mikegr

Members-

Posts

827 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikegr

-

After experimentation and research i found out that the mini compressor is not working good enough with acrylics. They need to be thinned a lot for a proper flow. That means extra thin white is quite hard to cover dark surfaces. In my next diorama i will be using a new compressor which I hate because of the size and noise. So finally I did it I turned the two quartet hulls into warehouse, bunker, shelter, call it whatever you like it. Space for land construction is reduced in favor of more sea and faster progress. Need to speed up a bit

-

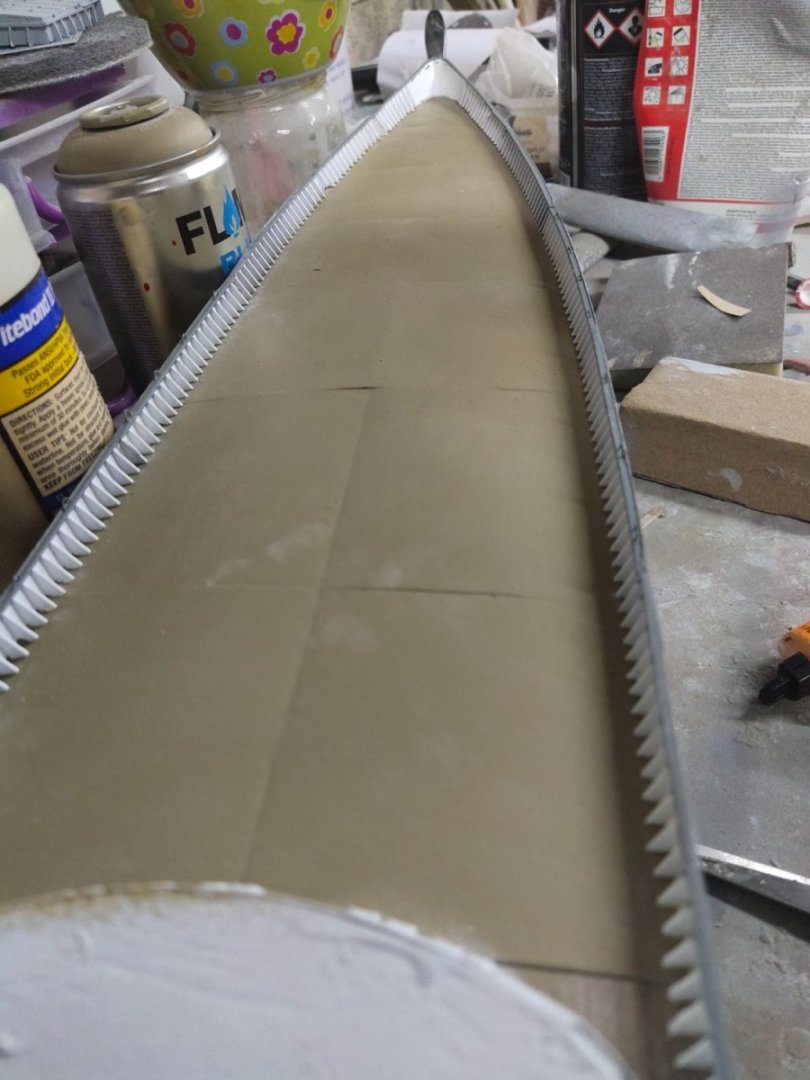

The work on the hull is almost done. The bow looks like Virginia Class nuclear cruisers. Rounded at the upper half, tighter and more straight lower. I was thinking to shape it by sanding. But I am a better butcher than a surgeon. I simply cut the lower part of the hull and replaced with a triangle one. The shaping effort now was tremendously less

