mikegr

Members-

Posts

832 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikegr

-

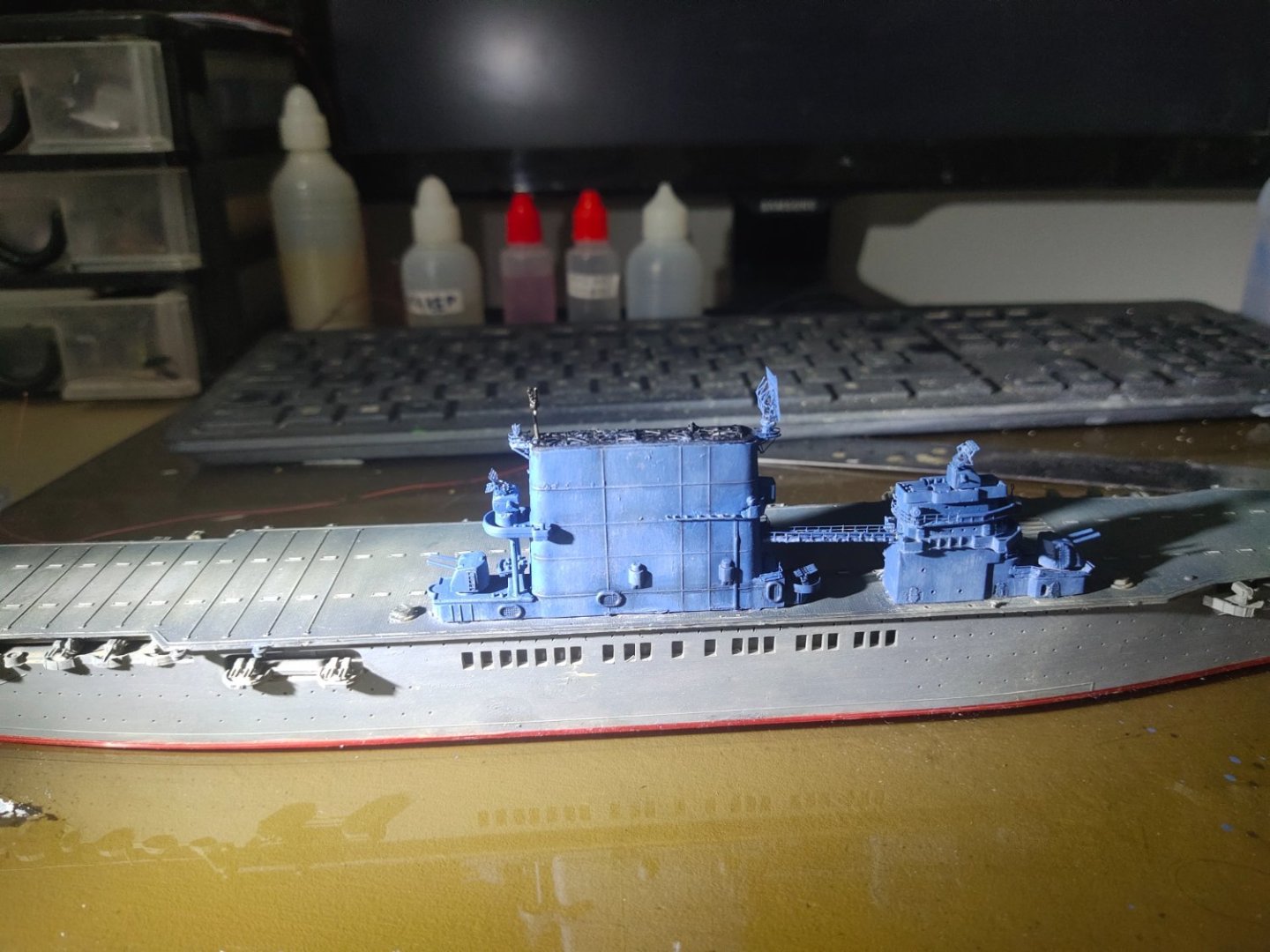

Time to fit the bridge and the big funny. First I paint them in Navy Blue like I will do with the hull later. Lighter shades applied for a color fade situation. Then dark washes applied during vertical and horizontal lines, rafts, etc. Last piece was the connecting bridge. Not a scratch built I'm proud of but it was a good exercise thought

-

Did some minor improvements, I printed the Oto Breda 76mm guns. The barrels were a product of scratch built using 0.4mm , 0,3 needles and 0.20mm wire brass

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

-

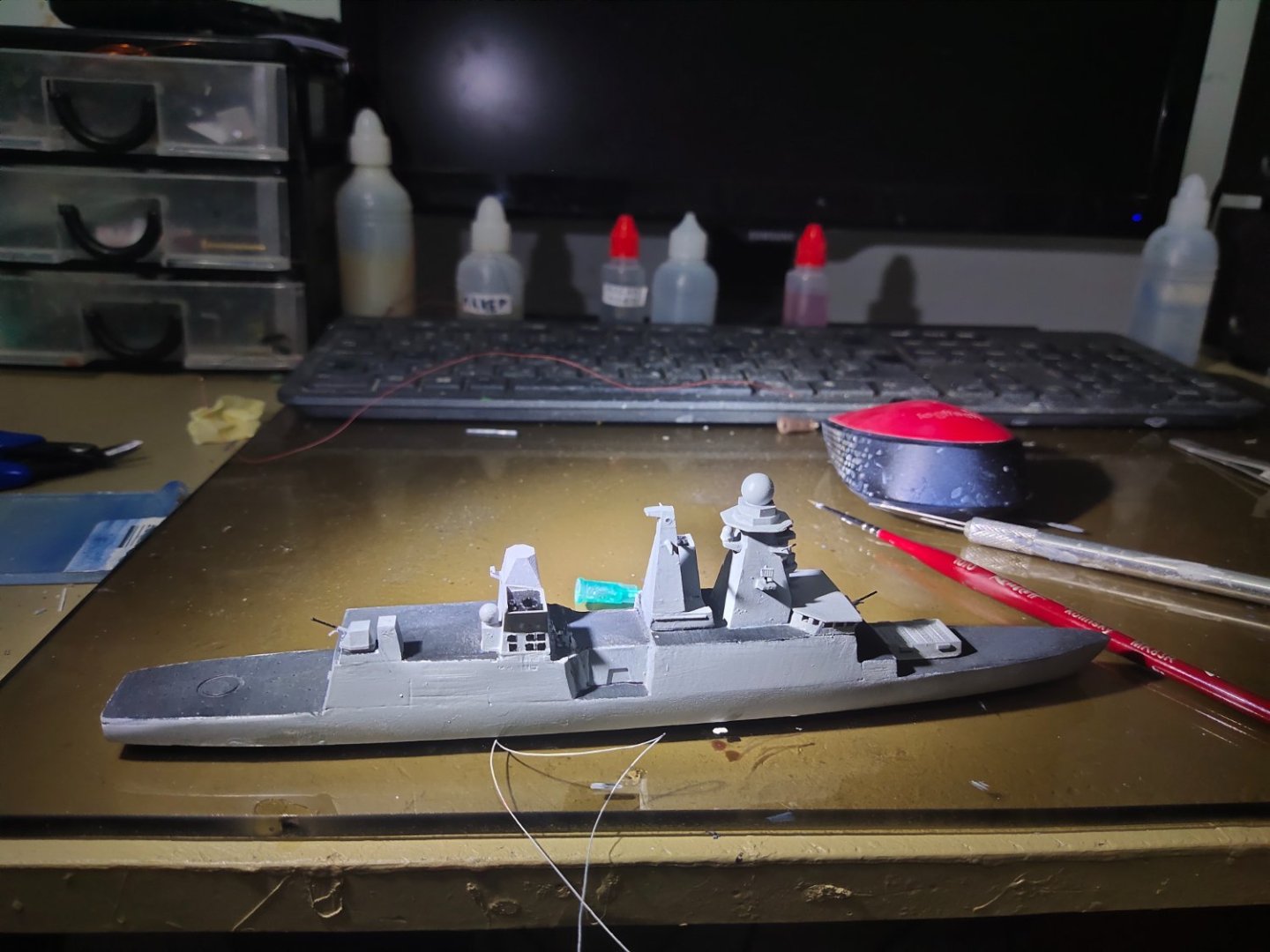

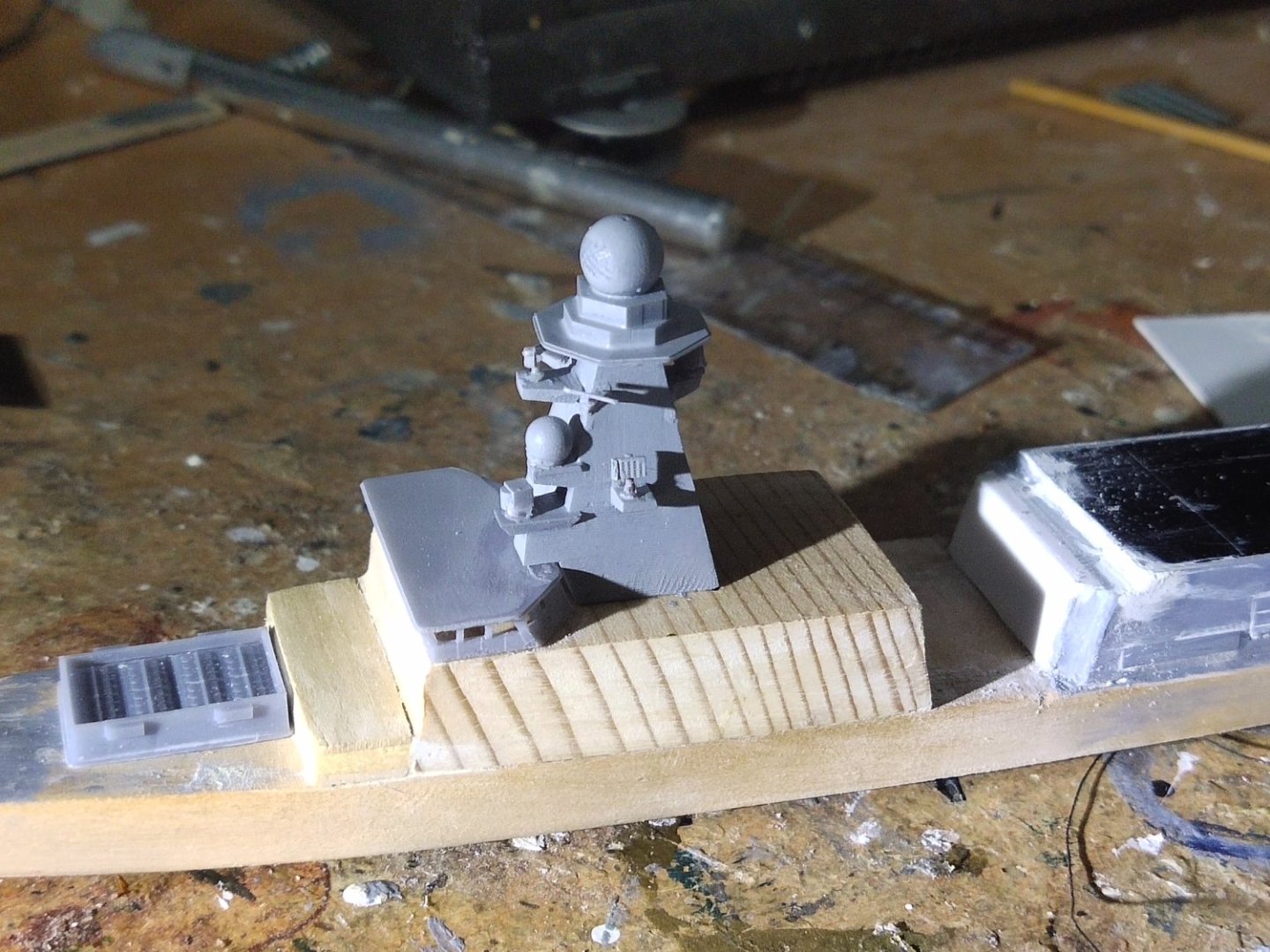

Last major piece in place except some putty on the joining point with the deck. It is the rear mack, (combo of mast and stack, very distinguishable feature in Knox class frigates). Time to put some teeth to the dragon while keep working on paintjob. Note the forward mast broken on top. Water washable resin is no where strong as resin used with moulds, I think polyurethane.

