-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Seamanpeter

-

-

As always Jo, done a perfect job with the lashings of the heads, could not be better.

Wonder the padlock will fit in there too! Must be a very tiny one.

Well then have a nice cup of tea and enjoy the Sunday (what is left of it)

As always

Peter

-

Proud on you my dear with your first built!

You have put in there all your life and forget the sorrows having!

Must say as this is your first time you built something in WOOD that it cannot been seen from the work you have delivered.

Keep on going until it's all done and when you rest in a chair with a nice glass of wine, looking at the built MADE by your hands only then you feel the relief and in the same time proudness of yourself that it was YOU that made it!

I would say, up to the next one!

I'm not so far yet as weather doesn't work good up here, raining, pouring rain and to cold to do anything outside like epoxy and painting!

So it has to wait but did other small issues like fabricate the mast and railings in the vicinity of the mast itself, also the kim keels.

Waiting for some spare parts from the Netherlands to arrive so I can do some more works to it until the weather outside clears up.

Ok, have a great Sunday down there and looking forward to the finished ship!

Peter

-

Amazing my lady, respect!! You will be a great sailer in your later life!

Keep on going also now with the mast (sails etc) and some lights.

Will look great, proud on you!

Peter

- SHIPSCAT, popeye the sailor, mtaylor and 1 other

-

4

4

-

Keep on going my dear, you will succeed and be proud on this built.

-

You doing well my dear Jo!

Looking at it and reading what you go through with this first building, amazing you still have the patient to go further and find alternative ways to compromise. That is all what is about building a ship and not having the parts there.

Keep on going and after all when all is done you can be proud on yourself.

Waiting for the finals as it looks like.

Don't forget the flag your lady is having.

Peter

-

wow, great combination of colours and all done.

You don't need to secure them though?

Also "screws" on the hatch are missing but guess will come later.

Overall, it is a nice "little" boat and you can be proud on it too.

Peter xxxxxxx

-

Wow, very detailed Jo, the little lady has a great owner and you doing well!

Sorry I put those pics here as looks like they don't appreciate that much but then again, they should read the whole contents and not just the pics.

Anyway my dear Jo, we know now and next time we can send each other a PB and only you and me can see that.

Keep up the good work and have a great rest of the weekend downunder,

Peter

- SHIPSCAT, SigEp Ziggy and mtaylor

-

3

3

-

Well Jo, the reinforcement is not the epoxy but the vessel strength itself but for making sure after 3 x filler and sanding I don't want the risk my built blub blub sinks to the bottom of the bath!!

No but seriously, this is for the imperfections I cannot see with my eyes if there is a tiny little hole somewhere on the line, afterall it is wood and you never know; beside it protects the surface as well for later any bumps with sailing in not deep waters or accidents.

Gives overhaul the extra protection needed.

But still waiting for the postman to come with the epoxy and then sanding again, maybe a second layer of this stuff.

Colors are like all vessels from BosKalis (owner these days of the "real" vessel) but will put a pic here from one of them in the company colors.

I had the privilege to visit the vessel in Rotterdam doing an inspection on her for the Bank, making an evaluation of the vessel's state and the value in money so yes I know nearly all corners on her.

I will keep you posted on that. For sure she will have a white line as "waterline" too.

-

Respect my lady!

You nearly finished all and it looks great, all in place and painted.

Already tested in the bath? No leakage?

Anyway, must say that you win as I'm not even that far!

Let me know when she finally is going to sail!

I'm just ordered the epoxy to have her watertight before painting the hull.

But not much time as going to school (uni) for my BSc so only weekends free.

I let you know when I have the colors in place and the waterline!

Take care there now and good luck with the little lady!

Peter

- Blue Pilot and SHIPSCAT

-

2

2

-

Well, in my younger years been travelling from Melbourne to Perth in a car we just bought in Melbourne!

Was a great trip and see many things what we don't see here in Europe and was shaking my head seeing those ROAD trains, amazing!

But did not see any animals like described above neither had the opportunity to go off this "road" as afraid I may get last there and don't want to end up as a skeleton in nobody's land.

Had after all a splendid time there and also later when my ship was coming into an Australian port.

Must admit, learned there to drink beer too.

Have a great time there down under and not to worry, I don't run that quick away from animals!

- lmagna, SHIPSCAT and popeye the sailor

-

3

3

-

Sure I'm scared now but bearing in mind that due to the fact she said <that's how bad my cooking is it puts holes in hulls > I'n not afraid to face that!!

Have in my life time dealed with ladies that having bad cooking skills, so hopefully the little boat can stay on the surface as fire and wood don't go together.

Either the boat goes in fire (what I don't wish) or she gets the hell out of my way so to speak.

But let's see who has the first sea trails as she has to use the wind as I can go with charged batteries away.

Jo, I was only joking as never ever I would run you over in that lovely little boat of yours.

Take care and hopefully we can both sail before X mas.

-

Sure but first you have to come near me before doing that. Got a chopper now so can locate you very fast!

Take care there my lady and let's see who finished first.

Peter

-

Wow, must admit, not followed some time you did came far! Well done even not finished, far as I can see looks perfect this built.

You can look into mine as well, just started again but having not much time in between school days will leave me with less time.

Anyway, most of the hull done, now like you sanding and filler to be used.

After this all done doing the accommodation and the rest like propulsion mounting the Schottels but you can follow that on my page here.

https://modelshipworld.com/profile/32387-seamanpeter/?status=1004&type=status

Take care now and will keep an eye on your boat not to run it over!

-

Good day all,

did post some latest pics here but guess I mixed up the site where to put it, sorry about that.

If you go here https://modelshipworld.com/profile/32387-seamanpeter/?status=1004&type=status you find the latest of my built.

Have a great Sunday you all.

-

Just go there and you can order on line, even shirts, hoodies and T shirts same design

Succes

brgds

Peter

-

Thanks Steven.

