Warnerade

-

Posts

175 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Warnerade

-

-

On 6/16/2020 at 2:43 PM, Liad said:

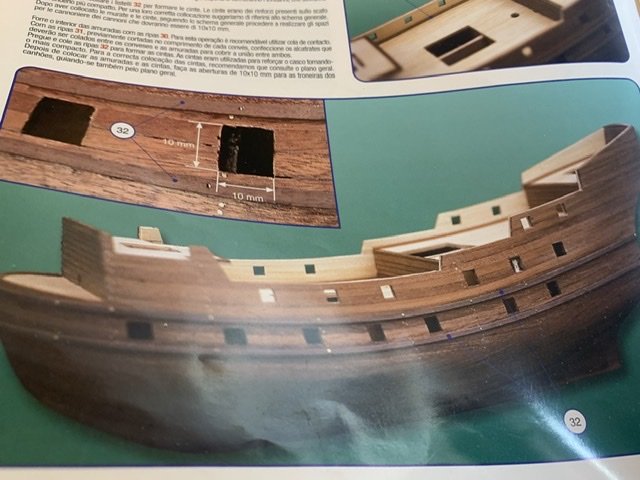

I’m actually not sure which version that is. To my knowledge there’s only two versions of the San Francisco and neither of them had open gun windows. The first version came with cast-iron window covers to glue on where as the second version came with instructions to build wooden window covers

-

I chose to make the entire case outnof red oak and then stain it using 2 coats of golden oak with about 5 hours in between coats.

Working on the base now, I’m a little torn on the overall design, mainly the height. As it sits now, it’s about bellybutton height where the boat will sit on the main base. At 14” wide, the overall center of gravity is going to be fairly high and I’m afraid it will be too unstable. I am currently debating on ways to essentially attach it to the wall it’s sitting against or make the entire case shorter, which would make the case less appealing as far as the “display” goes.

that being said, before starting this post ~2 years ago I had never even used a table saw, so any errors or rookie moves, please let me know as I’m having a blast learning about wood working while in the process of ship building as well. It’s a great mental break from work.

- Osmosis, GrandpaPhil and ccoyle

-

3

3

-

With the weather finally hold out and giving me some nice days I decided to take a few big steps on the display case. I did a little research and ended up purchasing an instruction .PDF to get me going. So far it’s coming along great.

