-

Posts

194 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Haze Gray

-

-

3 hours ago, Egilman said:

I'll be talking about it Craig, once it gets here and I've had a chance to set it up.... Still need to finish my Solidworks courses... (as life allows) But I think I'm making progress.....

Egilman - what version of solidworks are you using?

-

-

Hi Alan, what kind of filament are you using? Also, does the print cooling fan turn on when you're laying down the first layer or does it wait until you have .2 - .3 mm laid down?

It looks like maybe the the bed might not be fully level as the corner brims on the left side are incomplete but the one on the right side is.

- Egilman, Old Collingwood, Canute and 2 others

-

5

5

-

I agree with Lou. I believe there wouldn't be much reason to print a ship that could be reasonably modeled in the material of the original, especially wooden ships where the detailed construction is so much part of the beauty and fascination - unless it was for some kind of board game.

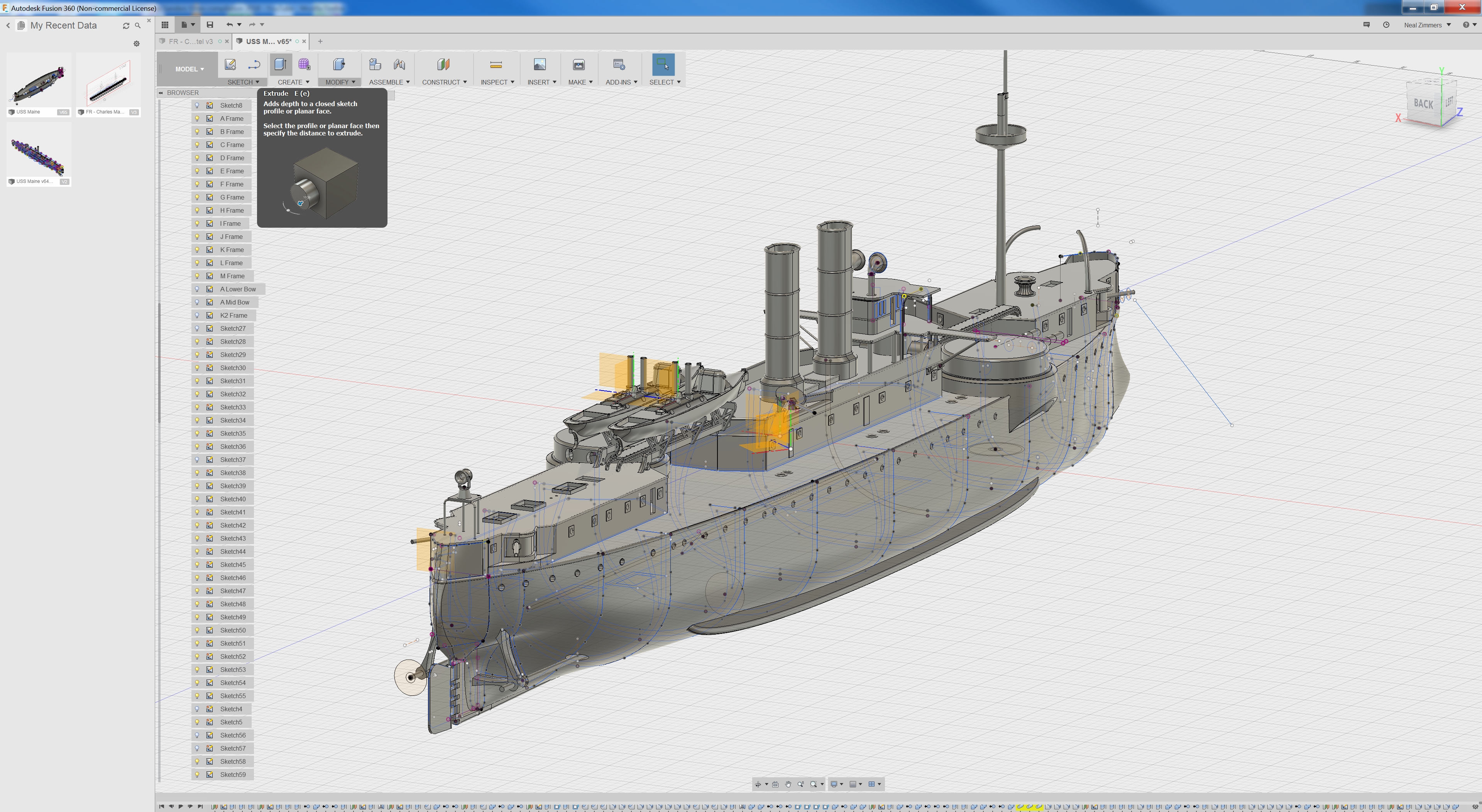

I'm having a lot of fun printing and assembling an RC version of the Maine, I always enjoyed plastic model kits and so I'm kind of getting to relive my childhood passion.