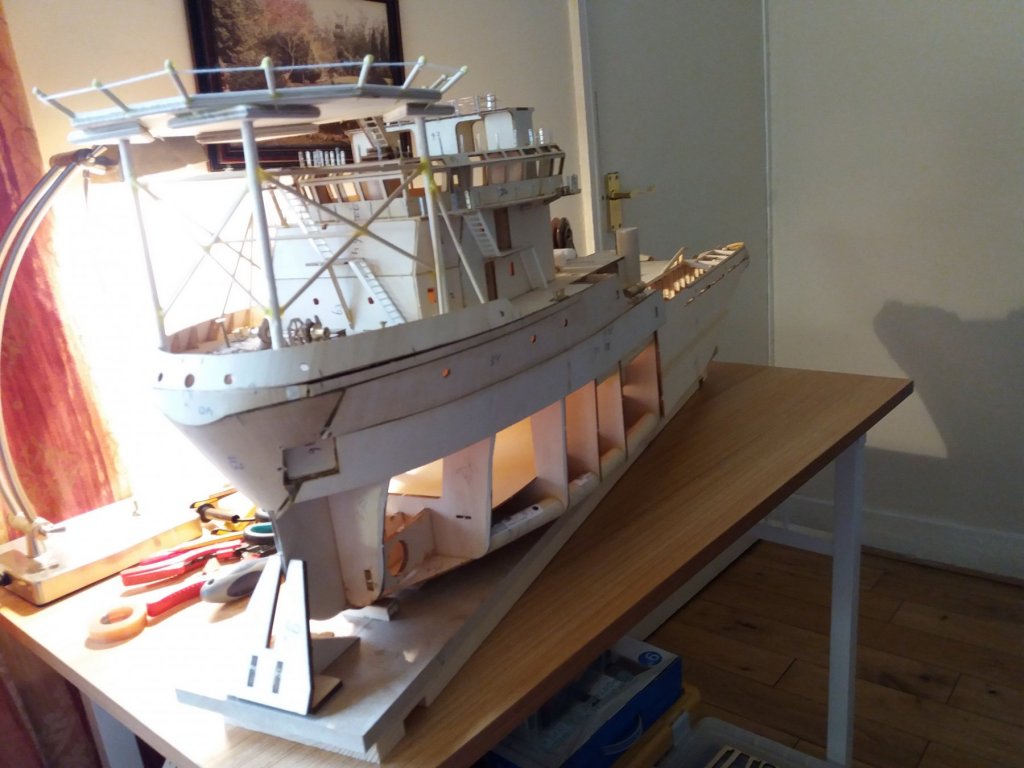

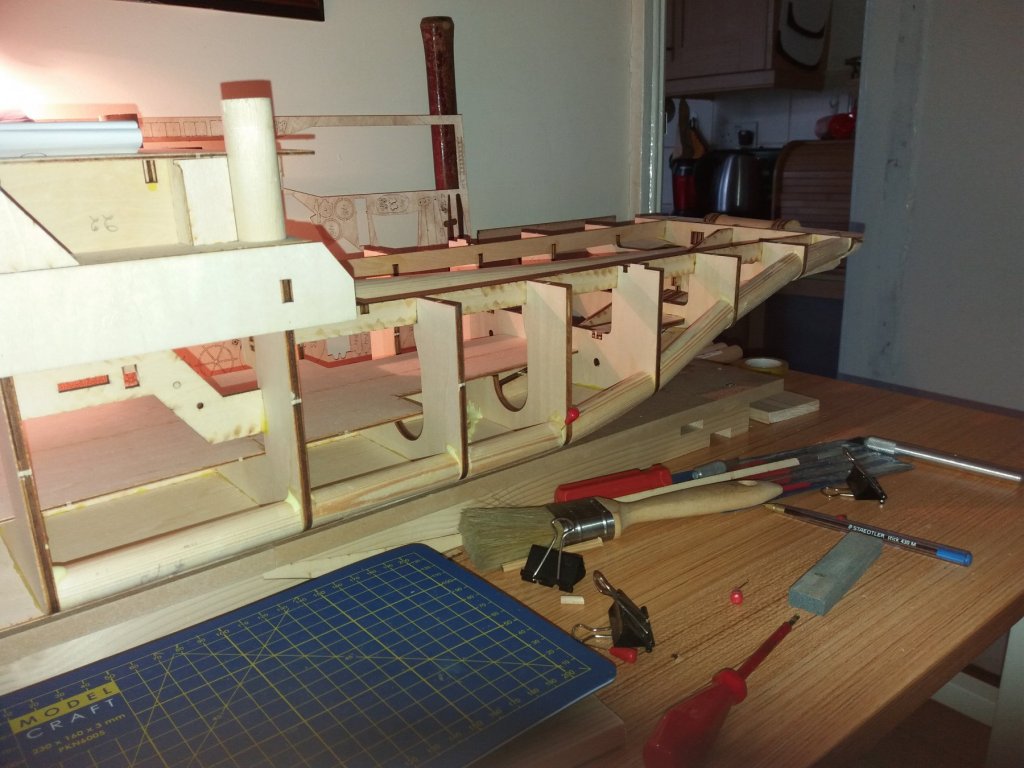

Yes I built it different then the original is doe as over the years working at sea as engineer and later as master on this kind of tugs I do have enough experience to made it in a way that I think it should be done.

Nevertheless, this is my interpretation of a sea going tug and also these days in the Offshore working environment to assist where possible.

At my age and been there long enough I made again my life work as hobby and with all respect, billing boats are great but you can make them stronger when you later want to use them so you will see that I have made supports to pick up the force and moments having a different kind of propulsion.

Also seen some of the buildings as RC in the water they are not that stable so I made a keel under her and will make also "Kim keels" having her more quiet in the water during sailing.

Yes I made also a helideck in the front as that what it's required giving service to the Offshore or any other project she may be involved in.

It does not going fast but in a regular tempo as what you have said yourself, you have to think carefully what you doing during this built, perfect you cannot get it but will try to come as close possible.

