-

Posts

5,518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

Well phrased shipmate. I concluded what I did and boldly spoke to the extreme accuracy of detail Johann has employed in this particular model. He has spared no detail...and it wasn't a stretch to imply he should continue that stretch and include the detail of properly treating the lanyards. Why go *Artisanal* at this junction, when in fact his entire build is a magnificent representation of his artistic skill. If, as an artist, you want to paint red lips on a pig.... be artistic, but if you want to aesthetically and accurately represent a pig, then you forgo the lipstick. Nuff said. Clear sailing. Rob

-

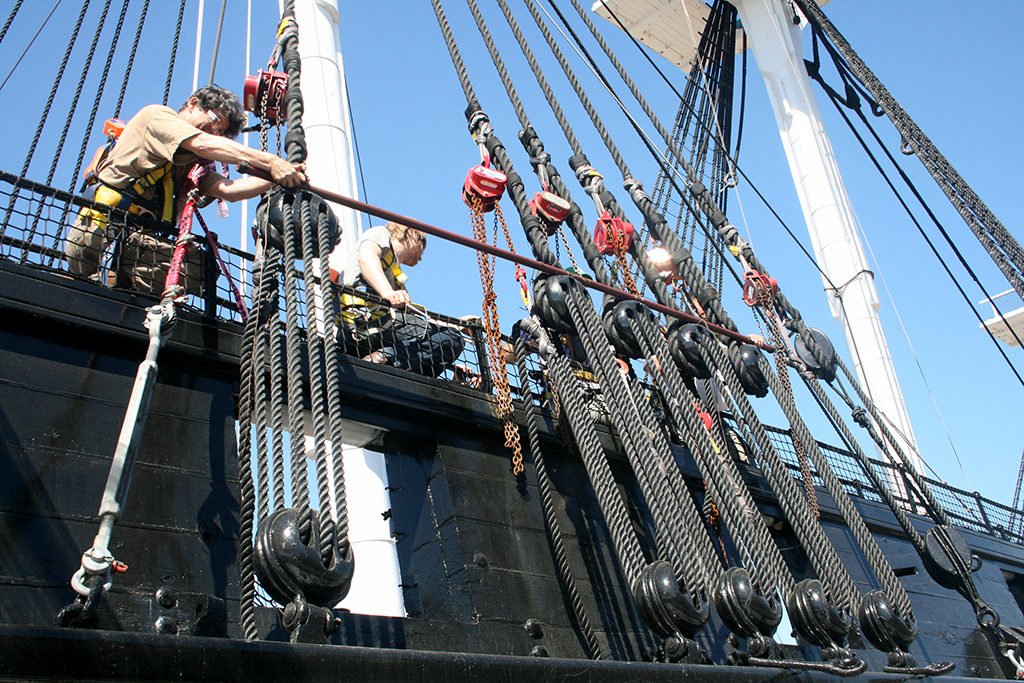

Then I suppose I'll remain wrong. From the details the builder is employing in the iron work and skillful application of every detail of his build...applying the appropriate tar mixture of preservation to the lanyards would not be considered inaccurate as Wefalk has concured. White lanyards are not accurate...no mater how contrasting they are to make a build look balanced. I used the phrase *show-boating* to delineate between what one thinks looks good to what was actually a practice...regardless of appearances. I meant no disrespect to anyone for stating the facts as I know them. I wonder where the marine historians and architects went wrong when rebuilding the constitution? Respectfully Rob