- GrandpaPhil, lmagna, Canute and 2 others

-

5

5

-

3 hours ago, CDW said:

That resin printer is magic. I have no understanding at all of the technology behind it, just that it's as different as night and day between it and the type of printer that produces the hull. Was it as challenging to learn? Does it use the same shape files?

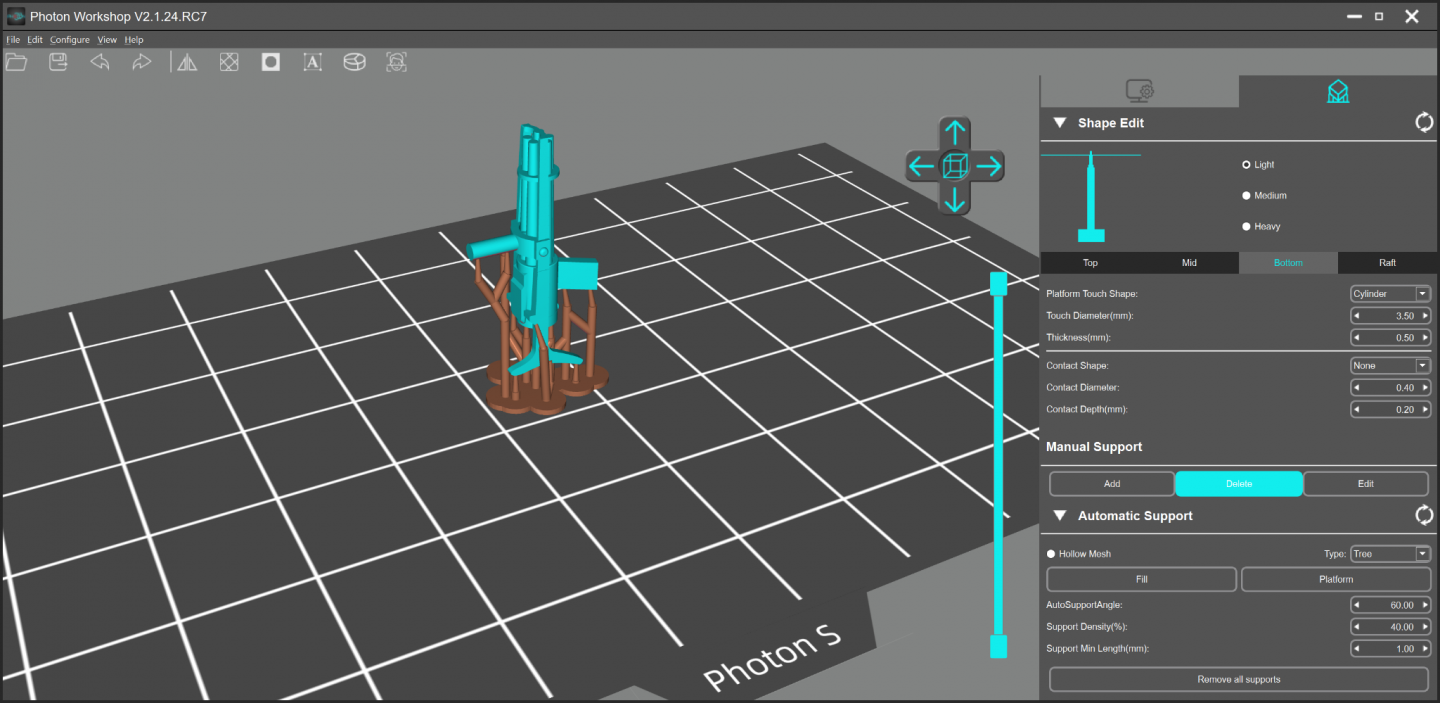

It was a bit of a challenge but not any more than learning how to use a regular filament printer. Similar to a typical filament deposition 3D printer, resin printers use .STL files that are sliced through a specific program - for resin printers they are converted to a format for 'stereo lithography' printing. I got the resin printer because I knew I would need it for some parts on the USS Maine that my regular filament printer would be challenged to successfully print. With a smaller nozzle (0.3mm) you can print small parts with decent detail but the resin printer takes it to the next level.

you do have to learn a bit about how to position the parts for the resin printer and then there's the whole issue of having resin and a wash station and curing box (or use the sun). I go through 2 pairs of rubber gloves every time I use the resin printer for something. One big advantage with the resin printer is is that you can print multiples of the same part in the same time it takes to print just one. So when I printed that last Hotchkiss revolving cannon I didn't do just one, I did 12 since I knew I have other ships in work that will need them.