Sure afterwards will make the additional extra's to her like lighting, winches, towing pins, smoking exhaust, helideck lighting, working fire equipment and all what is on the market.

By the end of the day it will be a realistic built with all the futures you can think off and as again, I was born on the water 71 years ago and still love it to get involved with ships, call it a passion.

I will post pics during the development here and if comments, you welcome to give your input.

Thanks Steven and take care there "down under".

- brentt, Louie da fly, Cabbie and 1 other

-

4

4

-

Right, being a bit slow this time as last my HD from laptop included most of the data so been busy to get this sorted out and after having a new HD mounted, now have to download all what I had before.

Some of the data also from the Boka Alpine is last but did manage to retrieve some of it.

Now then, did some work on the building but is still on the slip making little progress to the hull, bow and deck.

The most difficult part was the mast, what shape, where to place it, as did not like the original one. Found a solution and that is what it will be, need some work to it like lights, radars etc, but that will be done later.

Already did use filler on the bow and other parts as still waiting for Cornwall to come with an solution for the 2 x Schottel's in the back side as previous ones where to high above it as only have less then 25 mm but it will be sorted out with 2 x belt on each one, 1 for steering 360 degrees and another for the propulsion.

Anyway, even the working space on deck is done with planking, my God what a work is that each plank cutting and glue.

Cranes will be ordered and also the buckle crane on aft deck will be done.

Railing works will be done by fixed ones and just bend / cut them where ever thy need to be.

Helideck will be illuminated but all lights will be done afterwards when all rest is finalised.

Still can take off most of it for later painting / lighting / epoxy etc.

Still have some up to date pictures here and hope you enjoy them.

Till next time with this building.

nb. some pics of the layout mast and what will be the Azimut Schottels, only mine will have long belts both sides as only have limited space above ca 22 mm. Cornwall UK is making them and waiting for arriving here. Also the helideck will be illuminated as pic show and after with epoxy made smooth.

need to get my image together to change mast

need to get my image together to change mast

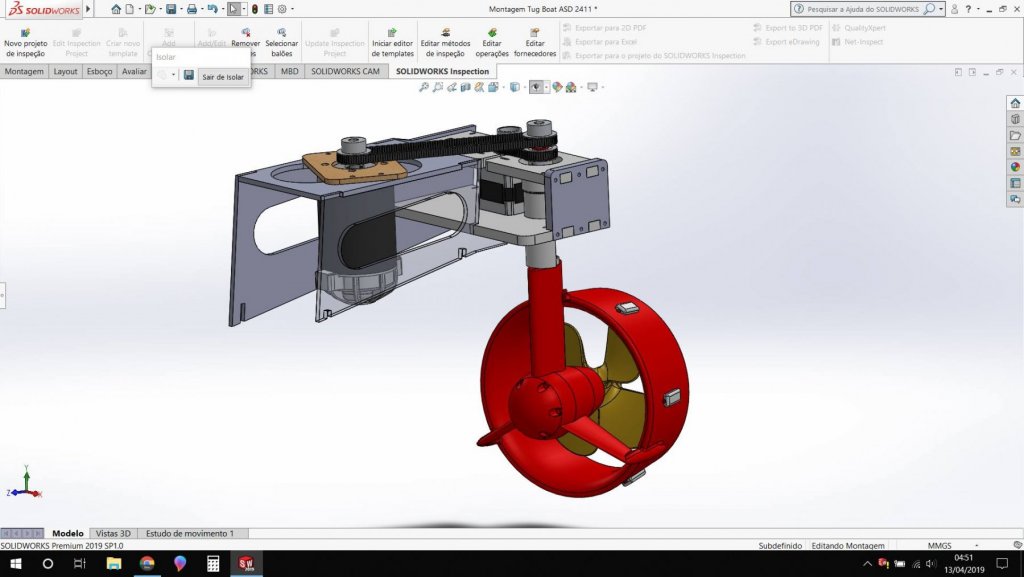

Principe of the Schottels working and those should turn 360 degrees so propulsion goes only 1 way, to go astern you have to turn the Schottel 180 degrees so to speak (as in reality it works)

I will make later similar lighting on the helideck

- gieb8688, GrandpaPhil, Cabbie and 5 others

-

8

8

-

Right, being a bit slow this time as last my HD from laptop included most of the data so been busy to get this sorted out and after having a new HD mounted, now have to download all what I had before.

Some of the data also from the Boka Alpine is last but did manage to retrieve some of it.

Now then, did some work on the building but is still on the slip making little progress to the hull, bow and deck.

The most difficult part was the mast, what shape, where to place it, as did not like the original one. Found a solution and that is what it will be, need some work to it like lights, radars etc, but that will be done later.

Already did use filler on the bow and other parts as still waiting for Cornwall to come with an solution for the 2 x Schottel's in the back side as previous ones where to high above it as only have less then 25 mm but it will be sorted out with 2 x belt on each one, 1 for steering 360 degrees and another for the propulsion.

Anyway, even the working space on deck is done with planking, my God what a work is that each plank cutting and glue.

Cranes will be ordered and also the buckle crane on aft deck will be done.

Railing works will be done by fixed ones and just bend / cut them where ever thy need to be.

Helideck will be illuminated but all lights will be done afterwards when all rest is finalised.

Still can take off most of it for later painting / lighting / epoxy etc.

Still have some up to date pictures here and hope you enjoy them.

Till next time with this building.

going further with making the re-enforcement in the tug as started before. I was still able to take of the complete superstructure incl the deck what now can see is an advantage as have works to do underneath.

make the life rafts also both sides and you see the re-enforcement all the way around

Also the top having this re-enforcement built in

Slowly but getting there, waiting for the bow trust

stb side re-enforcement also nearly done

Just a view how it looks like and still on the slip

Just a view how it looks like and still on the slip

first filler used without sanding until that time

aft deck done with all the planking!

aft deck done with all the planking!