-

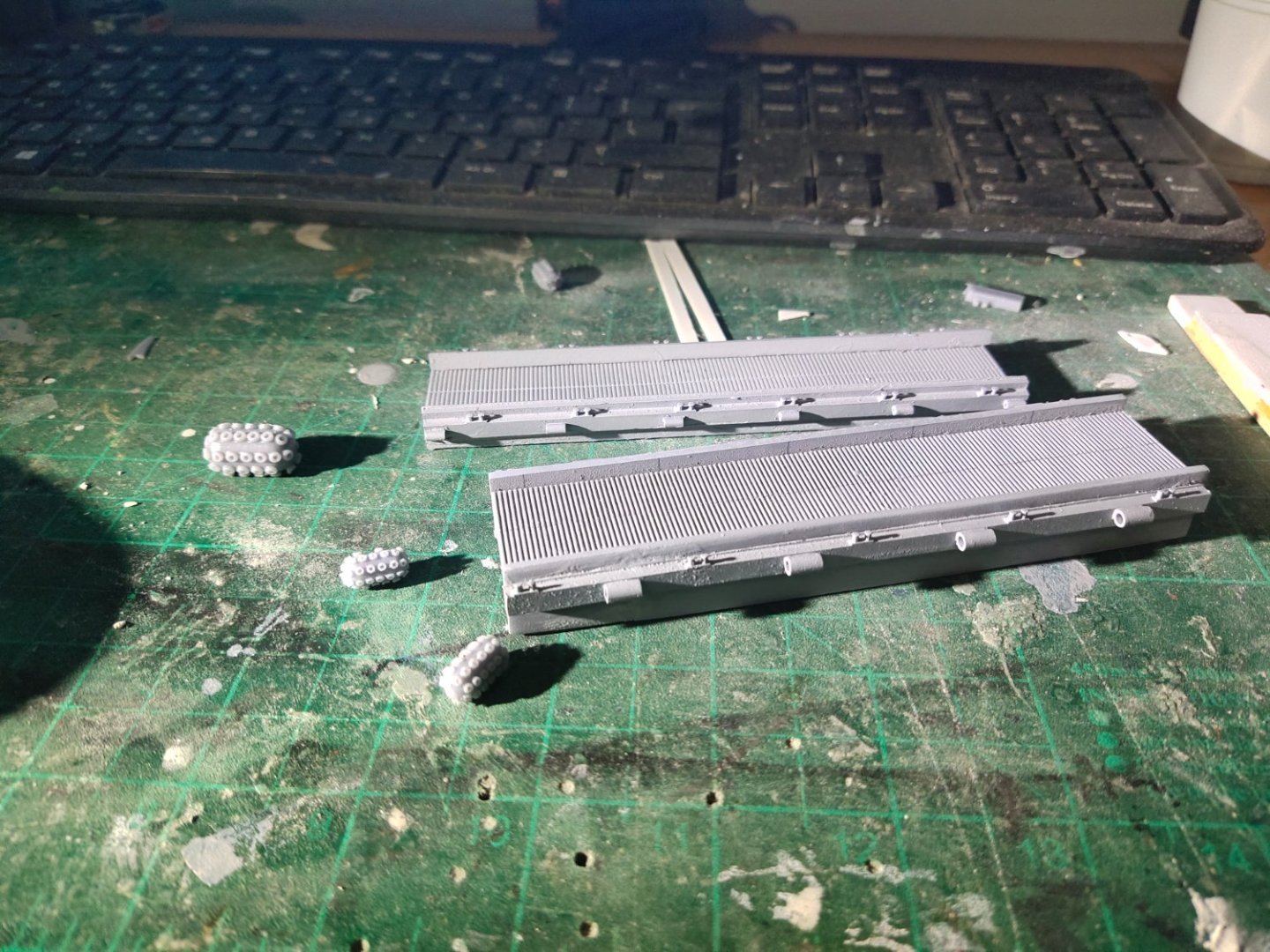

This is the hull after a few hours of work. A plastic sheet was glued as a main deck. I need to work on details and give the bow the right shape. If I was given this in the age of 10 I would probably be the happiest child and would go straight for bathtub tests. But im a greedy adult and i need mode detailed work, rigging, photo etching and more, to satisfy my self