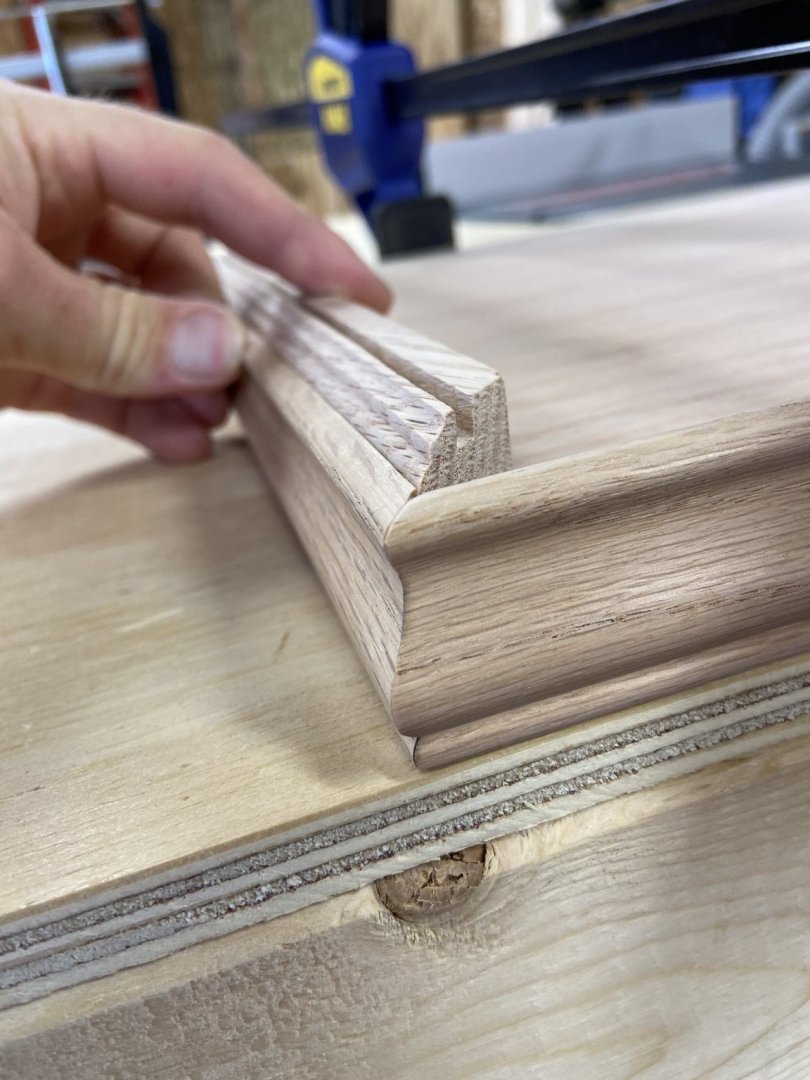

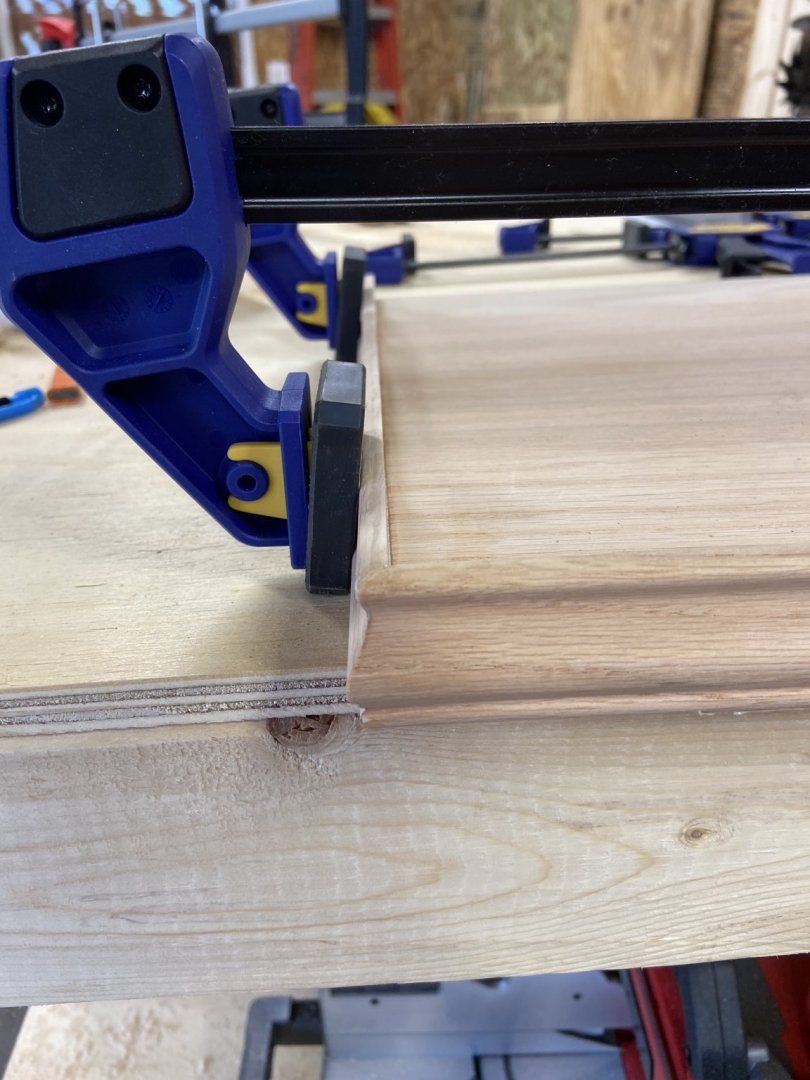

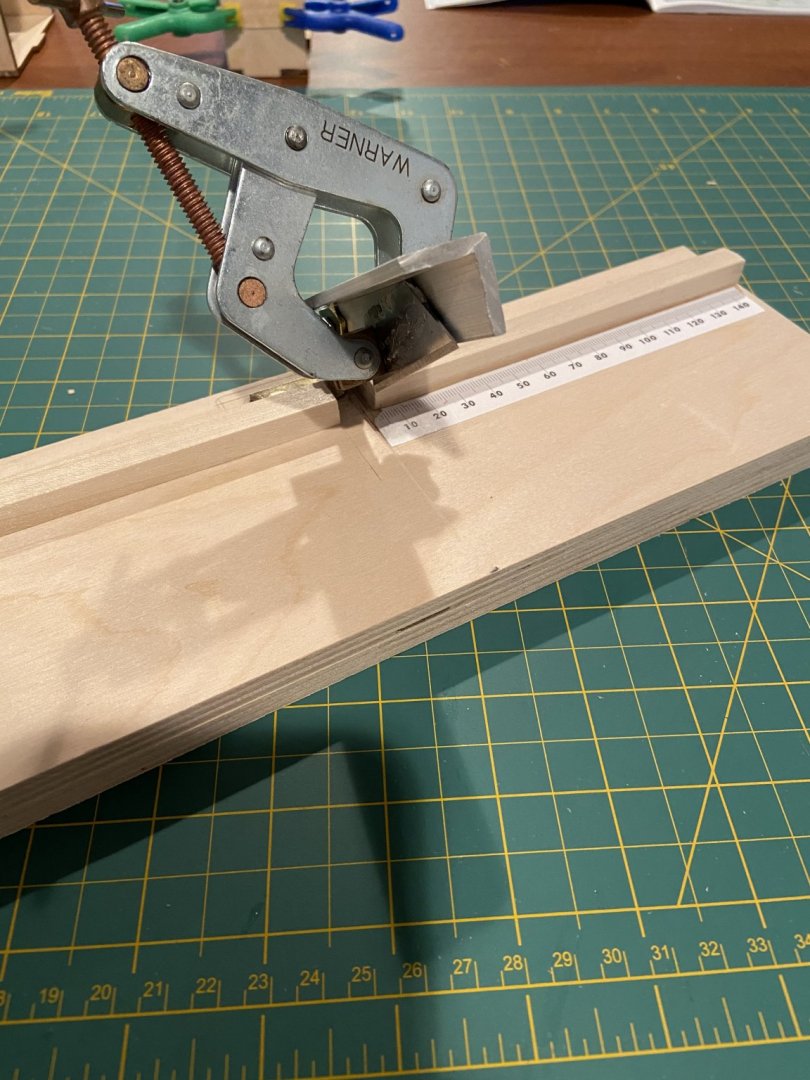

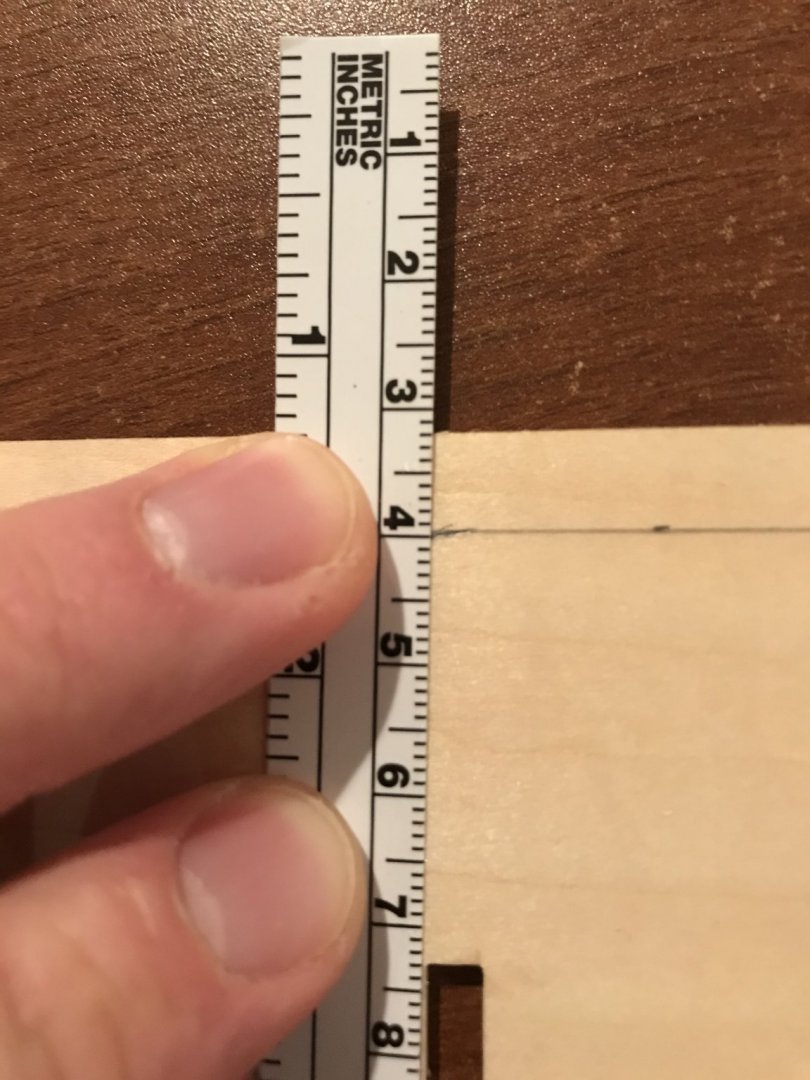

first I cut strips of red oak 3/4 x 3/4 for the borders, used my table saw to cut 3/16” slots 3/16” deep all the way down for the glass to sit in. Then I cut them to length using my craftsman adjustable mitre box. After that I used my router with a 1/8 cove and bead bit to cut a nice border.

(repeat this step for the top sky glass as well)

Once this was all glued together and squared up I cut a solid piece of red oak to match the dimensions of the glass frame with roughly 1/8” to play with on both dimensions.

then I cut and glued oak trim to the outside of the solid oak base.

once the glass box is complete it is going to sit nicely inside the base.

starting with 3/4 x 3/4 again, I cut slots inside the stanchions (upright corner pieces) to hold the glass up, and then I actually planed down the outer surfaces so it will line up nicely with the routed base frame.

- oneslim, GrandpaPhil, VTHokiEE and 1 other

-

4

4

-

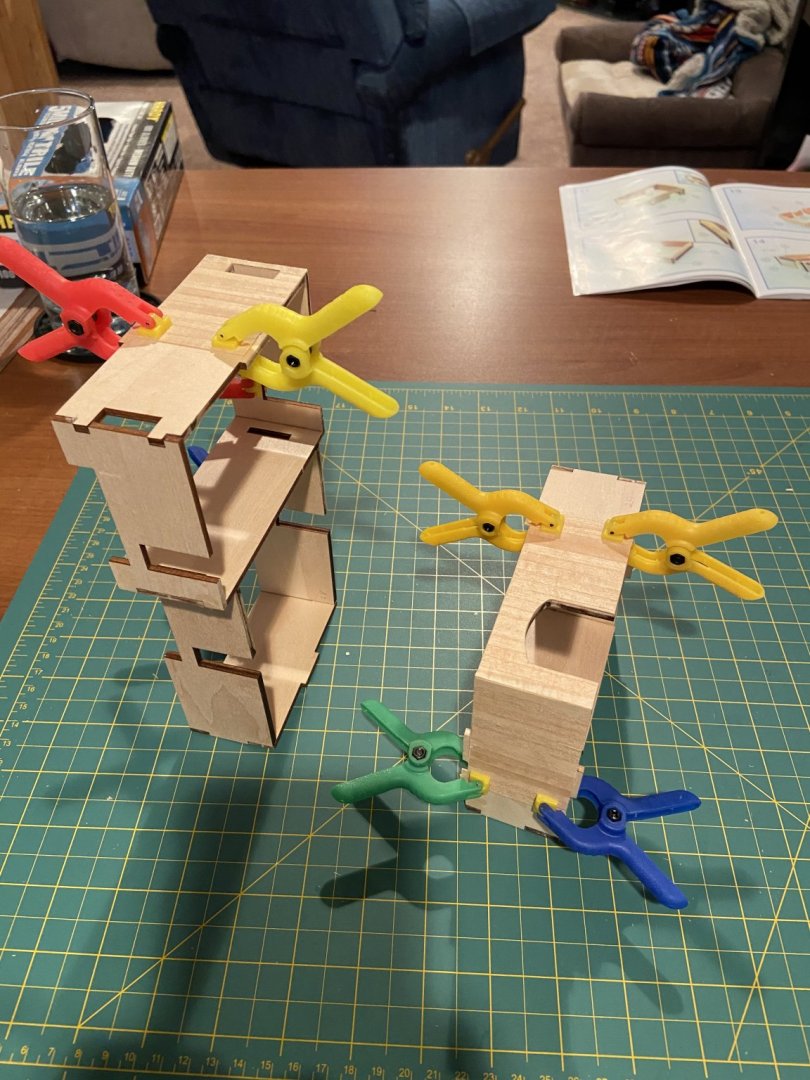

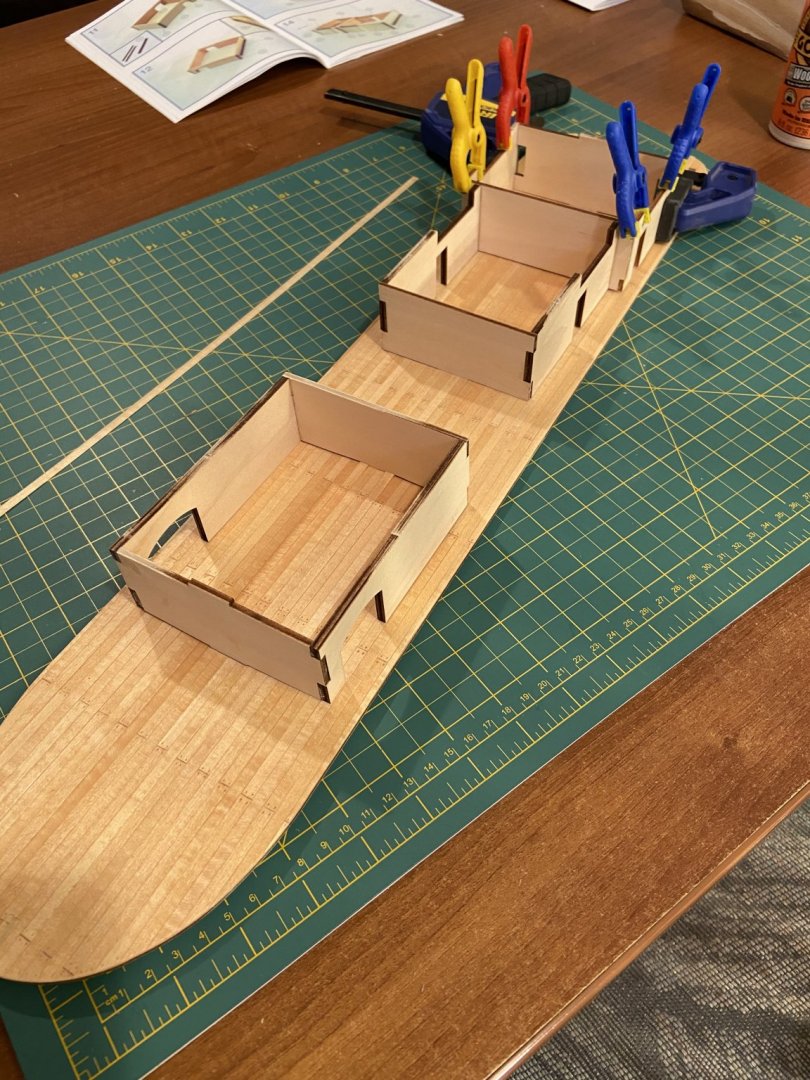

Little more progress on the first level rooms and the second level deck.

I always get nervous about the integrity of gluing things that hang off/have potential to be bumped. So I added a little reinforcement. I drilled small holes and then put a brass pin with superglue inside of the “stabling box” and then lined up the holes on the wall, drilled, and used wood glue for the box against the wall with superglue on the brass pins. I used this technique on my previous build and everything held up great.