Just a nice view of the tug

Hahaha, night on board but still working on it

- Sea Hoss, GrandpaPhil, brentt and 6 others

-

9

9

-

Wow, so far so good. Came far my dear.

Sanding is not so difficult, take care not to much as you cannot built it up again.

Take a side plank and keep it against the frames on the outside and then you will see how much you have to take, is an easy job to be honest, just get used to it.

Anyway, wish you luck and you come that far, the rest will also be great.

One at the time and specially, give it time to dry!!

Good luck and we talk again.

Peter

- popeye the sailor, src and SHIPSCAT

-

3

3

-

Jo, thanks for follow this built, the total length is ca 1 Mtr, she will be ca 25 cm stb to ps, and the height is around 48 cm (top mast - bottom).

How heavy she will be cannot tell you as no applicants built in yet and also no ballast so all depends.

Hope she will not sunk to deep into the water but that's to find out afterwards in the bath!!

Will take some time to have her all done with all I want to built in her with lights, propulsion, winch, batteries etc etc.

Those are the heavy parts, the rest is hardly giving weight to her.

But as time goes by I keep you all posted.

Till next time, take care and hope your built will be finalised too.

-

- SHIPSCAT, BenF89, GrandpaPhil and 3 others

-

6

6

-

Not to think that I stopped here, nope just goes a bit slower then I thought as needs to alter the building.

I'm the first one that is building this tug with Azimuth's without stern truster and also NO rudders.

The Azimuth's can turn 360 degrees so no need for them, also the stern truster is closed and will not be used.

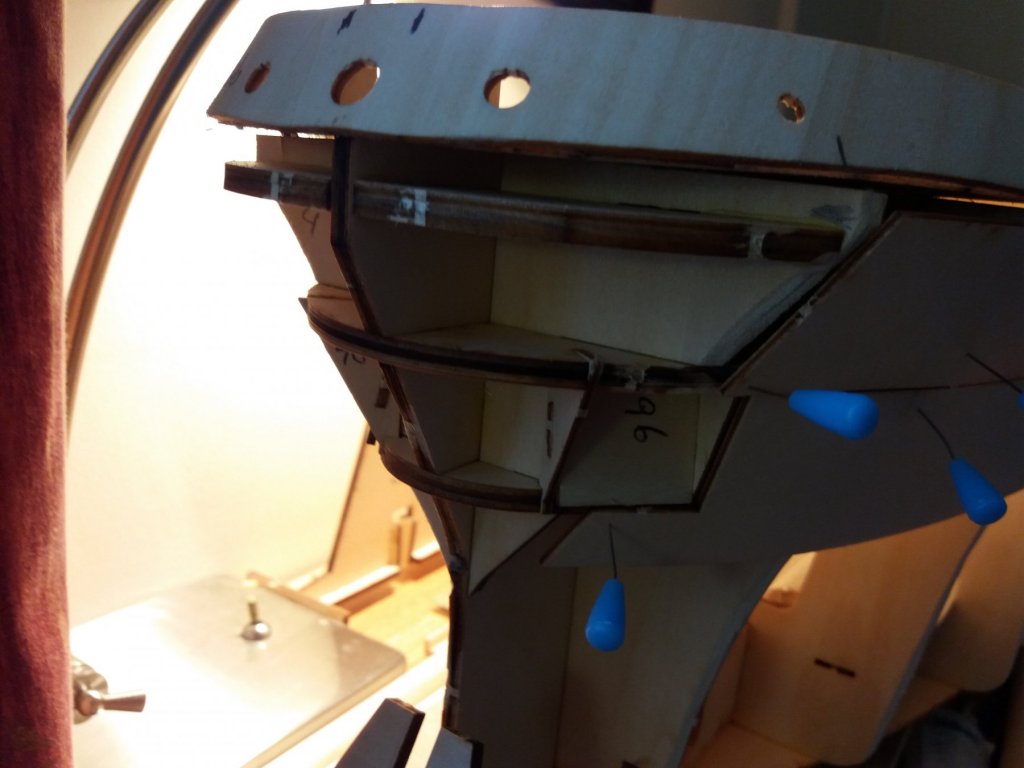

Now here comes the tricky part as I have to do that a bit different then the "NORMAL" propulsion and need some more supports to have the strength into the building. Also due to the Azimuth's I altered the keel and raised her 12 mm to have more space underneath her and there where the Azimuth's are coming.

I made side (bottom) supports on both sides, also in the middle from the last frame until the midships frame a support.

Personally, Billund Ships are ok but if you alter the propulsion I think that this building is to weak for that and made those supports.

You can see on the pictures below that I struggle a bit with the stern top side small plates to have this in 3 corners bent and also the aft outside corner.

Managed it with help of hot water and steam to pre-bent them and stick it to the building, leave them for a day before finally glue them in place.

Presently the aft part is 90 % finished but still in a fashion that I can take of the top deck aft to enable me afterwards bringing in on the bottom the epoxy making her watertight, secondly in the event that I have to alter the stern in way of the Azimuth on top I can more easy alter the deck.

So far so good and now will start further with front part, doing a little more to the frames to guide the shell plates more and then the bow itself to be bent and glue to the frames with the anchor pockets.

Planning is to have the bow trust in before finalise the bow but could be that I change that plan depends on the status of the shell plates who have to be in place and glued.

I made some plates under the building there where the Azimuth's are coming to have a good strong support.

Also I still use the slip-way as due to the raising of the keel I managed to have her on the "BLOCKS"

As I don't need anymore the original propulsion + rudders, I did give it away to a friend in Holland that is presently making the same building but 10 years old and rebuilt her and was in need of those parts.

Wish me luck to start with the bow and shell plates!

