-

Posts

232 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by John Gummersall

-

-

Cathead,

Thanks for the information. I will check out yours and Brian's latest builds. As I have said earlier, I am somewhat new to this so I have a lot to learn.

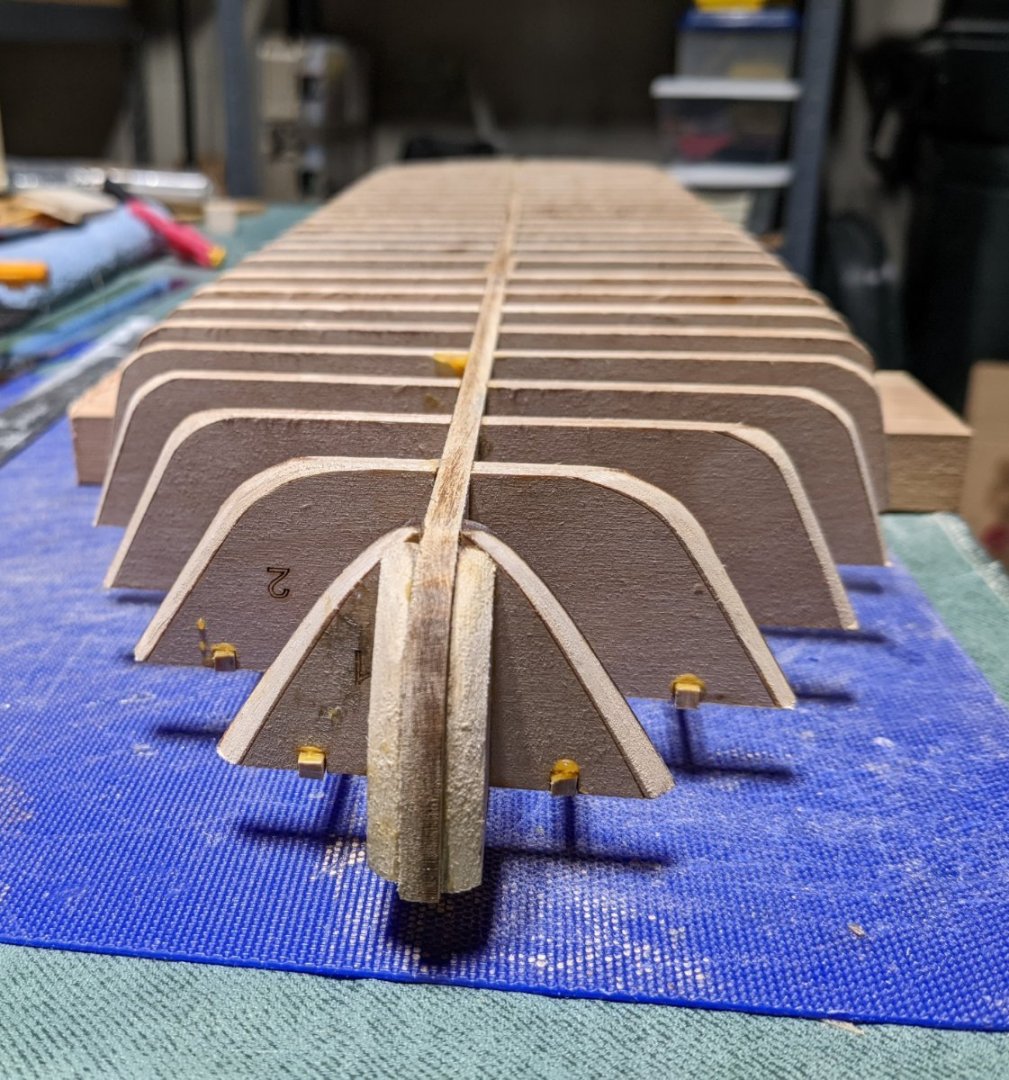

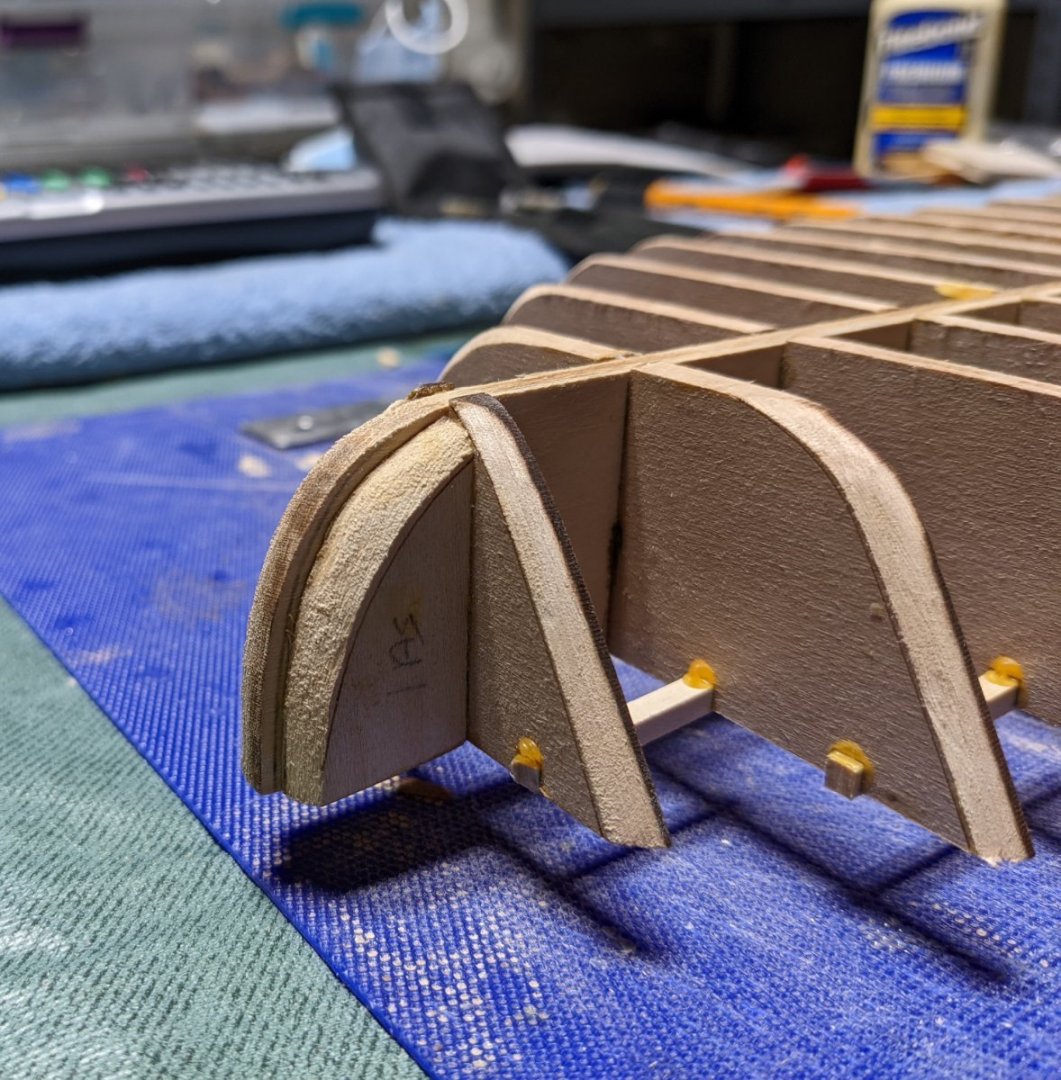

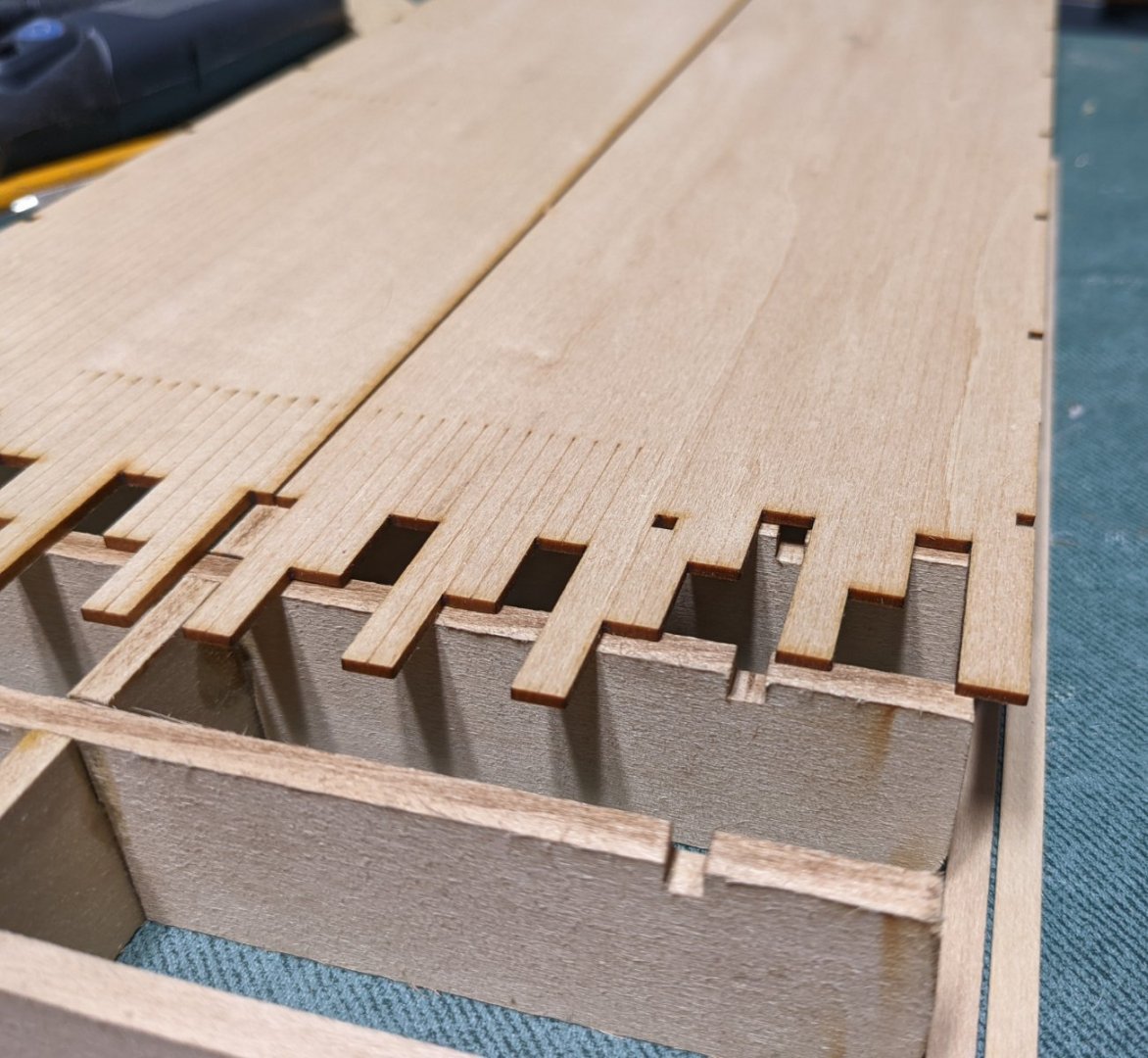

It has been a few days since I last got a change to work on the ship. At this point I have completed fairing bow parts 1A P/S and bulkheads 1 through 5. The supplied etched lines on these part are pretty accurate. As trimming progresses be sure to verify the angle with a piece of planking to insure the planks will have a good gluing surface.. Also completed was the fairing of the stern parts 29A/B and 28A/B on both the starboard and port sides. As before this is pretty easily verified as you trim will a piece of planking.

Box sections:

Stern sections... In the pictures they look to be a bit cock-eyed... They are somewhat, but not as much as what is shown in the pictures. Earlier when I repaired the stern section, I thought I had it square, but somehow in the clamping process a little bit of tilt came on. I have dry fitted the decks above and from what I can tell, the very slight tilt either goes away or is not noticable.

Having said that, I may still try to dampen the last part of the keel and try to get it back to square. I have had issues on other models when the keel/bulkheads are not true. It is an error that can really keep coming back to bite you throughout the entire build if you are not careful. We'll see what happens.