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

-

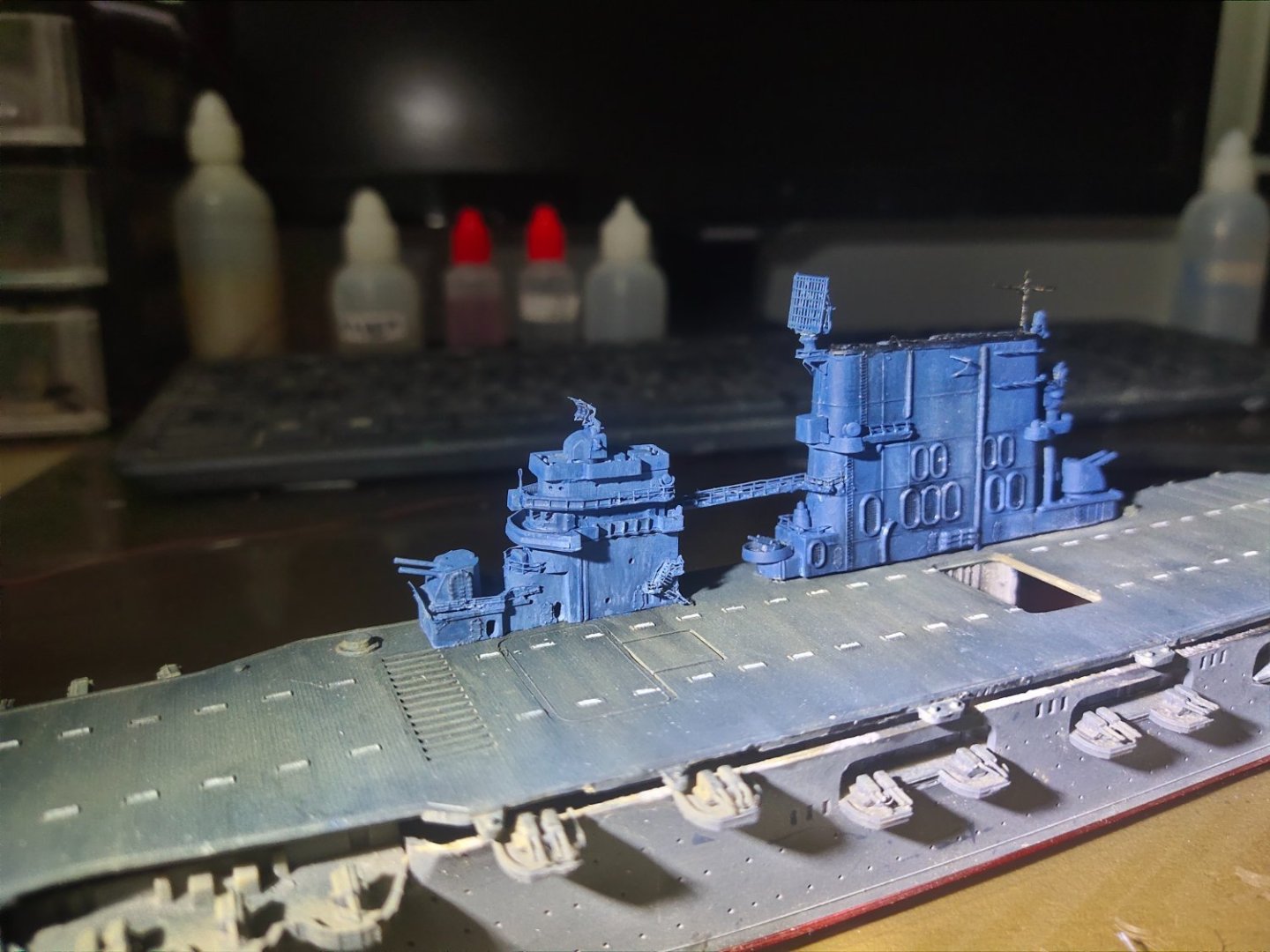

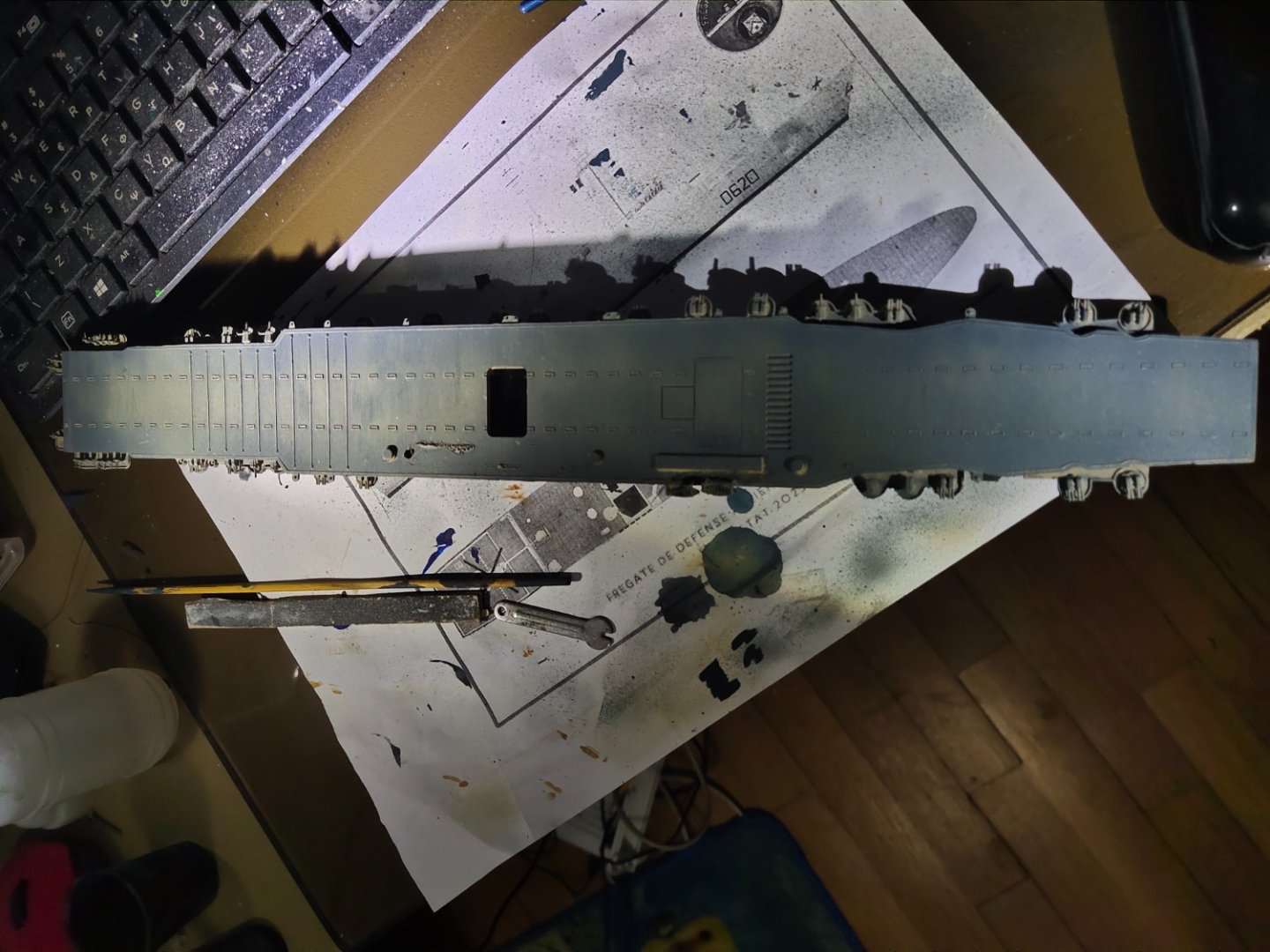

Time to weather the deck. I sprayed a light coat of tan color. After it dried, deck was given a coat of hairspray. Finally navy blue was applied. Using a sand paper folded on half, I scratched the deck horizontally, to give a color fade effect. Then I sprayed thinned tan color especially in the areas of the deck which is most heavily used by planes like the rear section, from arresting cables and below. Next phase is washing, oiling adding tyre marks etc

-

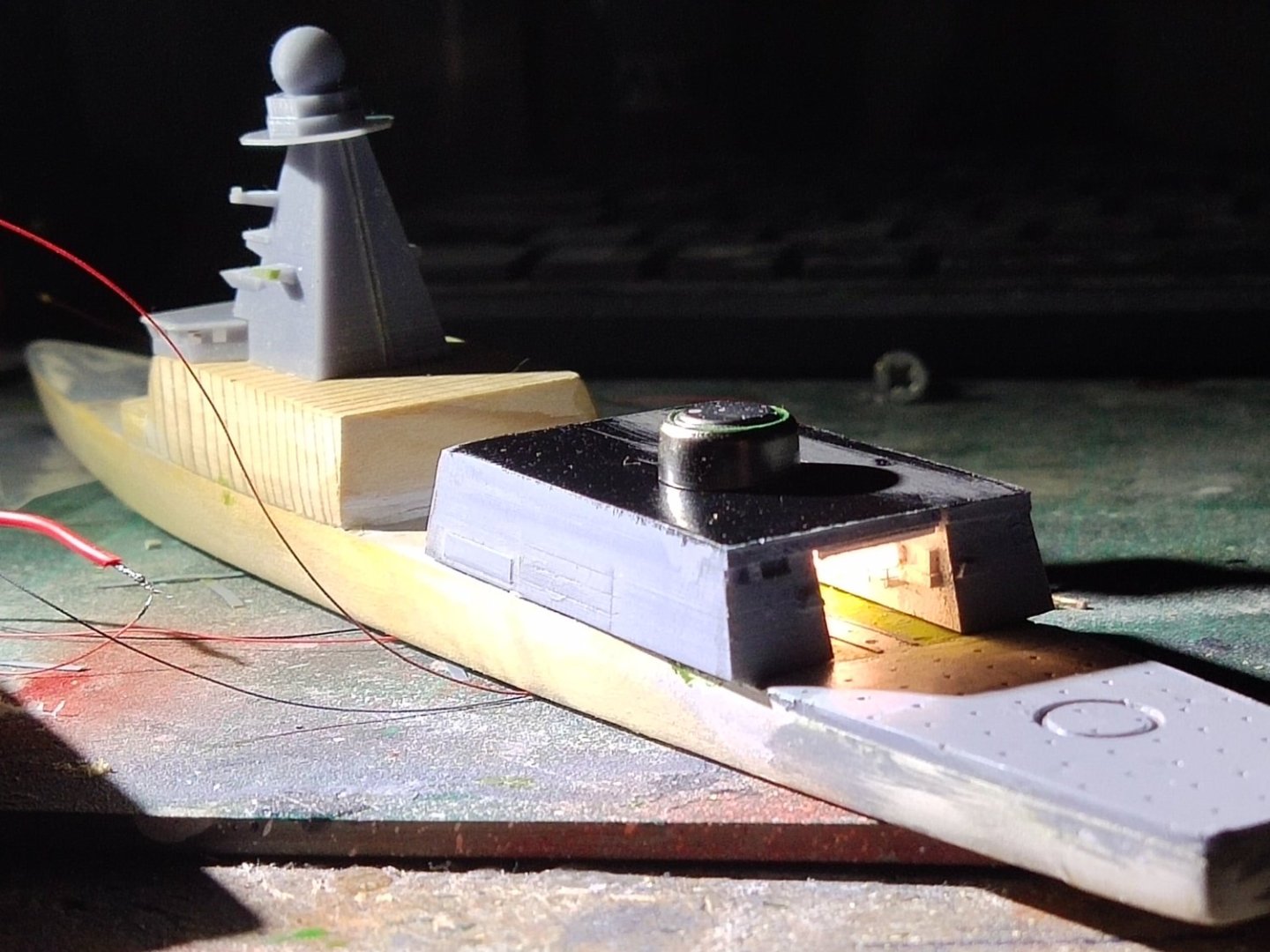

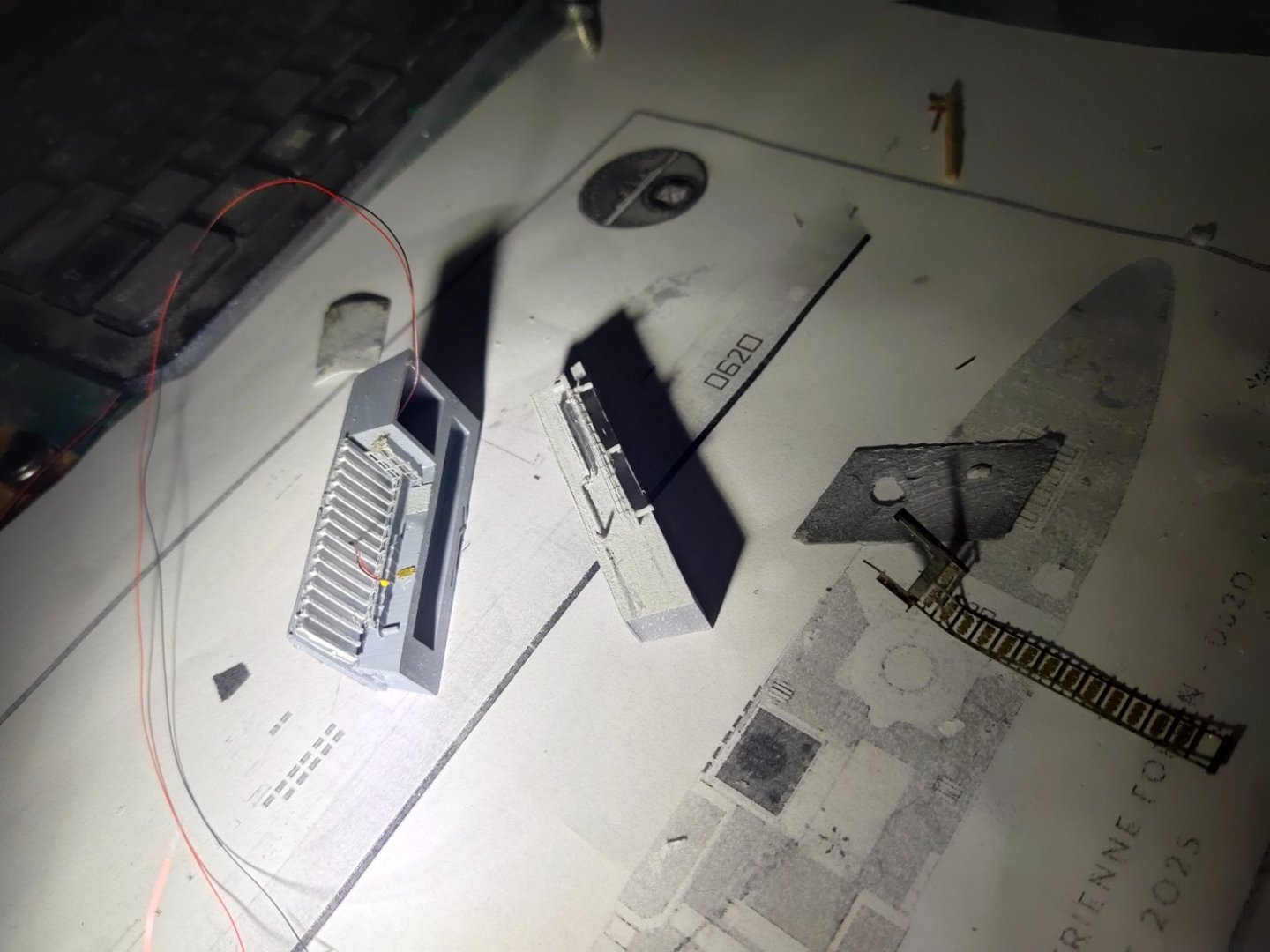

.Next part after gluing superstructure and main radar was the funnel along with the base and the secondary mast. I made it in 3 pieces and glued them together. Then I paint it before test fitting. Finally I scratch built the middle section. Only main pieces left are SMART radar and rear funnel.