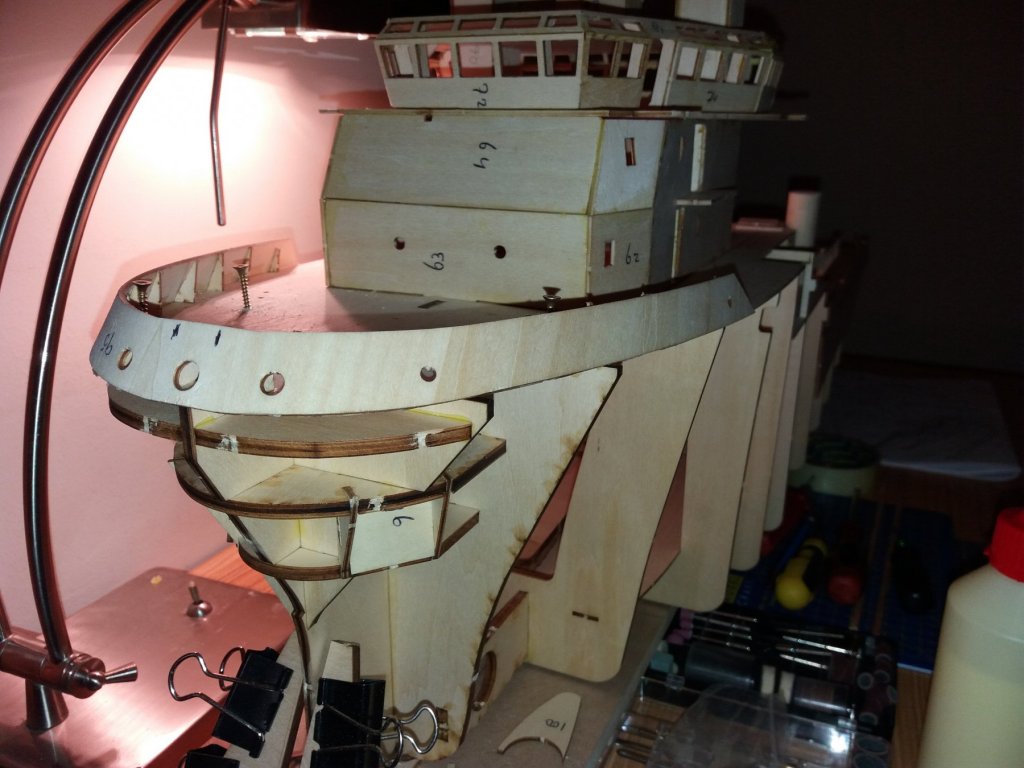

Been some time now but slowly we are coming there.

Had some other work to do at home so the building was second in line so to speak..

Anyway today we have the 12 April and done with the helideck and her supports for that, thought that material I ordered did arrive but apparently they are still on their way to me.

Yes I did make a helideck, this days it is a MUST to have one if your vessel want to keep up with competitors so looked around to find some ideas and the result is not to bad if I may say so.

Also on the forward part bow all fittings done and the winches behind the accommodation as well the 2 x boilers ER put in place , the MOB fit and also the second fast rescue boat.

I ordered 2 x cranes to be mounted on the aft part as where the pillars are presently as well an Atlas crane on the aft deck below.

The 2 x tucker winches as all supports aft deck done and in place.

As you may have noticed the supports ps and stb side are done below bottom are glue inside so we have more strength into the vessel itself.

As still in discussion with Cornwall for the Azimuth delivery we came to an option to have an el. motor for the 360 degrees continue running and no stop and go back, did that as with real Schottel you can do that so why not in a model? You only have to use an el motor that runs with a slow movement (or gearbox, reduction) in order to have the steering movements by means of belt and the el motor (vertical mounted) to be done. Means having inside 4 x belts, 2 for the propulsion and 2 x for the independent steering.

So in the end there will be not so much el motors or other parts like an original and have due to that more space underneath the deck.

Having said that the height under decks iwo the Azimuth was only 24 mm so not much space left for the 2 wheels mounted on top of the Azimuth where as the belts are running from to the el motors for the previous named movements.

Still the weather here in the UK is not so good to work outside, still have zero degrees at night so have to wait for the shell/hull plates and bow until this goes better.

Anyway, did work enough in the mean time and still can manage to take off all parts such as complete aft part and bridge / accommodation as well to make it more easy for painting and putting epoxy afterwards.

Also it is more practical when I'm building in the lights and other parts as under deck (midships) I want to have a working towing winch so made already a platform where as this is mounted later on.

Enjoy the pics and if having questions willing to answer them, until then have a great one.

As told before, the aft part was glued together as a section but still could be removed from the tug until such time I was finished works below deck

I only had 24 mm under the deck plate but as found out after info I got from the maker this would be enough.