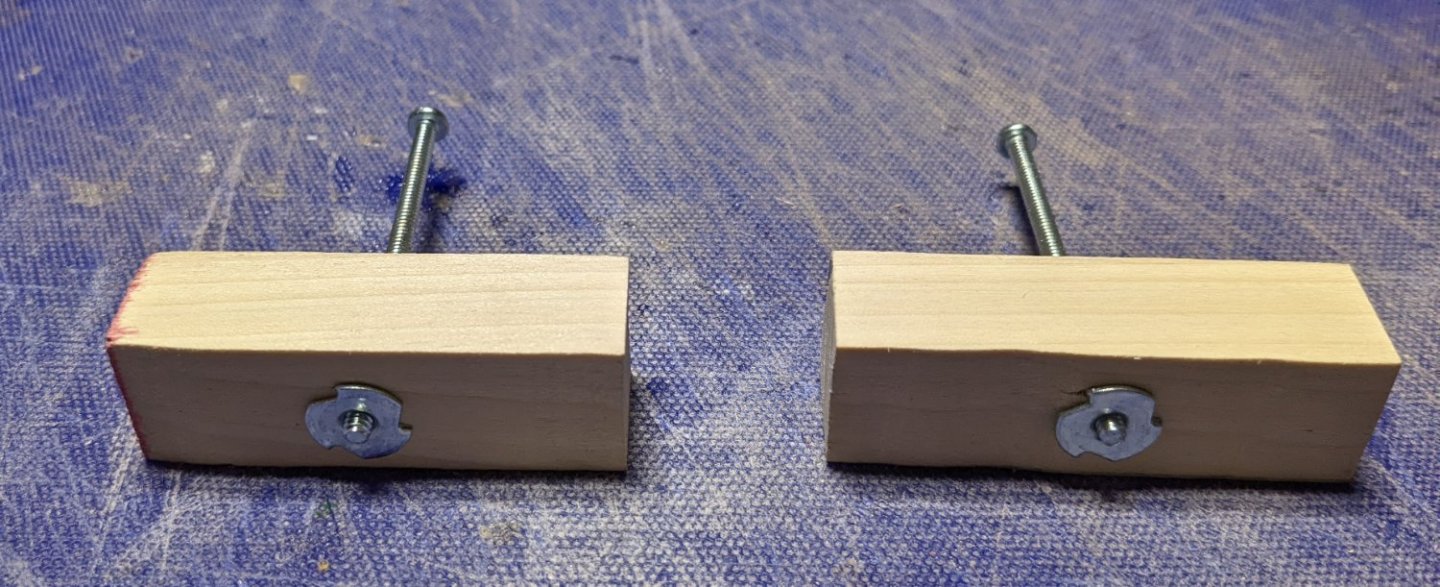

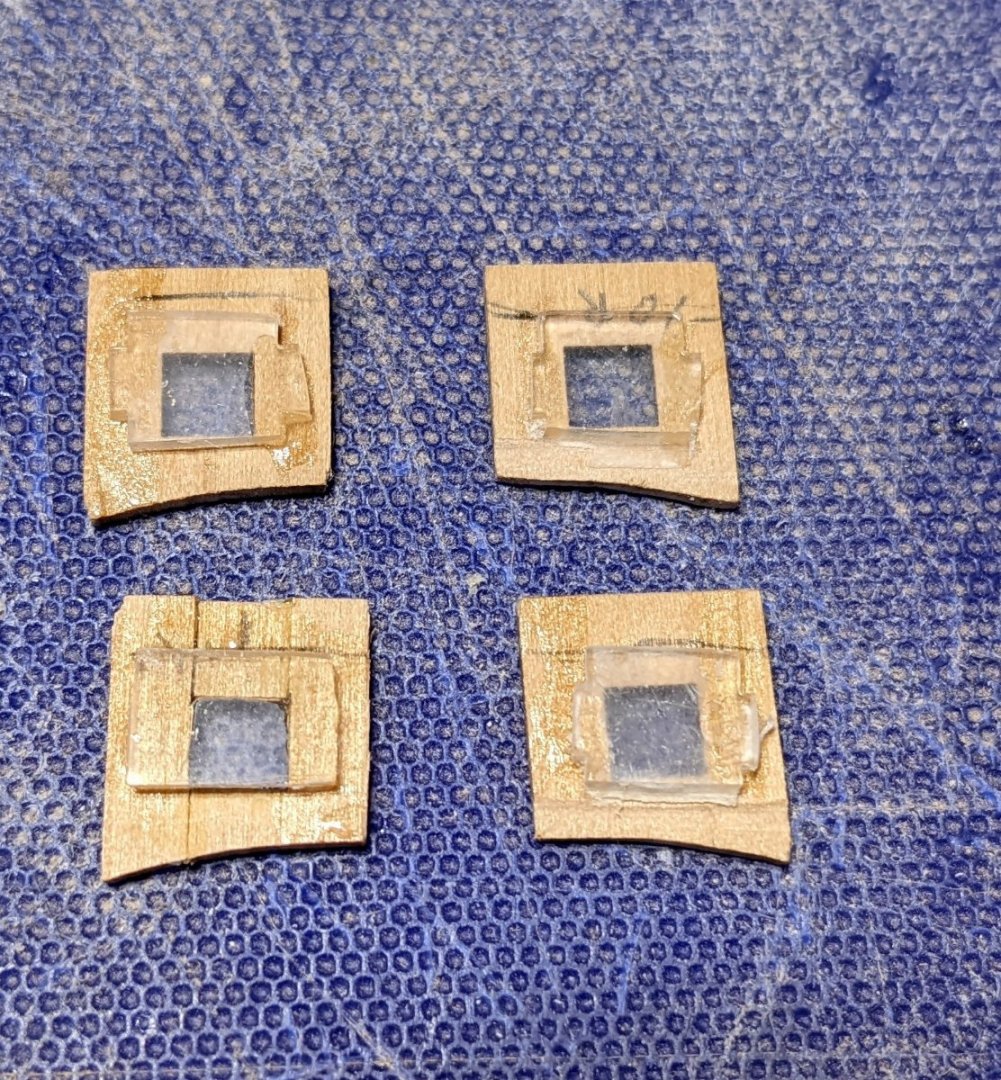

Now the part that really terrorizes me.... As others have done I decided to use a 3 prong Tee nut and bolt for the stand. As such it has to be done at this phase. Below show the two blocks made to insert between the bulkheads with the bolts.

Main scary part of this process for me (at my still level) is cutting the two bulkheads where the blocks will be inserted. The part to be cut out is shown in red below. To strengthen the area a little bit before the cut I added a few strips of wood. Basically the bulkhead will be cut down to the added strips and the block inserted. Once the block is inserted and glued, the area will be far stronger than before, but during the cutting process, I easily could see me breaking what was left of the keel.

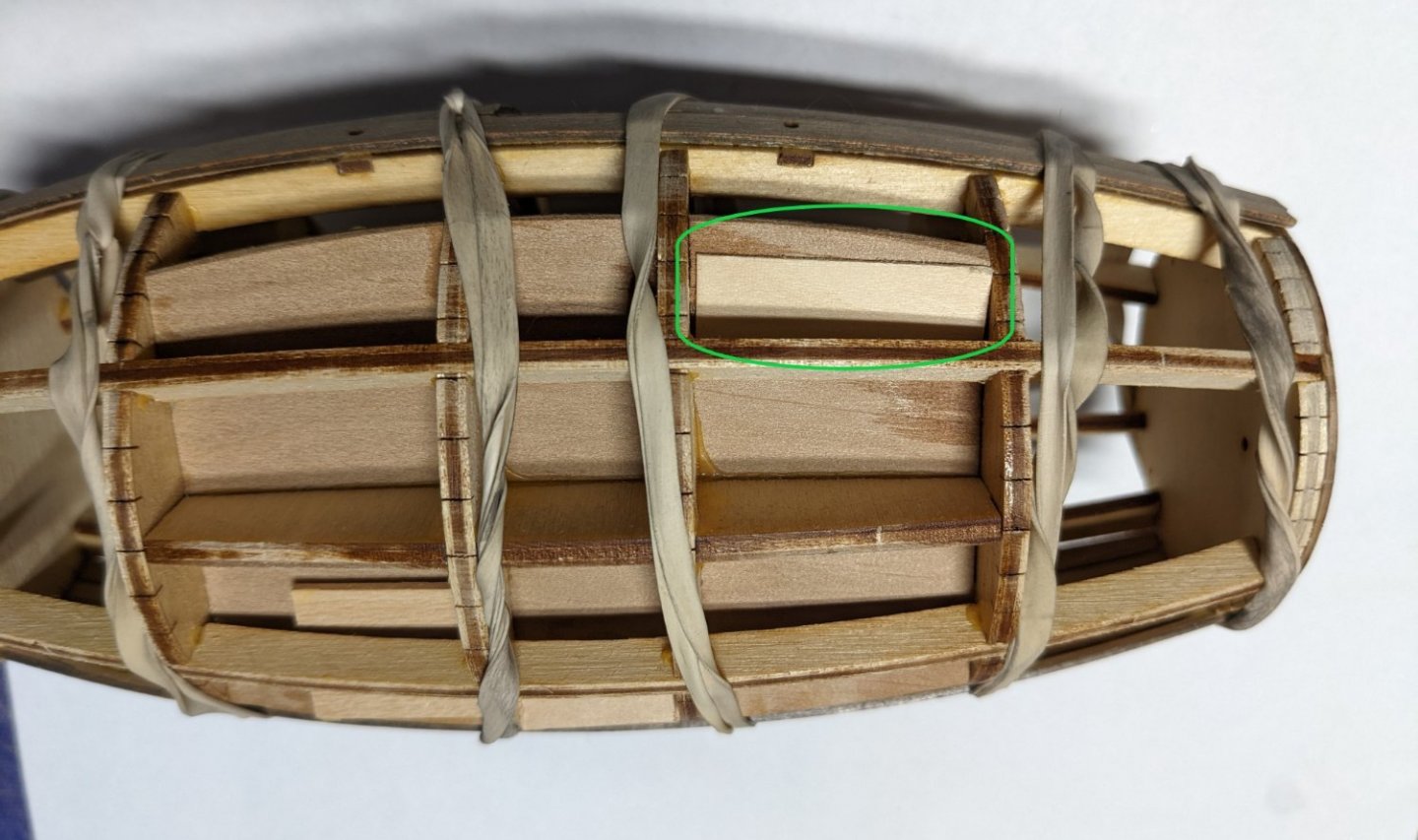

Anyway, I had a lot of fear for nothing.... with a fine tooth saw and a little patience, I was able to pretty easily cut out the section of the keel and insert the block without breaking the keel. Below show the first block inserted and drying. Tomorrow I will take on the other block. As I do not have the final stand for the ship, with some scrap wood I will build a temporary stand to hold the hull while the decks are built. That is the beauty of the Tee nut and bolt - easy access to take the ship on or off the stand.

Below will be the temporary stand for construction. Basically one 1"x8" board on the bottom and two 1"x3" boards on top leaving a slot in the middle for the keel. Bottom board is a little longer than the top boards to allow for construction of the paddle wheels at the stern. I have drilled the holes and verified the ship will sit properly in the stand. Ship will not be actually bolted to the stand until after the hull is planked.

- Ryland Craze, leclaire, Cathead and 2 others

-

5

5

-

-

Brian,

Thanks for the confirmation on the rub rail and lack of backing....

As for breakage, I always seem to find the weakest points in every model the hard way... Thanks for the word of caution on the deck extensions. However, but even with that caution, I have a feeling I will be getting a first hand knowledge as to how weak they are. 🙂 I might look into, in addition to epoxying, maybe also pinning them. We'll see at the time what thing look like.

john

-

One additional comment for those who later are interested in building this model. Below is an extract of one of the above pictures. I would like to point out that in addition to the missing lines on one of the deck pieces, the pieces that are actually lined are very faint. In the extract below, the lines more toward the center of the hull are OK, but as the lines go out to the side they get fainter. I may be wrong, but to me if I was to prime and paint the deck, those lines would completely fill in and not show at all. This is also true for some of the etched line on structure walls. I will show those wall later on when I get to that stage.