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

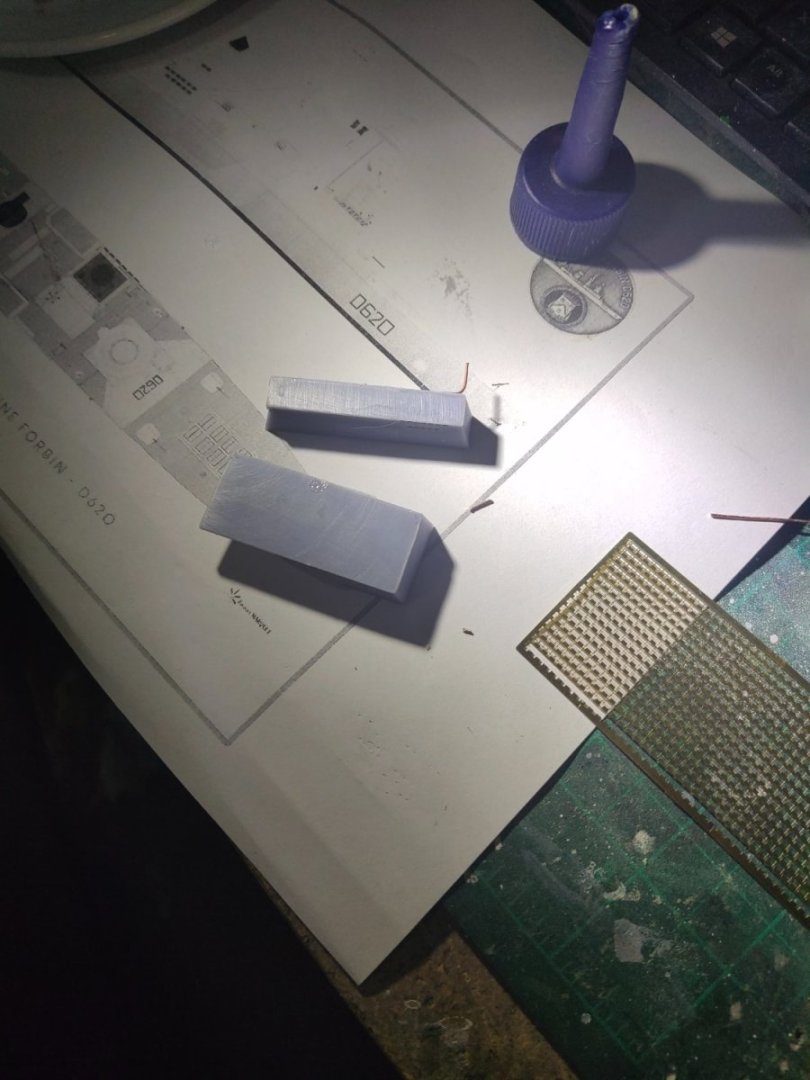

-

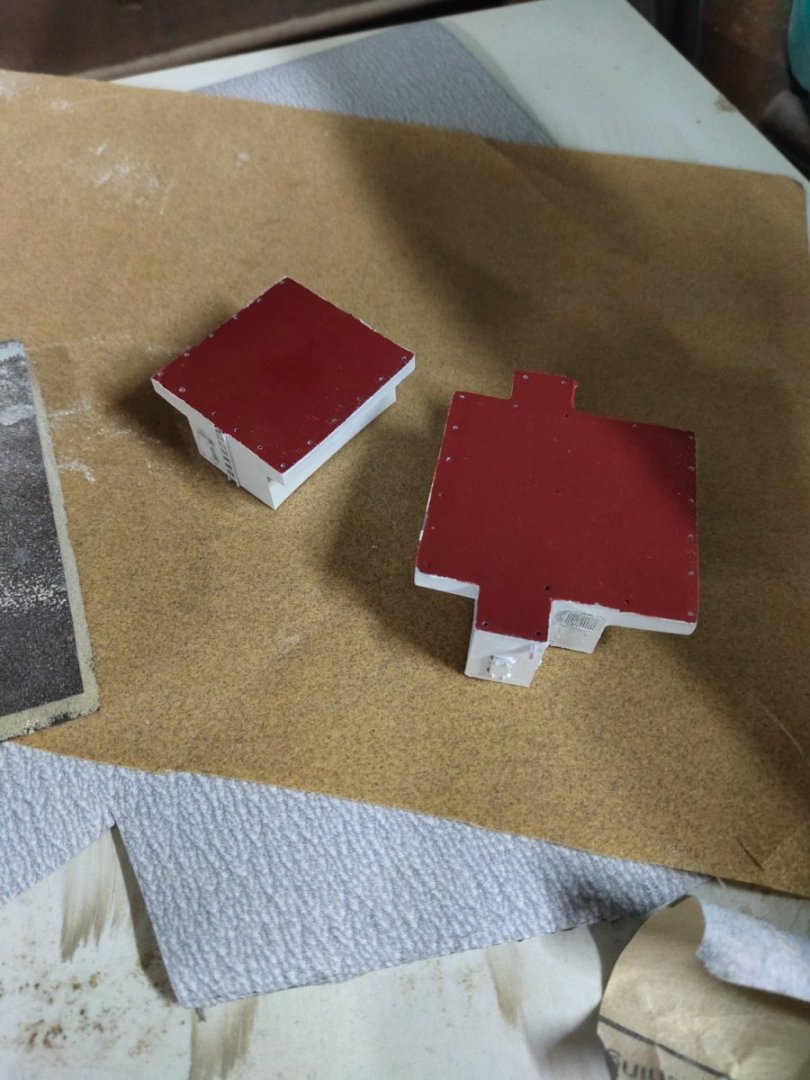

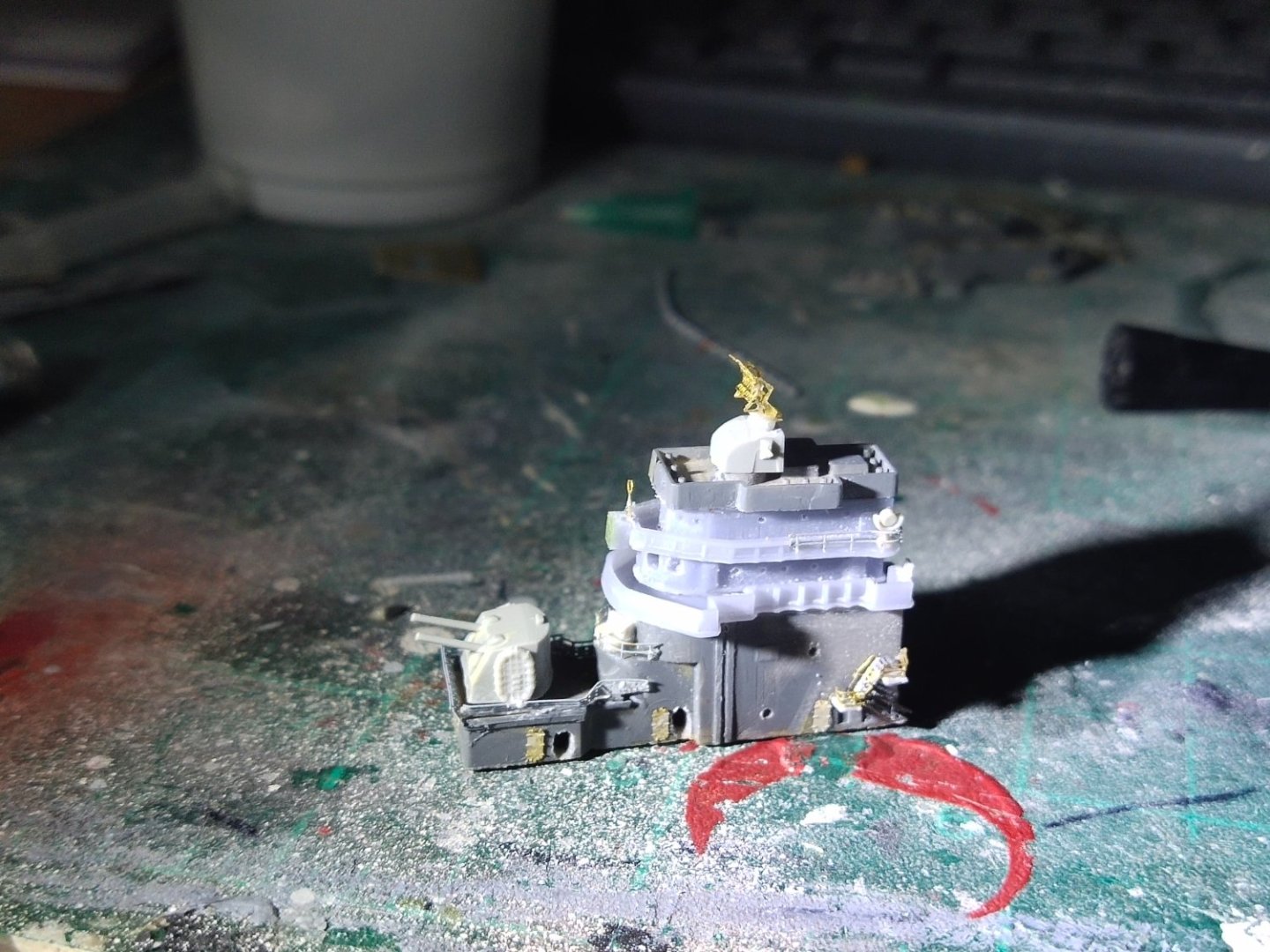

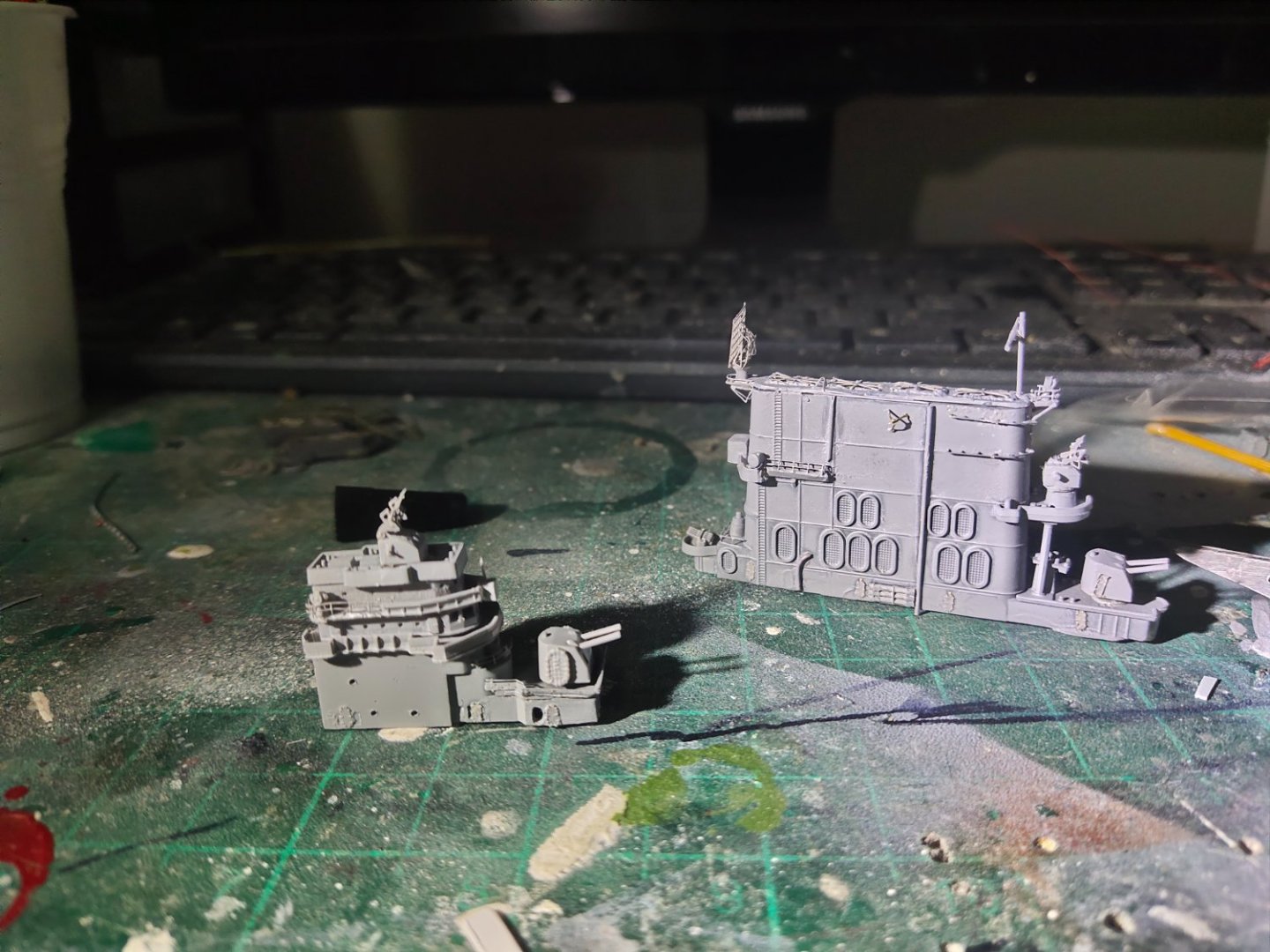

Time to make the bridge. The method I followed is a bit... interesting. In order to give a correct shape and add details I separated the parts, though some were glued together tightly and were simply cut with a rotary tool. Base and top part were re used with added details, railing , ladders, portholes, guns and fire directors. Middle parts were reprinted and assembled all together. I coat them with primer and added some last detail on funnel. Now I only need to make the mast and add the connecting bridge between funnel and superstructure after their installation on deck.