-

- Nunnehi (Don), VTHokiEE, Canute and 8 others

-

11

11

-

55 minutes ago, king derelict said:

I'm preheating to 65C and printing at 63C. maybe that's a little too warm but I got to those values while suffering from bed adhesion problems. Maybe I am running it too hot.

Thanks for the suggestion.

Alan

Usually going hotter would reduce the stress - so you're probably fine there unless you're seeing problems with the first layers spreading out like an 'elephants foot'.

- Old Collingwood, mtaylor, lmagna and 2 others

-

5

5

-

Alan, I've been there done that myself! bit surprised the epoxy gave way but the mating surface area for the hull joins on the corvette aren't super big - One question I have looking at the sections on the work table - when you join them are you somehow clamping the sections to the internal shape? 3d printed parts in a U shape will tend to have more tension on the outside and want to splay open a bit so I assume that's probably something that you have a method to deal with.

-

-

-

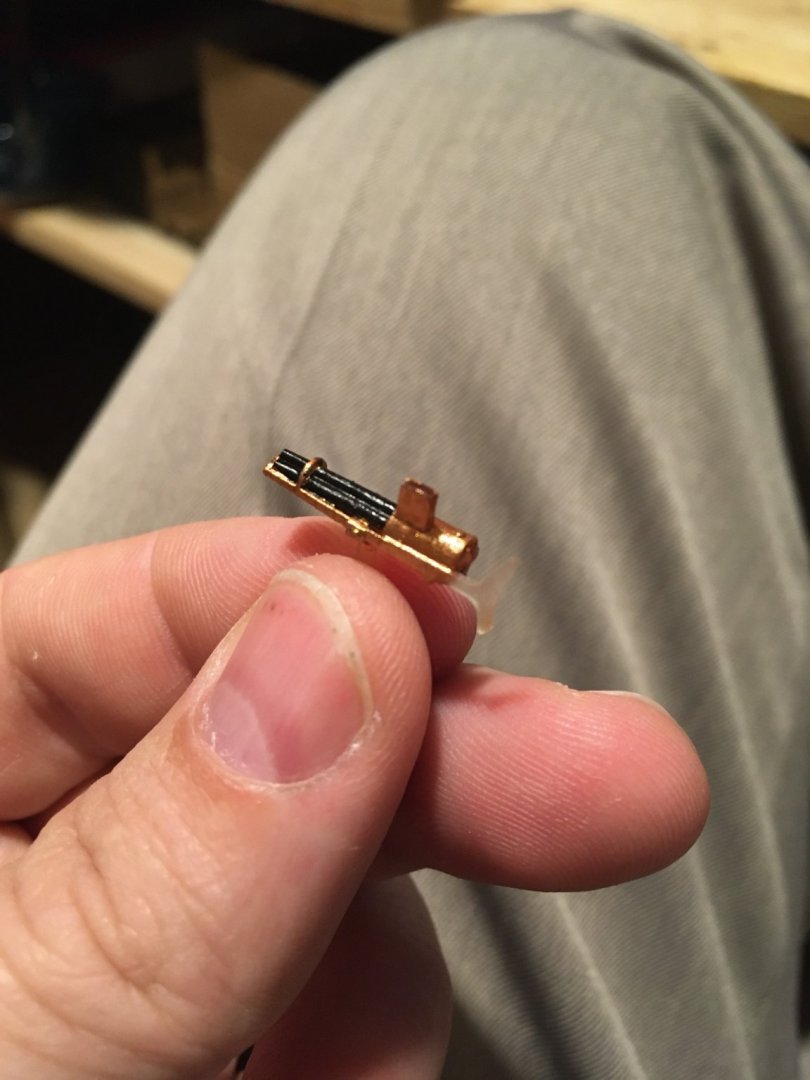

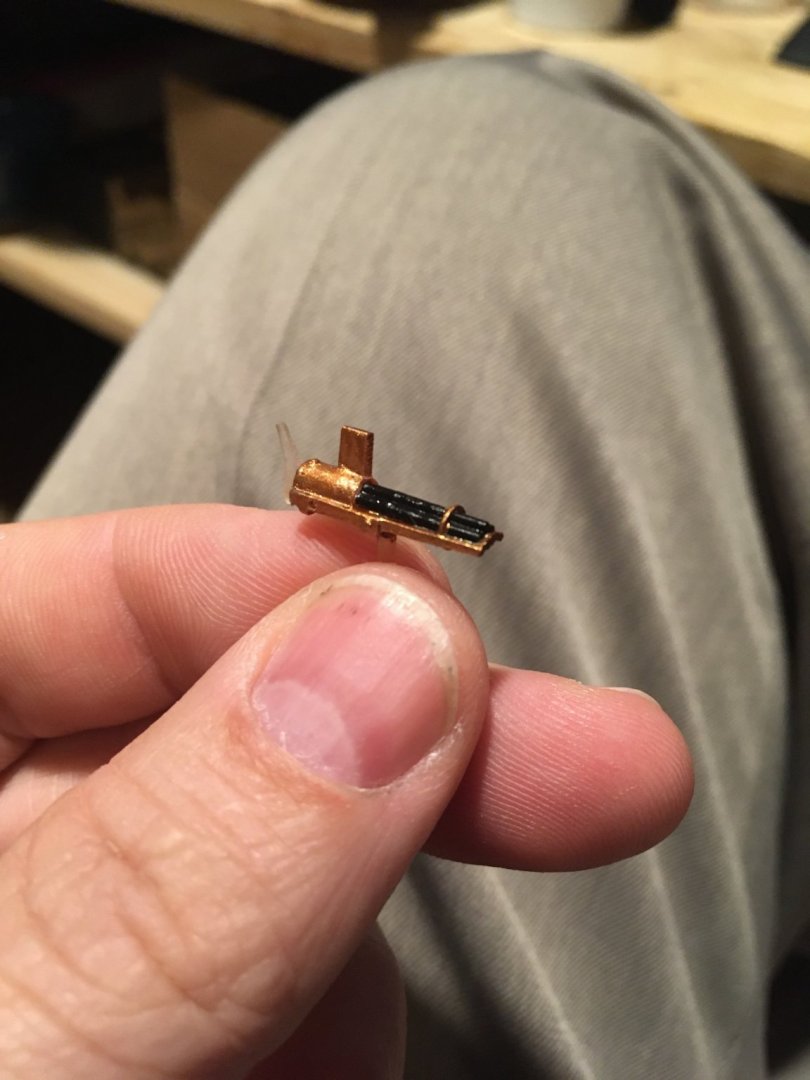

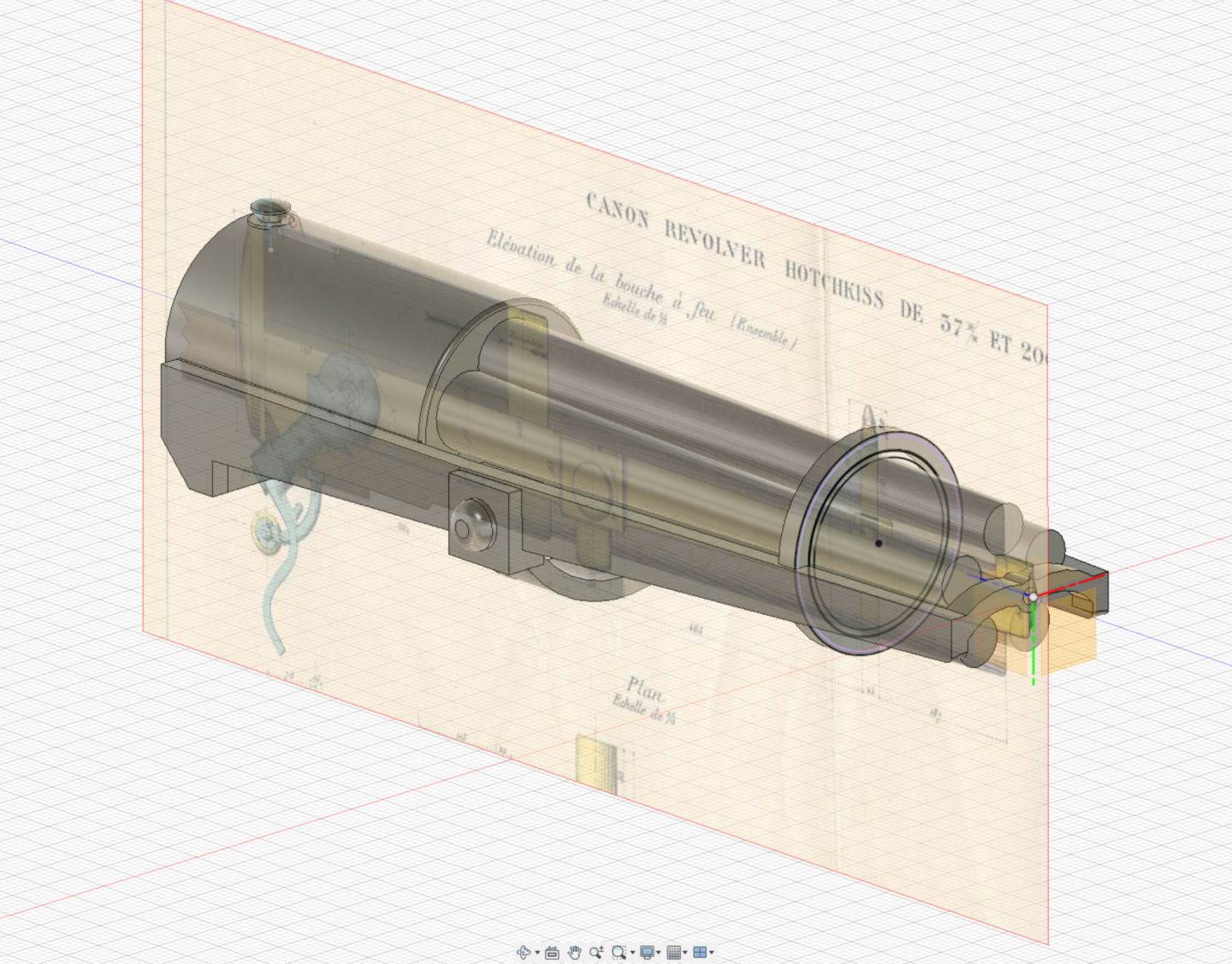

So on the topic of can a 37mm Hotchkiss cannon be printed at 1/72 scale - the answer is yes - I think....