I had an outside conversation with MBP521 and he indicated that for the structure walls that were to show the etched lines, he had to go over them with an scriber tool " to increase the depth of each line prior to painting. Sound like that painful process is in my future for the walls I plan on painting and want the etched line to show. - Ugh

-

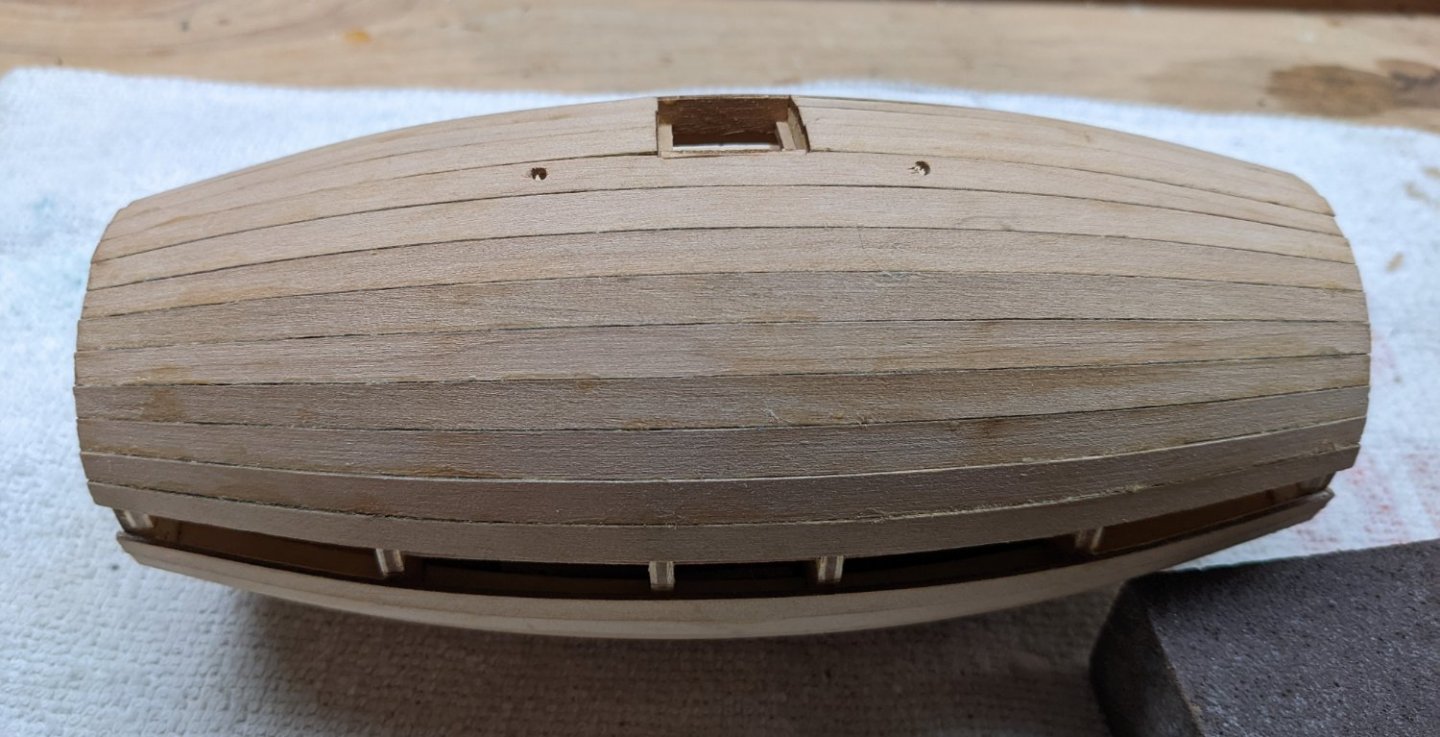

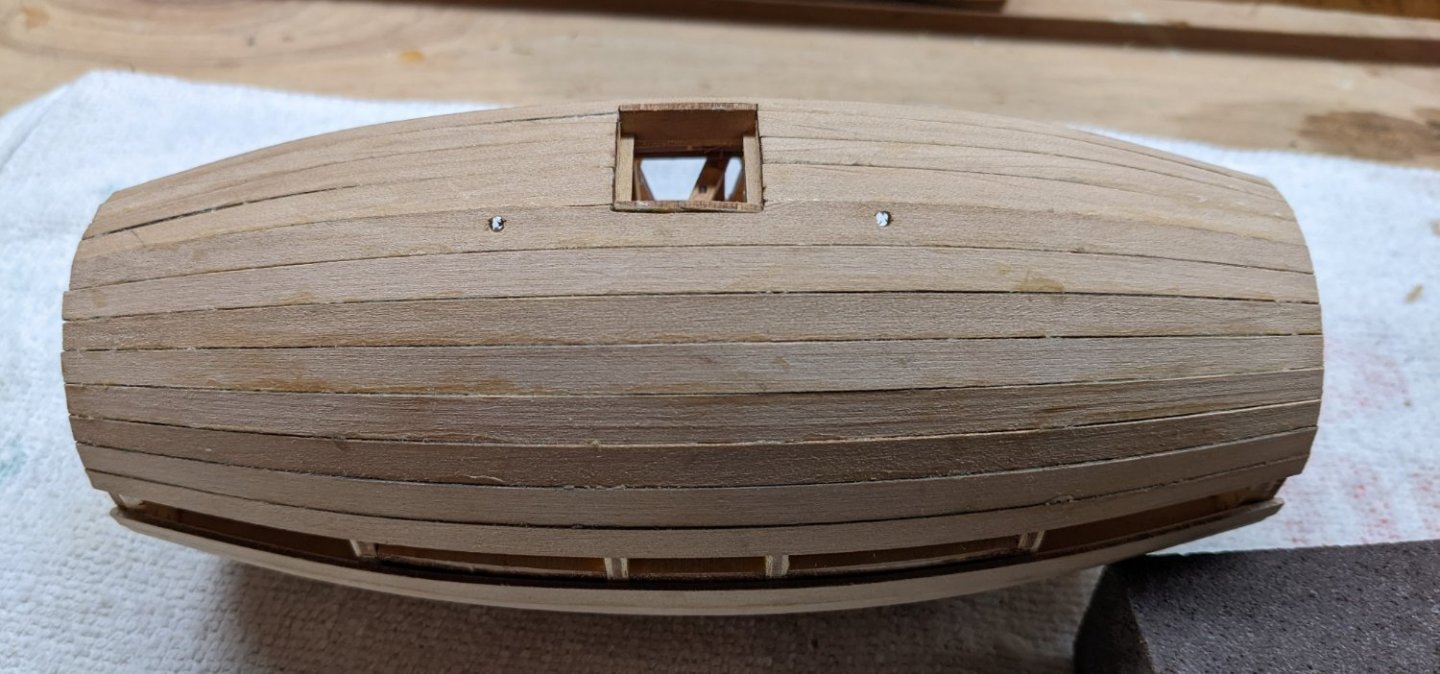

Planking finally complete. A slow process as I only glued a few bulkheads at a time - hoping to keep them straight. Be sure to insure all bulkheads are straight - Should be a consistent 13/16" between bulkheads. Next step is to carve stern parts (28/29A/B) and bow parts 1A/B and glue them in.

Below are parts 28/29A/B and ready to be glued to bulkhead 29. Starting about bulkhead 27 the keel starts go up and gets much thinner between bulkheads 28 and 28. When gluing 28/29A/B to bulkhead 29 be very careful when clamping the parts to the bulkhead and keel. It is a very weak area.. Ask me how I know this 🙂

You guessed it,,,,, the keel between bulkheads 28 and 29 broke off. I do not have a picture of the breakage, but below shows my repair. In my panic I over compensated and decided I wanted a block (patch) that would be glued to both the Keel and bulkhead 28. In reality you only really need maybe a 1/16" piece of wood on both sides of the keel between bulkheads 28 and 29. In fact, I would suggest you do reinforce that area before you glue on parts 28/29A/B.

Below is patch after drying. It still has to be trimmed, but it will be totally unnoticeable when covered with planking and decking

Up until this point (if you ignore the breakage) the build has gone very smoothly. Bulkheads fit easily into the keel parts.

But now it starts to get (shall we say) "interesting". I started laying out the deck pieces onto the hull just to see what we have going... Two issues have popped up.

First issue is more of a Model Shipways issue. The four deck pieces should all have etched lines on them simulating planking. As you can see from the picture below, the port stern section (35P) has no etched lines. Even though I plan to plank the Main and Boiler decks, you need the etched lines to show where the structures are to be placed.

Below shows part 35P with missing etched lines.

In contrast it's partner part (35S) has the etched lines

Model shipways is very good about replacing missing/broken parts. I sent them a note today and I expect the replaced part to be within a week. This is not really an issue.

Looking ahead, the second issue is more of a question... There is a 1/16" x 1/4" rub rail that goes around the entire main deck. Problem is,,,, For most of the hull, the Main deck extends beyond the bulkheads by 3/8". And in the bow and stern sections the deck extend much more beyond the bulkheads. I guess my question is, is this 1/16" x 1/4" rub rail only attached to the edge of the main decking and just hangs down in the air? Seems like that is not much gluing area and a rub rail should have some sort of backing. I could always put some additional wood behind the rub rail but I figured I would ask the question of those who have built Chaperon before. Is the rub rail really only glued to the 1/16" main deck edge?

Here are a couple shots of the deck pieces at the middle of the hull. The 1/16" planking on each side of the hull will take up 1/8" but that still leaves a large gap and not much area to glue the rub rail.

- Cathead, Ryland Craze, mbp521 and 1 other

-

4

4

-

Gsdpic,

Thanks for the comment. I appreciate it... But in this case it is an optical illusion. As I go I measure each bulkhead to insure each one is exactly 13/16 apart. In addition I have a triangular ruler that I put in the slots to insure all is straight.

I have been down that road before with uneven bulkheads. If they are not exact you will keep paying for that mistake over and over again throughout the build. It keeps coming back to cause problems.

Do not hesitate to question anything you see in this build. I am sure you will see errors that hopefully I can correct before it is to late. Here is a picture of my ruler in the slots as a triple check of the alignment.

- Ryland Craze, Altduck, Cathead and 3 others

-

6

6

-

Yvevidal,

Welcome aboard.... Glad to have to follow along.