- GrandpaPhil, Bob Fraser and Cathead

-

3

3

-

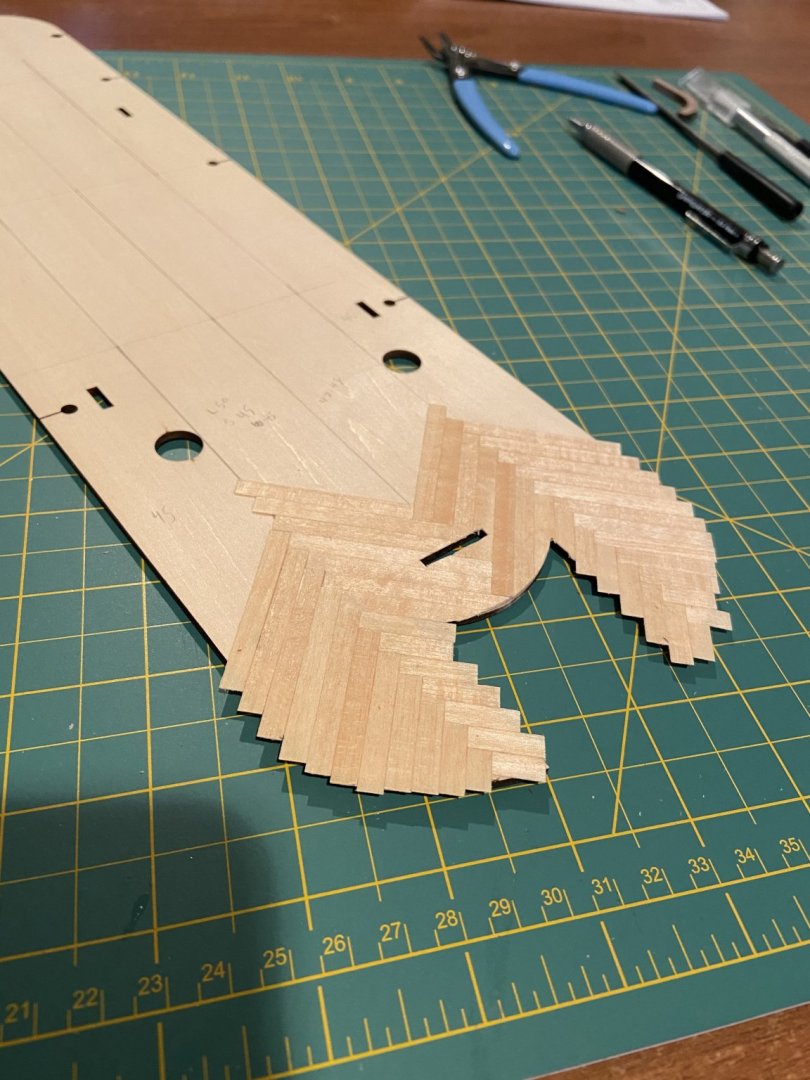

Finished planking the first floor rooms, just getting started on the trim and I’m also jumping ahead and planking the second deck. I have a feeling I’m going to move extremely slow on the second level deck due to the 45 degree angles, or as the directions call it a “herringbone” pattern.

i am using the same push pin technique that I used on the first deck planking on the room wall planking and also the upper decks.

- GrandpaPhil, Bob Fraser, Cathead and 1 other

-

4

4

-

- Osmosis, GrandpaPhil, Cathead and 1 other

-

4

4

-

I actually did come across that, but given the scale of the model, my slight obsession for the “clean” look, and that most likely, and that likely no one who will see this model in person will know that I skipped a few holes haha.

I do agree there is a place for authenticity, but, from my limits experience, it’s not on AL models as they are typically built more for a “good build” rather than authenticity.

