize

-

(and 2 more)

Tagged with:

-

Delicate work there Joe. She’s looking very crisp.

- 140 replies

-

- benjamin w latham

- model shipways

-

(and 1 more)

Tagged with:

-

Kia ora John, This site brings all the talent of the world to these far flung shores. Always plenty to learn by watching others but I’d suggest the best way is to have a crack and start a build log. You won’t regret it.

-

Servo arms would probably be easier than drums if you have the room in the hull to get the length of pull needed. Keeping tension on the lines on a drum can be problematic. Have a look at Jerry Todds' build logs for some mechanical inspiration.

-

Just caught up BE. That's a great build. Love the touch of the coins on the base. It complements the superb model nicely.

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Joe. It's a pretty light breeze and lots of unscale-like bobbing in that vid compared to when she's running her best in a consistent wind with sails bellied. However that's when more concentration is needed and I can't pick up the phone to film. She's a great talking point. When I had her out yesterday for a couple of hours I had a steady procession of four individual gents who each had to know all about her. One thing I've found is it brings ship modelling to a wider public and that can't be a bad thing. One said he'd he'd often thought of picking up modelling that he'd last done as a kid. He was daunted by the thought of something like this, but the great thing this site and the people here teach you about modelling is that it's just a series of small tasks and problems that when solved add up to something bigger- eating a the proverbial elephant one bite at a time and all. Also....Looking at your Cruiser... I think the foc'sle and aft platforms you've got on Sophie look really good and are more typical for the class from what I could find. The need to get at a moving tiller for potential repair ruled it out for me. The Sophie you've created is a lovely, purposeful looking ship, but I am biased, having a daughter by that name. I couldn't call mine that for fear of being accused of favouritism, as much as I like the O'Brien novels. I hope our builds coincide on another subject. You've been a good mate through it all.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.