-

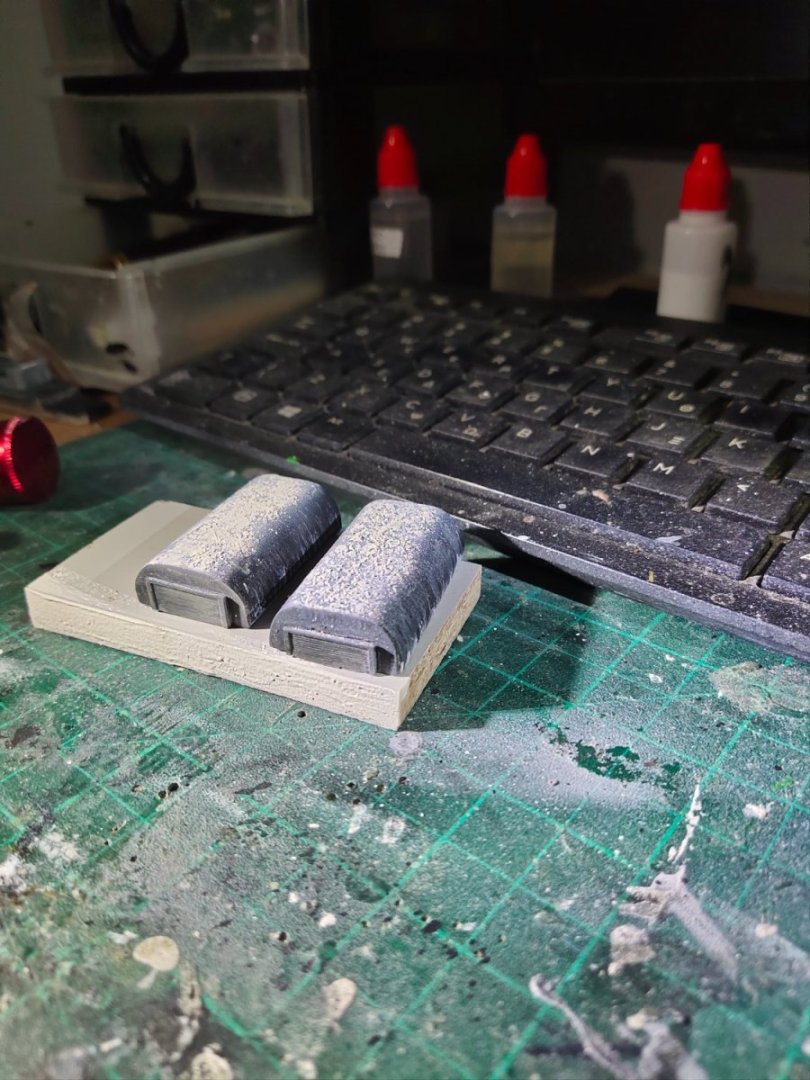

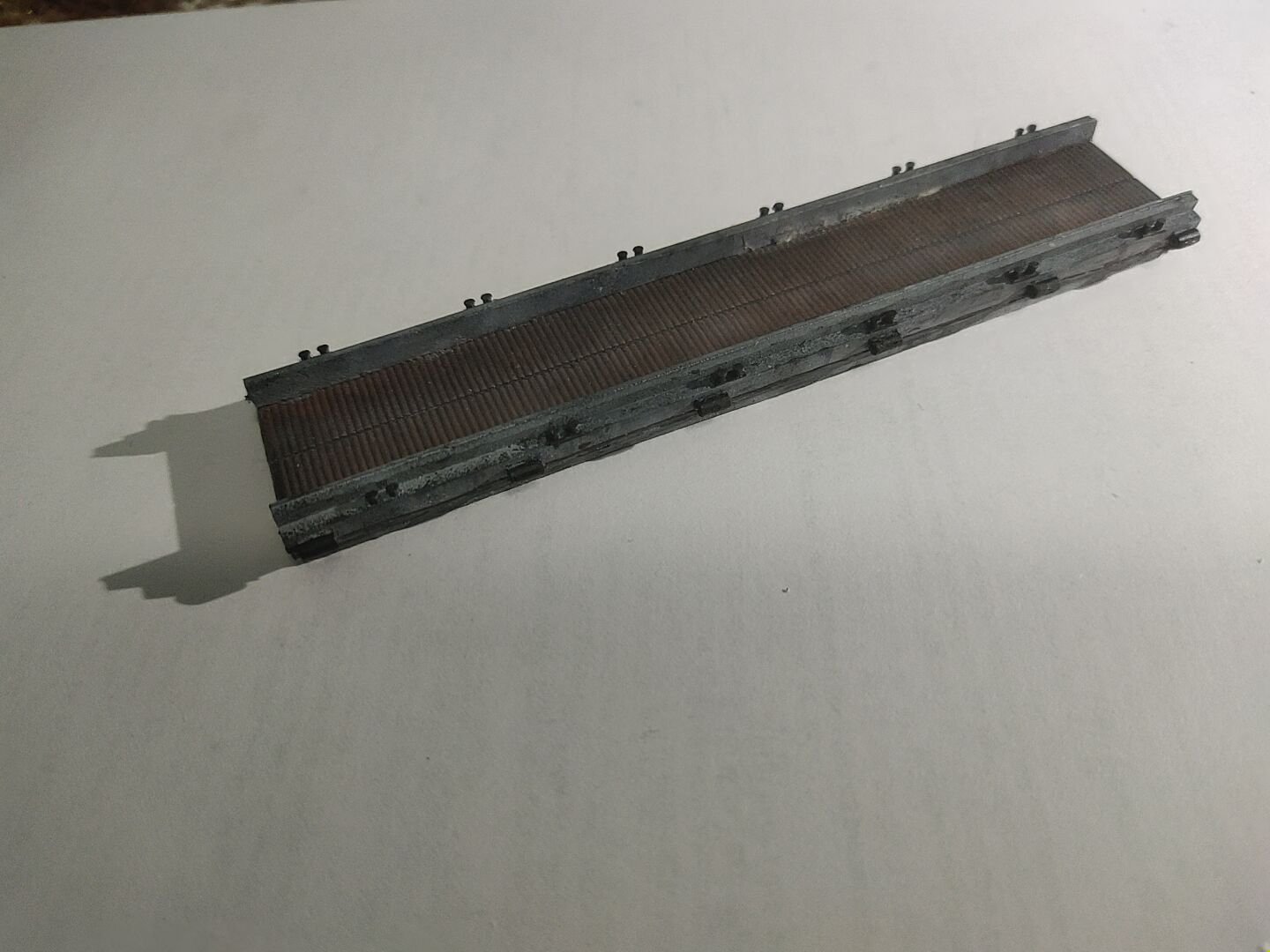

Done painting the dock. Epoxy primer, grey paint, (red brown road), dark weathering, light weathering, black wash. Finally put the cable holding the rubber fenders. I may add some green at the base were dock meets the water. And some light rust streaks at the base of those black things that ships are using to tie the ropes which I can't recall the name and I am too lazy to google it