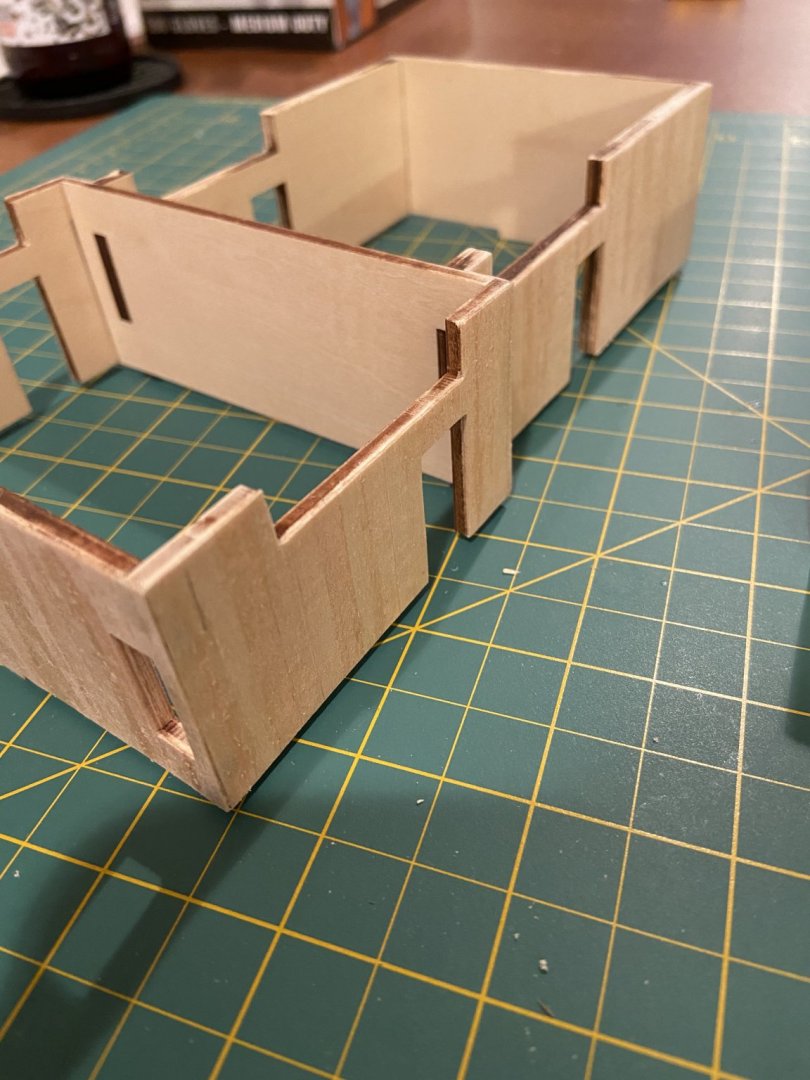

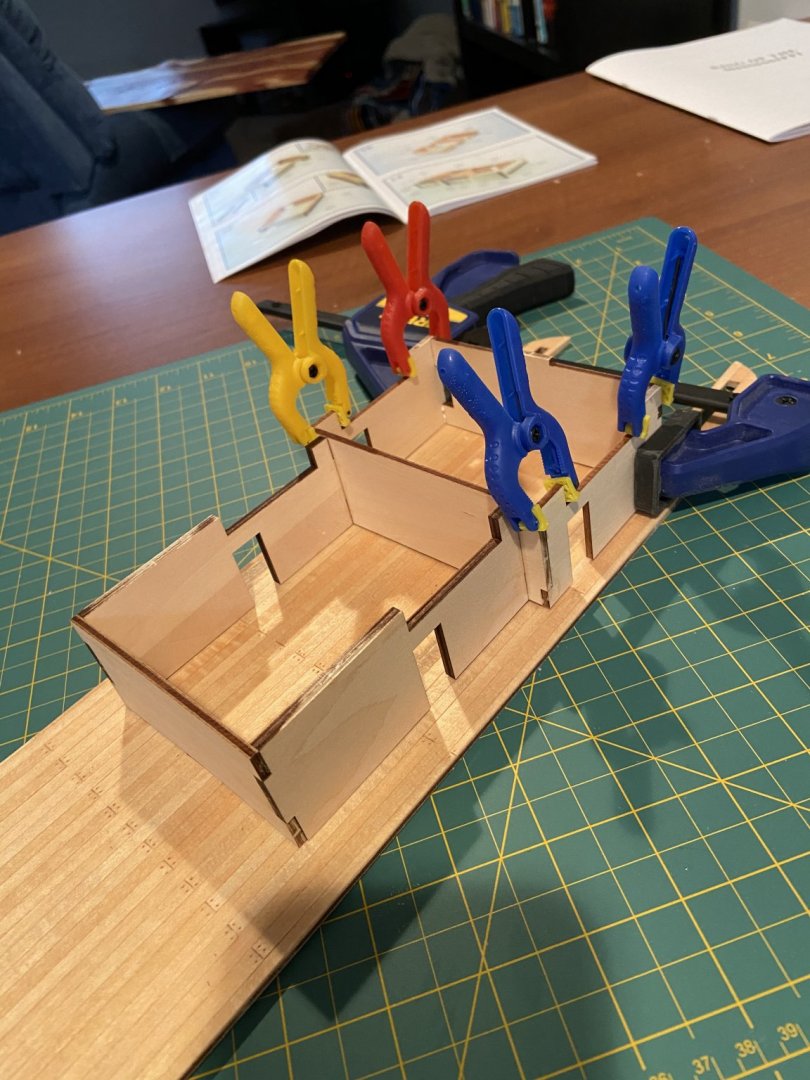

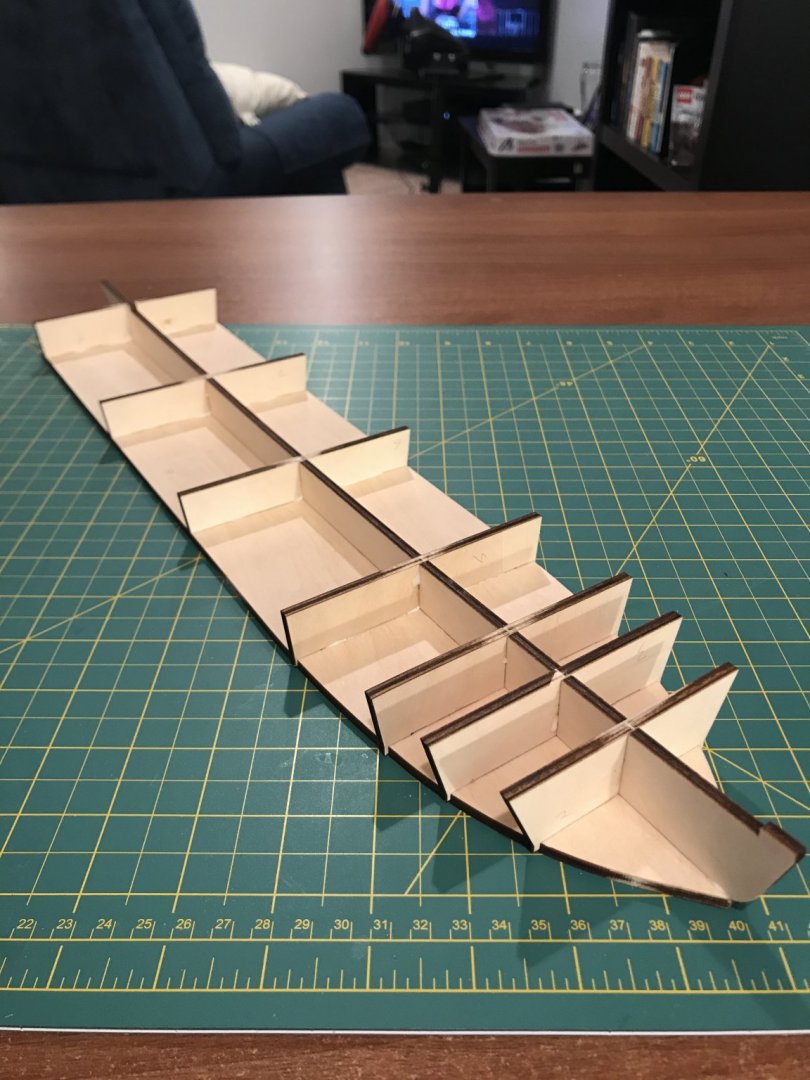

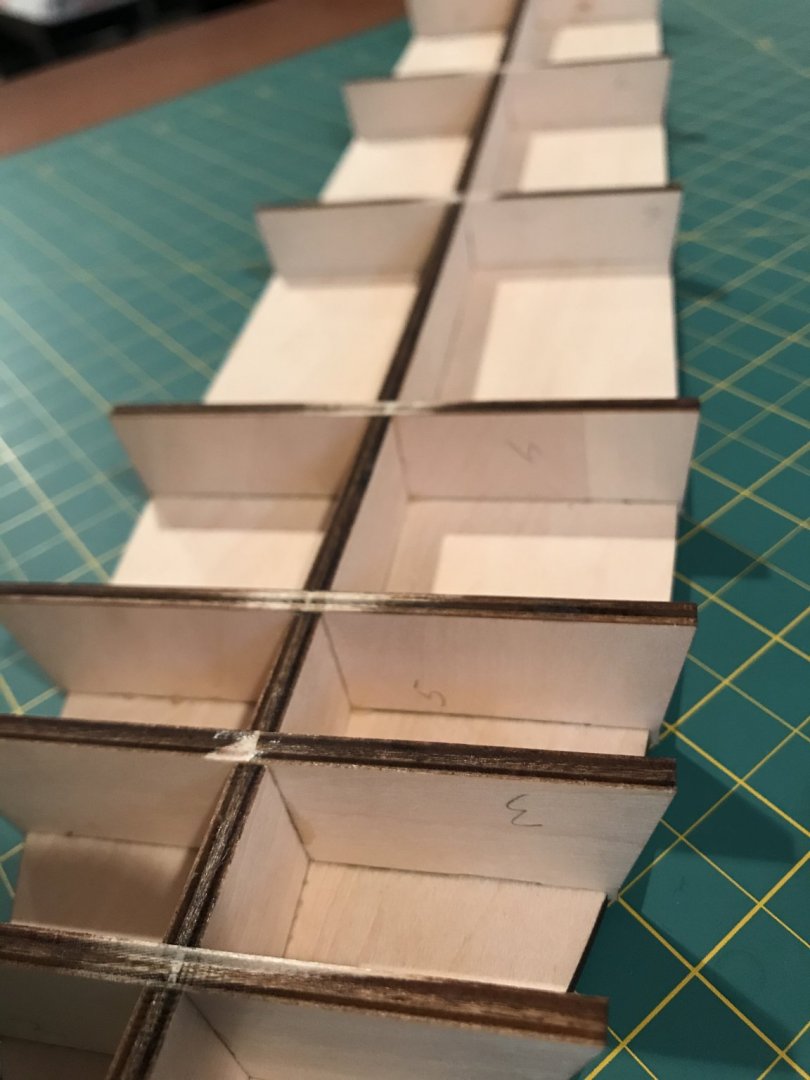

made a little more progress today, got the hull planking 3/4 finished, popped out the first floor room walls and fitted/glued together.

my original plan of putting a small “casino” on the first floor may be hindered now as all of the dollhouse casino stuff I could find is about twice as tall as the rooms. So I may be making my own card table and we’ll see what I can come up with.

Overall the fit of the rooms was good except once it was assembled it required some force to get it back into the deck slots.

- Bob Fraser, Cathead and GrandpaPhil

-

3

3

-

- Bob Fraser, Osmosis, GrandpaPhil and 2 others

-

5

5

-

On my last build, I purchased and studied a few different techniques (well after the fact of needing it of course) and it mentioned a way to get realistic nails in the deck by taking a pin and poking holes, sanding lightly over the deck and allowing the dust to accumulate in the tiny holes. Then staining the deck and allowing the dust to take in the stain more so than the surrounding wood. We’ll see how it turns out!

- Osmosis, GrandpaPhil and Cathead

-

3

3

-

Yup, I am definitely learning that...I’m a little disappointed so far with this kit. I just finished the AL San Francisco II and everything seemed to fit together great. Ah well. Just needs a little work and it’ll look perfect in the end, it always does.

getting the hull braces glued in tonight, tomorrow I I’m planning on finishing up the deck and putting it on the hull.

I also already learned how easy this plywood separates. When I first put the the deck on the full there is a slight curve up and the plywood separated with that. It was pretty disheartening that’s for sure

- GrandpaPhil, Osmosis and Cathead

-

3

3

-

I am a resident just finishing up 6 weeks in the ICU, in the center of inner city detroit. It’s a disaster. I’m healthy as can be though, I got lucky.