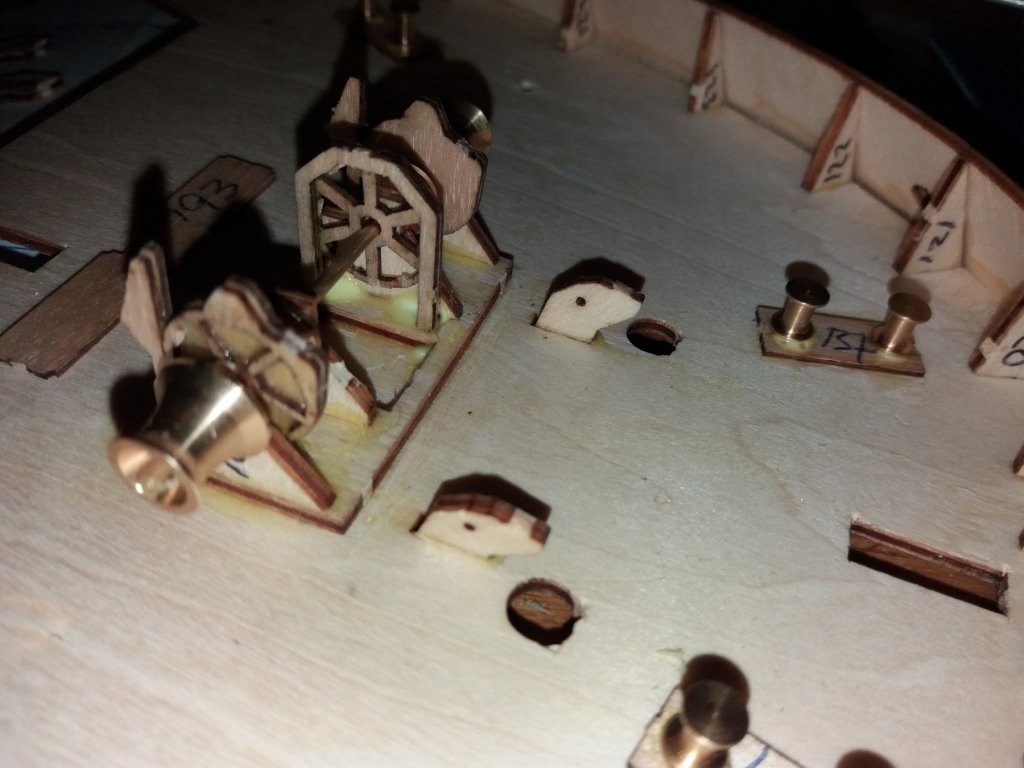

Made all what was needed on the fore castle like anchor winch and bollards

Looking good after have them done

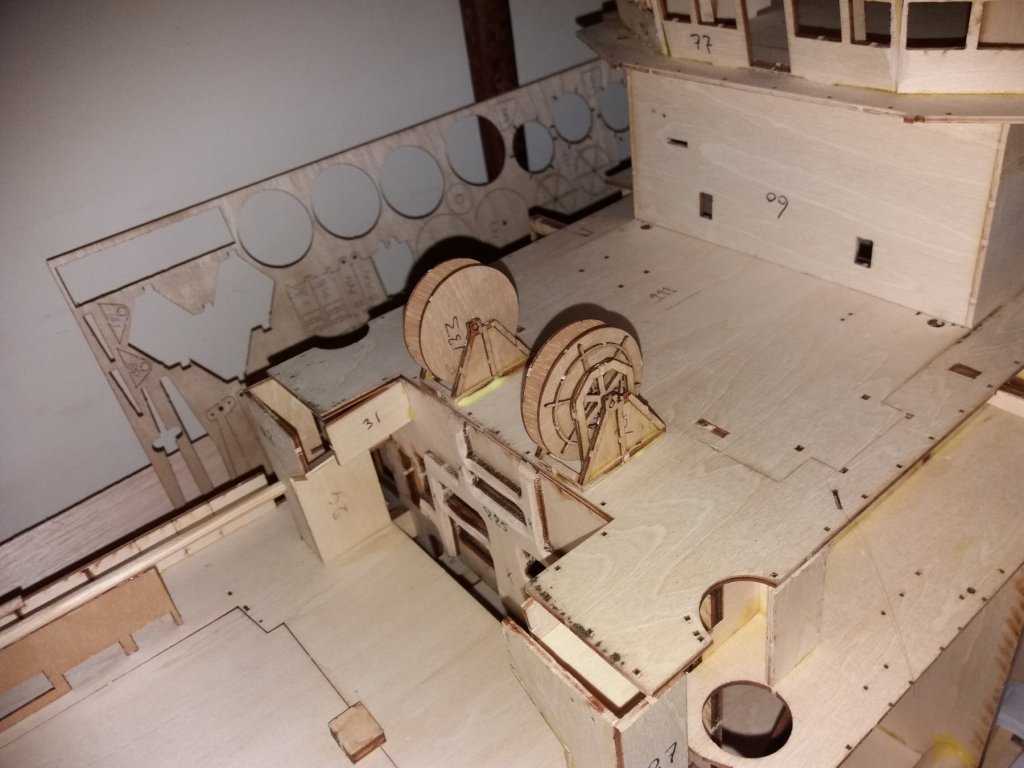

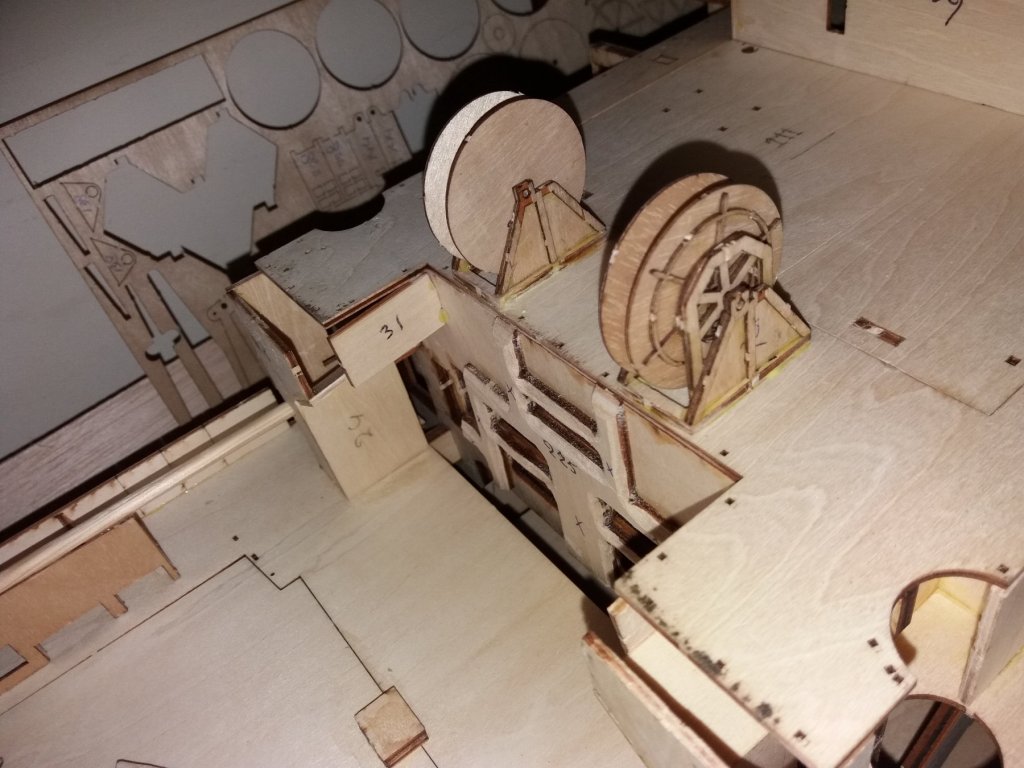

Also behing the superstructure where the spare drums are mounted done

Was not an easy job but managed it. Still they all can turn too.