-

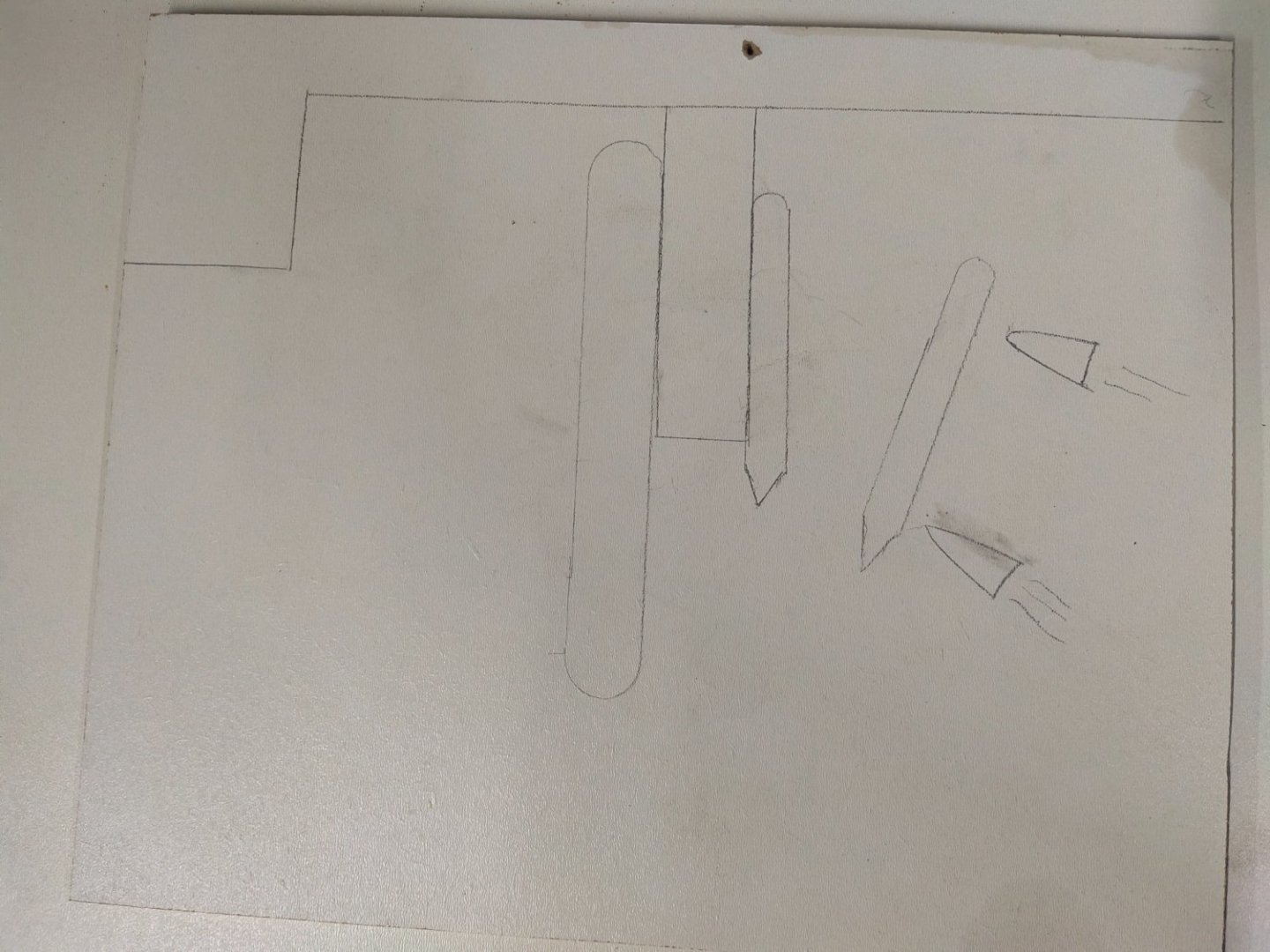

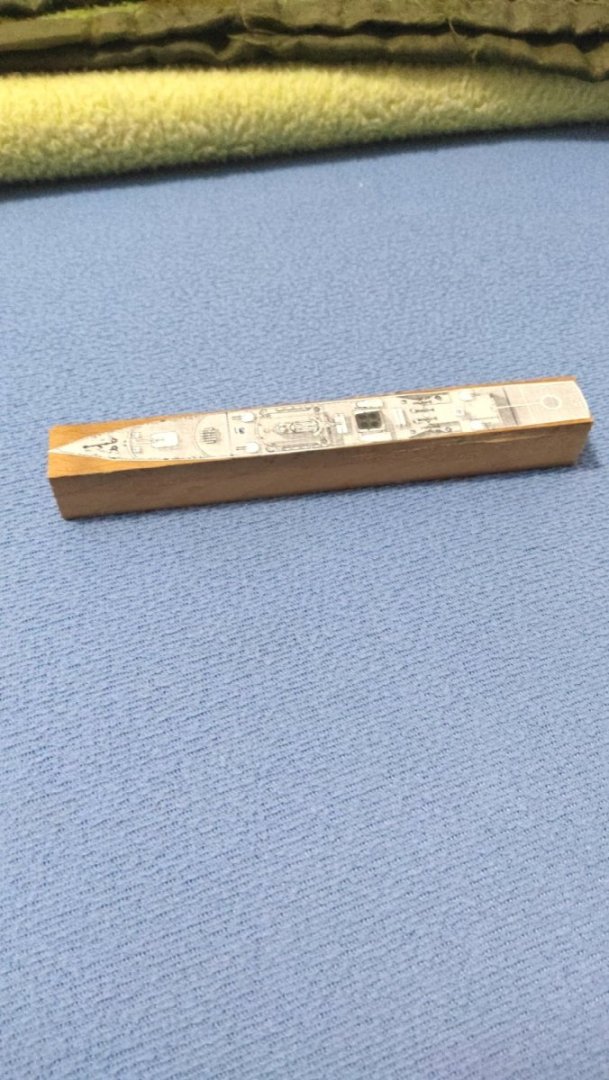

So I decided to print the hull. But the shape is not that simple as in Horizon class or like type 45 Destroyer that I was looking. Spend quite some time without having the desired effect. After printing drawings to 1:1 scale, hull was estimated to 16 cm. Deck plan was glued to the most -close dimension- piece of wood I could find. The smell of sanded wood filled the air replacing the resin odor. I kinda missed that. Let the fun begin.

