-

Posts

5,520 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

I’ve owned my workmate for over 30 years and have built my ships masts this way since I owned mine. So much detail can be done this way…..easily and safely. Rob

-

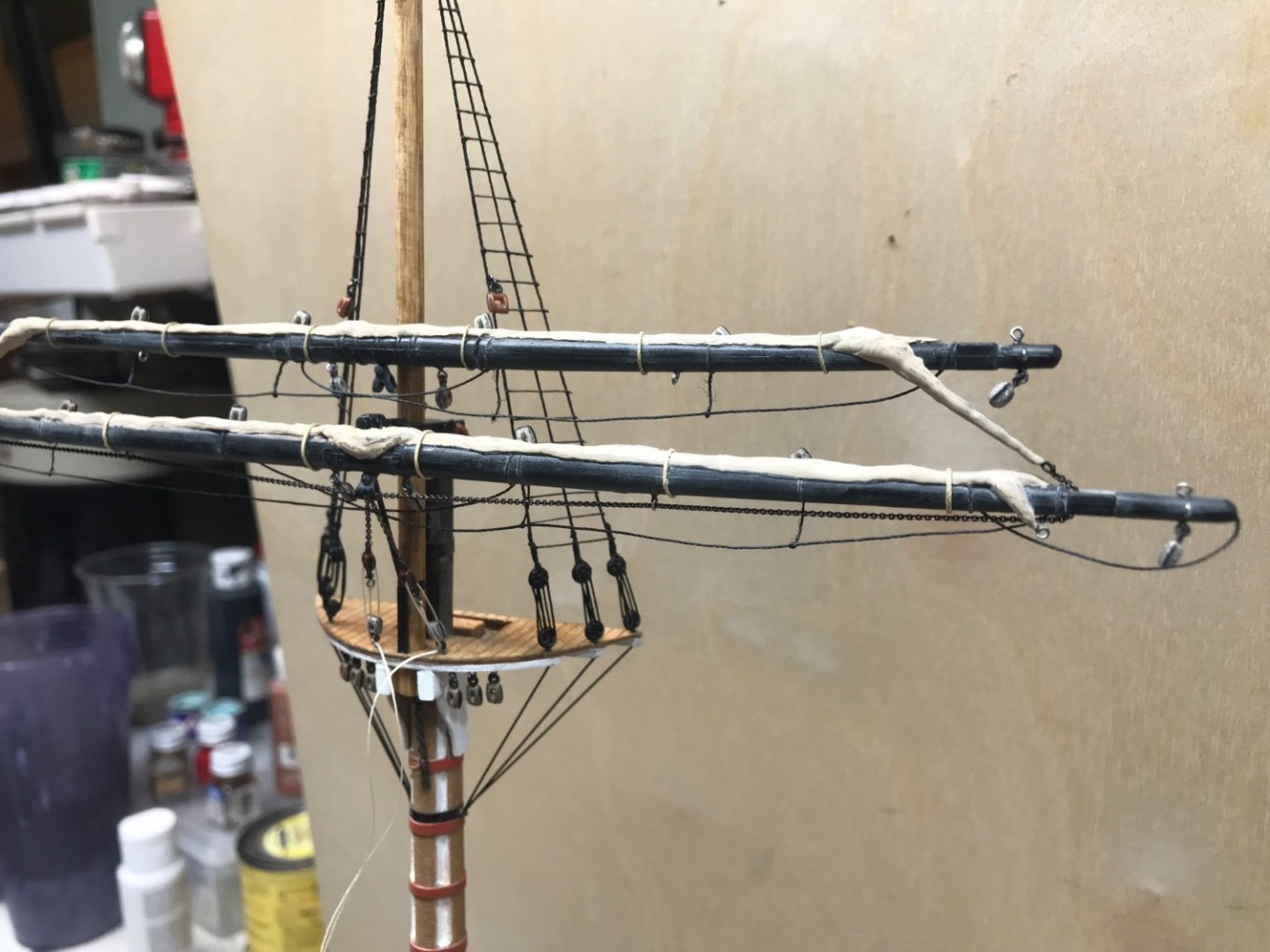

Thanks Druxey, that means a lot.. Authenticity was the greatest challenge and the scale made that even harder. I think I may have reached my goal. Actually, I don't see too often, models rigged with tight furled sails, but as photographs clearly show us...while in port the sails were made weather tight on the yards....meaning...a clean pressed tight sail was a sign of sharp seamanship and the sail almost acted as a covering for itself....no loose untuffed sections that could attract quantities of standing water and critters. We wanted to look good while we were in port....all those peering eyes and such. And if you were expecting a long stay in port...you unbent the sails and stowed them in their locker. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Bill, that means a lot. I hope I’m staying true to my subject matter. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks a lot Michael. At this scale I surely didn’t want bulky. Tightly furled sails are not easy to pull off convincingly. Thanks…..your approval is worth millions. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