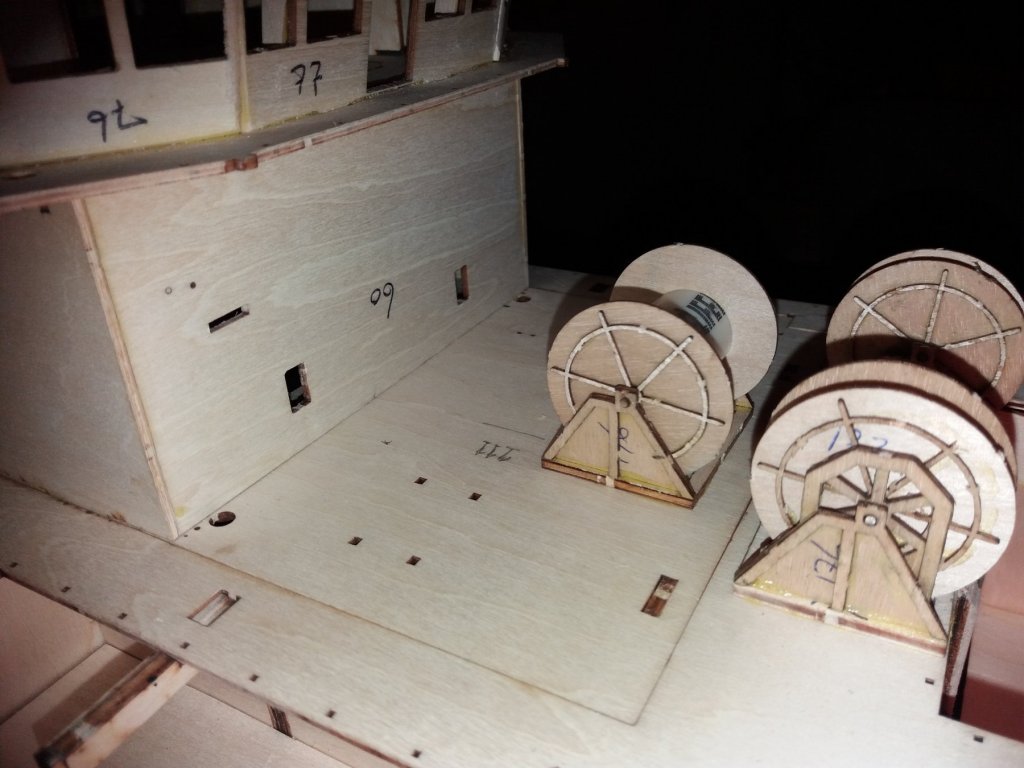

Both spare drums mounted / glued to the superstructure deck aft

Also the heavy big drum for the spare towing wire done and glued, can also turn too.

All 3 drums together, now still need to turn around the plate 60 as not done until now.

the 2 small tucker winches for the aft deck, turning too.

Made a mast but not content with it so this will be changed afterwards

Getting there but need much more. I also changed the no 60 plate from the superstructure.

Boxes placed on ps deck

Here I start to make a helideck for the tug

not looking bad and need some more works

not looking bad and need some more works

now how to go there on the helideck!

now how to go there on the helideck!

made the stair way to the helideck but is to complicated so will change afterwards

Not to bad the direct uptake from monkey island to helideck

Safety net to be made and also start with railings

complete supports for the helideck

other view supports helideck

- BenF89, SHIPSCAT, GrandpaPhil and 4 others

-

7

7

-

Not to think that I stopped here, nope just goes a bit slower then I thought as needs to alter the building.

I'm the first one that is building this tug with Azimuth's without stern truster and also NO rudders.

The Azimuth's can turn 360 degrees so no need for them, also the stern truster is closed and will not be used.