-

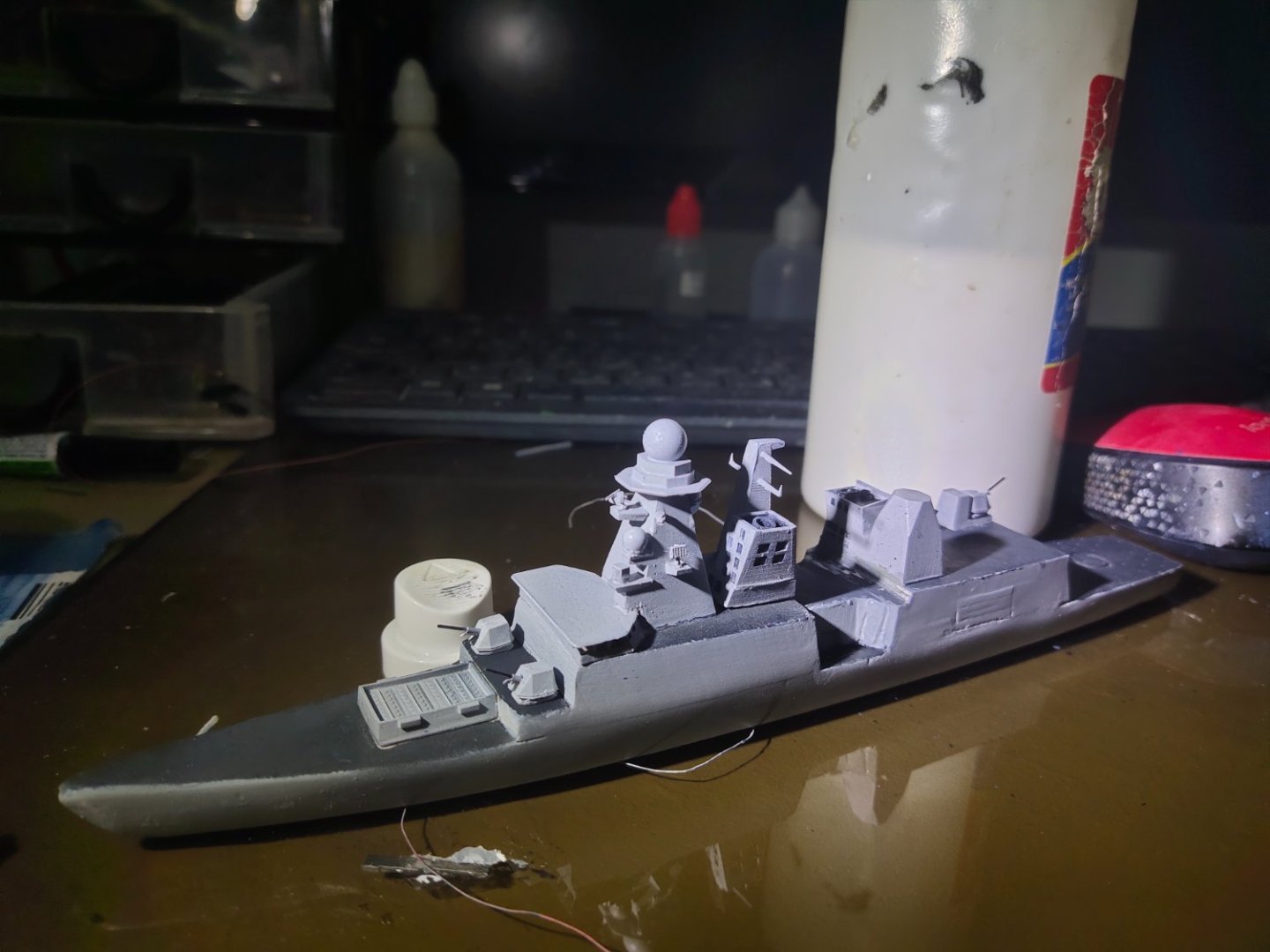

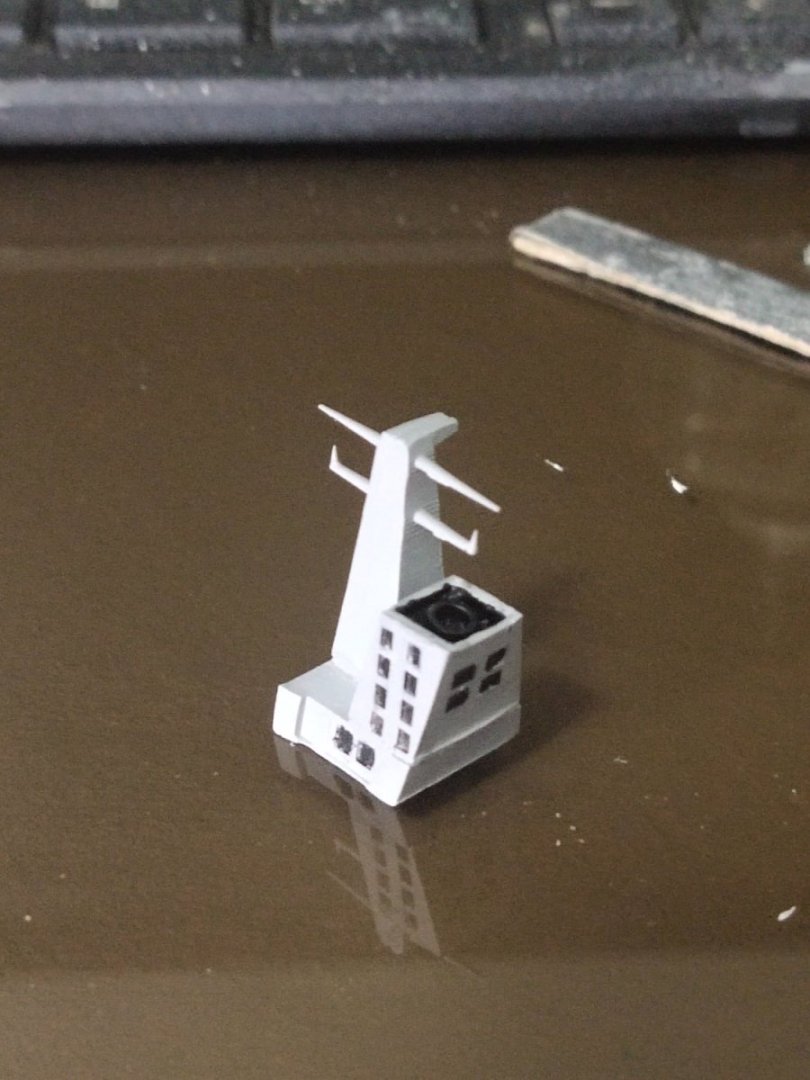

Back to work after recovery from some neck pain The mast is ready. It was printed in two halves. Then I added details by hand. Not easy to mess with brittle resin tiny parts. But there supposed to be some fun right? Besides the final outcome was satisfying so worth the effort. Next part was the vertical launcher in front. With such details only a print was possible and it came as expected. One of the few parts that there was no need for a reprint.

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

-

Cold weather caused me some back neck pain which kept me out of work for some days. Anyway I managed to add some details. Funnel top in reality is actually curved towards sides not straight as in the model. I decided to work on it as it is. Added radar, mast, new platform with railings. Replaced Mk37 director with PE parts, new 5" and 0.5" guns. Added piping using brass wire and added doors. Gave it a coat of primer. However I de

-

Cap San Diego by mikegr - 1/160

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

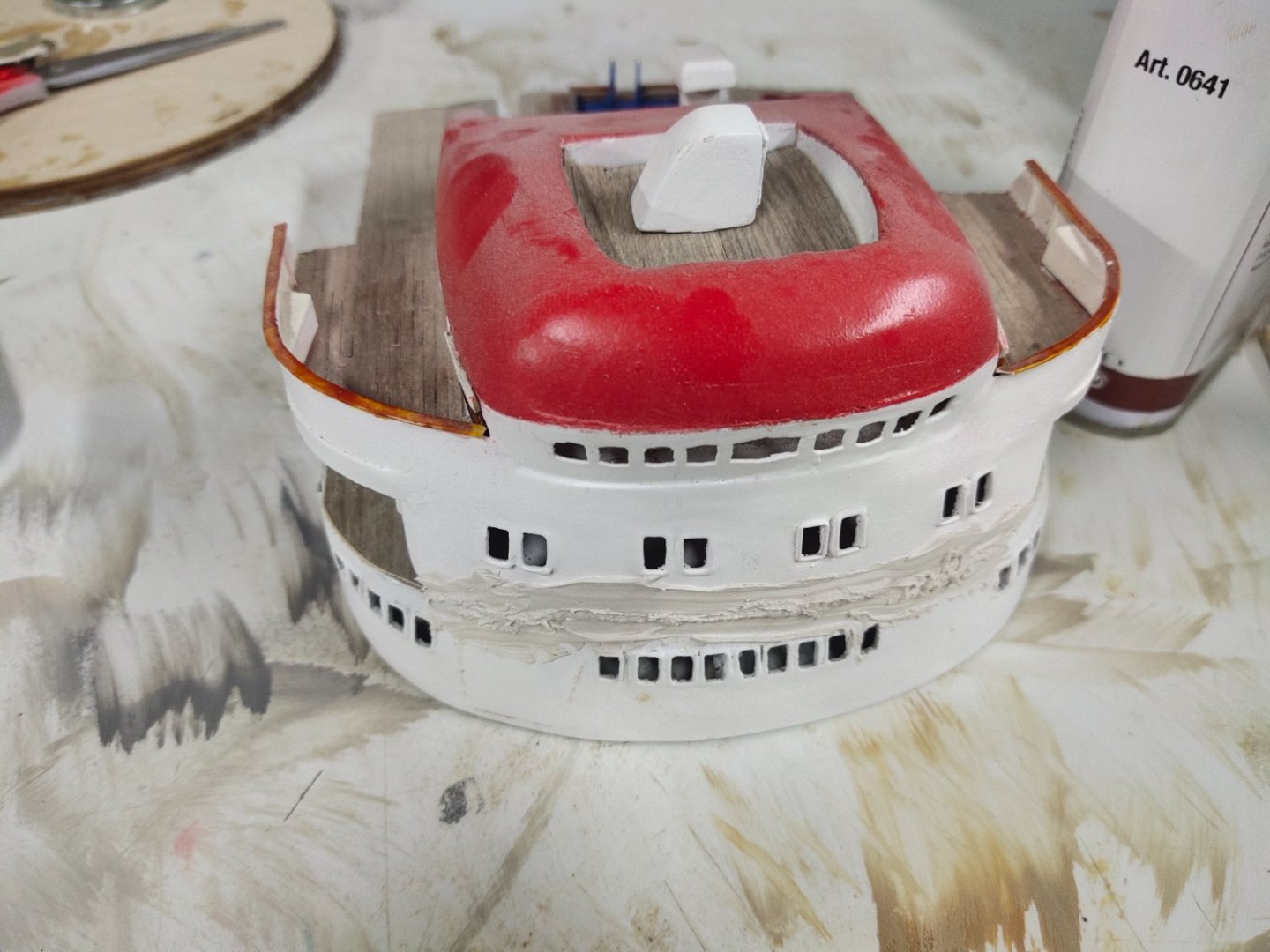

Like in the rear section I printed the crane bases-rooms for the front part. The cargo holds are already in place. I took the long time abandoned superstructure pieces and joined them together with wood glue and body car filler on the front side. After sanding it become smooth, needs to br painted. All parts were placed on deck for final fitting and evaluation. -