-

Normally this is a scratch built not a model. However its too small compared to other mega projects here and I like to have it in the same section with my other 1/700 built, with mods permission. Not sure how I came up with this idea. , probably found some detailed drawings while searching online for modern frigates info material, so I convinced my self to give it a try. Modern ships are easy to be built especially as waterline models, cause of the less complicated lines. The Type 053H3 (Jiangwei II) is the first multi role frigate of the PLAN Navy. They displace 2.500 tones at 112 meters long. They are replaced by type 054 frigates.

-

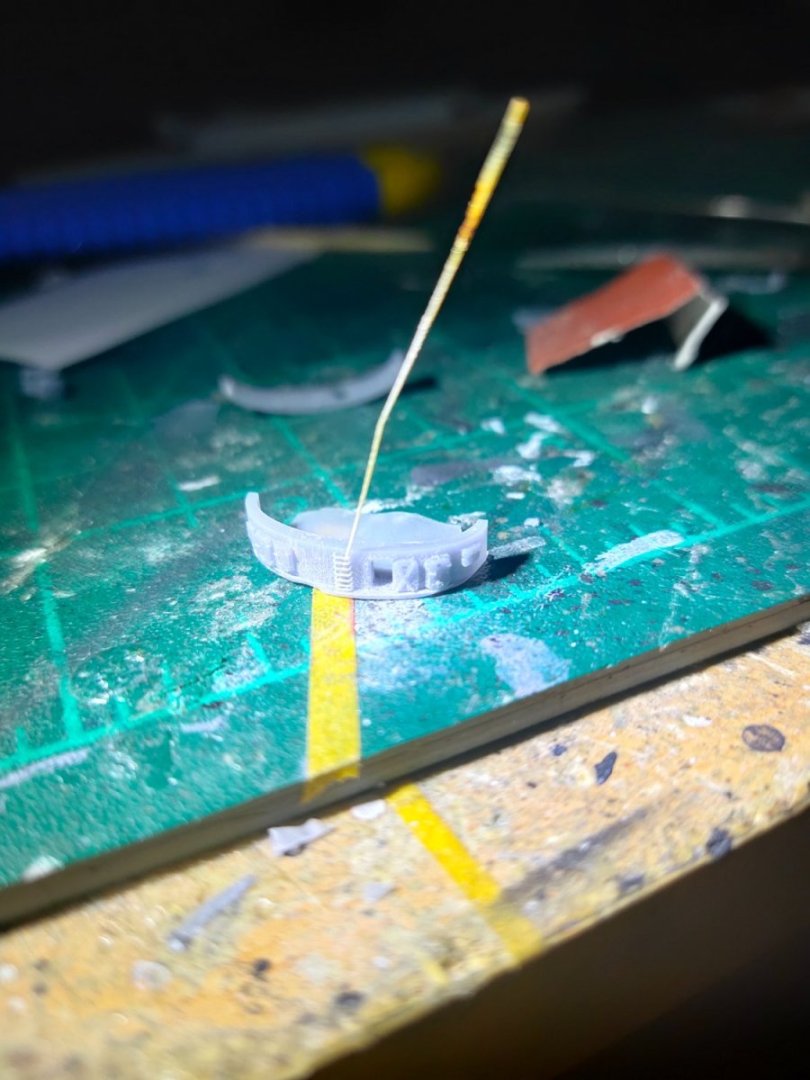

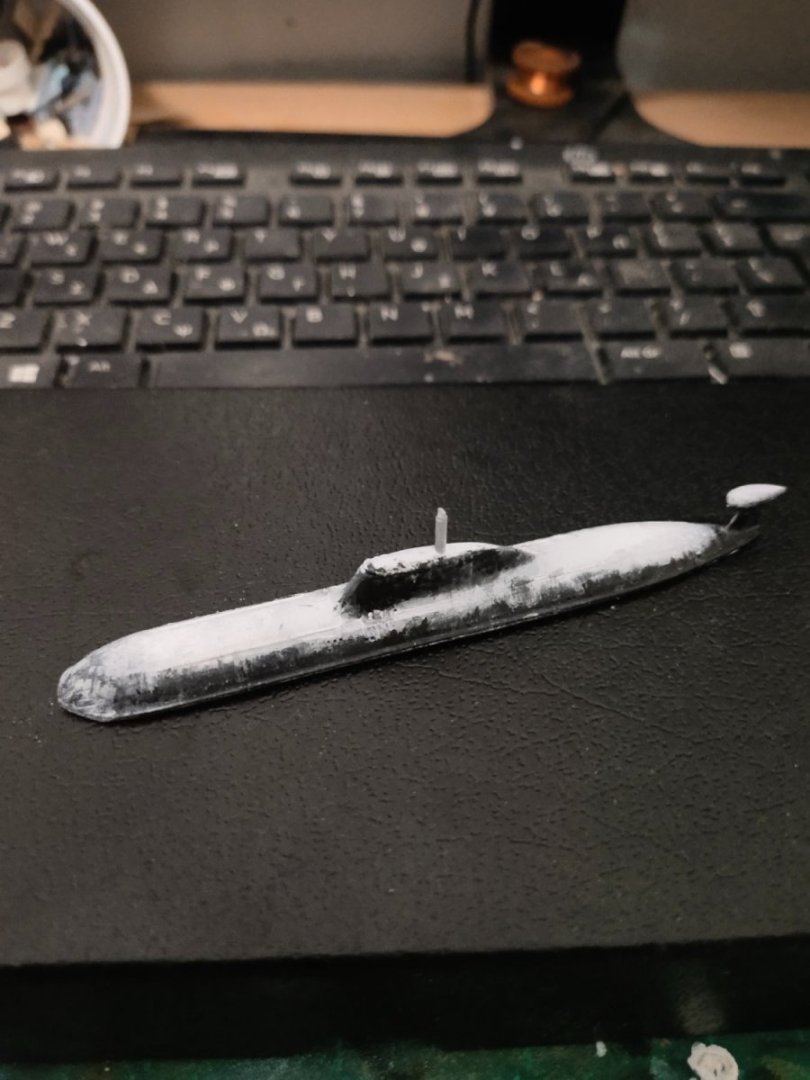

No update for 3 weeks depsite 3 weeks of daily work from half an hour to whole evening. Typhoon was a different story. First I had to fit extra bulges around the tower area like in the real sub Then I tried for a snow effect. But those large areas actually gives the optical illusion of a larger scale so more detailed job should be considered. For my bad luck I didn't want to give an easy flat snow finish, something more challenging caught my attention After few failed attempts I noticed that engraved details, particularly the cover of missile silos have gone. It was time to not only reprint the front hull part but to interfere in the file and make the lines more clean. With the right modification this was successful. Painting failures went on for several evenings. Finding the right thickness on white paint to spray over large black area was a disaster. From, say 30 hours of work, 29,5 was spend on paint testing and airbrush cleaning. I even suffered a break down but thanks to online information airbrush was repaired quick without need of wasting time ordering spare parts online. The missile silo hatch missing is due to a file problem. After a not so good scratch built attempt and new paint failures it was time for a re print. And as usual, further design modifications were necessary. This time were also more extended. New tactics were used, a home made snow paste was used and some chalk powder. After several tests I scored a result that prompts me at least to proceed to the next stage Perhaps the hull leftovers can be modified to shelters or bunkers😁

-

Cap San Diego by mikegr - 1/160

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

Small update I have been working on the bow. I used some epoxy putty to shape the bow. Very easy to shape but hard to sand. Smaller gaps filled with body car filler. Some hull imperfections were covered with glaze putty as well as epoxy in order to make a smooth surface. After bow shaping I will concentrate on eliminating last minor hull bumps and gaps. Nexts pictures won't look much difference but there definitely some work to be done -

Cap San Diego by mikegr - 1/160

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

After slow progress and piece by piece assembly all sections are into place. I painted white the internal part and grey the upper side. Externally putty was applied at joints then sanded but not primed yet. I need to do some work on the bow. The deck at the anchor area is a bit "fat" and it should be trimmed somehow to meet the slim frame. The bow is also quite sharper on the upper end like the real ship and needs to be aligned with the rest of it. Finally there are some design lines that must be deleted so frame will have a smooth finish like the rest pieces. -