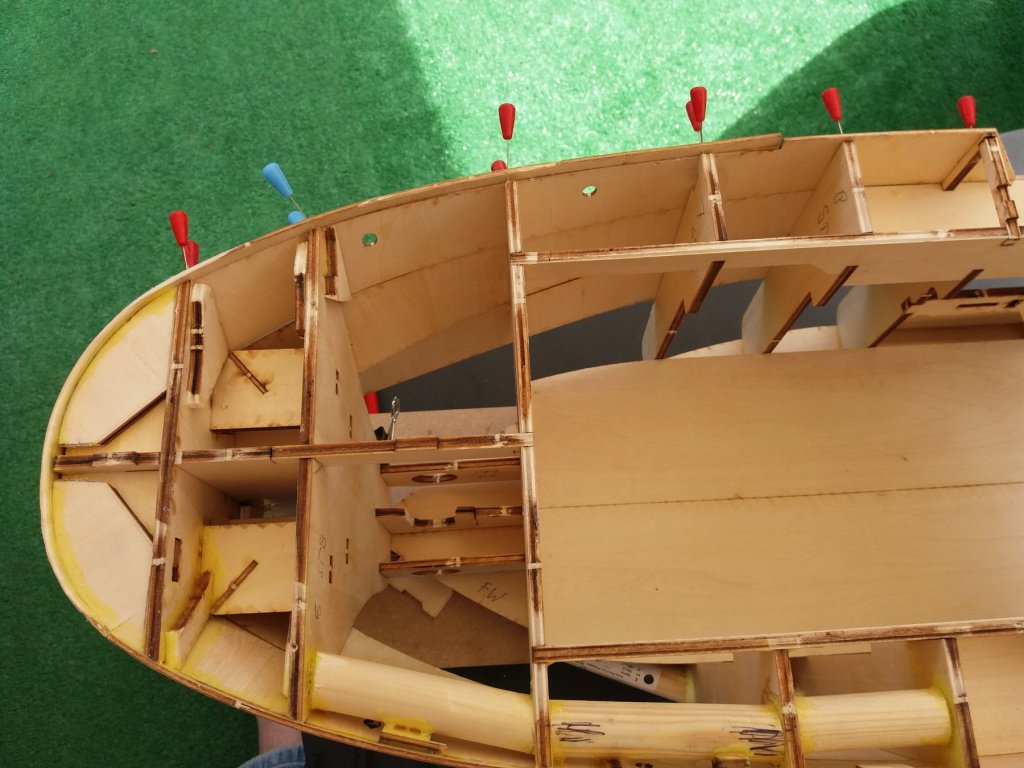

Now here comes the tricky part as I have to do that a bit different then the "NORMAL" propulsion and need some more supports to have the strength into the building. Also due to the Azimuth's I altered the keel and raised her 12 mm to have more space underneath her and there where the Azimuth's are coming.

I made side (bottom) supports on both sides, also in the middle from the last frame until the midships frame a support.

Personally, Billund Ships are ok but if you alter the propulsion I think that this building is to weak for that and made those supports.

You can see on the pictures below that I struggle a bit with the stern top side small plates to have this in 3 corners bent and also the aft outside corner.

Managed it with help of hot water and steam to pre-bent them and stick it to the building, leave them for a day before finally glue them in place.

Presently the aft part is 90 % finished but still in a fashion that I can take of the top deck aft to enable me afterwards bringing in on the bottom the epoxy making her watertight, secondly in the event that I have to alter the stern in way of the Azimuth on top I can more easy alter the deck.

So far so good and now will start further with front part, doing a little more to the frames to guide the shell plates more and then the bow itself to be bent and glue to the frames with the anchor pockets.

Planning is to have the bow trust in before finalise the bow but could be that I change that plan depends on the status of the shell plates who have to be in place and glued.

I made some plates under the building there where the Azimuth's are coming to have a good strong support.

Also I still use the slip-way as due to the raising of the keel I managed to have her on the "BLOCKS"

As I don't need anymore the original propulsion + rudders, I did give it away to a friend in Holland that is presently making the same building but 10 years old and rebuilt her and was in need of those parts.

Wish me luck to start with the bow and shell plates!

Closing up the holes for the tail shaft penetration as not going to be used, also made iwo Schottels the ground plates and you see the keel I raised having more clearance under the tug for the Schottels

Here you see the plates made for the Schottel penetration later as need more strength in the bottom

another view of the fixed penetration plates for the Schottels

Having built Billing boats in the past and noticed the weak points in their buildings making re-enforcement into the building as want more strength in the tug having a different propulsion.

Made the strength of the tug in the bottom and top from stern to bow.

starting the top of the aft deck

starting the top of the aft deck

Not looking to bad but need some sanding to be done to the top

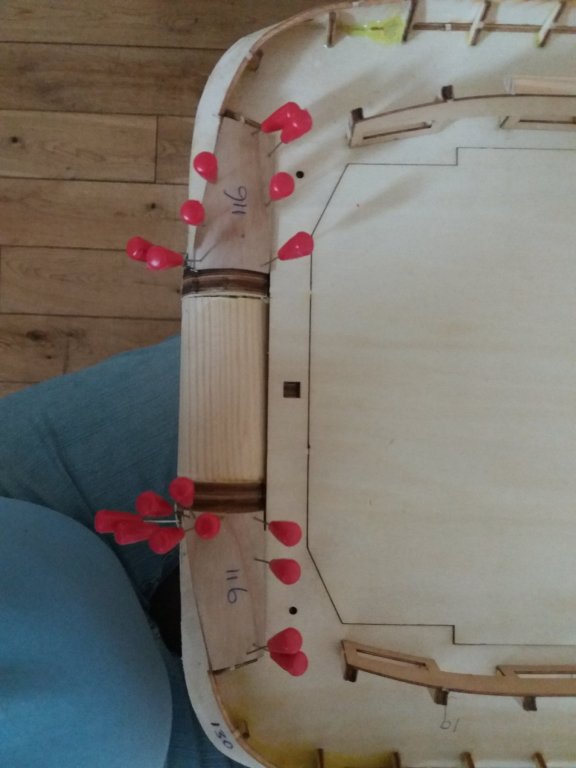

back side / stern the plates using hot water and afterwards model pins to have it all in place until dried after glue

Looks a bit funny but no other way to support those small plates with bending etc

stern roller temp mounted as want to alter this.

stern roller temp mounted as want to alter this.

prior fixed the penetration plates for the Schottels made some altering for the correct place of those penetration plates

starting making the strength in the tug

Secured the tug on the slip as it is 5 mm higher on the keel

mounting the hull plate iwo the anchor pocket

Have to shape the frames where the hull is touching to have the same angle

It's coming there, most parts now in place

forward view of the tug

Nothing much to say about this then parts are slowly coming to be in position, next step will be the hull.

those parts I did not need and give them away to a friend in the Netherlands that was making a restoration of same built and was in need of those parts.

-

Congrats with this building / project!! Seen a lot in my life but this is an exception and the works / effort to built this one is one of a kind!!

- Canute, popeye the sailor, mtaylor and 2 others

-

5

5

.thumb.jpg.01eb78ddd26fe9e56368b6bc83844e8c.jpg)

IL Leudo by SHIPSCAT (Jolene) - Mamoli - scale 1:34

in - Kit build logs for subjects built from 1851 - 1900

Posted

Dear Jo,

very clever solution found for the padlock!

Looks great and not to worry, you can always change something for the better as we all do with out building.

You did a great job my dear and can be proud of what came out of your hands.

Have a great day there down under,

Peter xxxxxxxxxxxxxx