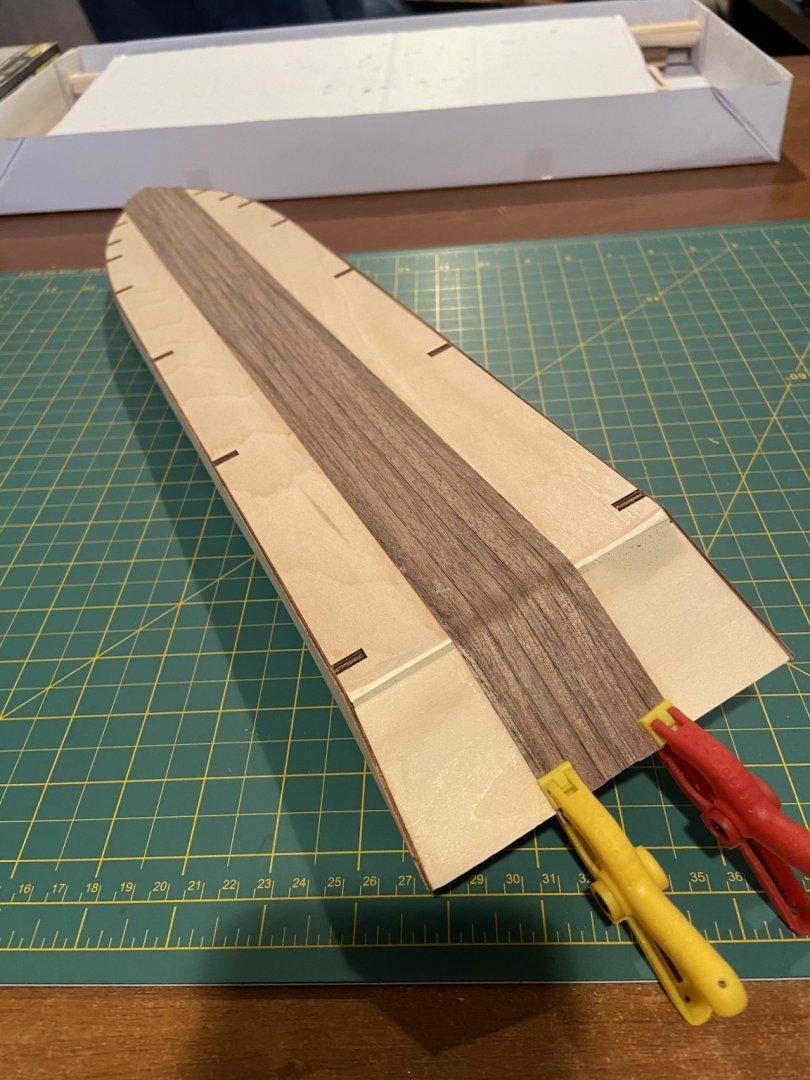

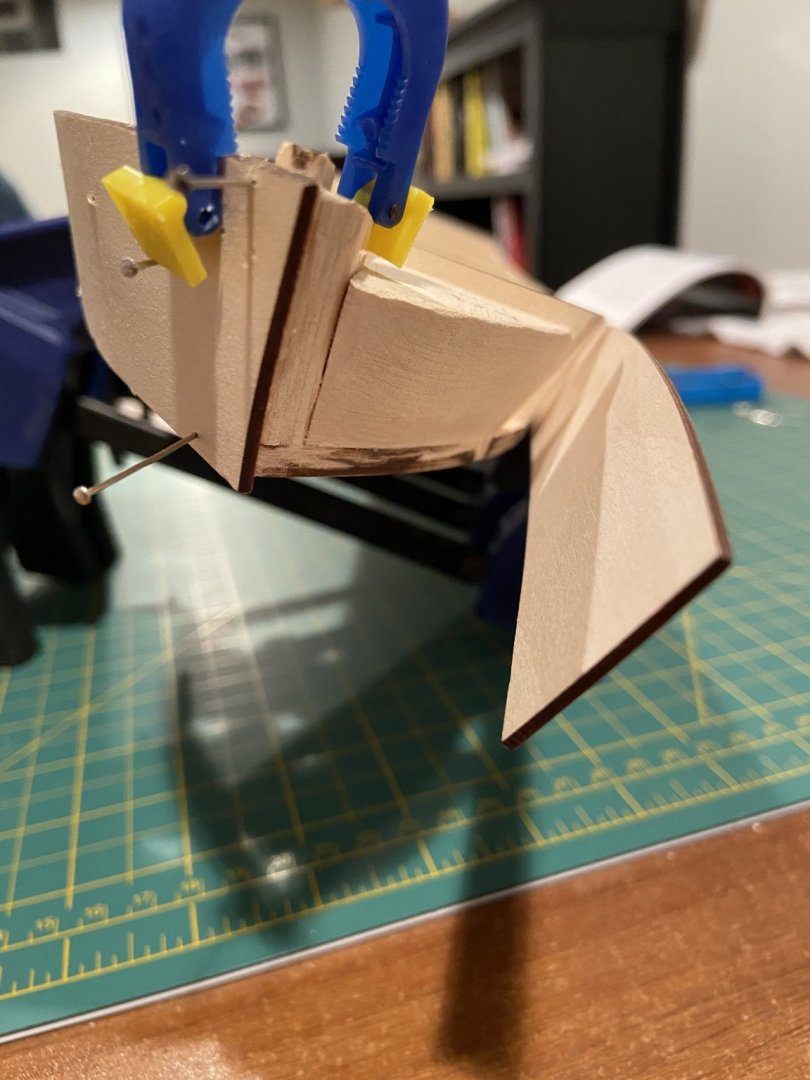

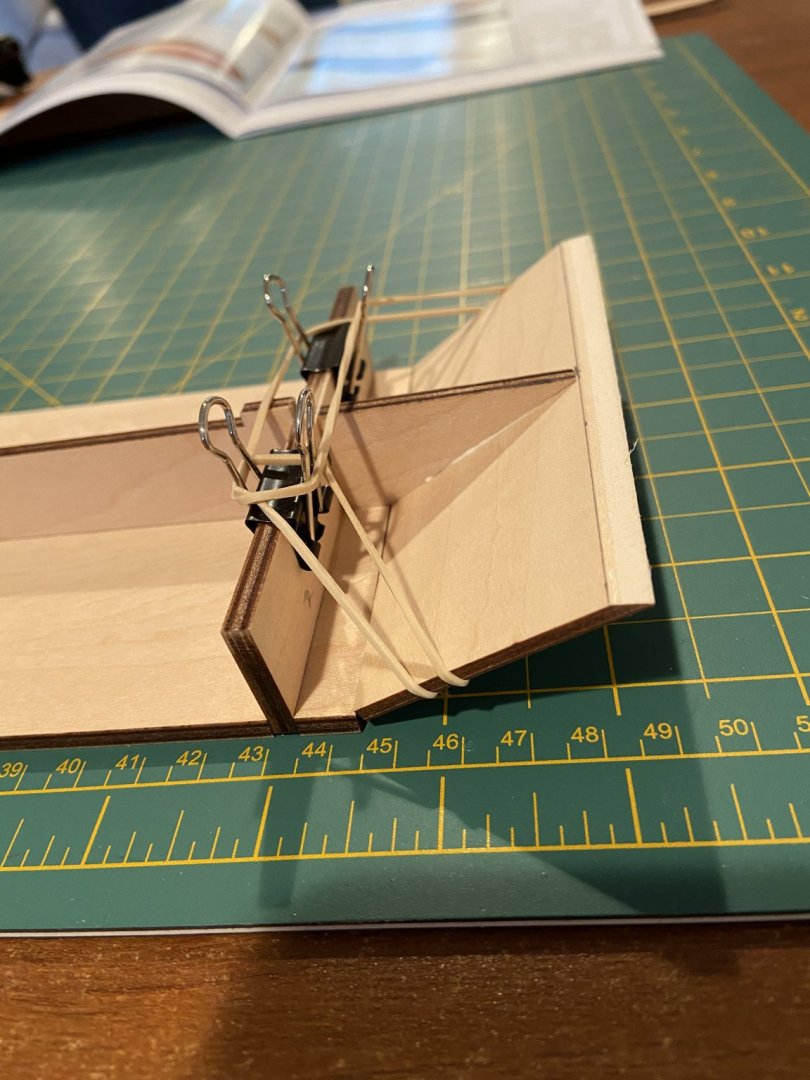

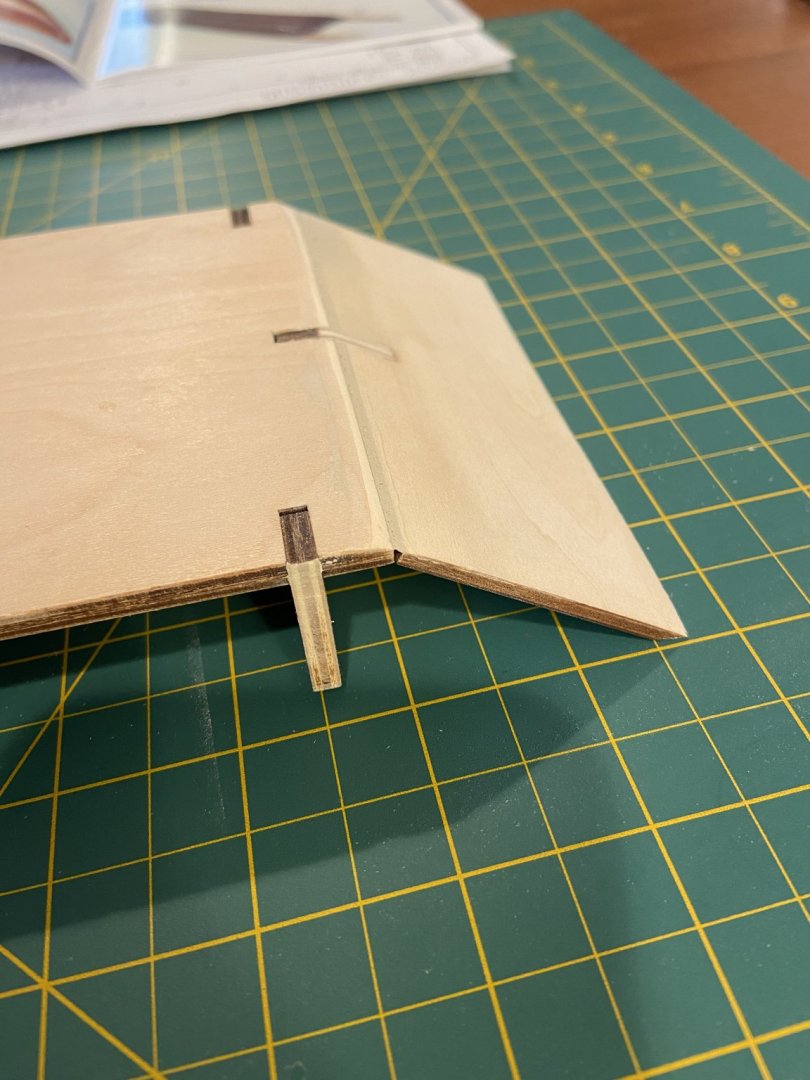

spent a little more time today putting the hull together. Instead of planking it comes with one solid piece per side and then gets .5mm planking over top of that.

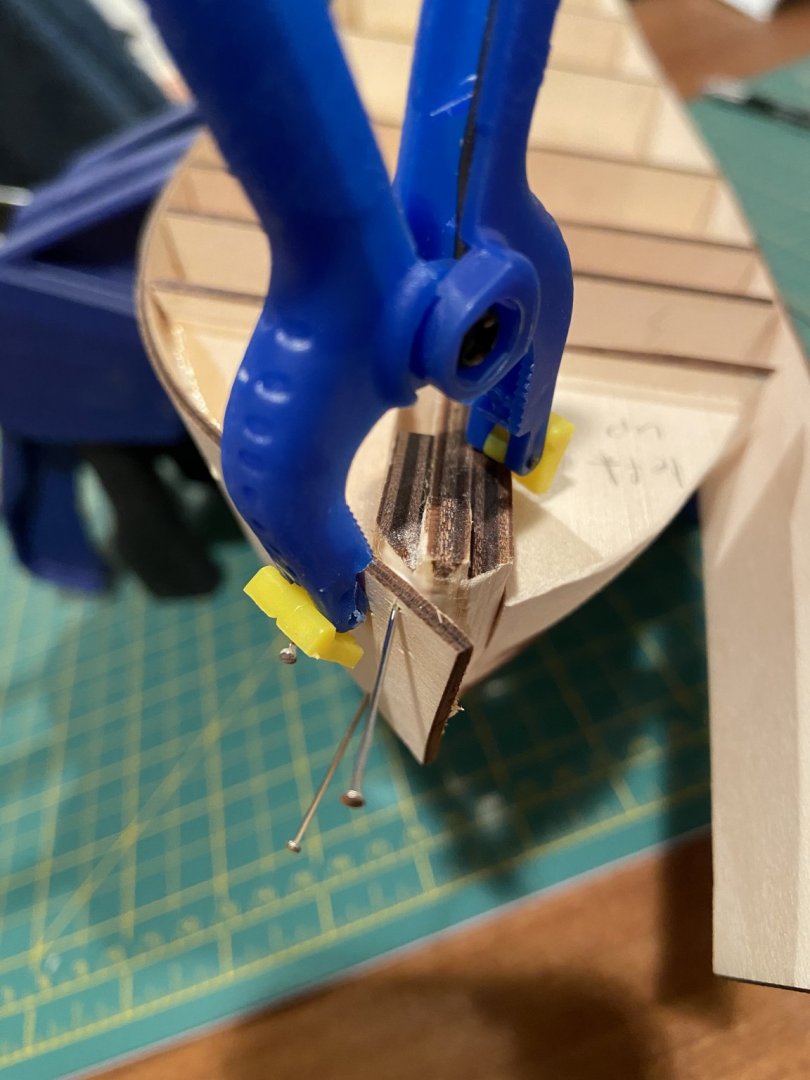

clamping and pinning the bow is always such a pain in the but.

the pieces were also a little too long, I had to cut the end flush with the midline so they lined up properly

- GrandpaPhil, Osmosis, Cathead and 1 other

-

4

4

-

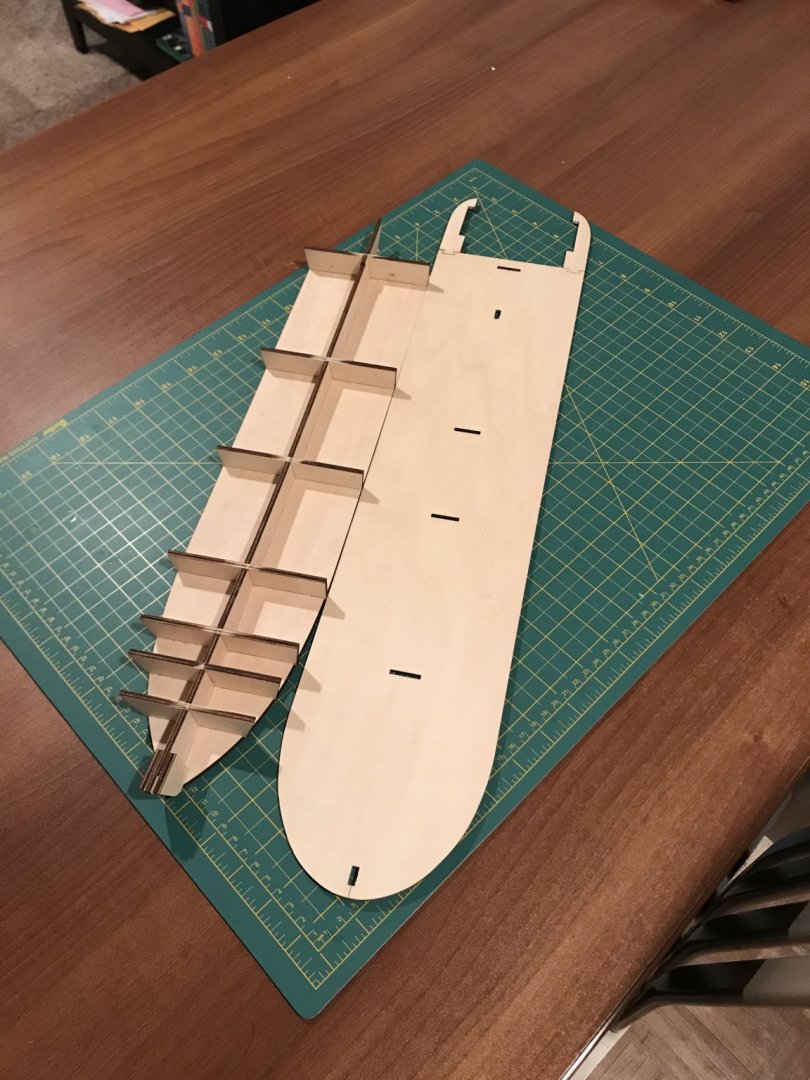

Well with the current state of this covid nonsense, I have essentially been living in the hospital and haven’t had much time to work until recently.

the pictures of my progress are pretty self explanatory, I haven’t done anything special to it yet.

Once the deck gets glued to the hull it’ll be more interesting, I am tossing around the idea of adding a casino to the inside of the first level room and lighting it. We’ll see.

hope everyone is staying safe

- Bob Fraser, Osmosis, Matt D and 4 others

-

7

7

-

-

-

I love seeing you back at it. Do you find the black clips modified like that work? When I did it I felt that some of them didn’t really clamp down hard to stay secure because the silver wire part kept the black clip slightly open. If that makes sense.

it’s looking really nice though

-

The kit itself came with 2 small pieces of laser cut plywood for the “filler” blocks to allow for more surface area when glueing the sides of the hull. I personally am a fan of bigger fill blocks to allow for more surface area, as Id hate to wake up one day to see the hull coming apart.