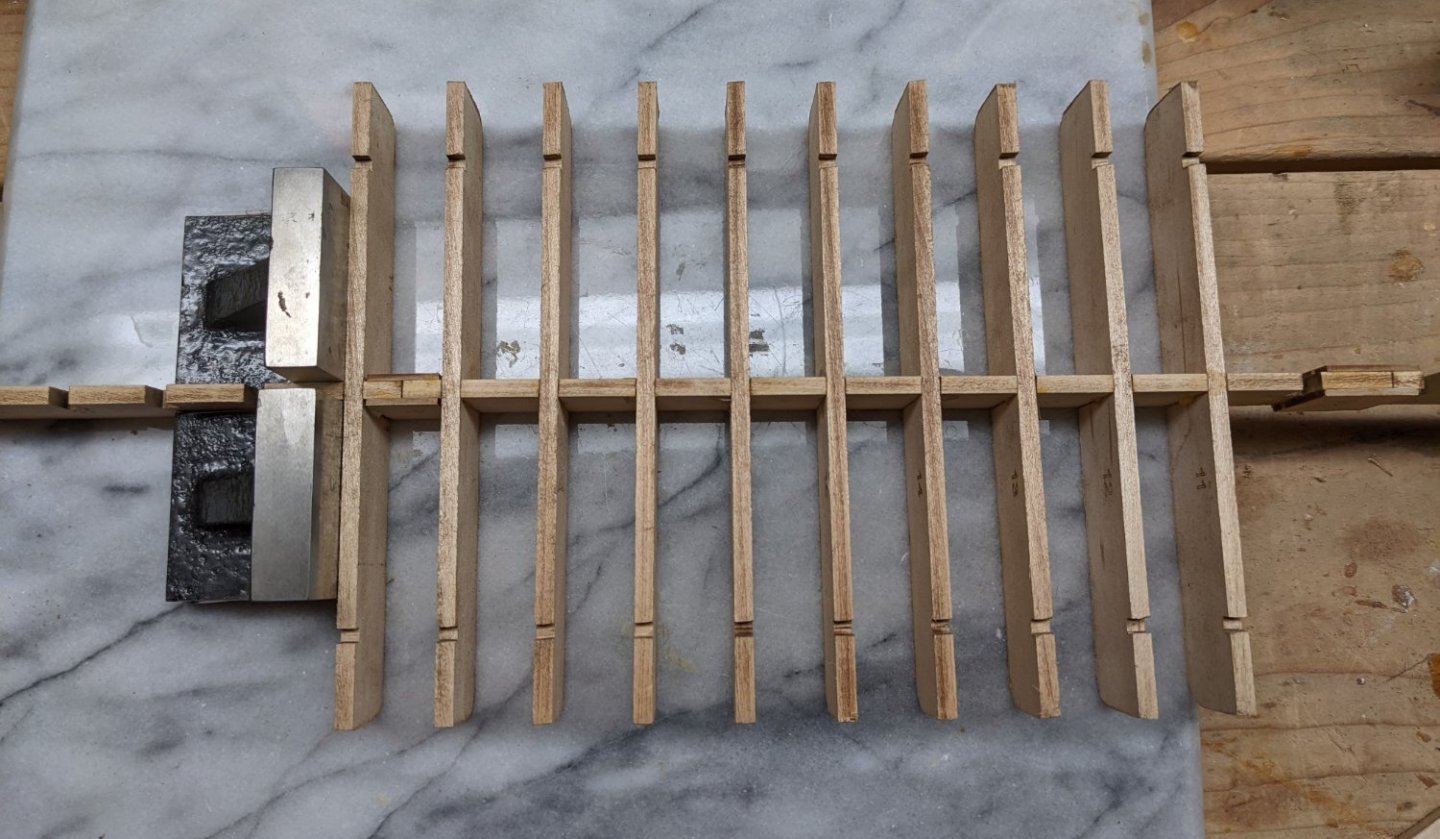

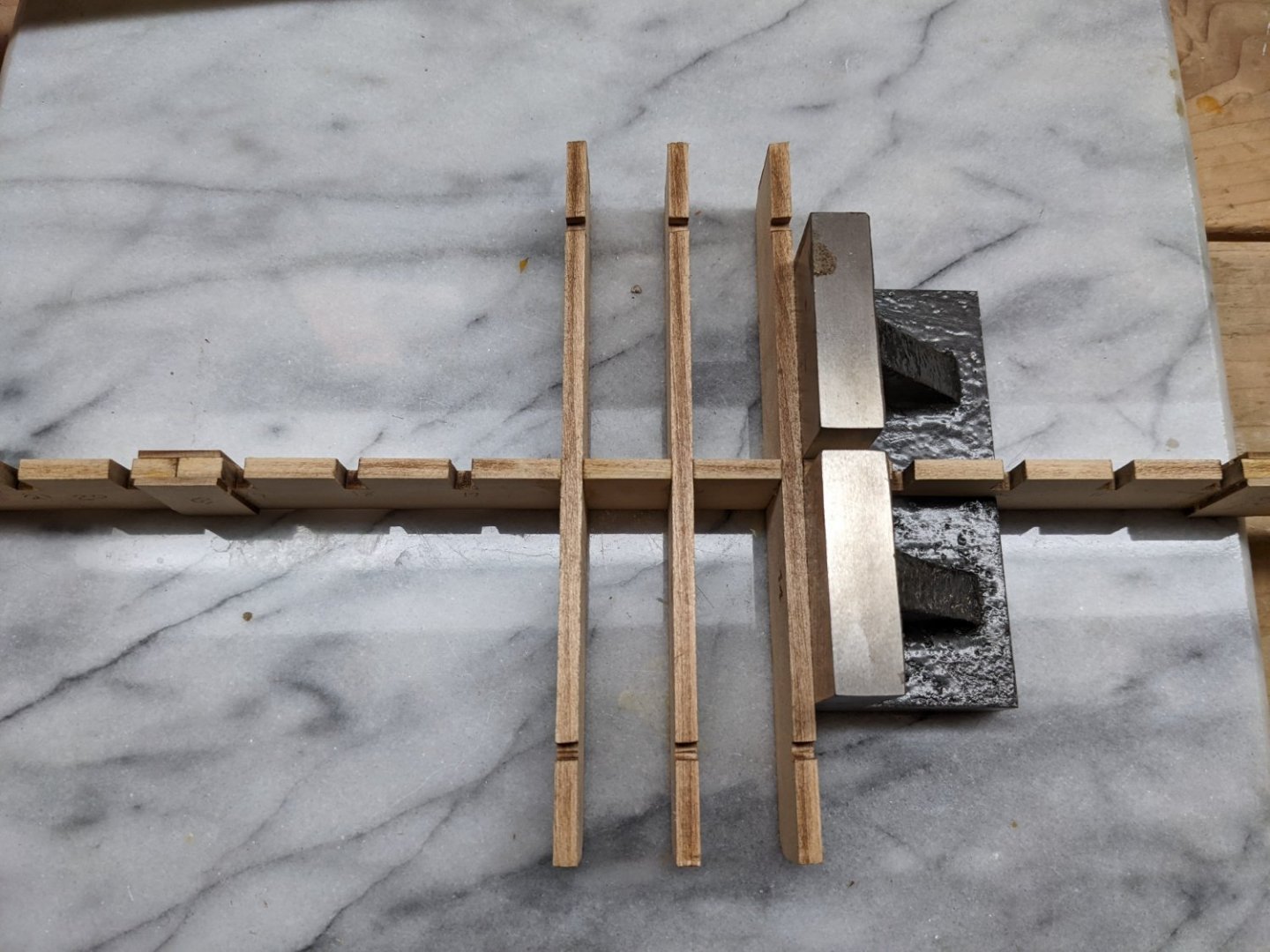

A few more bulkheads installed - 10 out of 29 so about 1/3 the way home. I have to say these bulkhead fit very nicely into the keel. There is a little slop in the connection so you will need some sort of square to keep the bulkheads straight. A little slop is easily accounted for with a metal square and a whole lot easier than having to file each bulkhead in order for it to fit into the keel.

In my case I used an angle plate to insure the bulkhead was square to the keel, but that is probably overkill. Any square block will do the trick. I have even seen some folks use the lego blocks or metal corner braces.. they are cheap and very square edges..

-

Just completed the Secret Vessel "Morel". What I call a "quick win" as it only took a couple months to complete. For those of you who have not seen the Morel model, I recommend you check it out. It is a quirky little model that is easy to build but looks really neat. And a definite break from the usual year long builds of most models.

Anyway, Now it is time to put my "big boy pants on" and take on the Chaperon.

I am by no means an expert builder - average at best, but as they say - the journey is the destination. And I do enjoy the journey ..... or the build in this case.I would like to say thanks to all who have built, and supplied excellent build logs, that have gone before me with the Chaperon model. There have been some excellent Chaperon builds - I would say museum quality. I will be shamelessly borrowing (stealing) some of the best ideas from those logs as I build my model. I am still too new at building models to have many original ideas of my own. My build will by no means compare to those who have gone before me, but I will have fun.