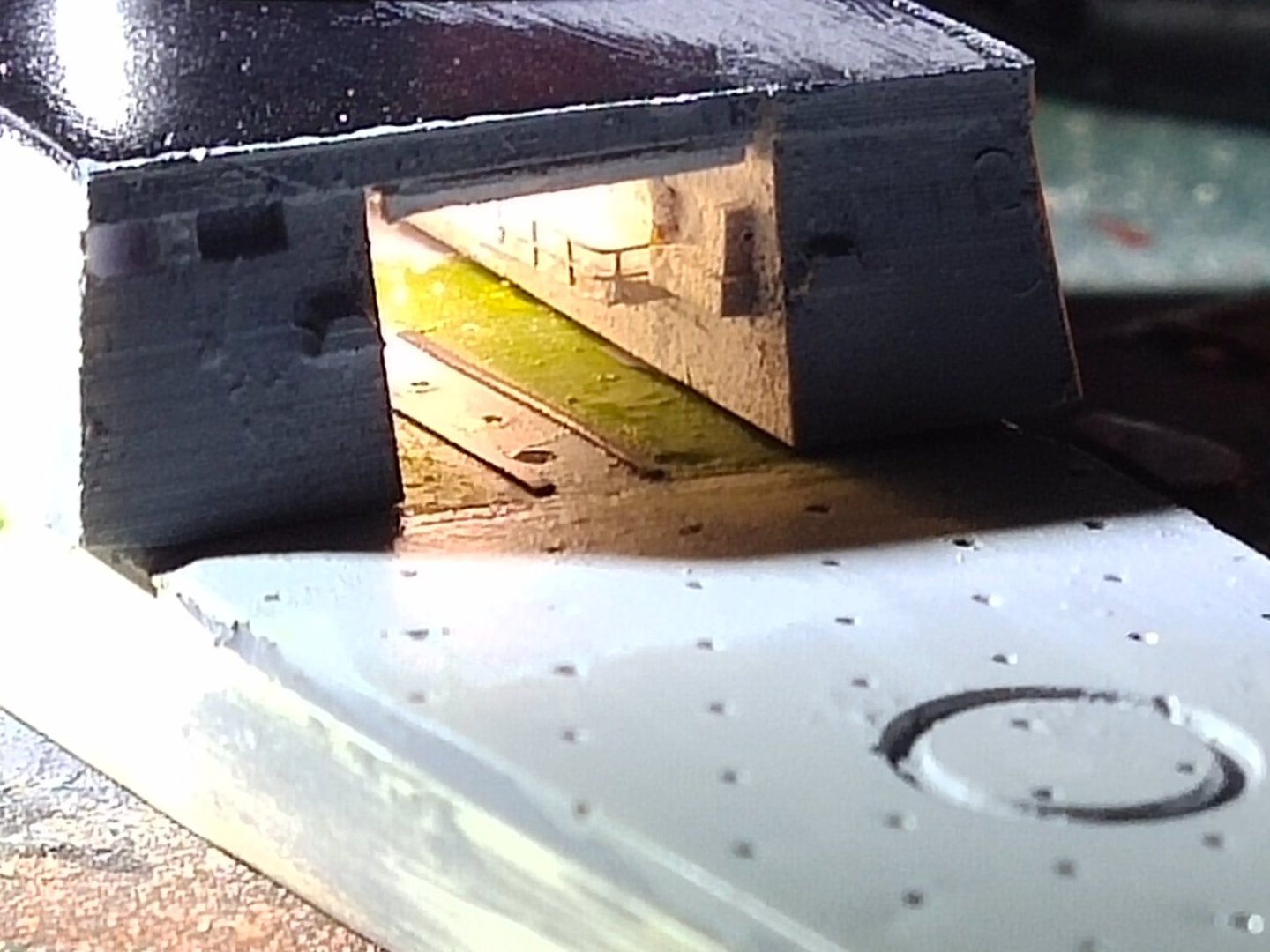

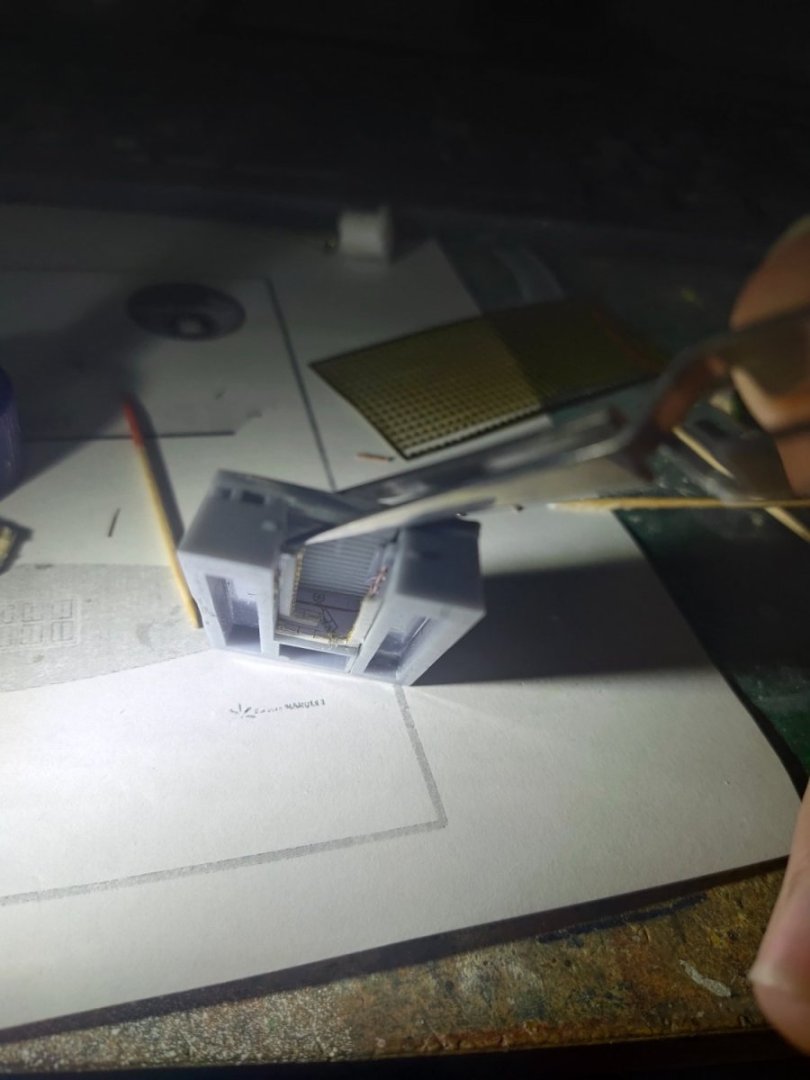

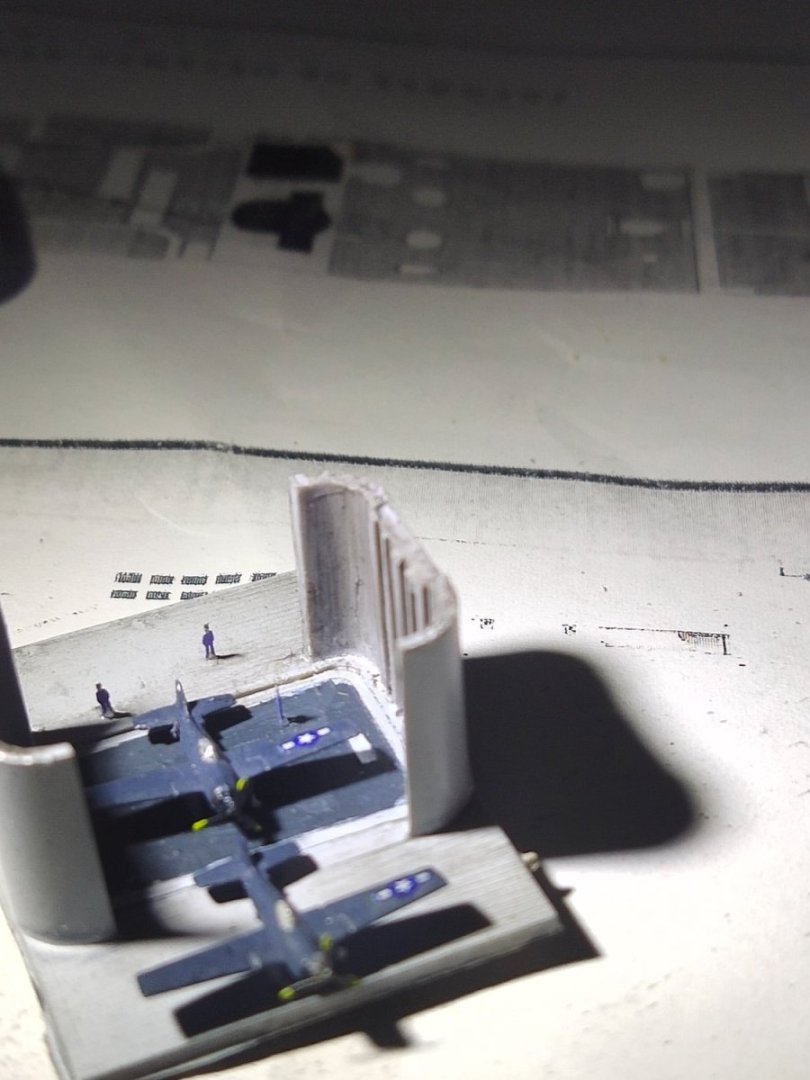

The hangar is complete. I did some test fitting experimenting with the LED fitting while paint was fresh yet. Then I test fitted some others printed parts, bridge and radar mast

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

-

This is a test performed at almost 0 distance and 0 angle. In a real situation, say 30k+ yards at an impact of 40+ degrees the result would be far different from the one shown above http://www.navweaps.com/index_tech/tech-040.php

-

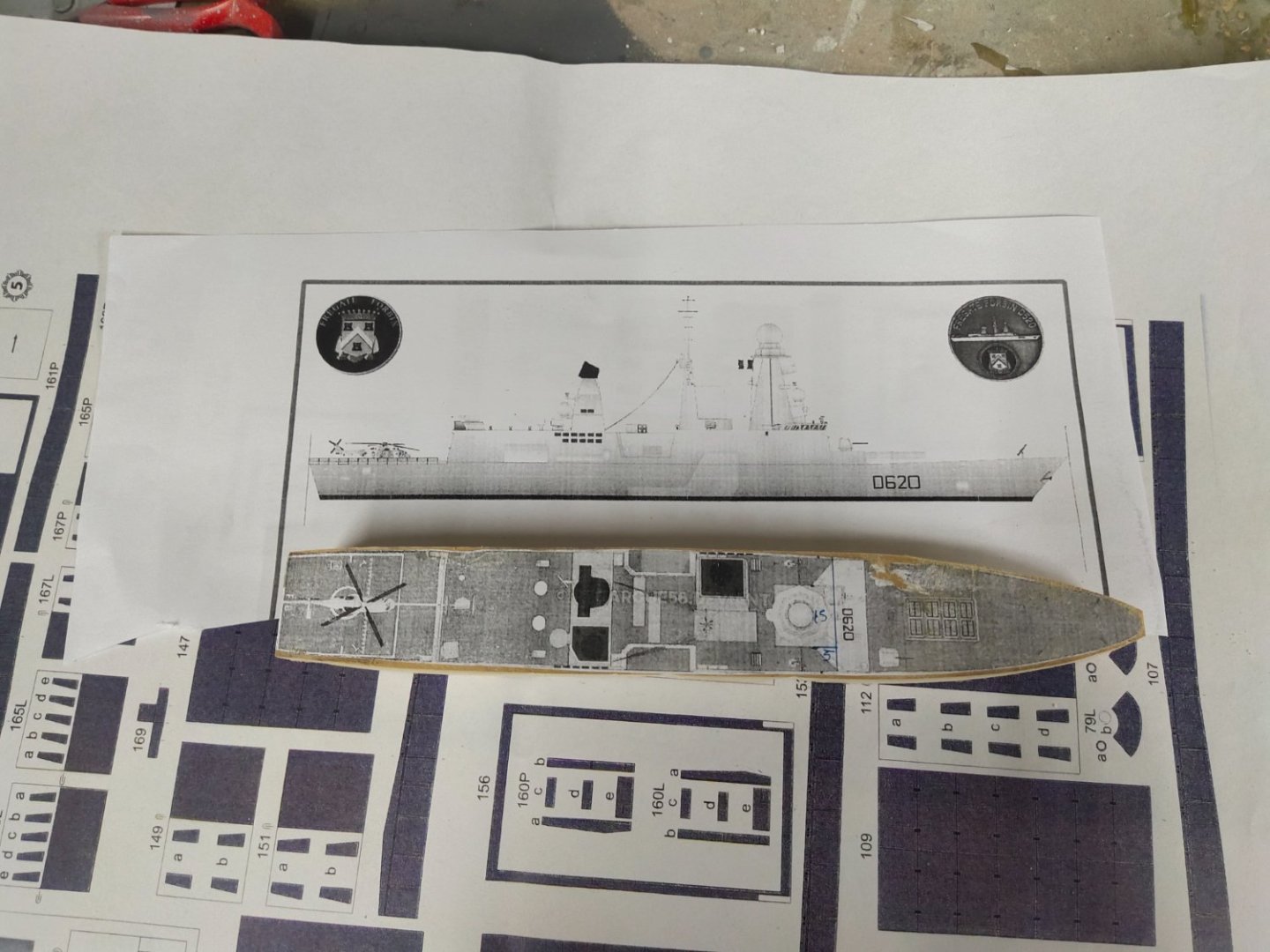

The next part was the forward superstructure. Sanded down to fit the hull then gave a coat of wood sealer. Then, bridge and hangar was printed and test fitted. Then I realized that I wanted to work the interior of the hangar, but at a dimension of approx. 12x30mm that was simply too narrow. So I decided to reprint it in two pieces splitted in 2/3 of the total width. Then work on interior begun. A paint disaster led me to a 3rd print but after work and experimentation I got a positive result.

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

-

Cap San Diego by mikegr - 1/160

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

Next step was to test fit rear area cargo holds and crane bases. Chain is a bit overscale maybe but the result is acceptable. Cargo holds are scratch built and crane bases -which are also storage rooms- are 3d printed. I need only to sand them down so they can fit with the deck which leans towards the sides. -