small one is actually too small (at 12mm) for 1/72, and the large one is too large (19mm) - so I've adjusted to the proportions (though it's still about 1mm longer than it technically would be at scale but) and added the shoulder brace and magazine and printing another one and hope it turns out!

- so I've adjusted to the proportions (though it's still about 1mm longer than it technically would be at scale but) and added the shoulder brace and magazine and printing another one and hope it turns out!

-

-

-

-

1 hour ago, CDW said:

I wonder how well Gesso would work for spraying on with an automotive paint gun, a small one like you use for door jambs or touchups? For a model as large as the Corvette, it could possibly come out a whole lot smoother spraying on vs: brushing it on. I think you could apply lighter coats as well and of course, no troublesome brush marks.

I've heard about gesso in a spray can but it's cut with significantly more water is my understanding - so many more coats required but maybe that's not an issue.

-

King, I want to add that you need to resist any urge to lay on the Gesso in a thick layer - especially if you don't cut it by 20-25% water. first time I used Gesso I laid three thick layers down and thought "this is amazing - I can make all those lines disappear"...but, once dry, it took me a really, really long time just to get to the point the left over brush marks were not so visible. Gesso can be quite a durable coating, especially if it's not fully cured and if you lay it on thick it's going it could take a long time to cure.

As mentioned before, test out what you want to do on a separate piece and see how it goes.

- mtaylor, Canute, Old Collingwood and 2 others

-

5

5

-

3 hours ago, king derelict said:

I foresee several days of sanding and fairing of the hull to get it tidy. I'm reluctant to use any form of rotary tool sander because of the low melting point of the plastic.

I am going to need some putty for some of the less than perfect joins. I only have the Vallejo plastic putty which my work but I would be grateful if anyone has any better suggestions for filling the thin gaps between a few of the hull sections and a few print gaps.

Thanks

Alan

Considering how the weld lines stand proud and separate the surface of the hull into multiple sections sanding the plastic directly would be somewhat torturous (and rotary tool would remove weld lines in the blink of an eye no matter how careful you are). A very thin layer of 75% gesso/ 25%water mix could help fill in the lines somewhat and then follow up with multiple layers of primer and then sanding could be a good way to go - but I recommend you print one additional of the hull sections to test whichever method you want to pursue since you will learn a lot about what works and what doesn't.

