-

Posts

686 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by lb0190

-

Thanks Popeye! I now have all 18 jack-screws made, with five installed. The prototype I installed a few months ago was removed and reworked. After looking at it for a while, I did not like the four handles. The new handles are smaller diameter (0.014 vs 0.020) and slightly longer. I'll post some pictures soon.

-

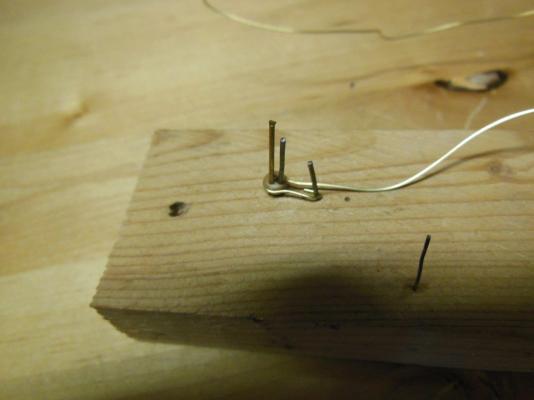

It's too hot to do much work in the garage so a quick minor update sounds like a good thing to do. I finished one channel with chain-plates, on the fwd starboard side. I'll use three steel pins and CA plus PVA glue to mount it in place. The photo shows it with the three pins holding it in place dry. The center pin hole is slightly too high on the hull which shows up in the photo. I'll make the center hole a bit bigger to correct the bow and secure the pins in place with med CA along with PVA for the wood to wood contact. I was going to start on the aft channel, but after giving it some additional thought I decided I need to finish some deck work so I do not knock off the boat davits and sheer bars that get mounted with the aft channel. I've been procrastinating on making the remaining carronade jack-screws (17) and rope coils. The jack-screws are simply a pain to make and I need to order more rope for the rope coils, but I need to finish these tasks before I paint myself into a corner. Below is a photo of a no. 90 brass hex head with a 0.017 drill bit. I drill the bolt head through in two locations 90 deg apart. Once the four holes are in place, I turn the bolt head to make it round, then add wire to simulate handles. The wire ends are dipped in CA glue to look like knobs on the end of the wire. I'll blacken the assy and then mount it on the carronade. I use my drill press to drill the holes and chase the holes with my hand drill. Four down fourteen to go. Here you can see the center of the channel is slightly high. Someone needs to stow that anchor before a big wave rolls it into someone and kills them.

-

I'm enjoying your build Popeye. I've never seen a plastic model with such detail and build quality.

-

Hi Grant, I'm late to the party but I hope there's room for one more chair. You have an excellent build log and a beautiful build!

- 456 replies

-

- finished

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Frankie, yes I realized the pins are way out of scale but they are all I had and my making them would look even worse. I have not glued them in place yet due to the size issue and may eventually look into buying some that are closer to scale. I have a grocery list of items to address or accept at some point. Thanks for pointing it out and for visiting my build.

-

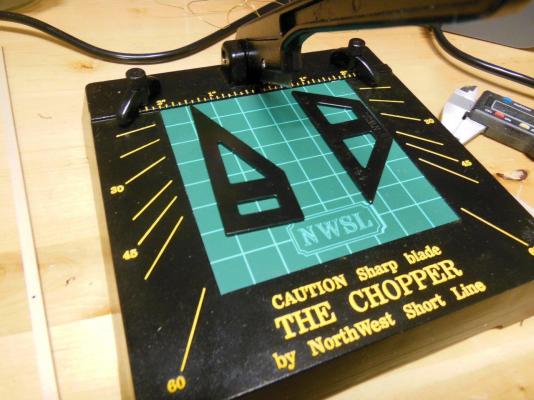

Hi Popeye, thanks for looking in. I wish I found this hobby years ago, but then again without MSW and the help from others such as yourself I probably would not had much luck at finishing one. Yes that chopper is really nice, did you see the "Caution Sharp Blade" written on the body? In case you were wondering if it's true, I confirmed its accurate.... I mistakenly left the handle up and that was all it took. Pain is such a good teacher nothening serious in regard to the cut but it was a quick lesson to leave the handle down! It seems inevitable that anytime I get anything new that has a sharp edge, it's not really mine until I cut myself.

-

Happy B day Mark. Your build looks awesome and is making me lean toward the dark side for my next build...

-

As time permits, I've been working on the channel chainplates. This is a first for me and to say it's a challenge is an understatement. I tried several different methods and settled on one using pins in a board to help shape the wire. I'm trying to keep the OAL within the drawing spec but I'll know how well I did once they are hanging on the ship. I also recently purchased a wood chopper from NorthWest Short Line and after market soldering station at a Hamfest. Both work great and after using the chopper a few times, wished I found it day one when I started with this hobby. Jig for deadeye, similar type wire jig used for links. Some of the links soldered. My soldering skills have deteriorated, no signs that I used to install and solder strain gages... One assembly together with first effort at blacking - needs more work! Once assembled, I'll rotate the deadeye to it's proper point and use CA to prevent it from rotating. Single edge razor blade held in by a single screw. Extra screws were provided. From the top, walnut, pear and basswood. All with very clean cuts.

-

Popeye, if your doing a little kit bashing here is an idea... I suspect you may have seen this but in case not

-

Hi Ken, I've been quietly following your build. In case your interested in using the hooks mentioned by Brian, here is how I used them on my Niagara: http://modelshipworld.com/index.php/topic/313-niagara-by-larry-model-shipways-wood-pob-164th-lb0190/page-35 As Brian mentioned, I also think they match the scale well. Take care,

- 440 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Micro-Mark MicroLux LaserKnife 2525 – A Review

lb0190 replied to mtaylor's topic in Modeling tools and Workshop Equipment

I hope to buy a table saw and thickness sander after I finish my current build. Hmmmm, Micromark or Byrnes? Maybe the above post will help me decide. -

I managed to get some work accomplished over the past few weeks. The catheads are installed except for the tension rod. I need to pull to fwd facing eyebolts and reinstall. I did not notice how crooked they are until after I took the photos. They were evenly installed but i noticed the spacing was not quite right so I pulled them and reinstalled them crooked on the other plane! The aft boat davits were also installed, as well as the fore and aft fife rails. I still need to install the cleat on the aft fife as well as the bitt knees. The fife rails and bilge pump are pinned but will not be glued in place until I'm sure they are in the correct position or do not need any rework. Next on the list are the channels and chainplates.... Again, sorry about the dust and paint nicks but after all it is a construction site...

-

Popcorn and another interesting build by Popeye. I think I'll pull up a seat and watch, plus munch on some of Sjors popcorn.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.