-

Reviewing some of my detailing...I owe an explanation to some why I use so much paint on rigging and such. From my own experiences and from that acquired by way of serious study...it was made clear to me that much standing rigging was coated in a heavy preservative. I've even assisted in its removal on the real McCoy. So, I've adopted the practice of coating my seizing's with ample preservative (paint). I hope my lazy, quick-shod technique of covering a multitude of sins is not a deterrent for the more ardent discrete of you. I truly am standing(or sitting at the work bench), with some of the most skilled, detailed acute, modelers ever assembled in one forum, and to have as many likes and positive comments about my build is truly amazing to me...I am deeply humbled and moved. Thanks MSW friends. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Better is always better...especially when Gale's are concerned. Thanks Druxey for your continual encouragement. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Thanks Michael. I threw that little jig together when I was building the Glory of the Seas yards, it's nice to move the clips around for different size yards. I use three different sizes of Alligator clips, with or without teeth..depending on what I'm working on. Saturday will be another big build day...so I hope to finish off the port mainstay and work my way up the mast and add more stays. After some study of how I want to progress, I realized, they need to be in place before I rig the fore mast halyards and their purchases. Once this is accomplished...I'll either move to add the jib stays or proceed to building up the mizzen mast yards and rigging. I hate to add the jib stays too early because they could be in the way of construction movement of the model. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Doris..where did you learn your skill set? Did you attend some art school to learn to sculpt. You have a learned eye for color application and perspective. It's a wonder if you learned all your techniques by way of self discovery without some form of formal instruction. Or are you a NATURAL? In any case... learned or by the hand of God...you are marvelous to watch. Rob

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

While the sail was drying...I opted to take another approach to adding the main stay. Instead of rigging them in place I decided to rig them off ship, one side at a time. Then once done I would rig them to the ship and secure them separately...but the connection will look as if it was one connection. I beefed up the bulls-eye iron strop/hook. Just to let all my concerned citizen MSW folks rest comfortably.

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Spent some time on the Great Republic..tidied up and added some rope coils and set in the other masts to get some perspective. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

After reviewing it.......I'm no closer then you are. the ring that is attached to the hatch in several pics might be an indicator that it is a secure ring for the *barrel* to fit over..it times of battle or storm...aiding it from sliding around the deck when either empty or unloaded. Unless you can find some plans of this vessel with said item identified it might be a guesser. Rob

-

Keith...I thought you had some secret knowledge concerning Lumps(Gotten by *thumps*), I had on my head that prevented me from accurately presenting a scale representation of forestay bull's-eye iron hooks. Swew....... I'm just a simple man........ Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Oh...you mean Thumb's up. I was wrestling with the Thump's part..... Riiiight Thanks..... Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Truly amazing what attention to detail coupled with extraordinary skill can accomplish. Well done. Rob

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Connecting Staysails to the stays

rwiederrich replied to vmwilson1's topic in Masting, rigging and sails

I have the correct wire...its just the fabrication. Your 3 pronged jig is doable...(I have used them before). I have 3 pronged pliers and I can also make them by wrapping them around them after they are grasped in the plier. They will need to be quite small and numerous. A 10in sail will require roughly 40+ hanks. 4 jibs=160+, 6 6"staysails=144+. Means I need to make roughly 304+ hanks for these sails. What a work out that will be. Rob -

Best part of all is that nearly everything we do in *Modeling* is a simulation of the actual...therefore, not requiring seals, grease, tar, oil...etc...etc. On the other hand, a 1:1 build might just push that envelope. Love your work..... Rob

- 2,215 replies

-

Connecting Staysails to the stays

rwiederrich replied to vmwilson1's topic in Masting, rigging and sails

I have to give this much thought when I arrive at making the stay sails for my 1/128th scale Great Republic. However, at my scale this detail can be over sized and over done if wrongfully approached. Were hanks placed at the distance of a panel? Rob -

I apologies for any overlooked detail. One great fallback when working in smaller scales....you are afforded the option to pick and choose what details are not significant enough to warrant attention. I spent a short evening working on the main course, the largest sail on the Great Republic. I left off with a final coat of paint left to dry...so I'll get to it in the next days. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Michael...fantastic job.... What material did you use for the window seal....you did include the window seal...right? You have included every other fine detail..rite down to the slotted screws and their perfect alignment.. not to mention just whipping out a couple more vents.... Your skill and execution of it is masterful........ Rob

- 2,215 replies

-

Thanks for all the acute observations. I used the average size wire I always use for these applications...because the detail is small and will only drive crazy those pesky ship model people.....I'll let this one slide. (I really hate redo's). However, if a blaring error pops up, I'm counting on all eyes to identify and alert. I know....it's what we do. Again, However, with that said, I will avoid using this light, wimpy wire for the remaining main and mizzen stays...not only for accuracies sake, but also for the sanity of my MSW friends. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

MONTAÑES by Amalio

rwiederrich replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

Man...your work is awesome..... Rob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.