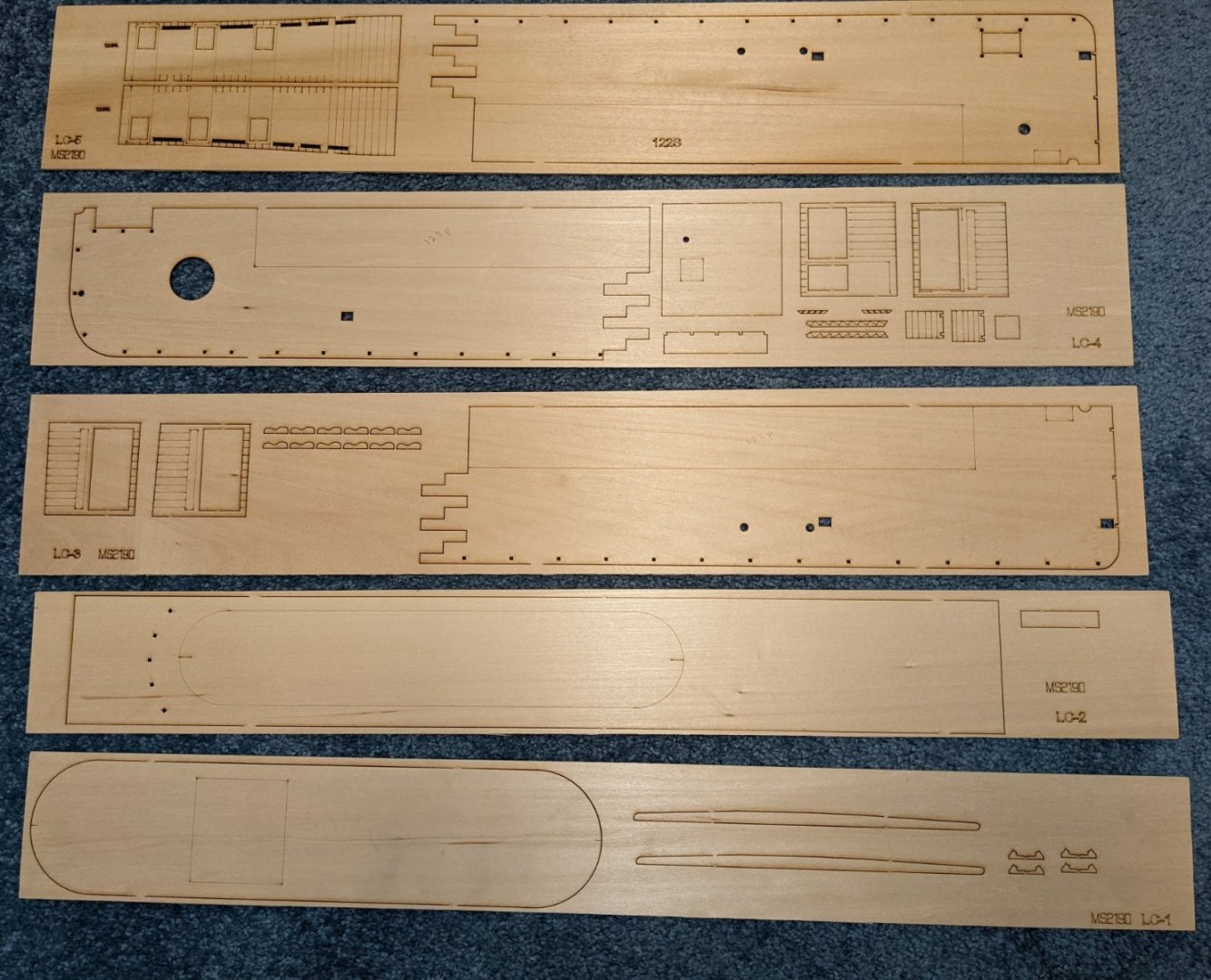

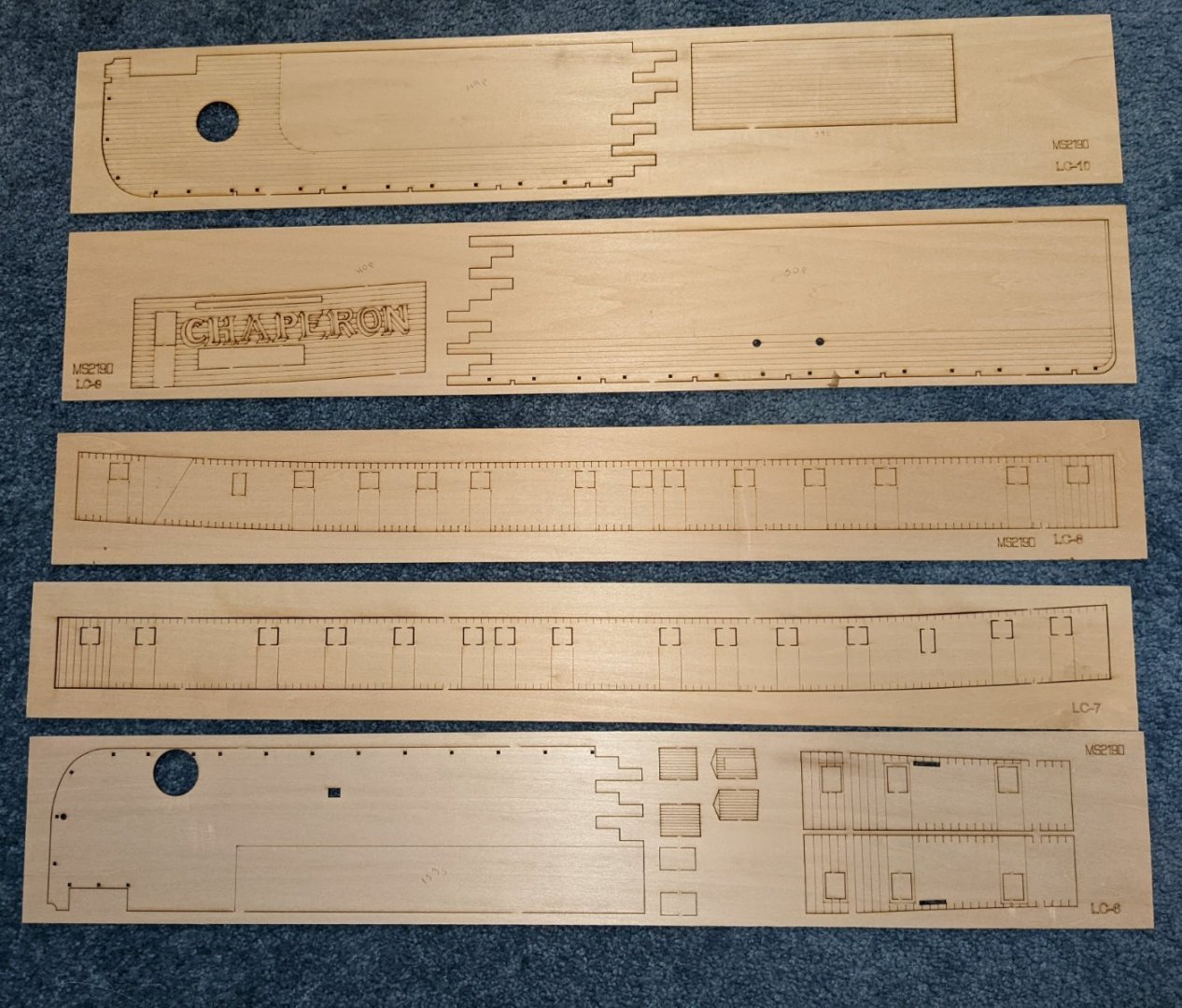

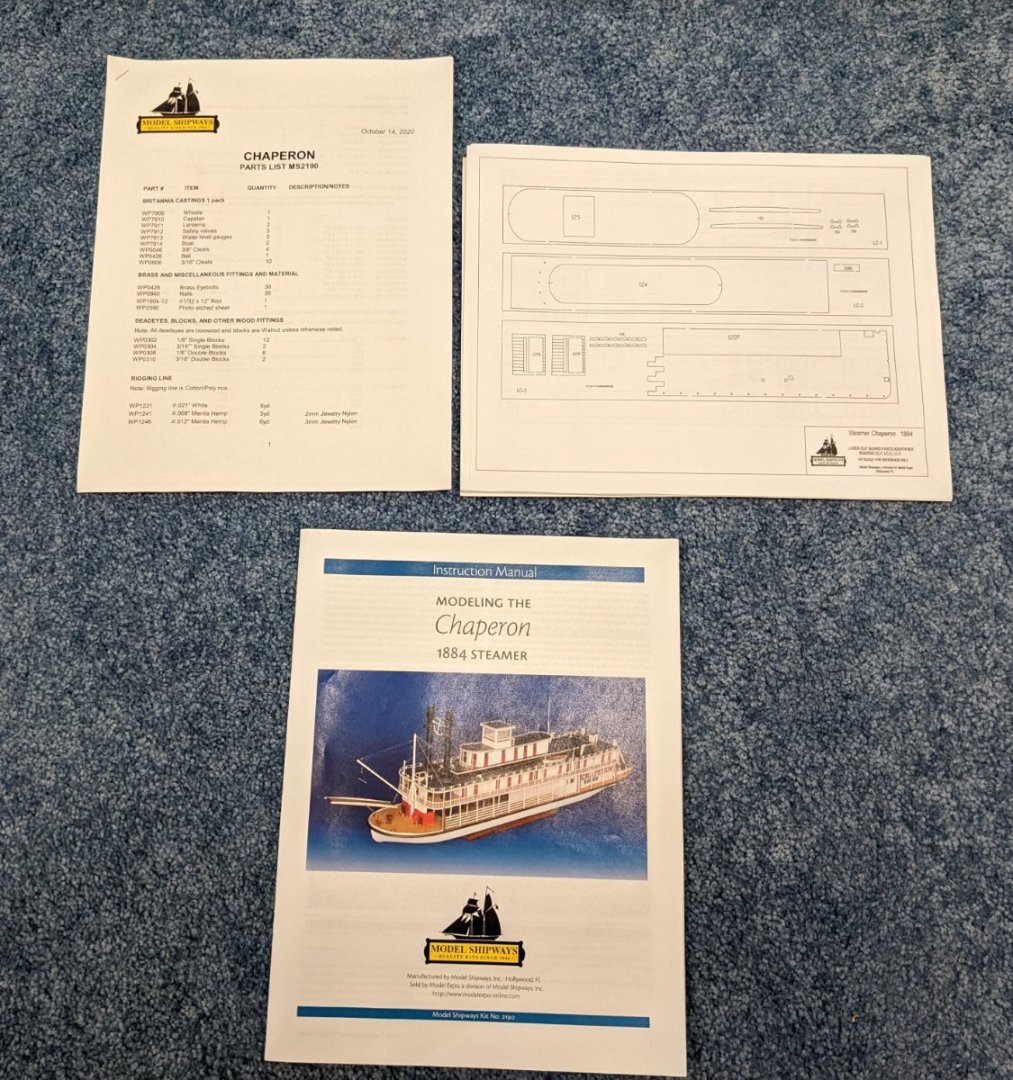

With that in mind I will start right in with the unboxing.... Most people can just skip over this section unless you really are interested in the box contents.