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

-

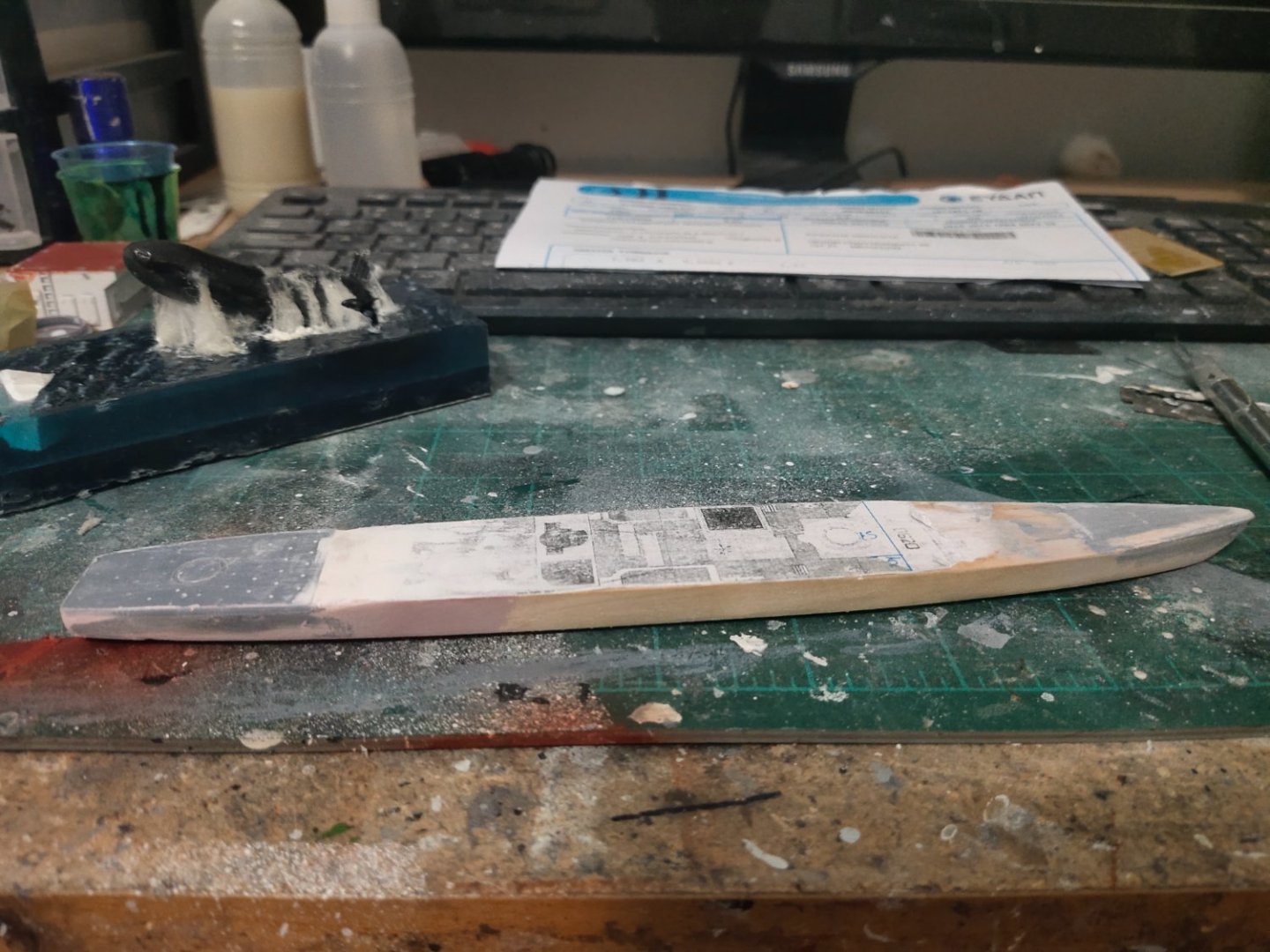

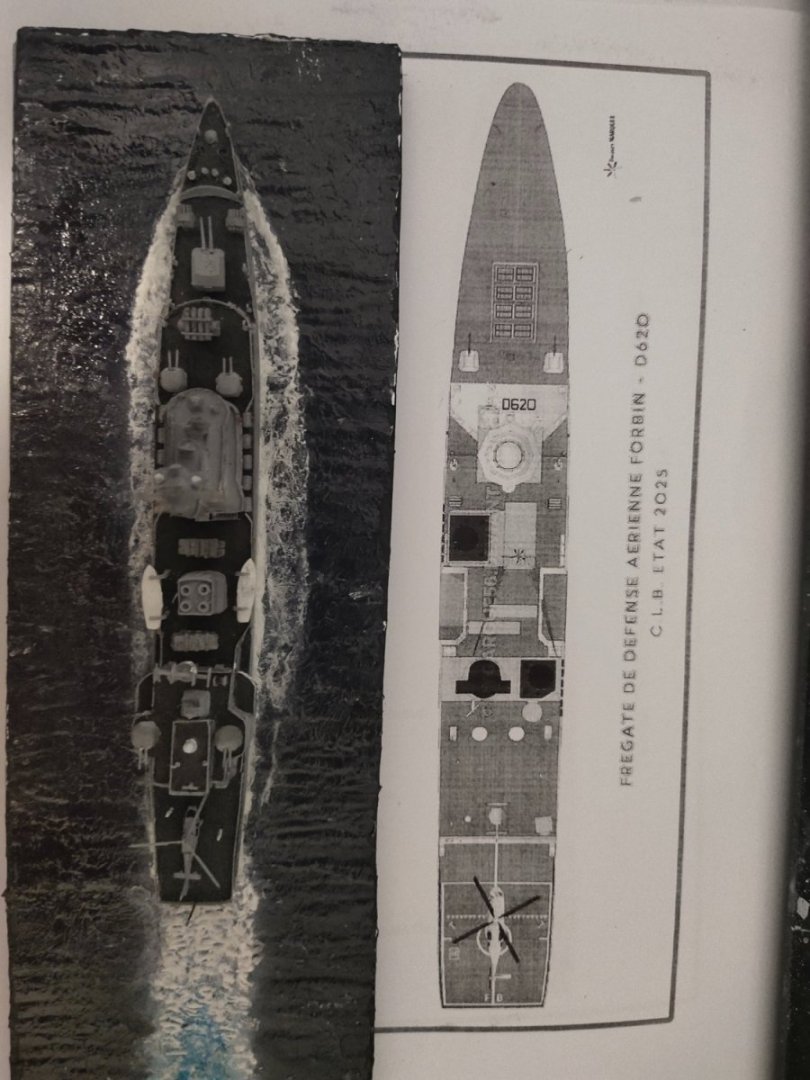

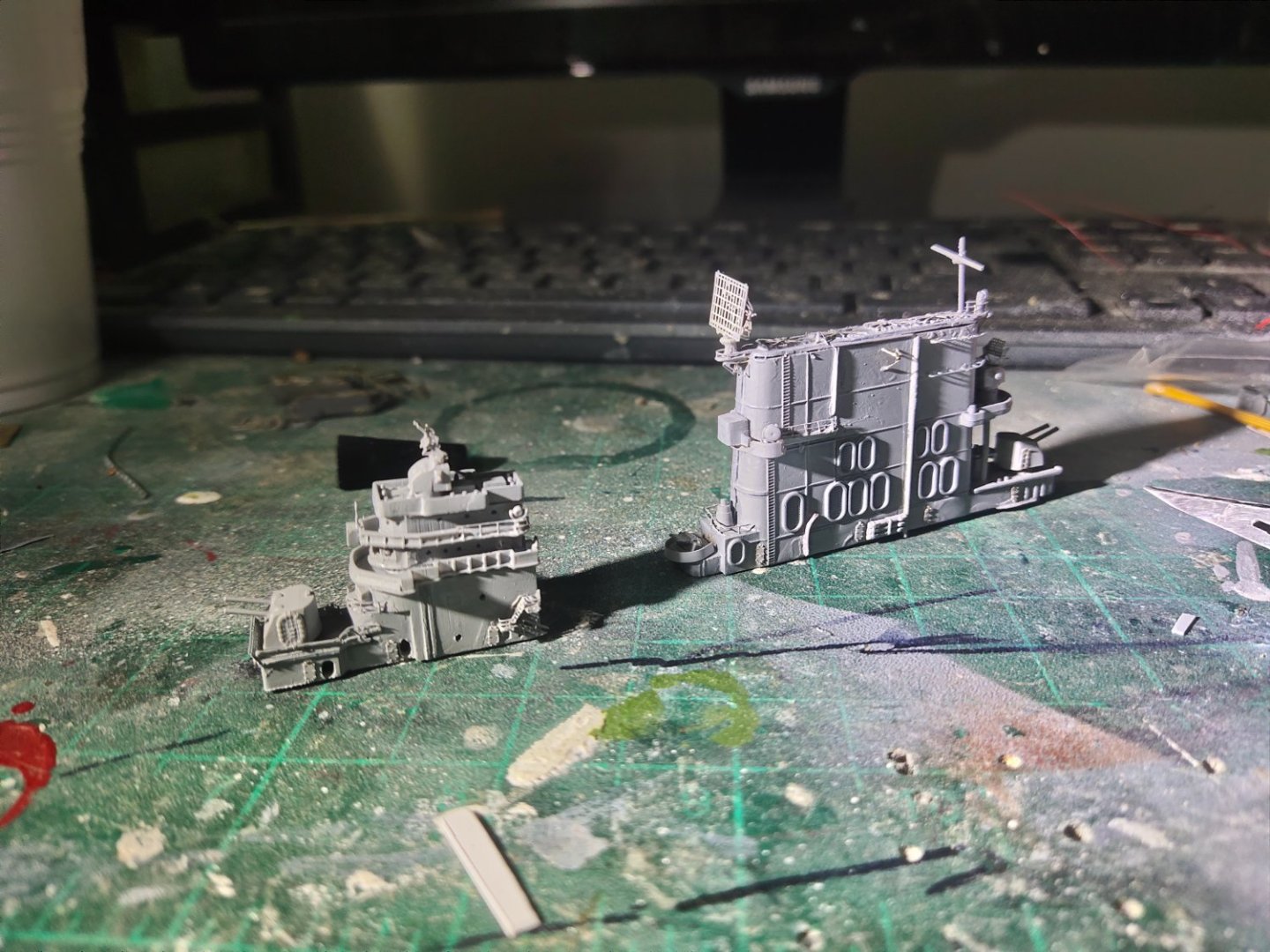

Horizon class is a modern type of warship a product of joint development by Italy, France and UK (which later withdraw to develop its own type 45 destroyer). Although classified as frigates at 7.000 dwt they are rather destroyers than frigates A comparison to the previous project

- 10 replies

-

- finished

- Horizon-class

-

(and 1 more)

Tagged with:

-

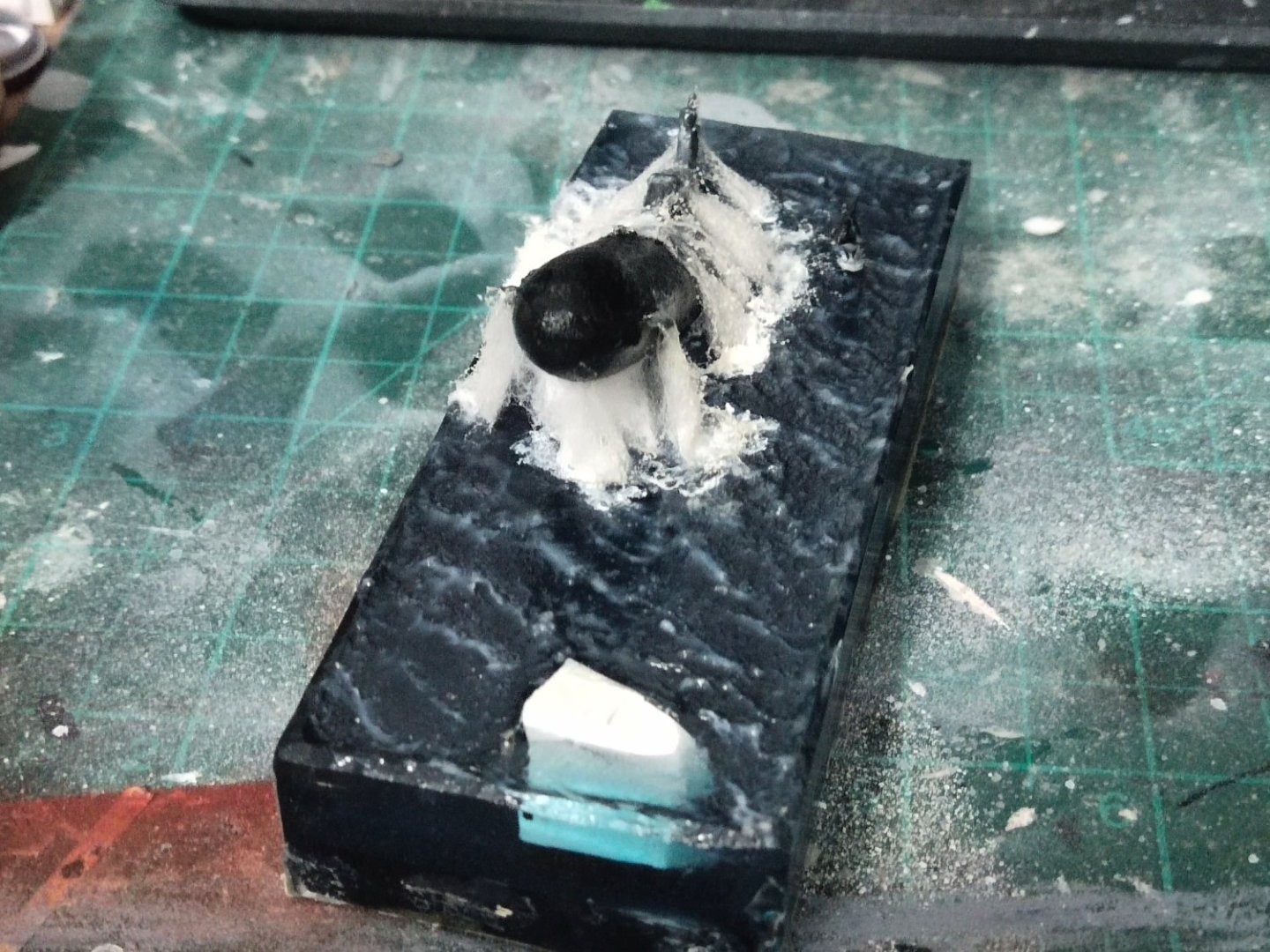

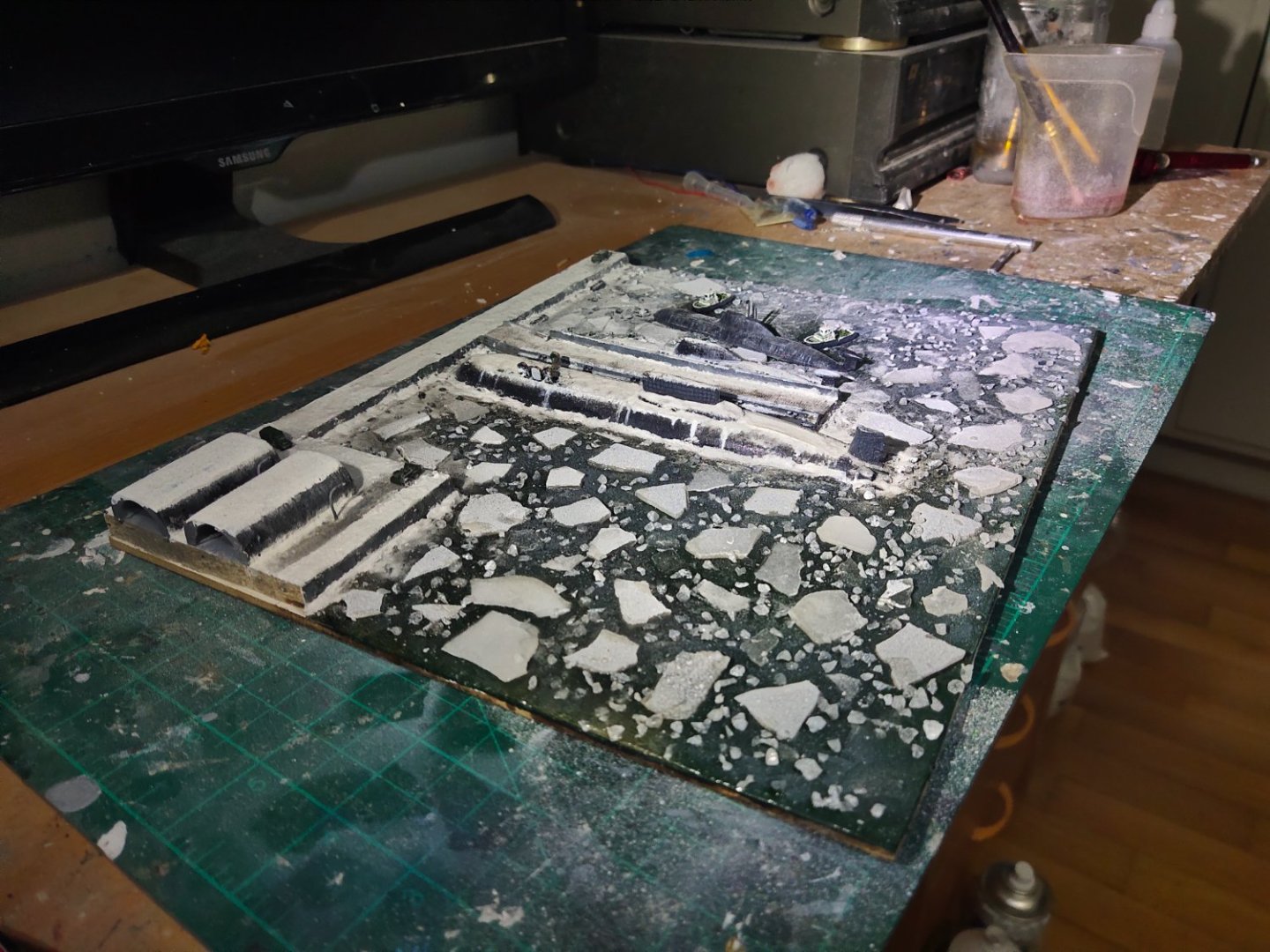

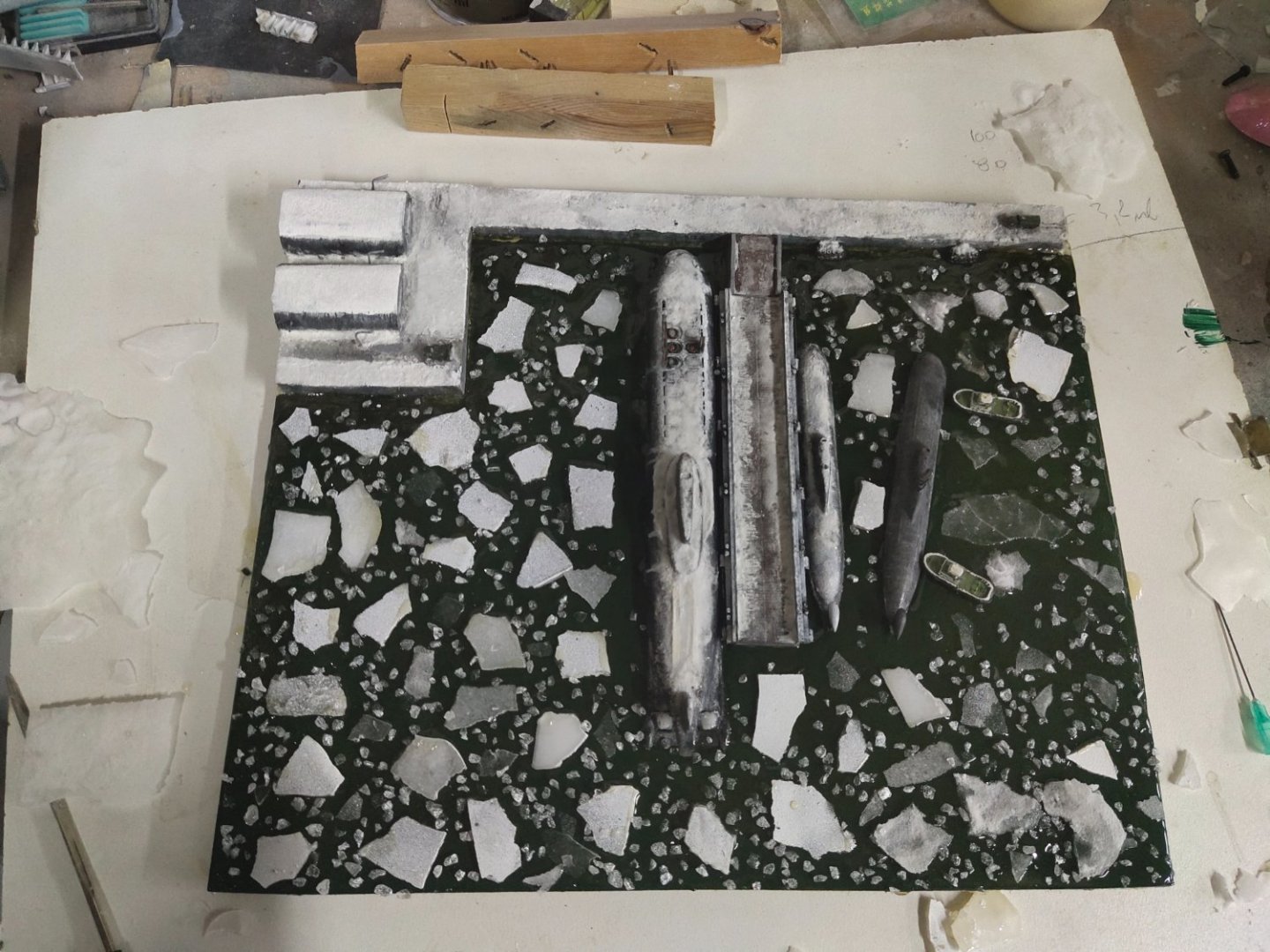

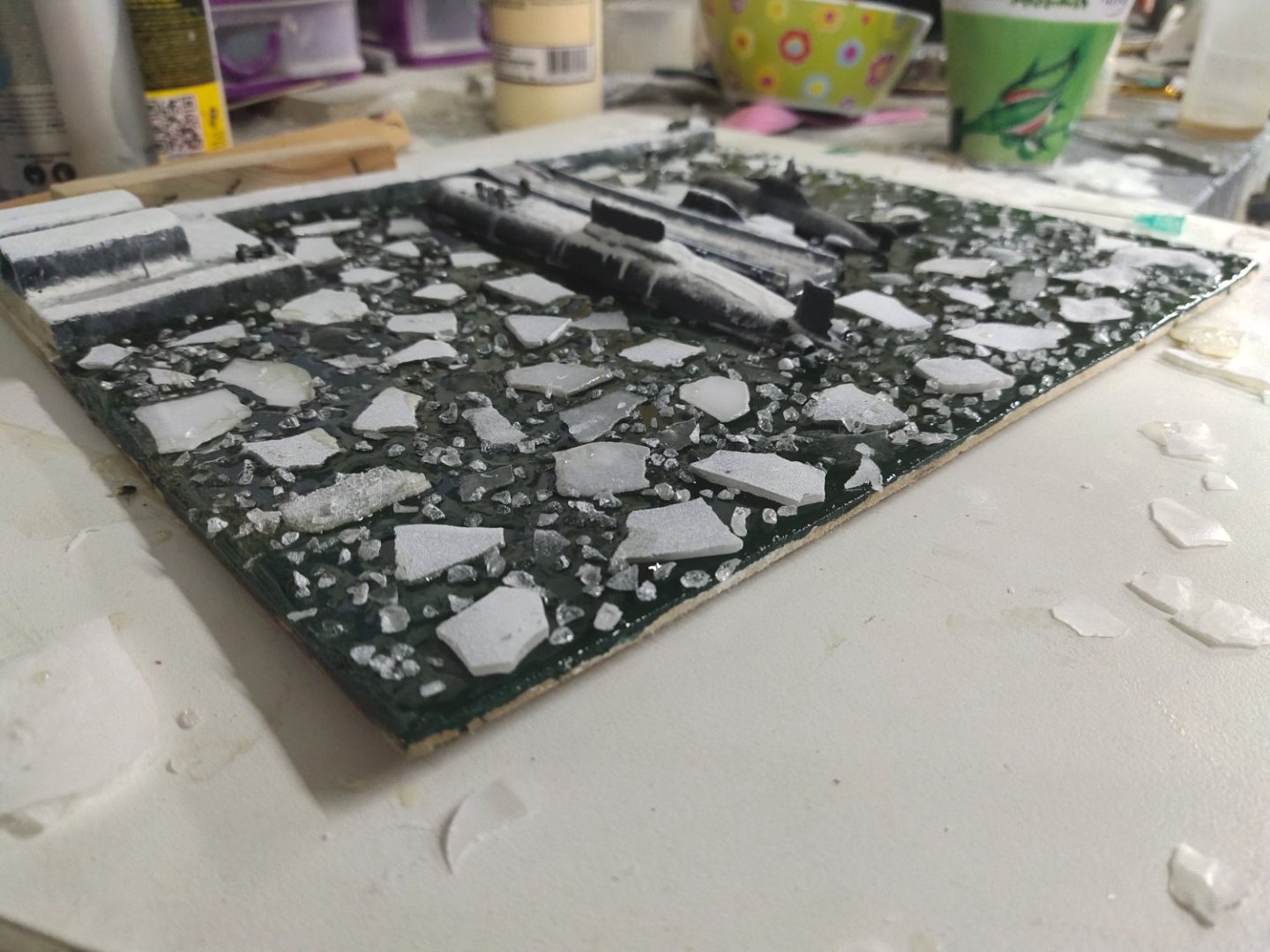

Had a partial failure yesterday. By the time small rocks were put into place, resin has mostly dried. Overconfidence and wrong planning led me to higher dosage of catalyst which dried mixture by 80% in 40 minutes. I tried to reduce them used dremel tool. Some were removed. But after using two pieces of sanding bits effects were minimal. It is the point of no return like I said previously. I poured some PVA across the dock and surrounding the Typhoon and glued thin and long paraffin pieces which were squizzed with a spatula to get a whitish effect. The target was to achieve a good accumulation of snow around the sub to look like it was immobilized for long time. Airbrush white gave the fog effect along with microballoons sprinkles mostly around typhoon and close to dock.

