-

Posts

7,409 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Hi Nigel, thanks for your "likes" and for visiting the Gorch Fock 2 on my Yards slipway, and for your nice comments. The GF 2 I am doing is very much orientated to the 1:150 scale Version of that legendary Plastic kit from Revell. It resembles the Version of the late 60`s. Unfortunately it is not produced any more since many years, and one must have great luck to get such kit e.g. per Ebay auction. I had luck, and so had very nice samples for the Rating dimensions, wich of course had to be magnified to scale 1:95, and the parts had to be scratch built. Still the plastic model remained unbuilt, so the complete kit could be sold further on to another happy modeller Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Thank you Mauro, I`m happy that you like the model Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Thanks David, same answer as to Michael today... The 2-componet resin I used is an ordinary liquid Polyester (like for car repair) mixed with appr. 3% hardener. It cures in about 15 minutes time and can then be removed from the mould Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Bob, I was wondering if anybody would recognize that.... that double pin was not my own Invention, I saw it once somewhere in tips for modelling and also found it great and worth remembering. Meanwhile I glued some together and always have them Handy in order to clamp larger distances with more or less parallel closing in clamp-toungues Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

A very beautiful built model Gregor, and a pleasure to watch your build log Well done ! Nils

- 210 replies

-

- Sherbourne

- Cutter

-

(and 5 more)

Tagged with:

-

S. Coleman, thank you for your comment Nils Michael, thanks for your comment. The 2-componet resin I used is an ordinary liquid Polyester mixed with appr. 3% hardener. It cures in about 15 minutes time and can then be removed from the mould Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

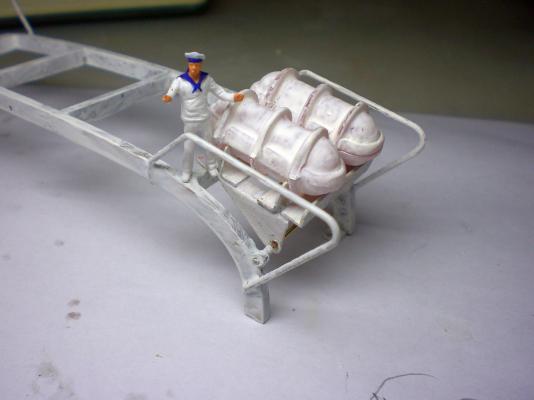

Build log part 28 bottom Planks an sitting benches fit well parts glued together and bulwark rails fitted a Little bit of painting done and rudder fitted the ouitcuts for the oars are done three simular boats completed the captains pinnace is done in wood Fittings attached the figure in the Cockpit is scale 1:87 (a bit too large) nav lights, bulls eyes and windowframes still missing Build log part 29 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

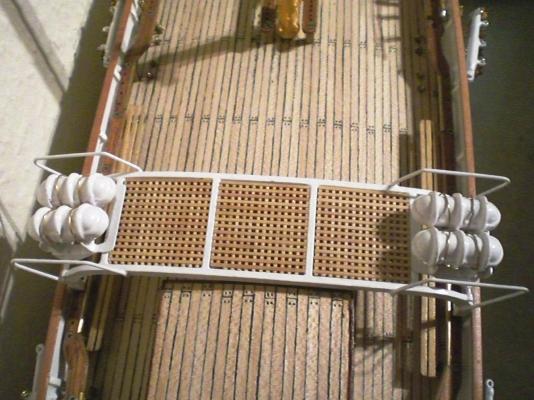

Build log part 27 this wooden form gives the inner space of the boat after removing it gratings for the boatrack aft bumpkins mounted middle bumpkins mounted produce 3 left and 3 right halves from the two moulds the deck inner portions are cut out made sitting Banks from Card templates and stained ply to match the boats interior contours ready for fit check Build log part 28 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