I have some balsa wood from a whittling kit that I use, it’s really soft. The glue I use for planking expands when it dries so in my head I tell myself that it will have a better fixation.

I still have to sand them down to shape, which I will he doing with a Dremel with a sanding flap wheel, file, and then a sanding block for the finishing touches

What are other options for good filler blocks?

- Alexisgm97, yvesvidal, Osmosis and 1 other

-

4

4

-

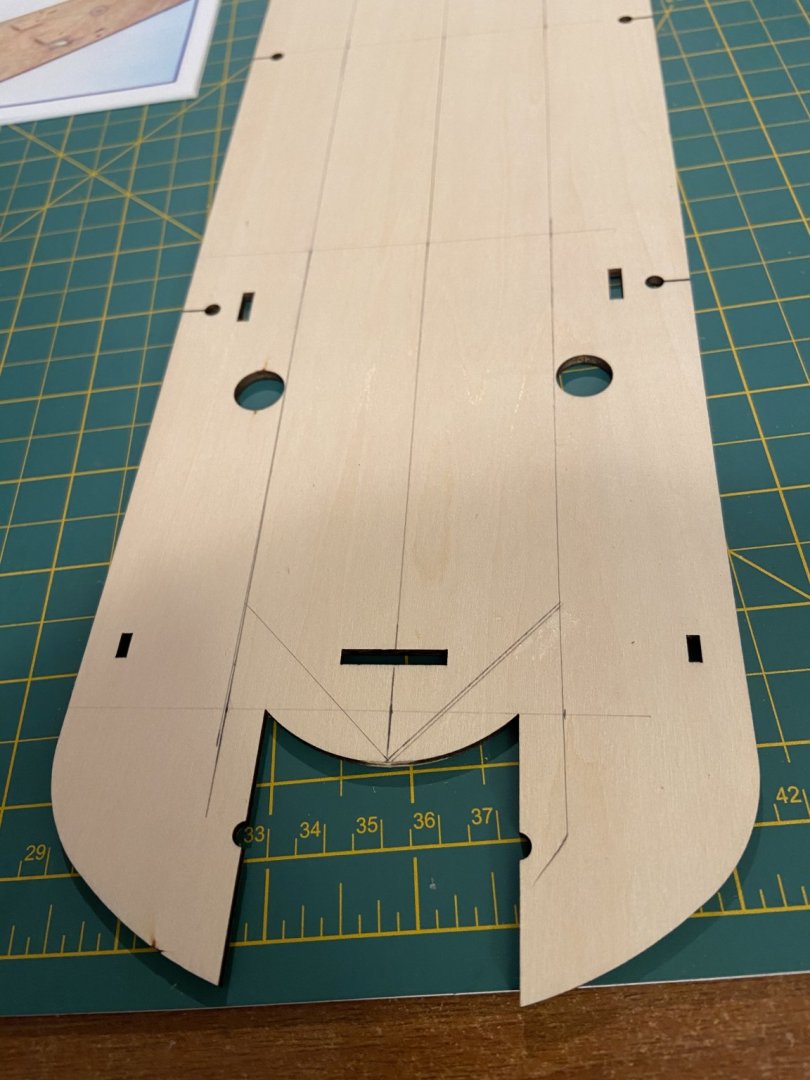

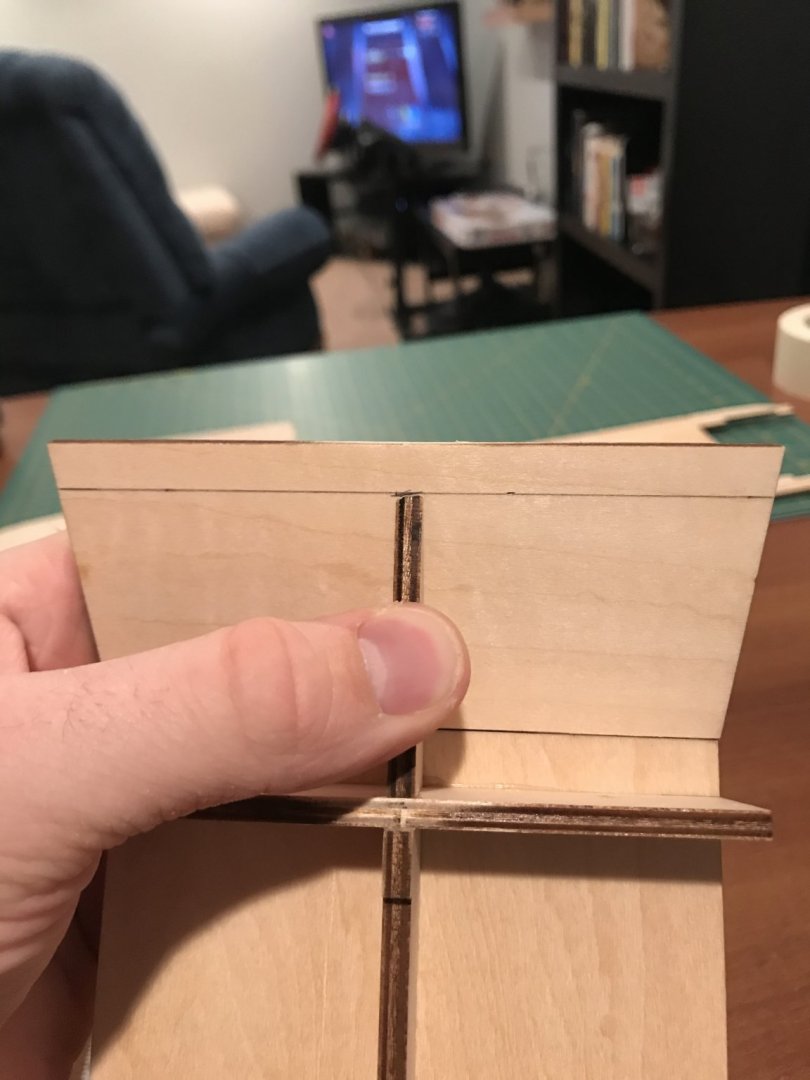

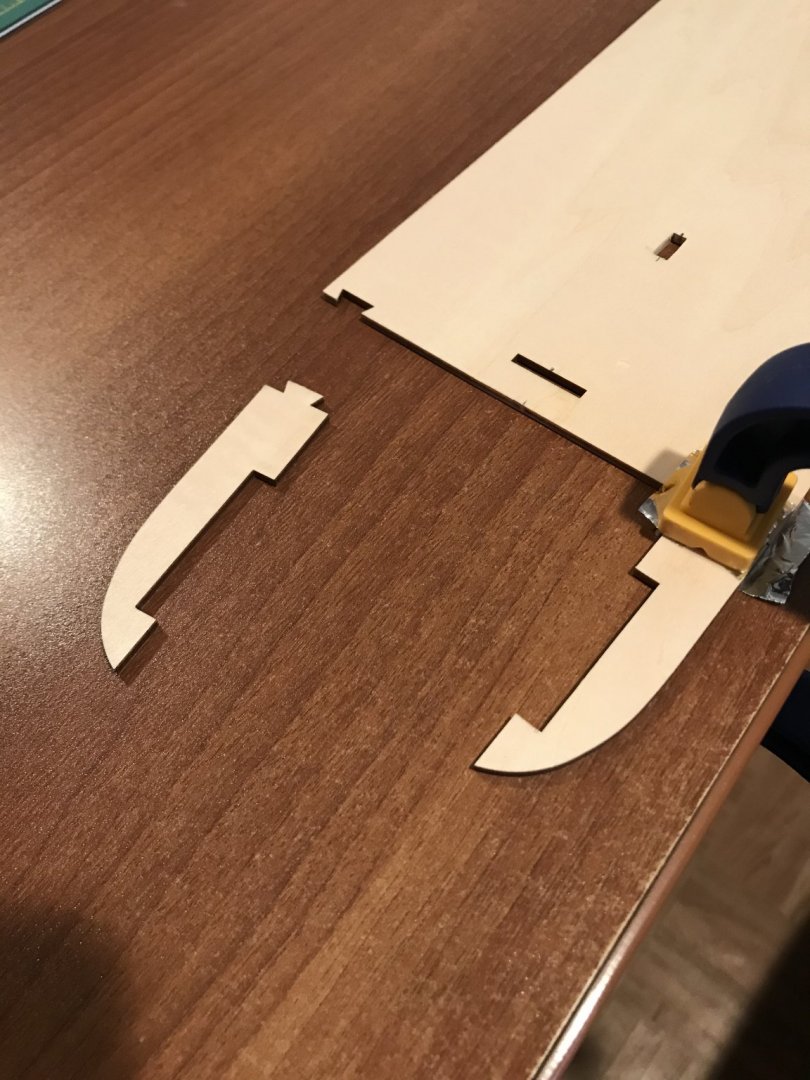

I started assembling the keel first, as per the instructions. I’m not sure how other kits are but mine extremely tight, to the point where I couldn’t not even dry fit them without feeling like I needed a mallet to get them into place so I filed down all of the connecting joints just a tad. After that they all slid right together.

howevet, I did find a mistake in the plywood labeling. The bulkhead pieces 4 and 5 were labeled backward. Other than that, so far so good.

- Osmosis, GrandpaPhil and yvesvidal

-

3

3

-

I just started this as well, I am still working so most likely you will stay ahead of me which will be a fantastic reference for me to use when the directions are less than satisfactory.

Also, yes, you can post from a mobile device. That is almost entirely how I post my images as I don't upload them to my computer. At the bottom of the "post" page, click the link next to the paper clip that says "click to choose files" and just upload directly from your device. The only issue I have found is that it often uploads them in a random order, not necessarily in the order you have selected them.