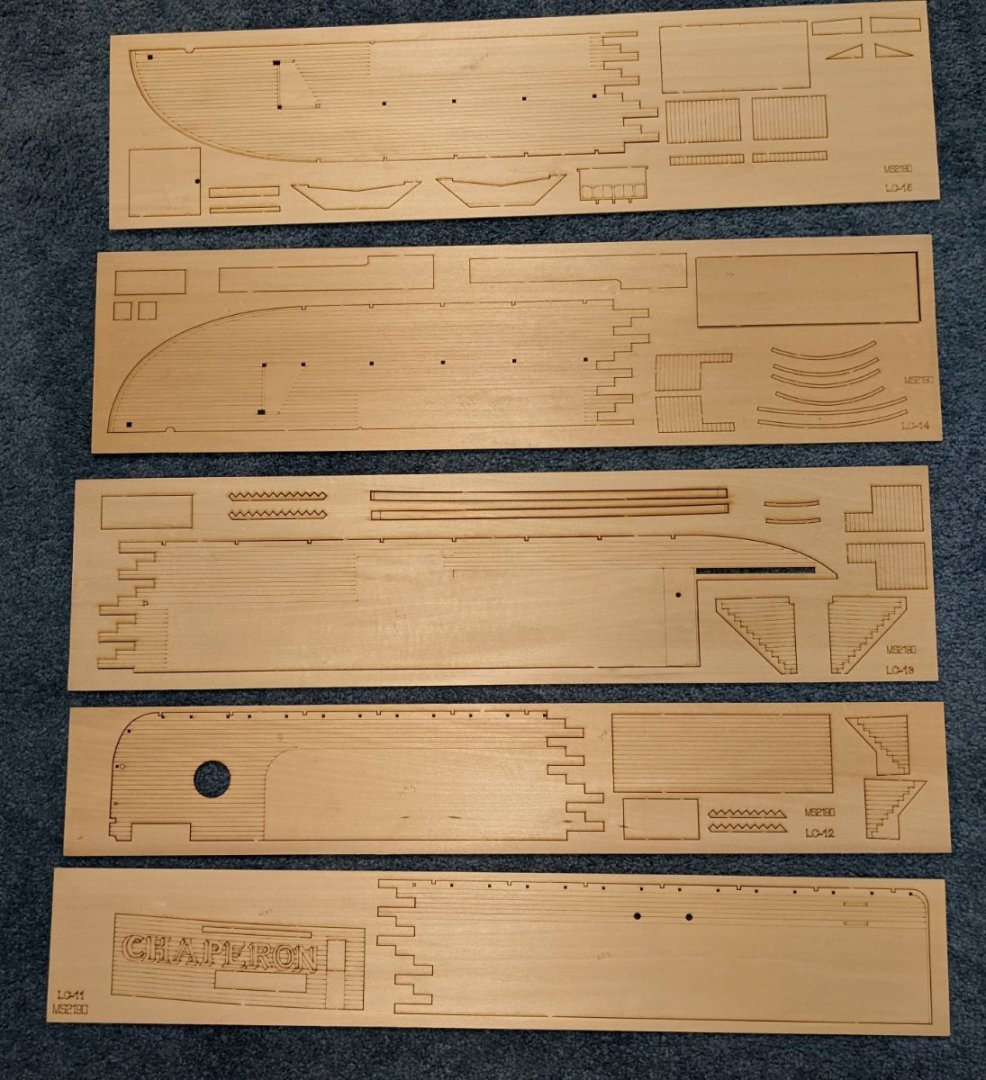

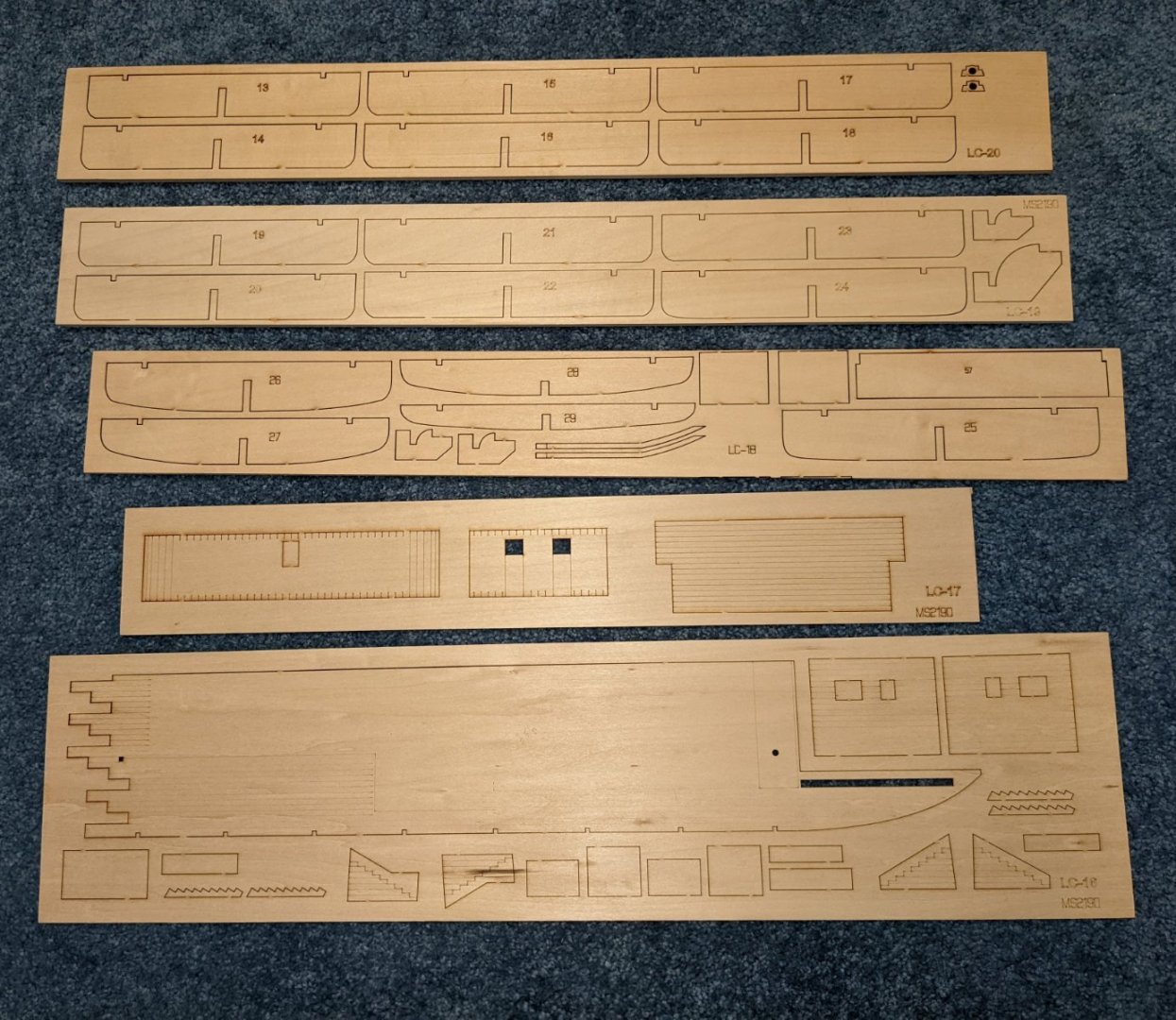

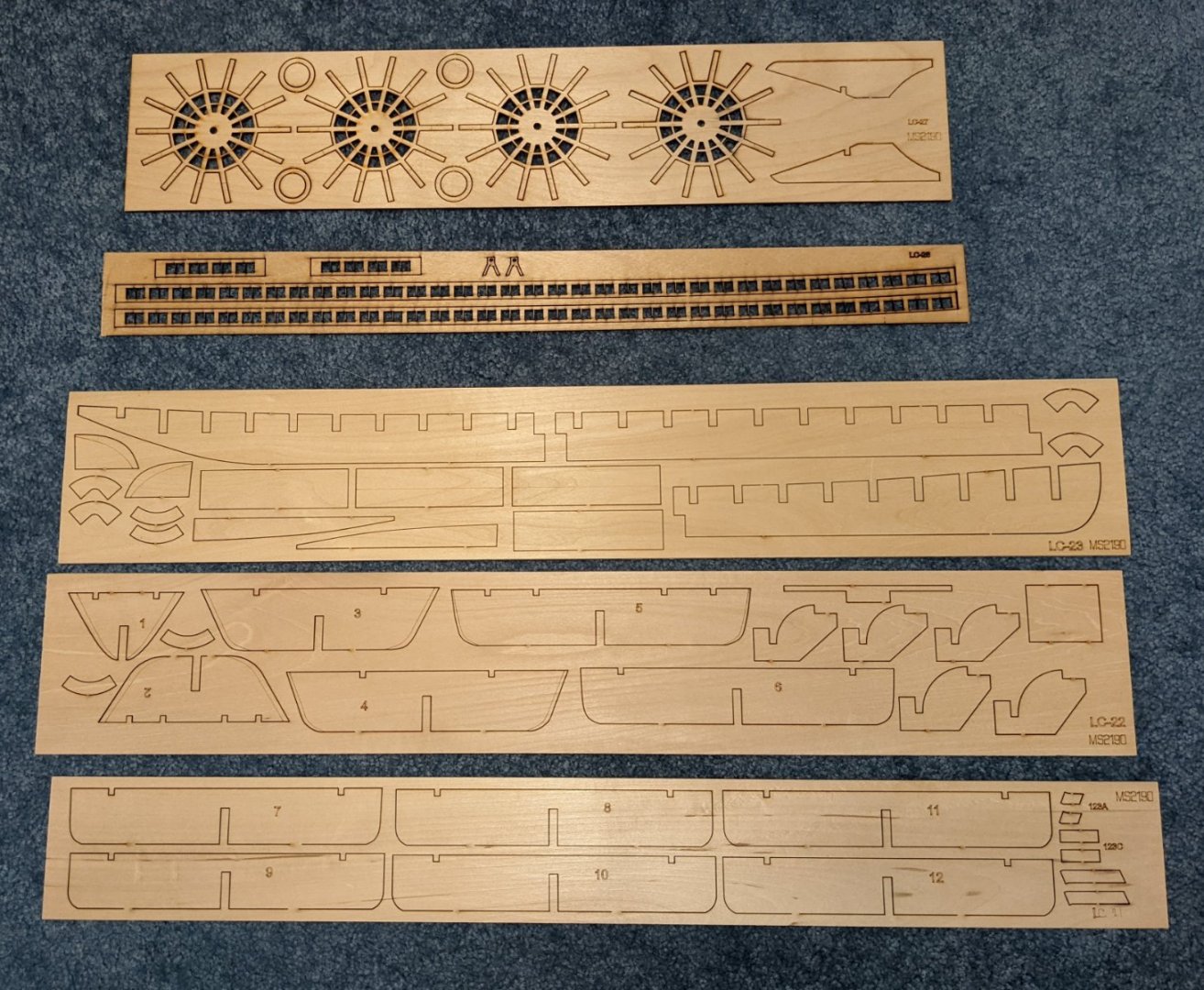

There are 27 sheets of laser cut basswood.

Note on this sheet and others some of the boards have lines etched in them... With this model they are to simulate planking. Not sure if my model is odd or not, but to me those lines seem very thin (faint). They look like after a coat of primer and paint they would be completely filled in. We will see what happens when I get to that stage, but right off the bat this model may get (shall we say) "interesting".

Included with the last laser cut sheet is one large photo-etched brass sheet.

pins, eyelets, and some nylon line..... Will probably not use this line as it seems to be pretty cheap.

A couple of britannia life boats and assortment of other britannia parts.

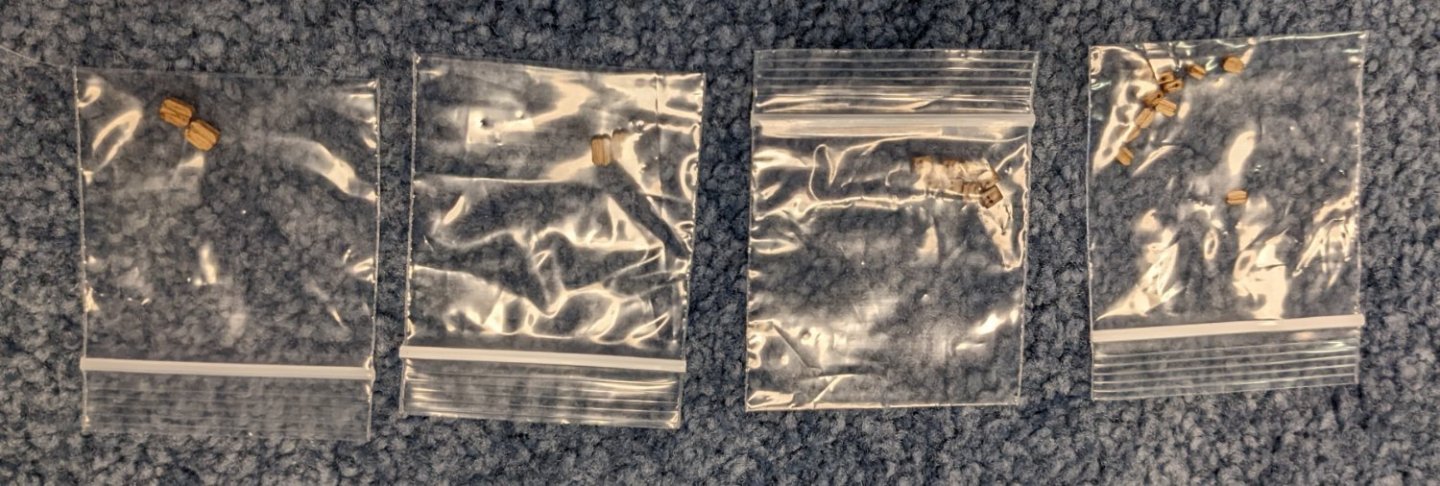

An assortment of single and double wooden blocks

An assortment of wood strips and dowel rods for the build

Inventory list of all included parts

A 12 page manual with a brief history of the Chaperon and the build instructions.

12 sheets identifying each item on the laser cut wood pieces and photo-etched brass sheet.

Not shown, but included are 5 large plan sheets depicting the various stages of the build

On to the build....

As with most builds that are larger than the wood sheets, we start by gluing the keel made up of three 3/16 pieces. The joints between the three pieces (under the weights) are reinforced with small reinforcement pieces (B1 & B2). The ruler was used to help keep the keel straight. As you can see, this is going to be a big ship.

With the glue dry and the weights removed you can see the reinforcement pieces (B1 & B2). There are a pair of them on each side of the keel. Each of the 29 bulkhead slots have been labeled to help keep track of the bulkheads as they are installed.

As so we begin the process of laying the bulkheads. Be sure to remove all the laser charred marks on each bulkhead before installation to insure the glue gets a good grip on the wood. I mention this now and will not mention it again, but that goes for all the laser cut parts. Char marks need to be removed from each piece throughout the entire build. Instructions say to start with the middle bulkheads and work your way out to the bow and stern. This will take awhile as you need to insure each bulkhead is square and need to wait for the glue to dry before moving on to the next bulkhead. It is going to take a few days to get all 29 bulkhead installed.

-

HardeeHarHar

You bring up an interesting point as to whether there is enough room to add "stuff" to make it look interesting. Below is a shot I took early in the build showing what is inside. Inside you see two benches and a ladder. As is, not a lot of room to add stuff...

However, if you decided to open it up, you would have to be creative and modify the benches to allow access to the bow and stern sections. In addition you would have to expand the floor sections to reach the box and stern. There is where the model is not very realistic as you see,,,, no access to bow and stern sections. Not shown here, but the final pictures show ballast weights that from inside are dropped when the ship wants to rise to the surface. Without access to the bow and stern sections, there is no way to release the ballast. So, if you open up the full ship allowing free access from bow to sterns, there is plenty of room to get creative with some flooring, small figures, buckets, stools etc..

Whether you open it up or not, this is a fun quirky model to build, looks good, and is a good break from some of the longer "marathon" builds. As I call it,.,,,,, a quick win.

- Archi, GrandpaPhil, HardeeHarHar and 2 others

-

5

5

-

Robert952

I just used Minwax Wipe-on Poly - Clear Satin.. I mainly use it because it is applied with a rag instead of a brush as normal poly. As such the finish is really smooth with no runs. Also, even though it is listed as satin, as you can see there is still a slight shine to it. To me just enough.

To me wipe-on poly is a great way to get a good smooth finish. But you have to use a number of coats as each coat is very thin. I think I have 5 coats on this model.

I am not sure what wood is comes with the morel kit, but it's not basswood. It is some other type of slightly colored wood. As such for me no stain was required just applied the poly over the raw wood. The 5 coats of poly also darken it up slightly despite the fact that it is "clear satin".

If you have not used a Wipe-on Poly you really need to try it. It works great.

One more point,,,, I have not tried this but wipe-on poly is really just normally polyurethane thinned to about 1/2 strength. So if you already have some polyurethane and have some paint thinner or turpentine, you could make up yourself a small batch of "home grown" wipe-on poly and try it on a test sheet of wood. Just make sure that you only use paint thinner or turpentine if you have oil based polyurethane. If you have water base polyurethane you will need to thin that with a water based thinner.

-

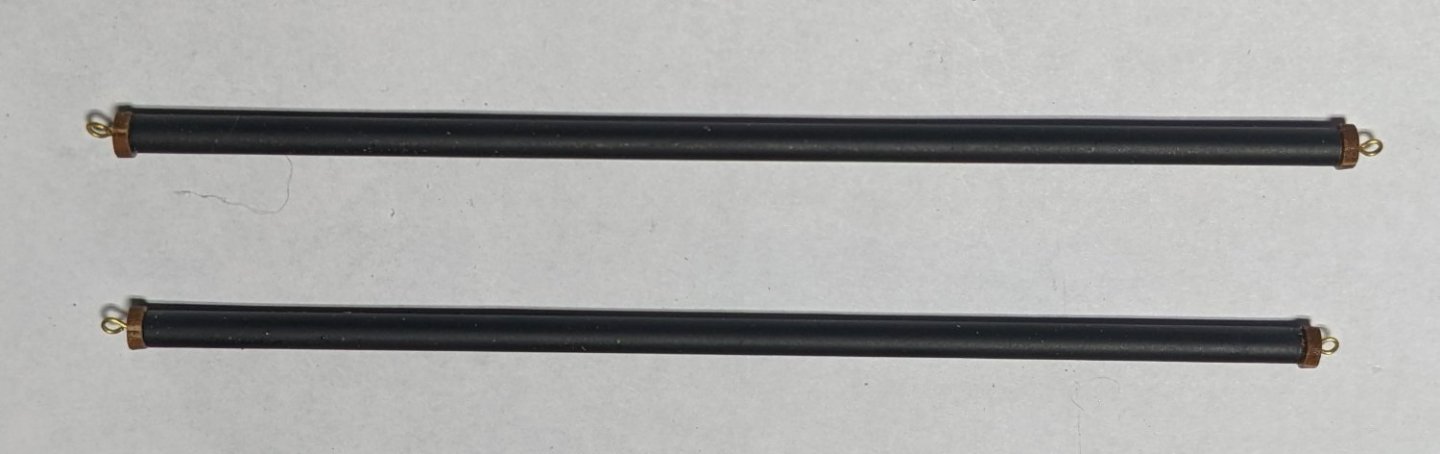

The metal straps (actually paper) have been glued to the hull. For the four rings that go on the outer straps, the instructions call to make the eye bolt and rings out of the .6mm wire. Not sure I had the talent to make a good ring but I gave it a shot, and to my surprise actually made from pretty fair circular rings out of the wire. Not as hard as I thought.

Fiery pipes attached but not fully strapped in yet. I ended up using one 1.2mm pin to pin the fiery pipe supports to the hull. I figured since they were being glued to the varnished hull, they might need a little more support.

Closing in on the end.... Ballast weights have been attached at bow and stern and the rudder attached. To get the steering line into the holes in the stern, .6mm line was used and the hole in the hull was increased to .9mm. From there the line could be inserted (poked) into the hull by a 28 gauge wire with a drop of CA glue on the end. Worked far easier than I thought it would.

Fiery pipes have been fully strapped in.

All that is left are the oars...... Once inserted I am calling it.....

I have totally enjoyed this build and as I mentioned earlier is a nice break from the year long marathon builds I have done in the past. Kind of like a reset before I start my next marathon build - Chaperon Sternwheel Riverboat.

There are not a lot of areas to customize this boat, and features like the flooring, benches, and ladder inside the hull are not even visible. If I ever built this one again (and I have thought about it) or for someone who wanted to do a lot of custom work, one idea would be to open up a portion the hull and show the inside of the ship. From there one could do all sorts of custom stuff inside of the hull. Might be an interesting build.

Final pictures are below..

-

Not a lot of progress today,,, only have a short time to work on it.. Today was the installation of the side ladders (or that is what the manual calls them). To me they look like large "hand holds" between the hatch and window. Here I used the 1.2mm pins as they seemed to be the correct size.

Port Side

Starboard side

The oars, fiery pipes and fittings, rudder, and ballast weights have previously been completed. Plan to add then on in the next few days. At that point I will "call it"... done....