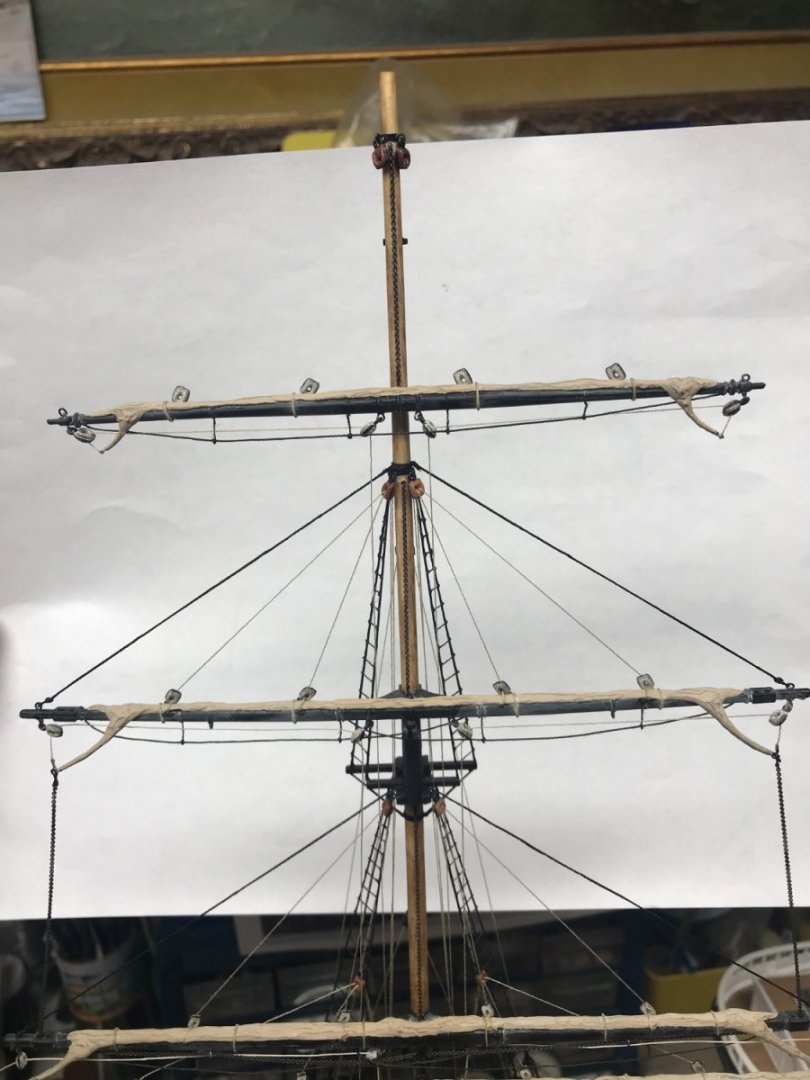

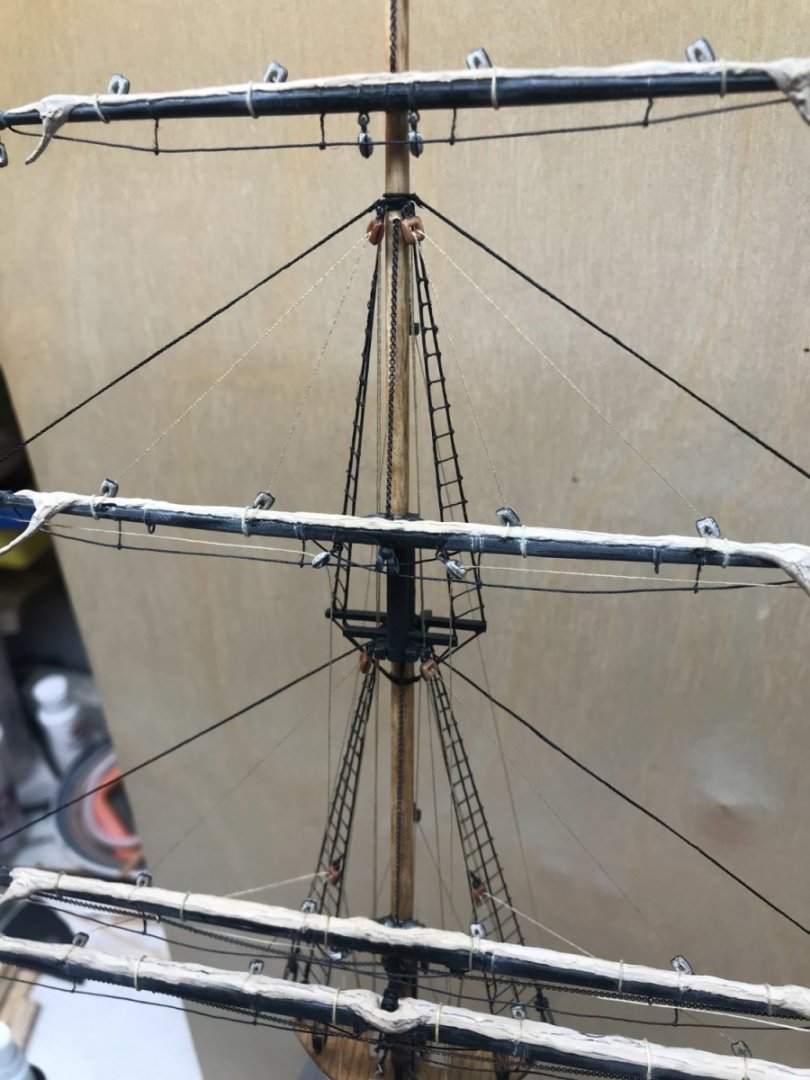

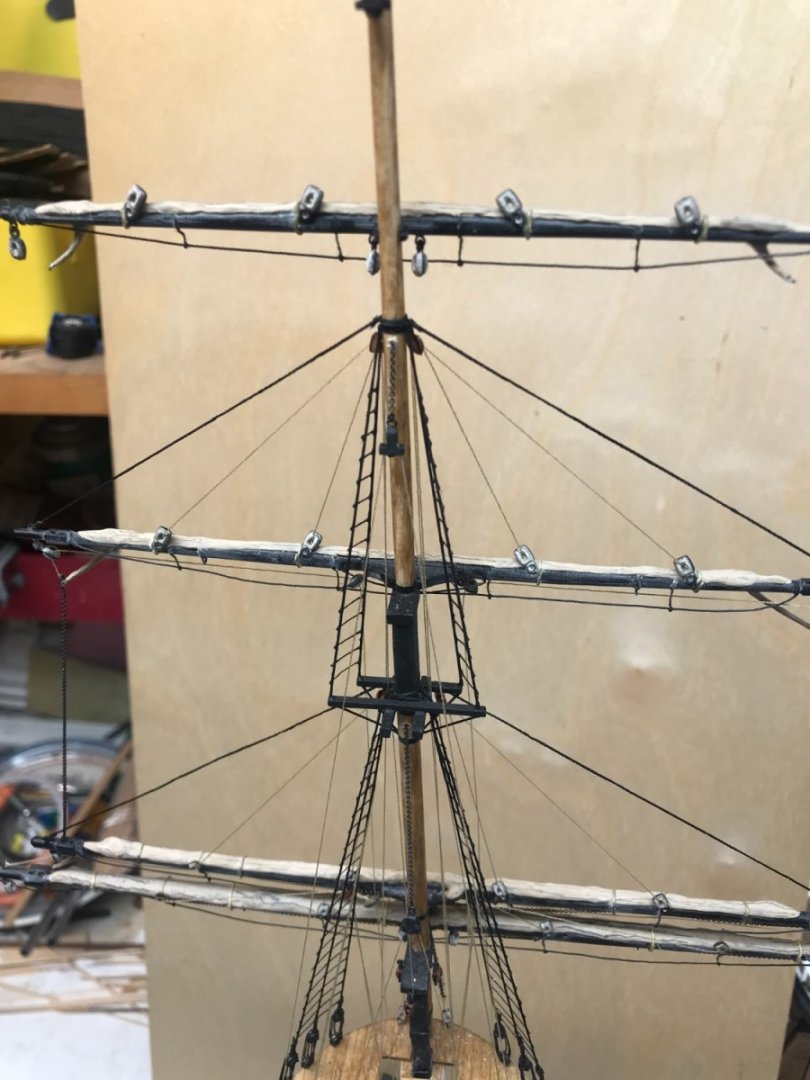

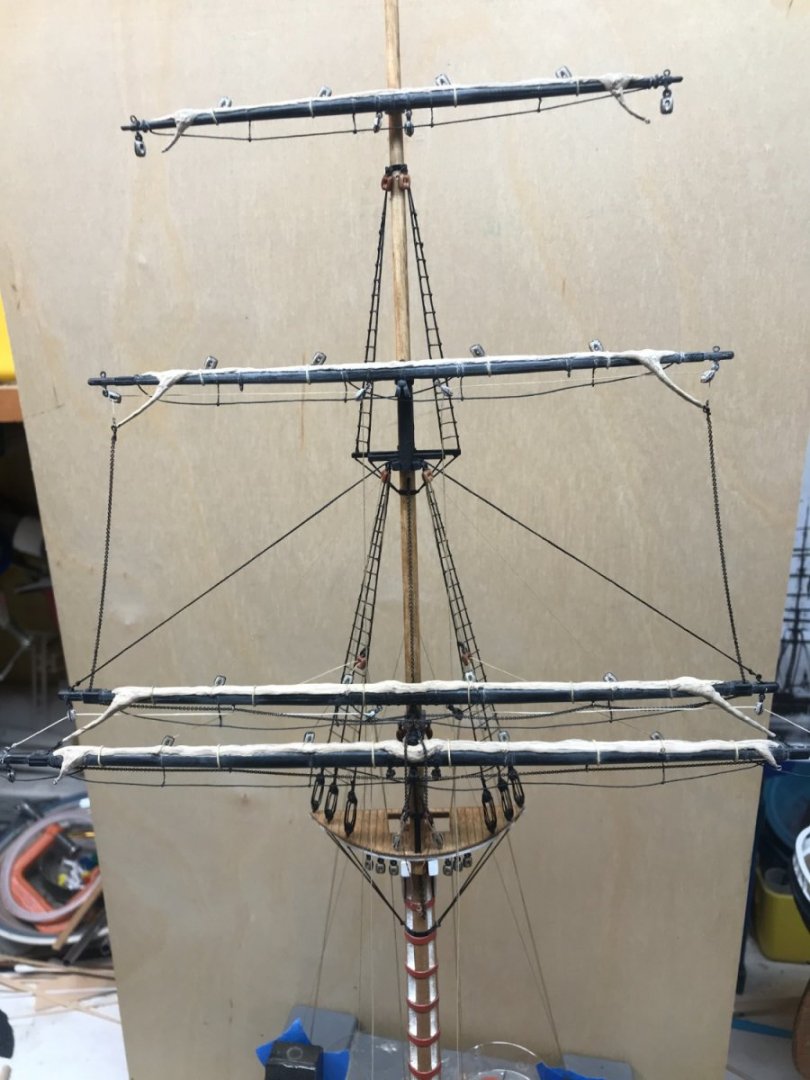

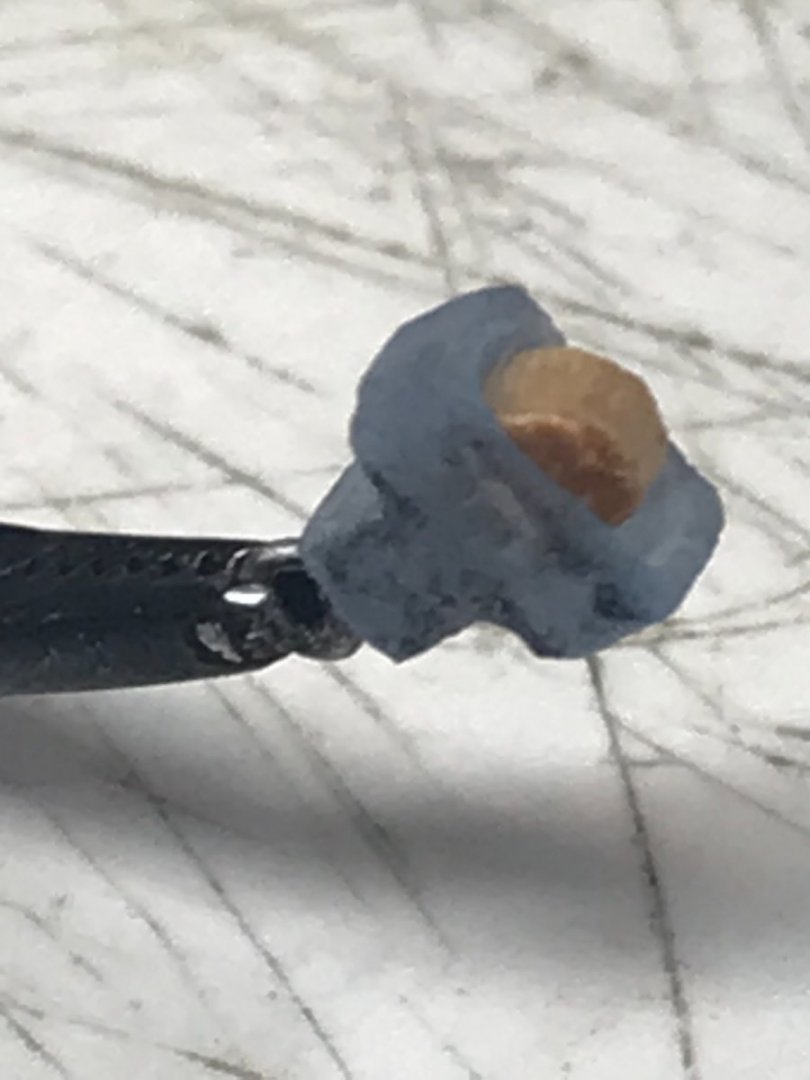

Thanks everyone for the fine comments and compliments on the progress. line has all kinds of variance in its diameter, the lifts are larger than the buntlines and the chain sheets . The downhaul on the upper /lower topsail is even of a different size. Here are a few more progress images. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

See Keith...you're doing as I do...with that workmate. It's sweet huh? Off model work for the masts/yards is the only way to go if you want to keep from breaking everything. Just sit at your bench and easily reach and work on all the rigging aspects. Great job for sure. The scale is far too small to tie knots for the ratlines....just glue them on. They will look great. That's all l do, then I paint the glue marks black. Looks like scale tar. (Given up secrets) Rob