-

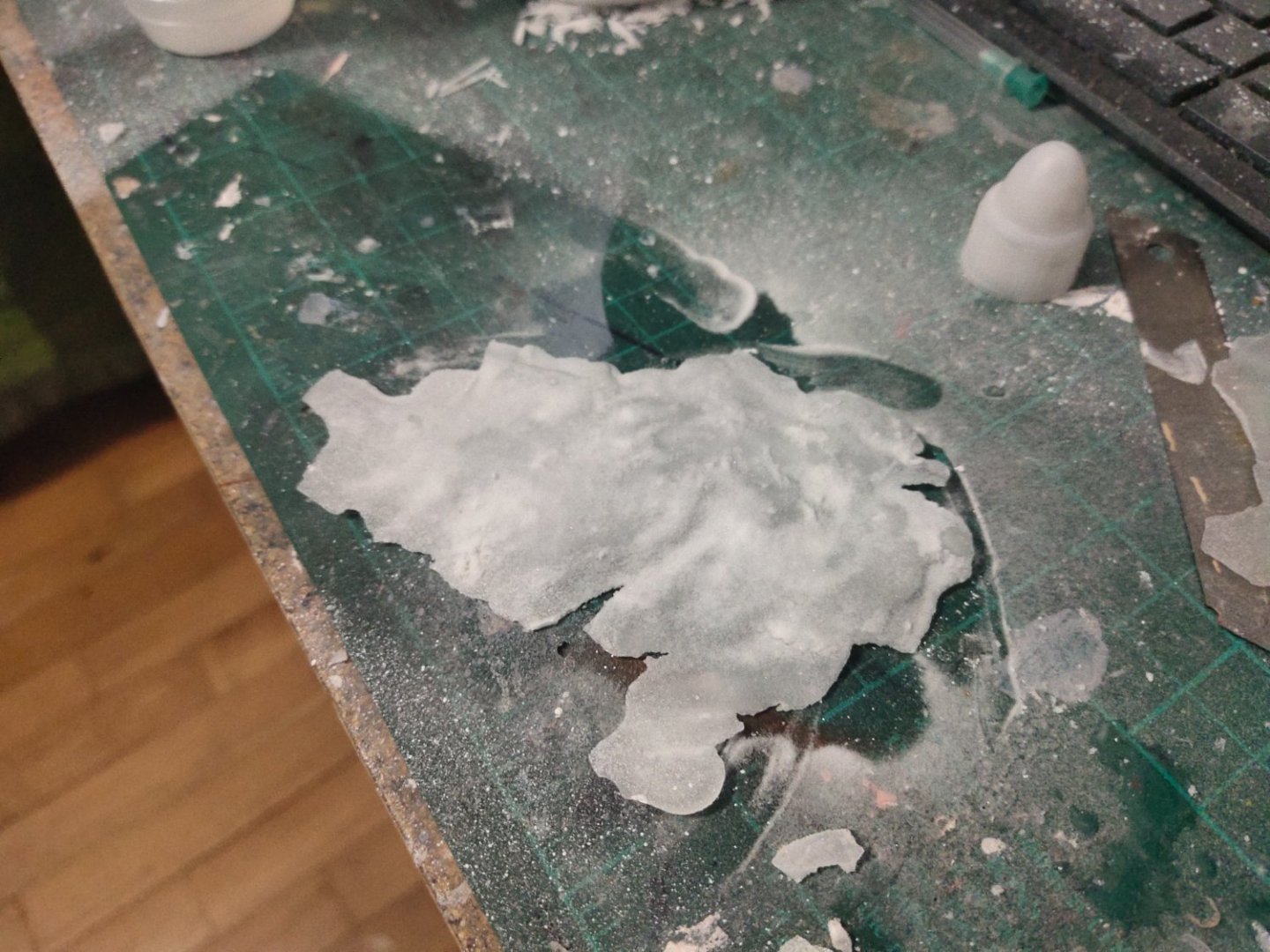

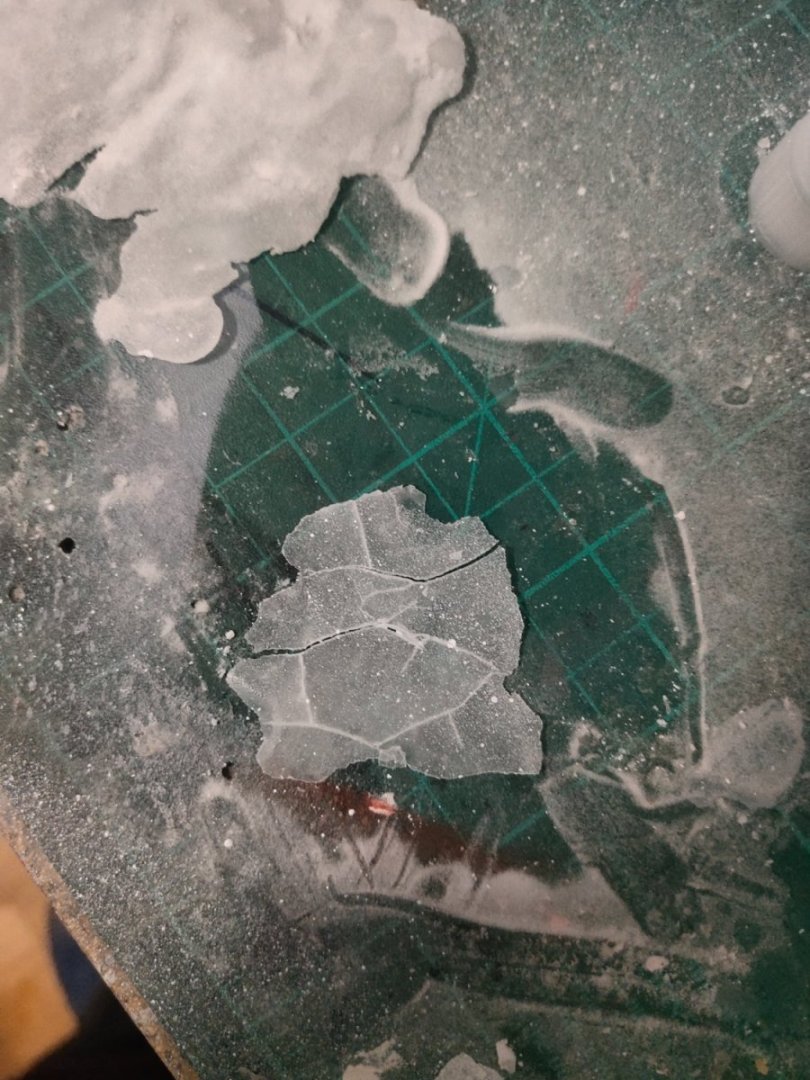

In struggling to find the right balance between ice and snow I came up with the following idea. Big ice blocks are pure white. These are the first to be placed. So I did. I've block placed and polyester poured around them. A bit tricky as this material is thicker and less self leveling than epoxy so I need to work with brush. Some less thick pieces where soaked a bit and turned greenish, a quite natural effect. Then I put the smaller ones. As my hands get sticky and messy I used pliers. The waxy surface helped, no need to grab them just touch and go After done with ice blocks I turned to my bottle of mini rocks.l choosing the tiniest ones It took half evening to fill this amount. I spread them on a surface and sprinkled them with white, giving the semi transparent effect . There were placed one by one, what a nightmare with sticky hands by I paid the price for being foolish enough not to have gloves or acetone nearby by. But the outcome was positive although there is work to be done yet.

-

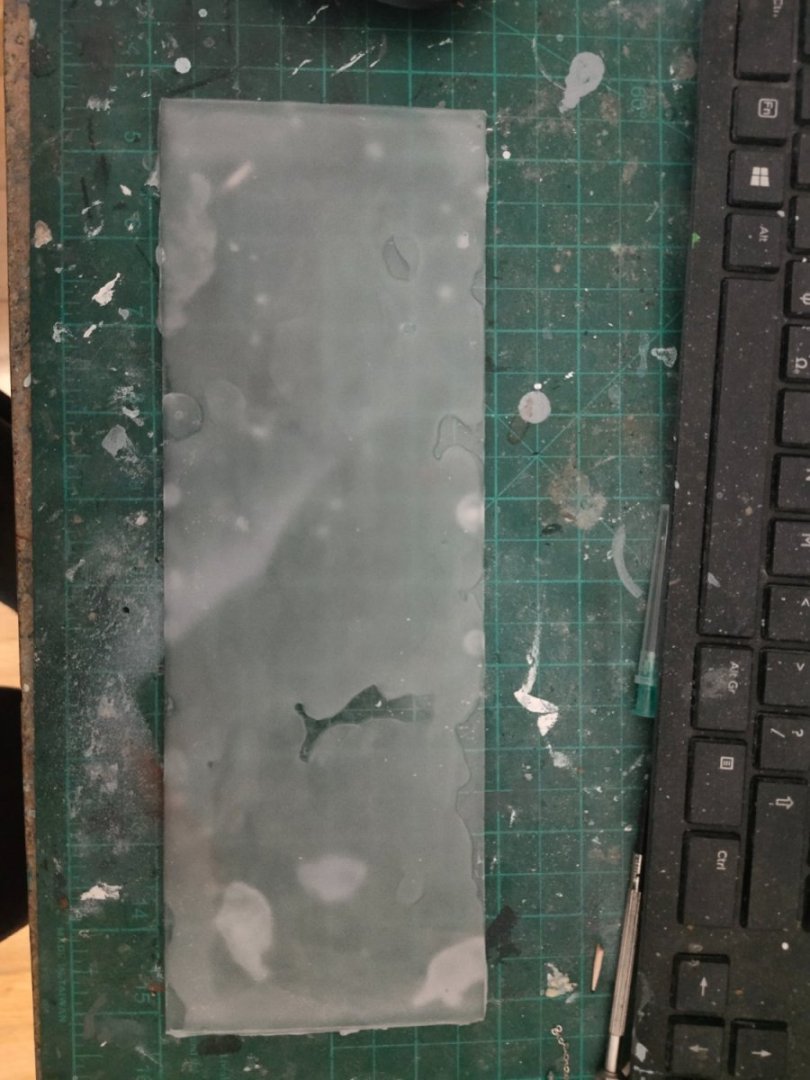

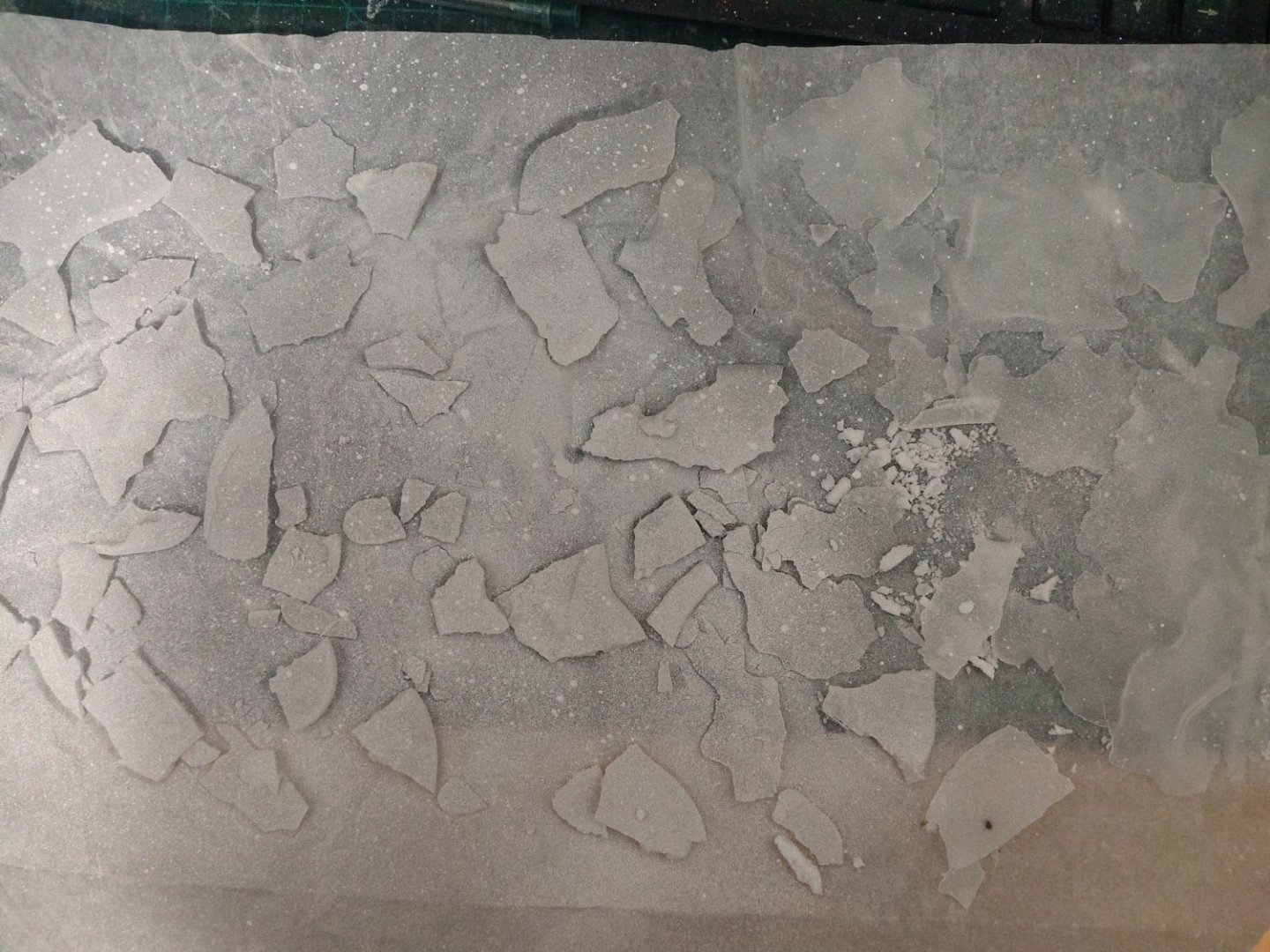

Thanks for the recommendations and support. I will probably must find a way to combine all. The amount of snow is absolutely a subjective preference. It can be 0 Or it can be that much that would look unrealistic if there was no real picture to verify it Anyway. I melted the material above low heat and applied it on plexiglass sprayed with Teflon. Desired thick was approx. 1mm It was a disaster as it stuck. A flexible base was needed. Retried on a shiny cardboard It worked. Just to be on safe side transparent primer was used before paint. Then a 3rd attempt on a thin naylon layer was decided. I was afraid of melting it but I wanted to try for an uknown reason. Could be the instinct of the modeler? Who knows. Anyway not only it didn't melt but the naylon base shrunk giving to the material a nice uneven surface effect. Like when strong wind blows during a snow fall By simply squeezing gently this wonderful material it gives the real effect of the crushed ice The more I work with it the more I learn

-

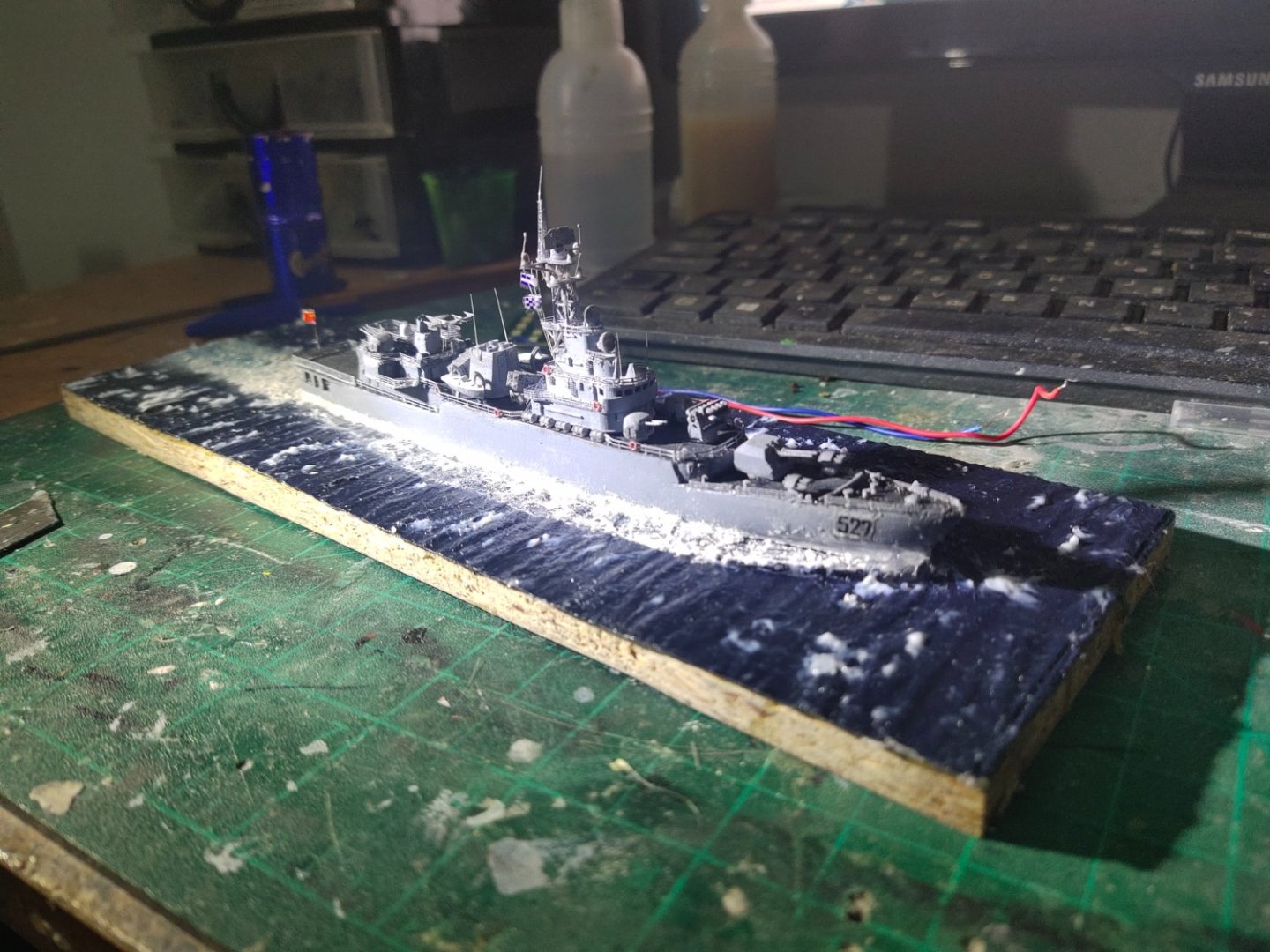

I worked on rear wakes with airbrush, then added white paste near the bow and gel paste right after. Then glazed over with transparent silicone. Waves were made with snow paste sculptured with toothpick. Waterline gaps filled with cotton soaked in PVA. Sea was covered with gel medium. Once dried it will get transparent and glossy.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

_on_14_May_1942.jpg.8481d430011dab0bbcfa4b1774f1b3e0.jpg)