-

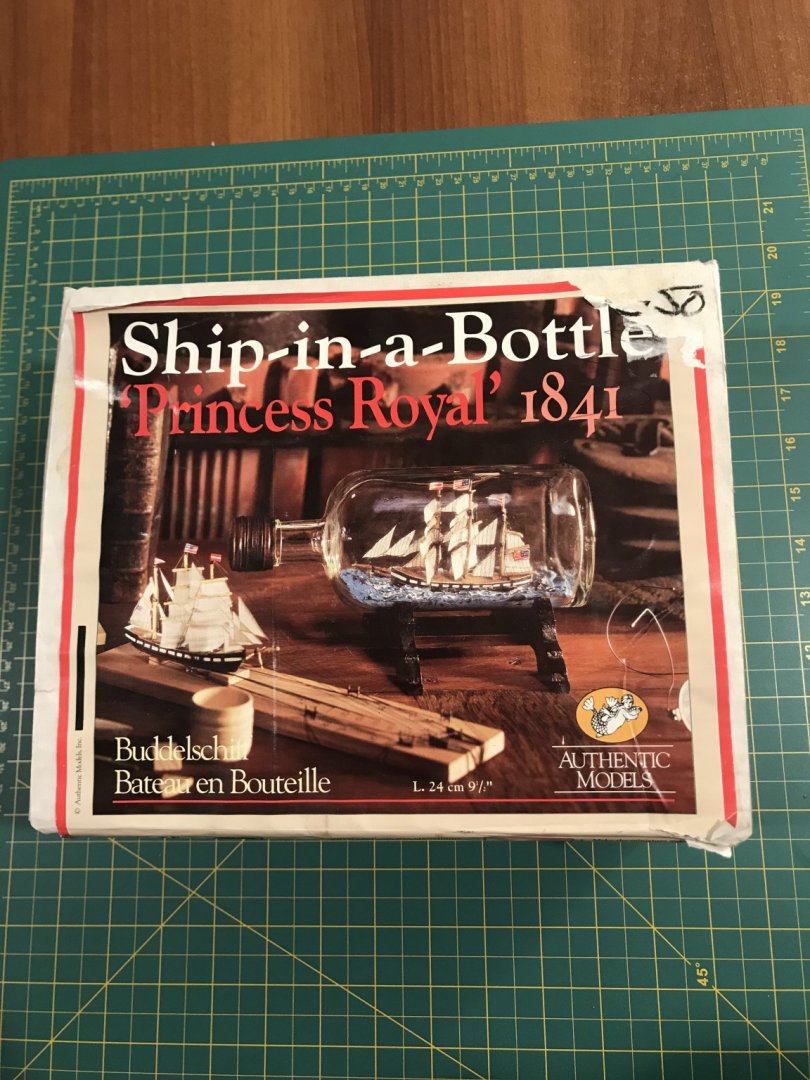

After finishing my last build (link is in my profile) I started a ship in a bottle. I am still working with that, but I can only spend so much time working at such a tiny level, I prefer the larger models. So I will be tinkering with the ship in a bottle intermittently.

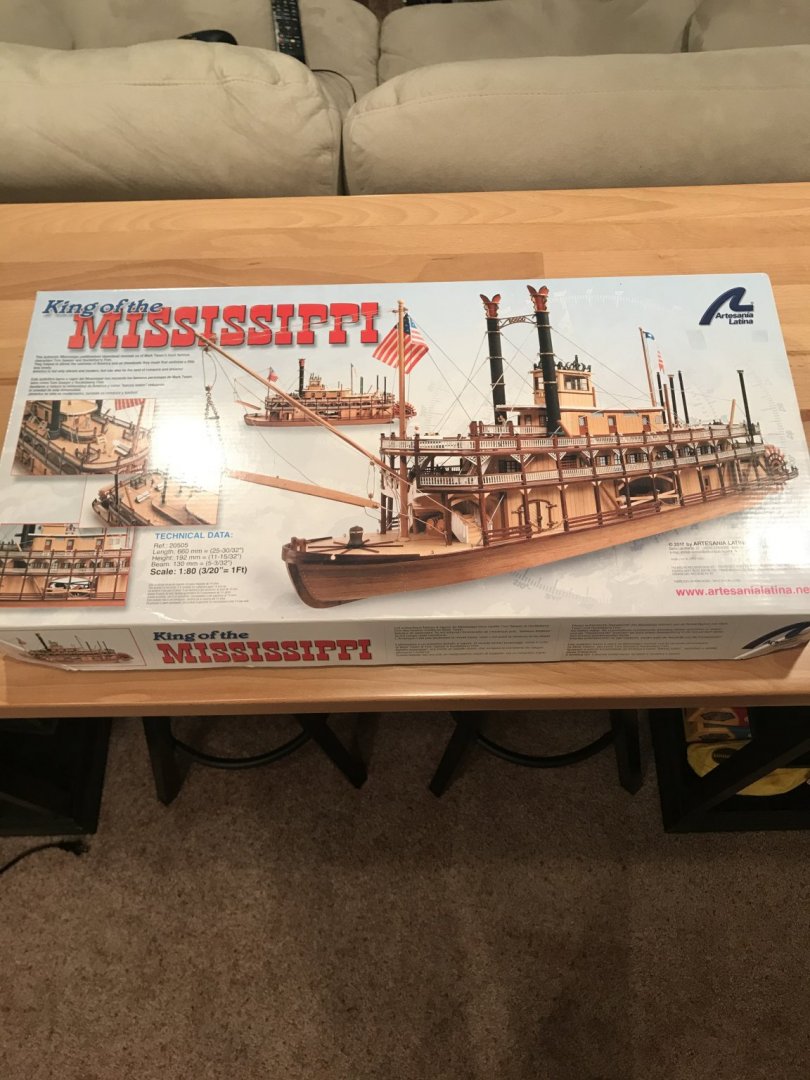

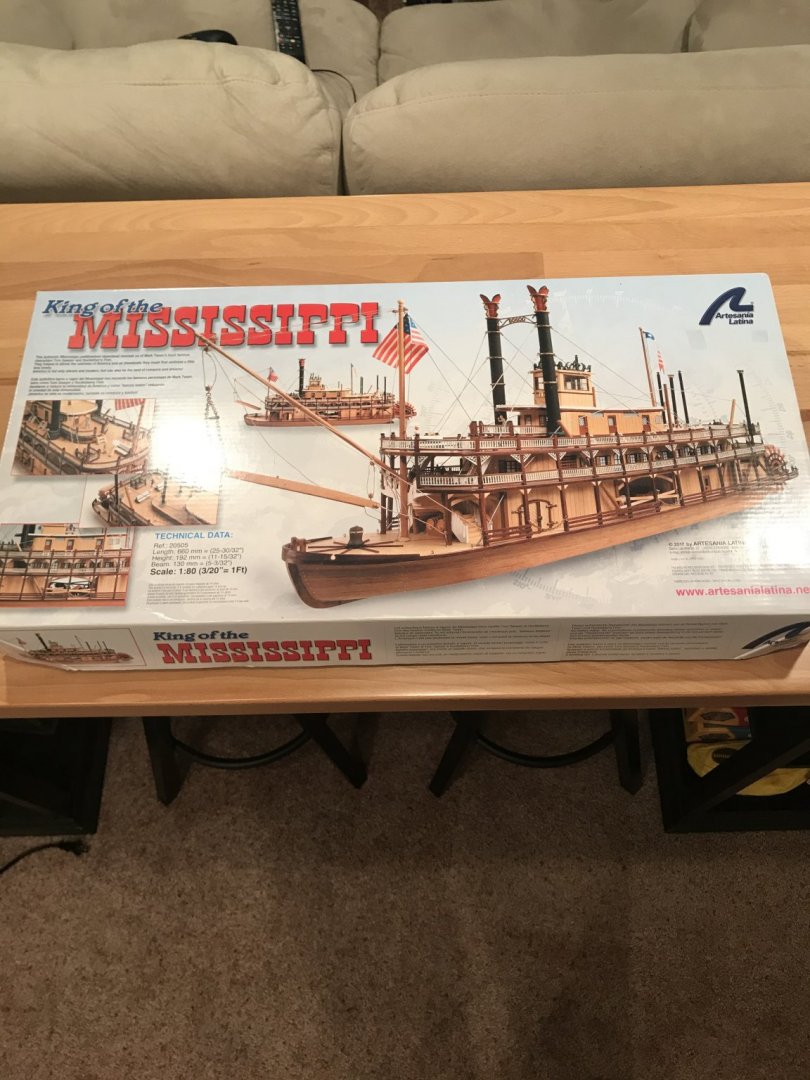

I was pretty bummed when I found out Artesania Latina closed their doors, and one day I was speaking with my fiancé about it. The local hobby store in her hometown just happened to have one more AL model on the shelf and she picked it up for my anniversary gift. I was originally planning on starting a victory, but I am beyond excited to start a different style of ship.

One thing that recently caught my interest while browsing other builds is the idea of opening up the doors and windows and finishing the interior as well.

I am still in the planning stages for that, but as of now I am planning on adding a small casino room, a kitchen (if I can find the parts) and a couple of bedrooms.

-

Well I decided I wasn’t done yet. Initially I placed the ship on top of my book shelf but I realized I wasn’t happy with it there so I am making a display case for it that will have a plexiglass cover made for over top of it to keep the dust off of it.

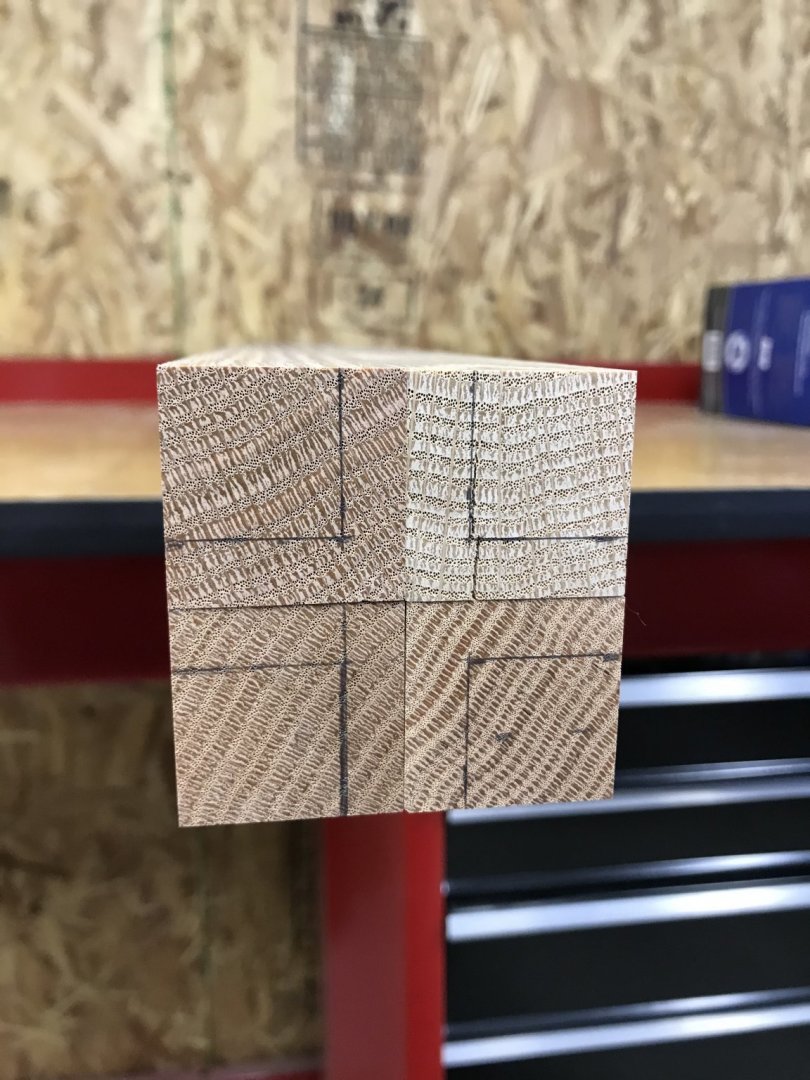

so far I think the hardest part of building the case will be finding pieces of oak that all match in shade and grain...the selection was pretty thin.i got started by getting some pieces of 2x2x4 red oak and then planed them for a smooth/flat surface. They were a bit rough coming off the saw mill.