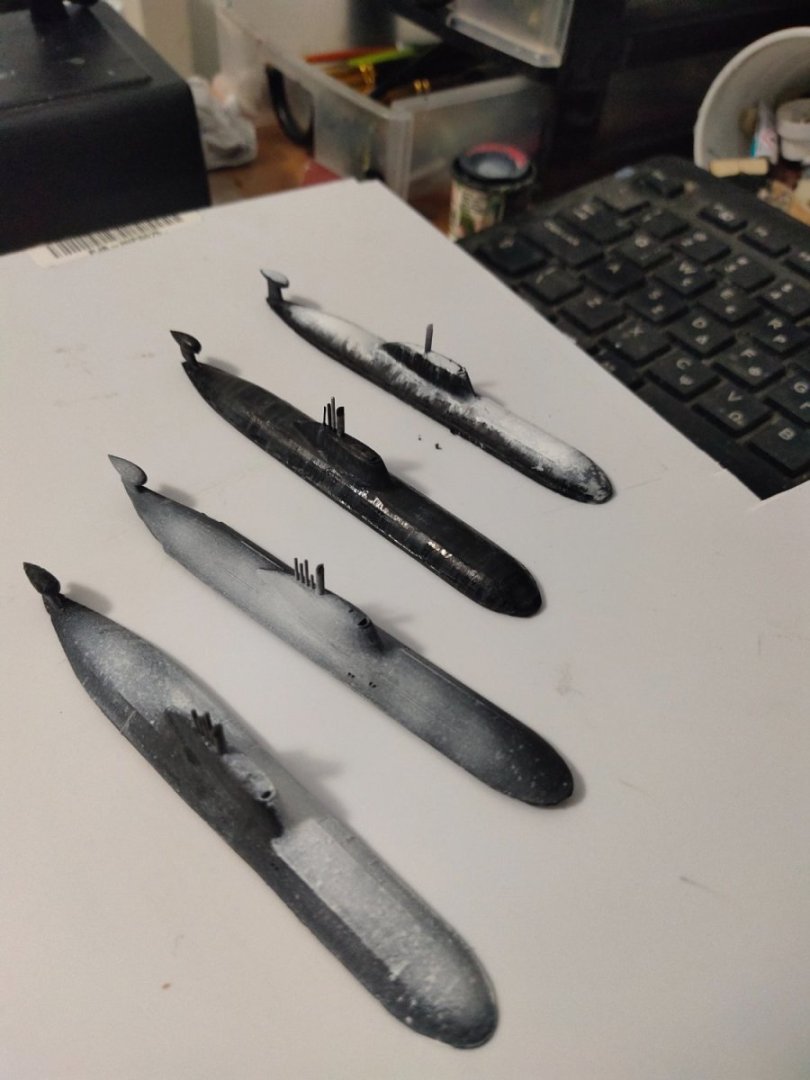

Spend quite a lot of time on the 2nd sub. Gray black color sprayed, then I added some lighter shades. Using cotton swab a fade effect was achieved However it will be of little importance. I sprayed white but airbrush was spitting paint creating a mess. Had to experiment with color thickness, cleaning the nidle many times and testing paints specialized for airbrush. So after many layers, chipping and brush weathering I managed to get a decent result. Or perhaps I felt convenient with it because I got tired. Tomorrow a closer look may change my mind. A comparison photo with both model subs and two test models

-

just noticed that this is another submarine project. Those drills are really fragile especially the thinner ones, i'm only left with a couple of these

- 65 replies

-

- X Craft

- I Love Kit

-

(and 2 more)

Tagged with:

-