-

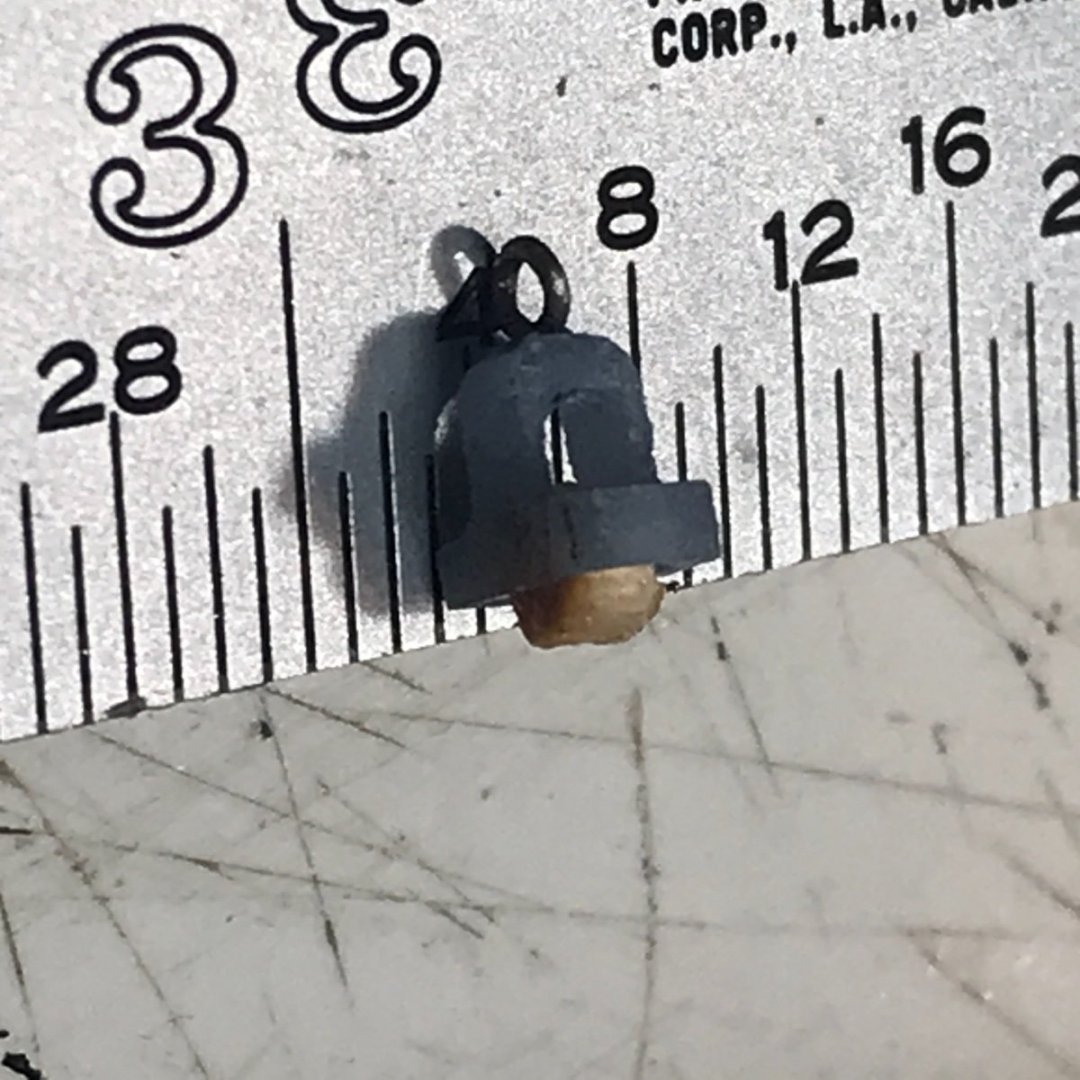

Thanks Ian. I worked this design out with lots of experimentation. It is tiny metal work, but it pays off. Again, thanks for commenting. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Just remember...many of his drawings represent the larger steel ocean carriers. You will need to focus on the wooden structures and familiarize yourself with the rigging practices used on Glory. They are quite similar to those of the big Iron boys, but are slightly different. Good luck. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