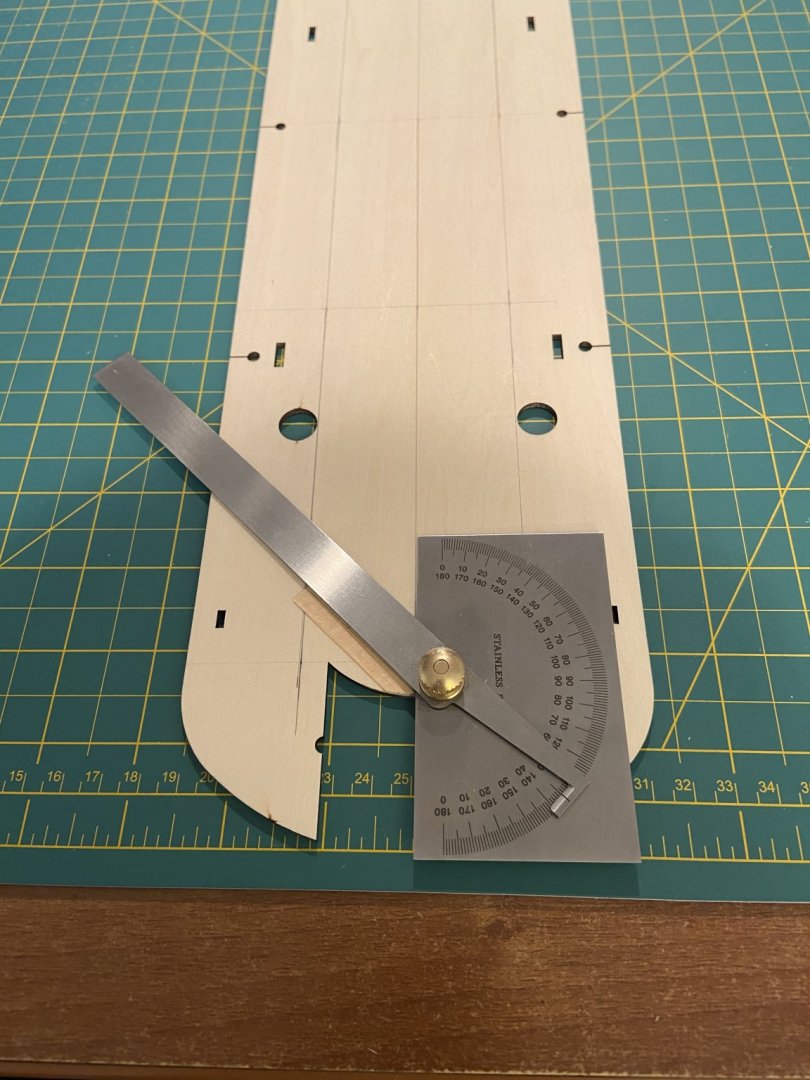

Then I measured 1” boxes on the bottom in the 4 corners to add a slight taper to the wood at the bases. I used a 3 degree taper.

- mtbediz, Osmosis and GrandpaPhil

-

3

3

-

Thank you everyone

osmosis, currently I am working on 2 much smaller project. A ship in a bottle (build log is already started on here) and a ferrari formula 1 car. I believe you have the same Mississippi kit. Let me know when your get started, I’m sure we can share some info back and fourth.

however, as soon as those 2 are done my fiancé did already purchase my next big ship for christmas. It’s another kit from Artesania Latina, the Mississippi River Queen. I cannot wait to get it started

-

I still have to build the display case, which I will probably wait to start until it gets a little warmer outside. But the ship itself is done!

10/11/2018 - 1/3/2020 approximately 500 hours.

it sort of bummed me out that Artesania Latina closed its doors. I am fairly new to the model ship world but I really enjoyed building this model and numerous people have asked where to buy this specific one.

- VTHokiEE, mtbediz, GrandpaPhil and 2 others

-

5

5

-

-

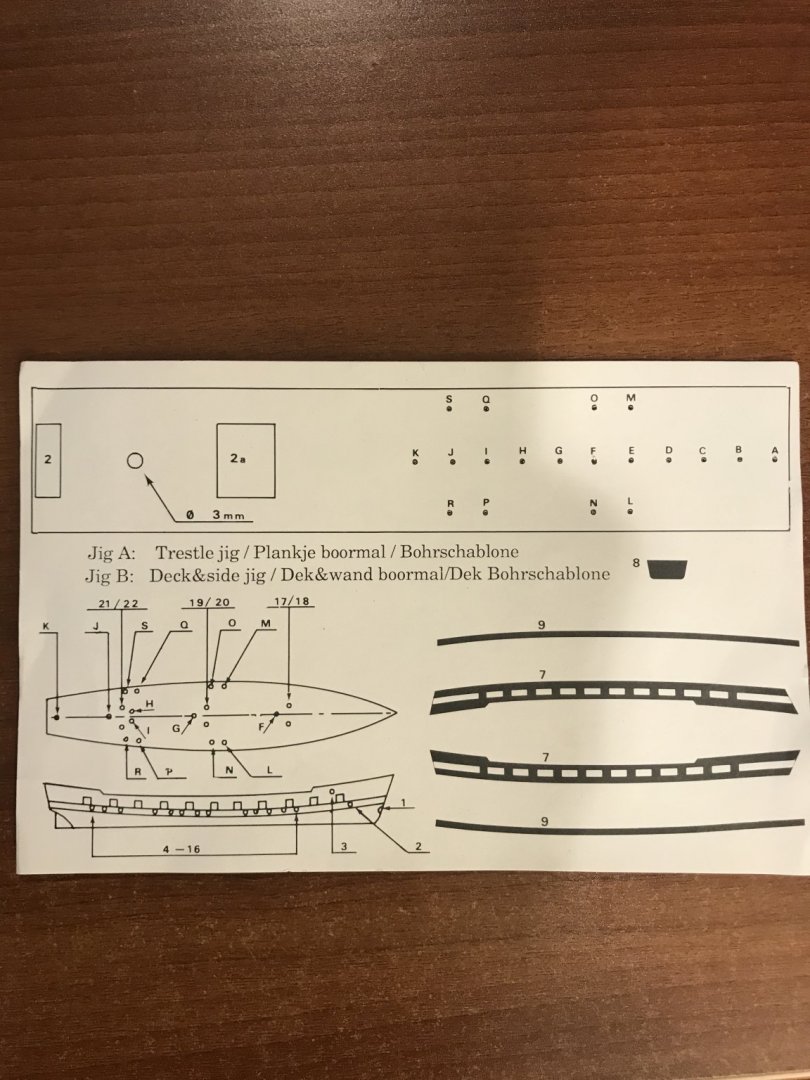

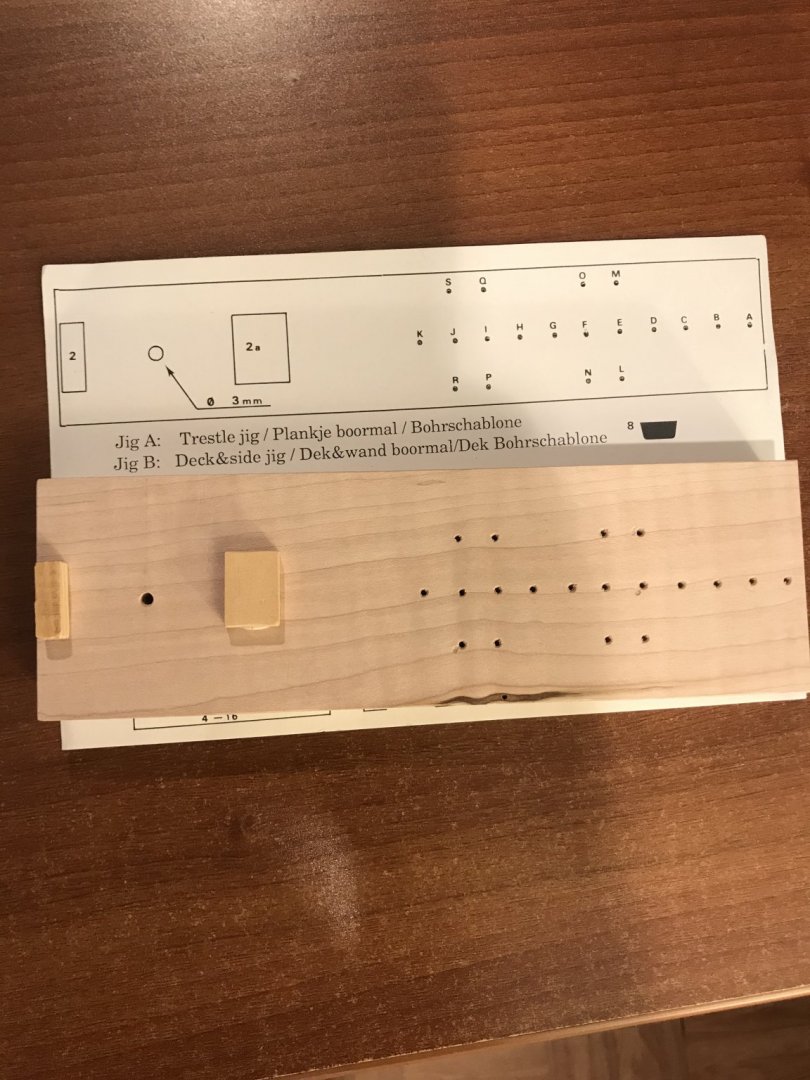

Today was my first day off of work for Christmas vacation so I got a little progress done on the jig that holds the ship while building it. While building the Amati it didn’t require anything like this, I’m intrigued to see how all of these holes will be utilized.

next the fore and aft cabins will be fitted and glued. The kit comes with very crudely shaped wood so it will require a little filler and quite a bit of sanding

San Francisco II by Warnerade - FINISHED w/ display case - Artesania Latina - scale 1:90

in - Kit build logs for subjects built from 1501 - 1750

Posted

Well I finally finished the display case.

It’s been ready for a while but I’ve been waiting for almost 2 months for Amazon to ship the display case lights to me. They arrived this morning and install them and here is the final product.Well I finally finished the display case.

It’s been ready for a while but I’ve been waiting for almost 2 months for Amazon to ship the display case lights to me. They arrived this morning and install them and here is the final product.