I did some research and found that most model companies recommend a dark grey/flat black color for Russian subs. Wasn't sure what to do so I gave it an airbrush paint with black and dark grey in 1:1 proportion to both test and proper model then I added some heavy weathering with tiny brush with more concentration this time. For wet areas I used Tamiya glue, quick drying and very glossy effect as I like The one with the raised antennas is the freshly arrived on harbor, so there will be no snow effect on it. I will proceed to the other Akula , the stationed one with less weathering and in icy condition

-

Cap San Diego by mikegr - 1/160

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

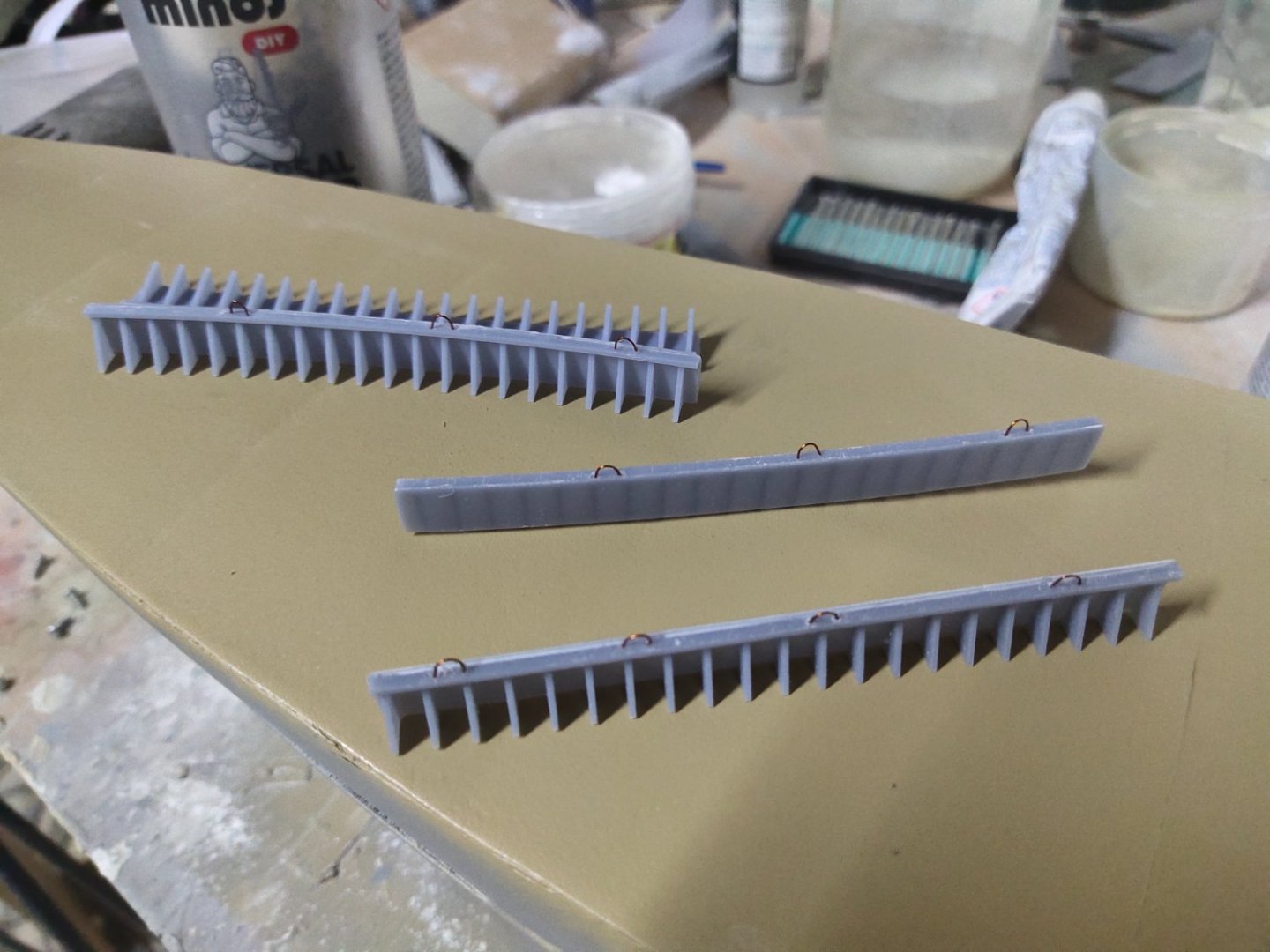

Recovered from the covid isolation, not much trouble and found time to do some other activities Back to the project I am working on the middle and forward sections. I design them myself as these are straight pieces. Besides with some heat applied resin can be curved without the risk of distortion like plastic. I forget to add buckles for rigging so added some with brass wire. Etch primer were used then white color for the internal section -