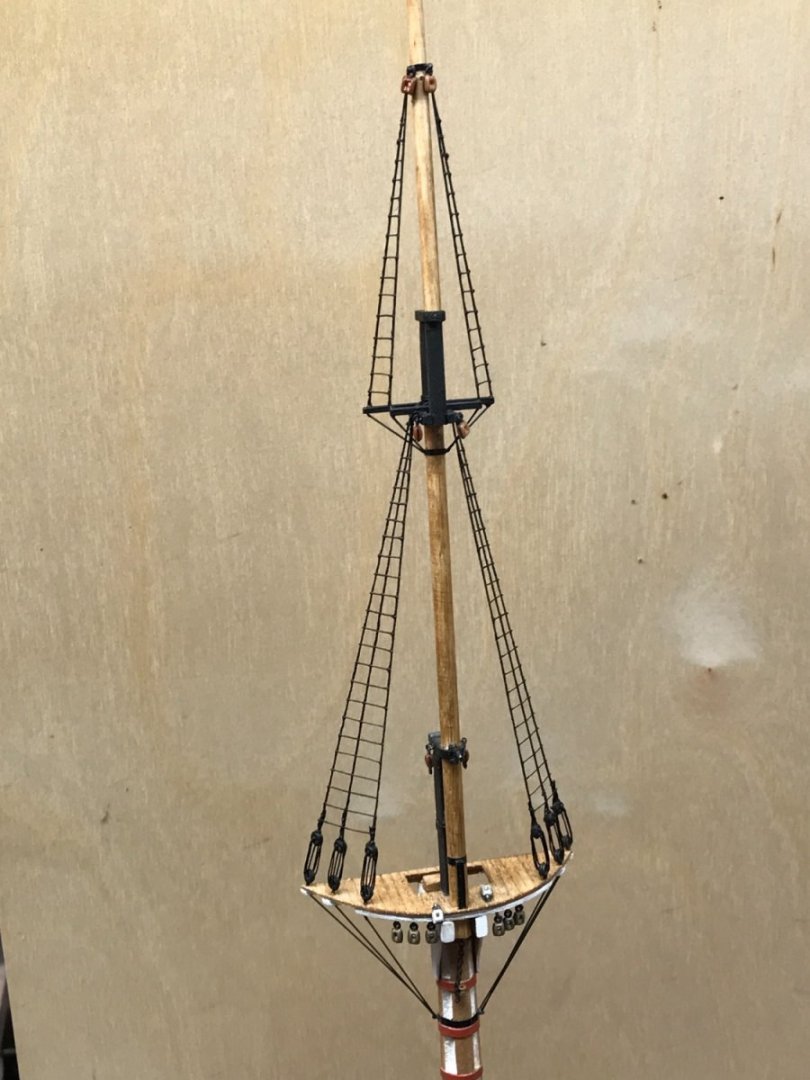

I hope I wasn't implying that tedium was in any way unpleasant? It simply means slow, detailed repetitive work...generally associated with long moments of pleasantried reflection and elevated endorphins. Like I said...I'll finish up the mizzen and then rightly move to rig the bowsprit. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Vlad. I’m just getting started, months…..many month…….of tedious detailing rigging to do. I’m glad I’ve devised a methodology to it all, to make it pass without me losing my mind. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I’m just now rigging the sheets. Once the bunt lines are added too and the lifts……it will get really busy. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

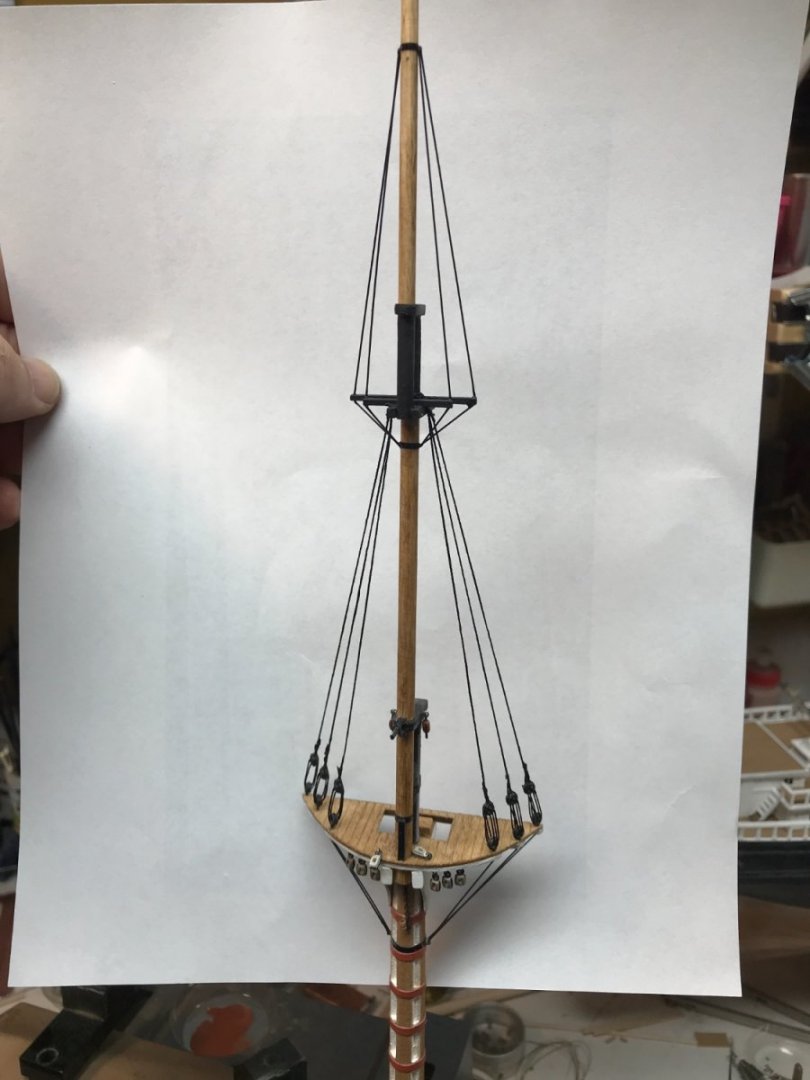

Adding the top gallant and royal. Now rigging them will take lots of work……so much to still do before this mast is ready to be set in place. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Finished up the mizzenmast shrouds. Now onto the ratlines and some minor drilling for the tye access holes. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

TBD......might look like...the Black Pearl swirling on the edge of a large maelstrom......? Rob

-

Problem with common rubbing alcohol is the additives. In my experience it reacts poorly with the India ink and never gives the good results I found with 98%+ It surely doesn't burn well...not clean at all. Thusly...evaporation is not as clean and the ink suspension is poor as well. Experiment and see for yourself. Rob

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.