- ccoyle, GrandpaPhil and HardeeHarHar

-

3

3

-

Have completed sanding and a couple coats of wipe-on poly. Hatch cover still need a little work as it got a little scraped up sliding the metal framing over the hatch. A little sanding and more wipe-on poly should do the trick,

I have also added the metal framing around the hatch cover, windows, and parts in the bow/stern.

Port Side.... Here I used the nails supplied with the kit for around the window. The nails around the oar ports where the 1.6 mm nails as the kit supplied nails are just too large.

Starboard side.... Same as on port side. Kit supplied nails around the window and 1.6mm nails around the oar ports

Stern view... Here even smaller nails were used (1.2mm) around the steering line ports and ballast port

Bow - again 1.2 mm nails used around the ballast port

Top view showing the nails around the hatch. Here the large kit supplied nails were used

- ccoyle, yvesvidal, HardeeHarHar and 2 others

-

5

5

-

Still have some final sanding to complete, but the hatch panels have been installed. Without the issue of the windows getting in the way, the panels could easily be trimmed on the bottom and sides to match up pretty well.

As mentioned earlier, in hindsight, and for those that follow me, I would suggest you dig out the hatch top and bottom panels so that the window are completely imbedded into the binding. Windows sunken into the binding is far better then having the window even with the binding. The panels (and bindings too) will take some (shall we say) "customizations" and not having to worry about the sunken windows make the job a whole lot easier.

But if you still have an issue,,,, do like I did and glue the windows to the panels and then you will not have to worry about them getting in the way as you trim things up. You just have to trim the glass to only be slightly larger on the top and bottom so that it does not get in the way of the bindings. You can have extra glass on the sides for a better gluing surface.

Stern view

Bow view

And a couple side views

-

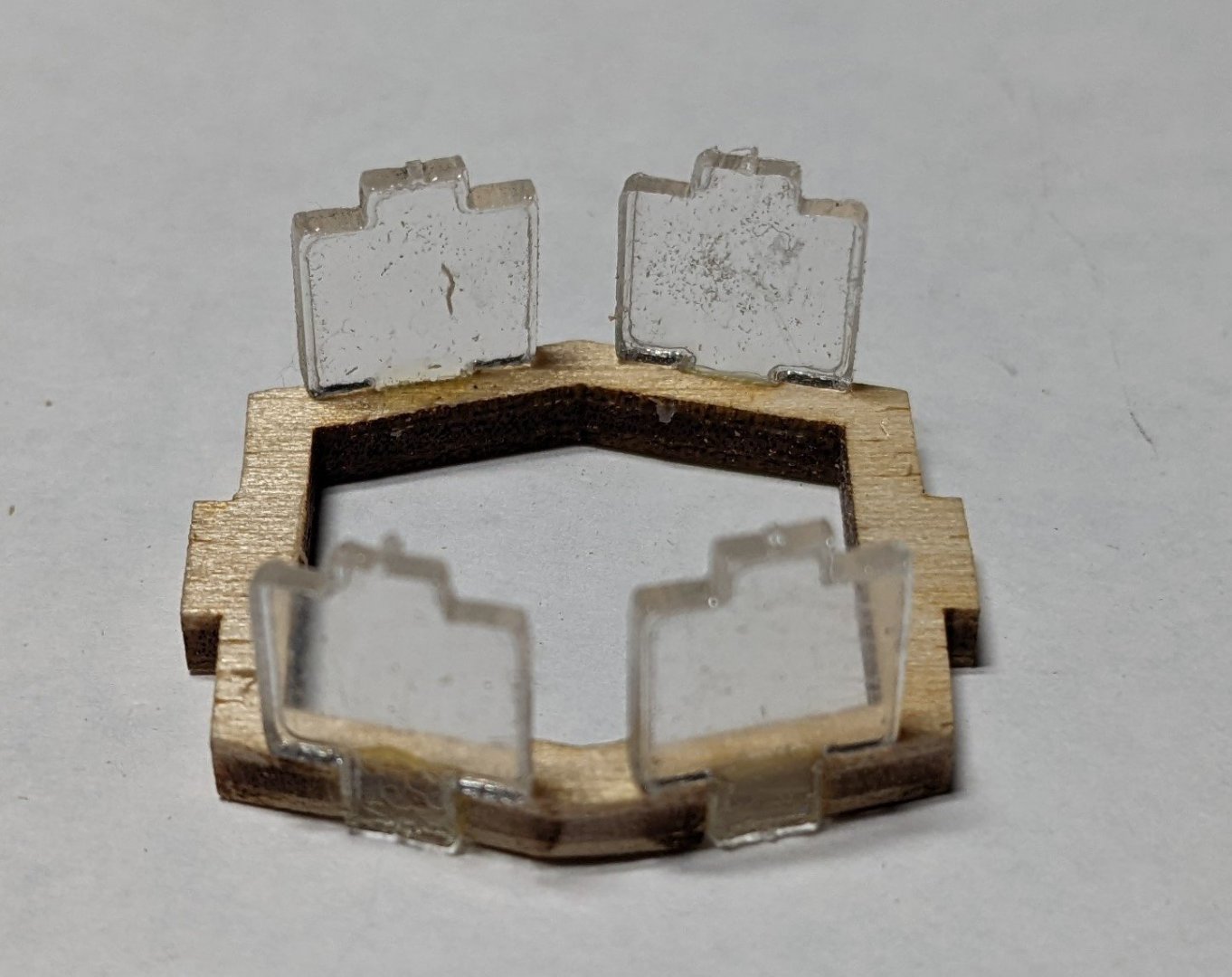

I mentioned earlier that I was pretty sure when the glass windows (currently mounted to the top hatch bindings) was going to get (shall we say) "interesting" when trying to line it up with the lower hatch bindings. Turn out it was "interesting" but in a way I was not expecting.

Turns out the glass windows on the upper binding fit pretty will when it was joined to the lower binding. The "interesting" part was getting the hatch panels lined up. Trying to get them lined up, on the bottom with the hull, and on the sides with each other. turned out to be a challenge. Main problem was the fact the the glass pieces were inserted into the top and bottom bindings. In my case I only fitted them into the inserts to where I thought they were fully inserted (flush) into the bindings. Turns out my pieces was a little warped and it stuck out just a slight amount from flush. This prevented me from getting the bottom and sides of the panels lined up for a good fit. I fiddled and fiddled with it but the inserted glass pieces really hampered my ability to trim the the panels for proper alignment. I finally gave up and decided instead of inserting the glass panels into the binding, to just glue the glass to the actual panels.

Below shows the panels glued to the inside of the panels. This way I could properly fiddle (trim) the panels and the bindings without worrying about the inserted glass panels getting in the way. Only thing you have to deal with is the width of the binding as it overlaps the panels. Note below the glass panel is just below the lower window. Any lower and the lower binding would hit the glass. From this point the side panels could be glued to the top binding and attached to the hull. From there the side panels could be easily adjusted to get a good alignment. All you have to worry about is correct fit on the sides and bottom. The top of the panel will be covered by a brass band, so if you need to "fudge" the top of the panel does not need to line up exactly.

In hind sight a better way would be to over insert the glass windows into the bindings, but that would involve trimming the already attached lower binding and I felt just gluing the glass to the panels was and easier solution. Easier for me that is... A better skilled builder probably would have a better solution.

Below shows the side panels glued to the top binding and hull. With the glass glued to the side panels it should not be a problem trimming and inserting them for a good fit. Famous last words,, we will see how easy it will be when the glue dries and I attempt to put in the panels. 🙂

-

The last plank was finally installed and a rough sanding completed. Still have to work with the window sashes some to clean them up too.

As noted before, I would suggest you resist any sanding during planking until the windows have been installed. I addition, put a small rag into the open hatch on top. With the windows installed and the rag on top this will keep the sawdust from sanding out of the hull.

Port Side

Aft or read end

Starboard side

Bow or front end

-

HardeeHarHar

It is truly refreshing to have what I call a "quick win" model to build. Defiantly needed a break from the marathon year long builds. I recommend it to anyone who wants a "reset" before taking on the next marathon. 🙂

Back to the build,,,

Worked on a few more items today...

Inserted the windows and sashes. The sashes still show a little bit above the hull as they have not yet been sanded. But they are in. Here we are dealing with some of the very small parts I listed earlier. I found stabbing the sash pieces with the exacto knife is an easy way to position them in the window. Stab mark will not show and much easier than trying to position them in the window with an tweezers,,, even a very fine one. Later on when the metal frame is inserted, these windows will look pretty good.

Port Side

Starboard side

Started working on the fiery pipe bindings. Two larger ones are completed and the two smaller ones not quite done. Note the 1.6mm brass pins inserted into the larger ones. They will go into the smaller ones too. I may put the 1.2mm pins into the smaller ones as even these see a little large for the part.

I mentioned earlier that the rudder, Window sashes, and fiery pipe fittings are really small. Two small tweezers and a vise to hold the part are really helpful. One thing I did not mention, ( and all experienced modelers know this)... and that it these small parts tend to easily get lost. Often they get lost getting cut out of the brass sheets, and other times they get lost as you are trying to work with the part. And if you drop it on the floor... forget it. Don't waste your time looking for it. For some reason the floor just eats them up never to be found again. 🙂

Everyone probably has their own way to deal with small parts, but I have found the best way for me is to have a towel on my lap. Even though I am working over a table, when those part fling, they fling a long way. And if they fling in your lap (without a towel), again you will never find it. Is it in your lap, on the chair, in you shoe, or on floor? It is just gone. I can not tell you how many times, the part has ended up in the towel on my lap. A true lifesaver.

Now onto the top hatch windows..... I am just getting started but I know this is going to get ugly. Below I have glued the glass windows into the top binding of the hatch. That is the easy part. From here this has to be inserted into the bottom binding of the hatch. What are the odds those four windows will easily line up with the slots on the bottom binding? And then the top hatch side panels have to lined up and installed. The bottom part of the panels have to line up with the curve of the hull and the top part of the panels need to line up with each other and the top binding. With my limited building skill and variations in the wood, this is going to be (shall we say) "interesting".

Fortunately there is a strip of metal that goes around the bottom of the hatch and another strip that goes around the top of the hatch (just under the top cover). Between these two metal strips hopefully they will cover up a ton of sins. We will see what happens..

Looking at the glass below they look pretty dirty. Not sure but seems the camera picked up a reflection or something. To my eye the windows look pretty clear... just not in the picture below. ugh

-

Completed the four stern section 1/2 planks on the top of the hull (highlighted in black). First dry fitted the four 1/2 pieces as I assumed they would not all fit. Since there was a gap at the bottom of the hull, it makes sense there would not be enough room for the last plank on the top of the hull.

Since I did not want one skinny plank showing on the top, I sanded down a little of all four planks. End result is not noticeable. I guess the moral of the story here is that early on in the build I did not line up the initial frame planks as exactly as I should have. I strongly suggest you spend some time when installing the initial frames that hold the bulkheads together. If you spend some time on that part you will not end up as I did with a gap on the bottom that had to be filled and some sanding of planks on the top.

Would have completed the four bow section 1/2 planks on the top of the hull, but I discovered I inserted two of them in the jig backwards. Thus they were bent the wrong way. The two planks were soaked again and are now back in the jig - hopefully bending the correct way. I am sure I will have the same issue as the stern planks and will have to sand a little of each before inserting into the hull.

- Justin P., chris watton and ccoyle

-

3

3

-

Justin,

Thanks for you support. I appreciate it.

Moving on with the planking up towards the top hatch.

You might have noticed that I have not been planking in the order specified in the instructions. The instructions call to lay a few key planks around each side window and then around the top hatch. After that then fill in the gaps with the other planks. To me that is just asking for a number of small gaps between the planks that will later need to be filled with sawdust putty. As you saw earlier, I started in the middle and worked my way to the bottom with one larger board at the bottom. That to me was a better solution.

I used the same approach planking my way up to the top hatch. Stopping with two planks to go on each side before the hatch ( as pictured below). I then could dry fit that last two planks and decide what to if the planks did not fit even with the hatch. In my case, the last to planks fit with only some very minor trimming around the hatch. So I did not have any planking issues as I had on the bottom of the hull.

Below show the last two planks around the top hatch with only the smaller side planks to go.

Hopefully the smaller side planks will not have any issues.

Side windows were assembled earlier in the build, but could not actually be installed until after the planking was complete. I figured this would be a good time to dry fit them and make sure they could get fully inserted into the hull - while I could still get my fingers into the hull. With some minor trimming the windows were fit but will be removed until hull is complete, sanded, and varnished.

-

HardeeHarHar

Thanks for your comments.... Progress is going along rather quickly,,,, and fun too... I decided on this build as I needed a break from the year long marathon builds I have done in the past. Wanted a quick win... And this is defiantly it. Kind of gets me ready for my next marathon already on deck - Chaperon Riverboat.