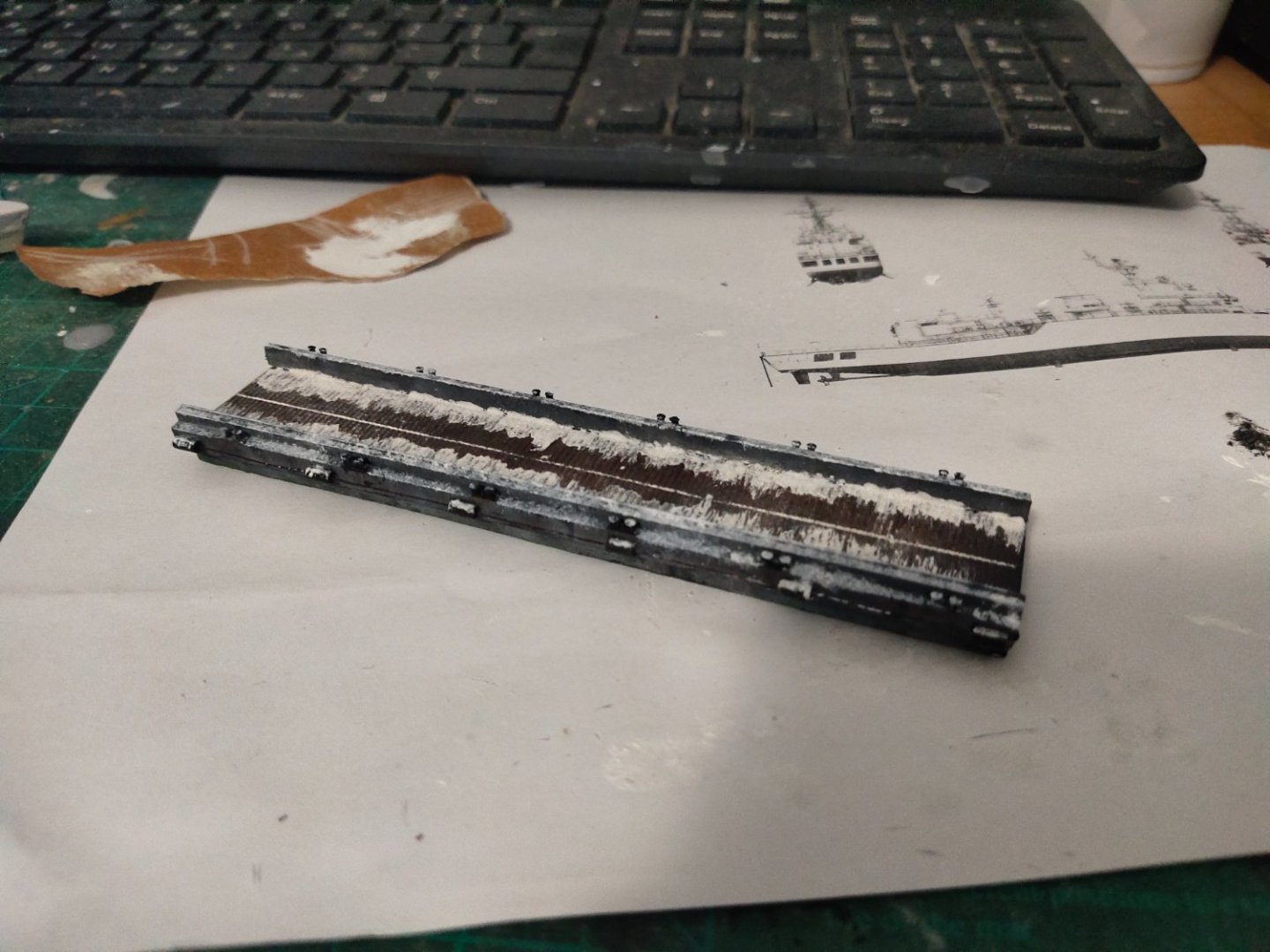

A warped model is used as a test bed for weathering experiment. Used some initial airbrush spray but in this scale I found that extra brush details should be added. With thin brushes I worked making vertical stripes with different shades of grey, then black then again grey sometimes before the previous paint gets dry, making an interested result. Added very few drips or rust, some chipwork on bow and gave a wet effect applying one ingredient resin, locally. I need to work harder to form the vertical stripes with thinner brushes and of course on color consistency.

-

The new world order is oil 100$ per barrel and dollar high so we have to adjust to the new standards. Yen is also quite low who ever can order from Japan can score good deals.

-

Cap San Diego by mikegr - 1/160

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

Rear section done. I started working on the main deck. There's a gap where bulwarks meet the deck as shown on pics.That means less work for me. There is some detail paint job to be done but can be done later. I wanted to update here. Time is running out. Tomorrow early morning I will travel to my other place in a nearby island for some self isolation as covid got me and its wise to avoid contacts for a while. Hopefully I will continue next week

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.