- lmagna, Old Collingwood, CDW and 3 others

-

6

6

-

On 9/9/2021 at 7:00 AM, shipmodel said:

Hi HG -

...........................Looking forward to seeing how the gatling guns will print out

yeah those are not going to be easy - there were 37mm Hotchkiss revolving cannons (very similar to this) and then there's the .45cal Gatling guns (which I don't think were actually mounted on the ship but on limber but can't be sure). I do have photos that show both 1lbr QF guns and the 37mm Hotchkiss revolving cannons mounted on the 4 points of the center island - and one of the drawings in the national archive calls out "gatling gun or 1lbr" in those 4 locations. "gatling gun" is is sometimes a generic term used for revolving multi-barreled guns - but I'm going to go with what I have photographic evidence of. I'm going to attempt to make the 37mm Hotchkiss revolving cannons but they are probably at the limit of what I can print so I might fall back on mounting 1lbr QF guns.....

-

So I looked closer at the video the way the bow breaks the water results in an extreme upward travel and a curl much further back - this really isn’t unusual for this bow shape (it’s similar to ploughing a field) if you look very closely at the bow you’ll see the waterline at the bow is actually above surface of the water but is quickly forced upwards and outwards.

-

1 hour ago, yvesvidal said:

I would say the ship is slightly too heavy on the bow, especially at the speed where you took it.

Yves

Yves, You're correct - but it might be more accurate to say the ship was too light in the stern, the tips of the props were not always in the water and I probably needed about 3/4" more draft!

-

8 hours ago, Nunnehi (Don) said:

This is really cool! Did not know that 3D printing could work at this scale. I’ve used some aftermarket parts for 1:200 scale projects (currently Titanic) and found them to be great! Can you post some more hull pics?

Don

Pics as requested - note though that I am still a long way away from finishing - I started painting the deck and don't like the color so waiting for more appropriate paint to arrive + there's lots and lots of detail that needs to be added.

- Nunnehi (Don), GrandpaPhil, lmagna and 3 others

-

6

6

-

Yes, I'll post some pictures of the ship at the current state - but with nice weather over the labor day weekend and fall (rain) on the horizon I put the Maine in the water to check how it floats and get a better idea of the ballast needed - here's a video...

Note: I removed the main guns and upgraded the offensive capability of the ship with sea-skimming anti-ship water bottles 😃

- mtaylor, Canute, Nunnehi (Don) and 2 others

-

5

5

-

I figured I should start posting some updates and I have been making progress on the USS Maine - most recently I have been attending to small details like the small caliber (calibre) weapons and launches, cutters, and other deck furniture using a resin printer.

here's some photos:

This one is a 32ft Launch - doesn't actually go on the USS main but I have a 33ft cutter in the design stage that's pretty similar:

Then there's searchlight and Driggs-Schroeder 6lb guns (yes they both pivot and swivel) unfortunately I have the searchlight rotated upside down in this shot:

And I'm working on a 27' steam cutter that will go on the Maine - this print actually failed due to operator error (I didn't tighten down a knob for the build plate):

will try to post some more pics later today

-

3 hours ago, king derelict said:

......I am looking at upgrades for the Ender and was wondering about their auto leveling system, I need to read some reviews

Thanks for the help and advice

Alan

Hi Alan, I think this would be a good thing to consider - it uses a BL Touch probe which is what I use and it is reliable. It can be used to do two things: a) probe the corners of the bed to help you level the build plate b) "bed compensation" for the contours of the bed if it's not completly flat - or, if it's not truly level it will adjust the z-axis movement up or down to keep the distance of the nozzle from the bed uniform across the print.

Technically 'bed leveling' involves the printer making adjustments automatically based on the probe measurements but I have one printer that does bed compensation and another that does automatic bed-leveling and they both work just fine.lastly, occasionally when a print of my has failed I've broken a few of the plastic probe needles but you can buy replacements for them (instead of buying a whole new probe unit)

- I bought a total of 4 BL-touch probes before I figured that out I could just by the probe needle and replace it %$&#^&$)%*!!!!!!- CDW, Egilman, Old Collingwood and 2 others

-

5

5

Flower-Class Corvette by king derelict - FINISHED - Bensworx Virtual Kit - 1/48 - a log for the less gifted

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Hi Alan, how many cans of primer did you end up using?