-

Bottom plank completed... It is a little larger then the other planks but I think it is a better look than trying to fill the gaps with sawdust filler.

I was correct in my earlier assessment of my skill.... It did take me two attempts to get it right. As mentioned earlier, there is plenty of spare wood in the left over planking sheets to create a few more planks.

Now moving on the complete the planking at the top of the hull.

I should have mentioned this earlier, but try to resist the urge to do any sanding until the planking is complete. If you start sanding before the hull is filled in, you will get saw dust into the interior of the hull and that will be hard to get out. In addition, before I do any sanding I will fill in the windows and top hatch with a rag to keep out the sawdust. But as I say,,, that comes later after the planking is complete.

-

Wlell,

Thanks for your comments,,,, As for Model Motor Cars, I learned about it from other modelers. I have not built any of their model cars. I mainly use it as I have with this build - to get very small bolts. It is amazing the really small parts they carry.

Planking the bottom half of the hull is almost complete,,,,

Port bottom half of the hull

Starboard bottom half of the hull

Earlier I indicated the planking was very accurate and matched up the lines exactly on the bulkheads. As the planking when on there actually was a few deviations in the planking to where some did not really match up with the bulkhead lines. One option is to stay with the bulkhead markings and later fill with sawdust putty. Other is to continue the planking without gaps and "fix" the issue at the last plank - on the bottom of the hull.

I choose this 2nd option. To me one larger gap at the bottom is better than having several planks on the hull with Sawdust filler. Note below the gap for the last plank is a little larger than the last plank.

At this time, the easy (and maybe smart) option is to just lay the plank in the middle of the gap and then fill both sided of the plank with sawdust putty. After all, this is the plank on the bottom of the hull, and when the model is mounted, no-one will see the filler.

But what would be the fun in that? After all "why do something easy when you can make it hard." I decided to make a custom plank that will completely fill the gap. This plank will be a little larger than the other planks, but there will not be the sawdust putty filler. Take your choice as to how to fill this gap. To me a little larger plank (on the bottom of the hull) is the way to go.

There is plenty of extra wood from what remains of the planking sheets to form several planks if needed. At my skill level, it may take me a couple attempts to get it right. Will show the result of my attempt after I complete the plank

-

Going with supreme overkill, I made a slight adjustment to the jig used to bend the planks. Again this is totally uncalled for and way overkill as the jig works great as it is, but it was easy to do and I think it helped getting a better bend.

Note in the picture below the top plank in the bender as intended. Note the plank ends (in green) do not follow the curve exactly. By inserting a spare 1/16 scrap piece of planking at each end of the jig, as shown the other planks, allows for a smoother curve. Just put the wet plank into the jig and then insert the 1/16 scrap piece of planking at each end until dry. Repeat for each plank that is to be bent.

Again,,, really overkill and not really required..

Continued on with other stuff as the planking continued.

Inserted the plugs (shown earlier) into the fiery tubes. They are really to install.

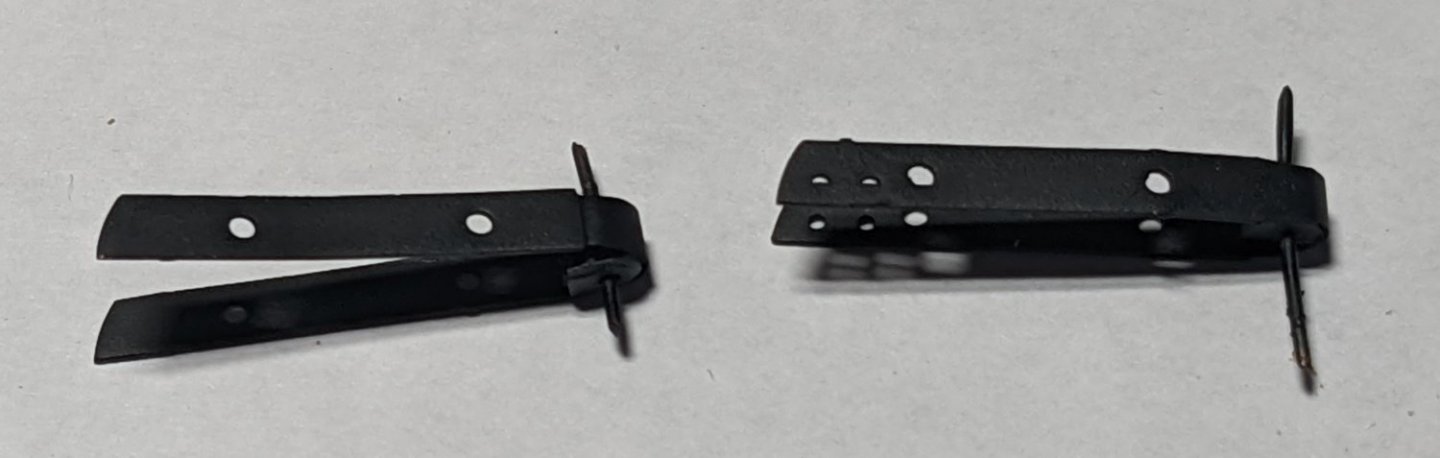

Completed the rudder hinges. Glued the insert (mentioned in earlier update) and ready for installation on the rudder. The wire shown in the picture is temporary and just to help with alignment.

One thing I should have mentioned earlier is that until the flooring is covered with the planking, it is very vulnerable to breakage. Working with the planking required a lot of adjustment getting the planks lined up correctly and rubber bands attached. Easy to forget the flooring is exposed and easily broken. In my case it was only cracked and did not break into two pieces. A simple patch below the broken flooring did the trick and is not noticeable.

Did I mention the flooring was really easy to break?

Two more later breakages where patches were required. I might suggest before you start the planking to support the under edge section of the flooring all around the floor. Will be hidden but could save you some tears during planking...

Started looking at the supplied nails intended simulate bolts. They are OK for bolts around the hatch and windows, but are way too big around the oars, ballast, and steering lines. Below shows what the supplied nails would look like around one of the oar fittings. It overwhelms the fitting. I had some left over 1.6mm and 1.2mm bolts from other builds and they seemed to fit much better. Unfortunately the ones I had on hand were chrome would not look correct. I ordered some 1.6mm and 1.2mm brass bolts from Model Motercars that should show up next week.

- Paul Le Wol, Ian_Grant and yvesvidal

-

3

3

-

While the planks were drying I starting working on the etched brass sheets.

Like some of the wooden parts,,,,, some of these brass parts are really small.

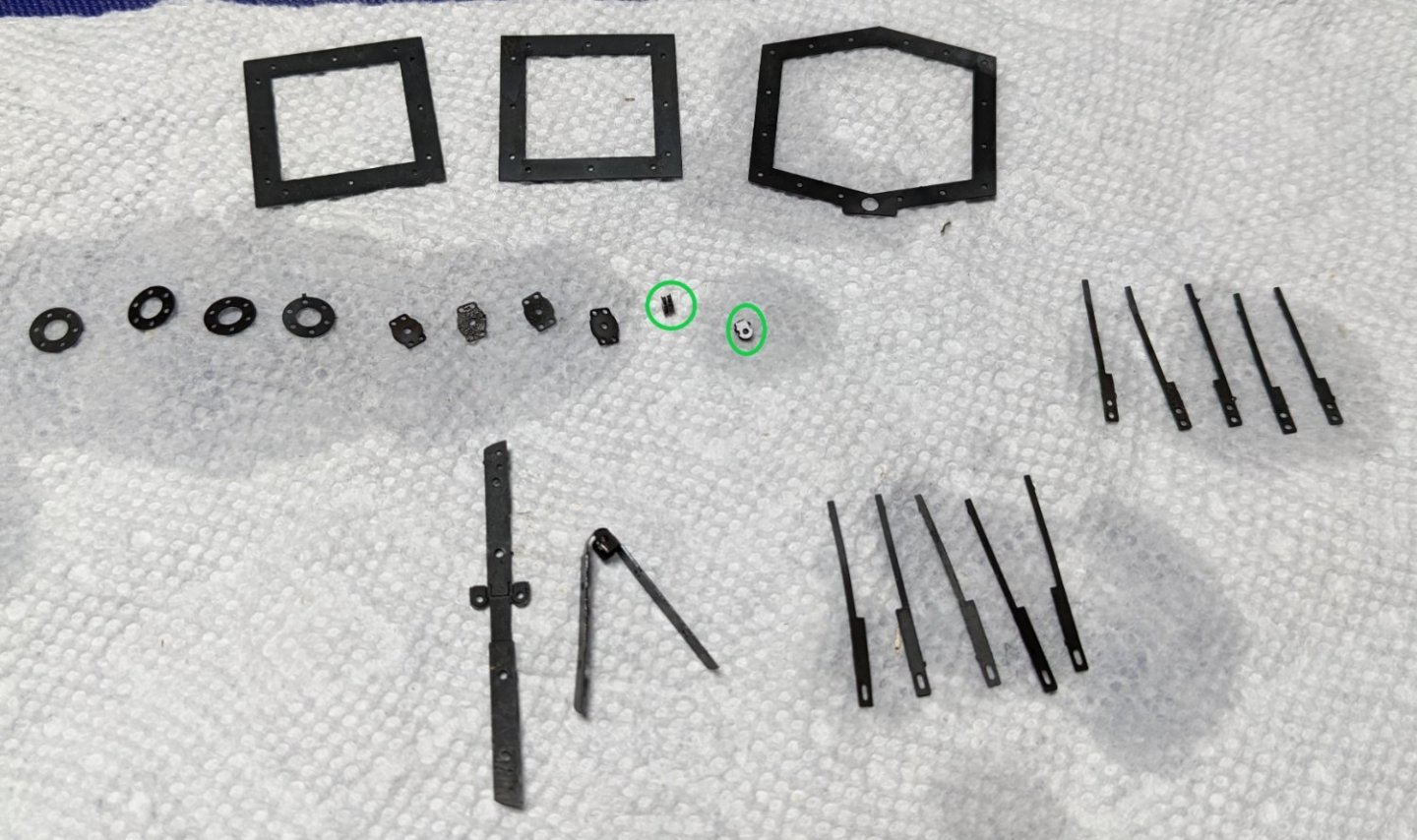

Do to the size, it takes some time to cut out each part, trim off the nubs, and somehow keep from loosing any.. Somehow all seems to have survived the trimming. On to blackening,,,, There are about as many theories on blacking brass as there are modelers... Everyone has their favorite. I use Novacan Black Patina. It is something folks who make stained glass windows use to blacken the lead between the glass. I have found it works great on brass at 1/2 strength. Below is the result.

The two green circles show the above brass part that gets folded four time to form the two rudder hinges. Needless to say,,,, a pair of very sharp tweezers are in order here.

I should have included a ruler in the picture. Picture just does not do justice on just how small and fragile each part really is.

First section of window planking is complete. I wanted to start out slow as I was not sure just how accurate planking was. I figured around the window was a good place to test out the accuracy of the planking. I have to say, all the planks were right on the marks. It really was easy. Planking should speed up at this point now that I know planking is accurate.

Never had a model before where planking did not require a lot of sweat and occasional nasty words. Hopefully I have not spoken too soon and the rest of the planking will be uneventful.

- yvesvidal, HardeeHarHar, Ian_Grant and 2 others

-

5

5

Chaperon by John Gummersall - Model Shipways - Scale 1:48

in - Kit build logs for subjects built from 1851 - 1900

Posted

That slight tilt in the stern got to bugging me. I just had to try to fix it. Below is my attempt. I soaked the last four bulkheads and then jury-rigged up something to try to straighten it out. We will see what happens tomorrow when things dry out.

More experienced modelers will probably get a good laugh at my expense, but I have always had a hard time keeping track of the various wood strip sizes. I have tried laying it out on a table, labeling them with paper and clamps or rubber bands. Labels seem to fall off especially with the very thin wood that only has a few strips. And over time, left over wood from previous models just adds to the confusion.

Nothing seems to be a good solution. Seems I always end up digging through a pile of wood trying to find the correct piece.

Anyway, I had some spare 1" PVC pipe around and started playing around. Below is what I came up with... Not elegant, and maybe even a little crazy, but for my simple mind it seems to work. The taller pipes in the back are 14" and labeled with tape. The shorted pipes in front are 3/4" and 5" long. They hold the same size as the larger pipe in back but for wood strips shorter than 14". I used tape for labels as it seems there are countless sizes of wooden strips and easier to change a tape label than if it was permanently marked. In this rack there are 25 slots so I can account for a number of different sizes.

Once complete I added the wood from the Chaperon and other wood left over from other models. I have to say, while some may laugh, I really like the idea of being able to go right to the size of wood I am after rather than continually digging through a pile of wood. Just thought I would share... but I know some will think I am crazy.