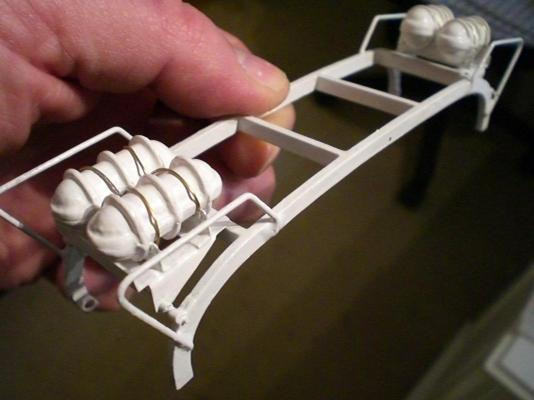

build log part 26 a boats model in Wood is built for making a mould the boatrack with the raft Containments is positioned two half-moulds are made from plaster for easy seperation I use car-wax before filling the Polyester in a inner form has to be placed half into the mould remaining Polyester is given into the clay moulds Build log part 27 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Bob, within tomorrows Picture lot there will be be pics of the making of the boats, but for the capt`s. Launch in scale 1:95 please do not expect a seperate build log. Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Great lesson Buck, thanks for sharing, it is a lovely boat you are presenting to all of us Nils

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Build log part 25 Need 28 halves of this raft Containment, so ist worth doing a mould..... the half of the metal model is pressed into schoolkids clay, this being the mould (s) when making the boats there is always, before it cures off, some Polyester left, so is goes into the moulds (without wasting it) sanding, primering, Fitting of the halves, and preliminary mounting (some cradles to be made first) fastening with brass wire straps fitted on to the raft Container launching flipboards a wooden model is made for the three boats of the Gorch Fock. The making of the boats Pictures shall follow later on Build log part 26 to follow..... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

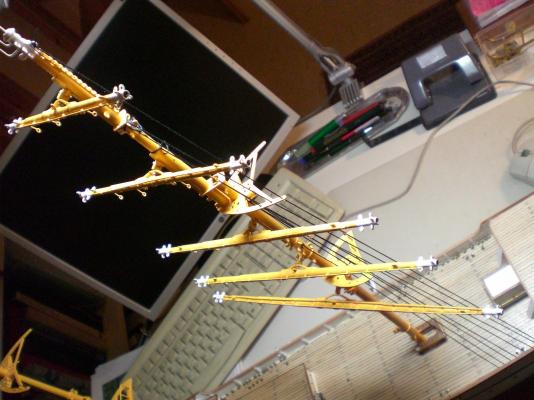

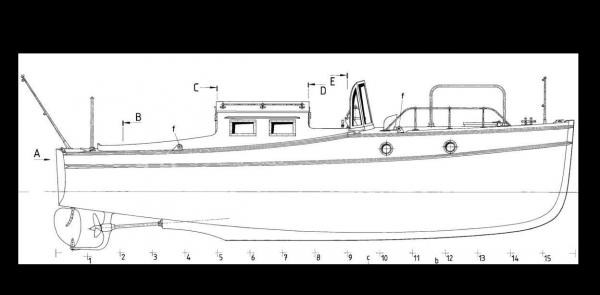

build log part 24 Preparing for the captains Launch (Pinasse 9,2m ) the Yards have to allow bracing to utmost Position before they touch the backstays checking alignment through topgallant platform before the final backstays are set the boats Derrick attached to the mainmast the mizzenmast bears no yards have the most masting parts done... the ventflaps for the scupper openings are attached my master raft Containment template for moulding the semi halves BUild log part 25 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

build log part 23 Here the mizzen mast unpainted.... hooters, Radar station lower platform antenna top antenna Mast top middle gaff boom bearing set of masts, yards Build log part 24 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

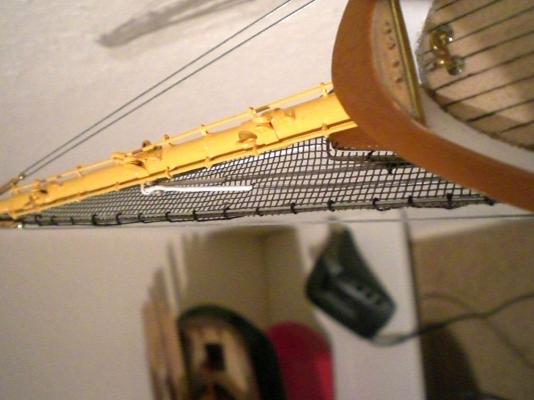

Build log part 22 the pinrails are removable for Access to the eyelets (shrouds and backstays fastening)in between mizzem mast pinrail, the nameplates are aside the poopdeck and at stern bowsprit netting swivible bumpkins for bracing tackle rope guides the tack Position of the Forward mast lower yard Build log part 23 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Spitzenklasse Drazen, I love your work on this great model, a delight to watch her grow... Nils

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Ed and David, Thanks to both of you for your comments Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

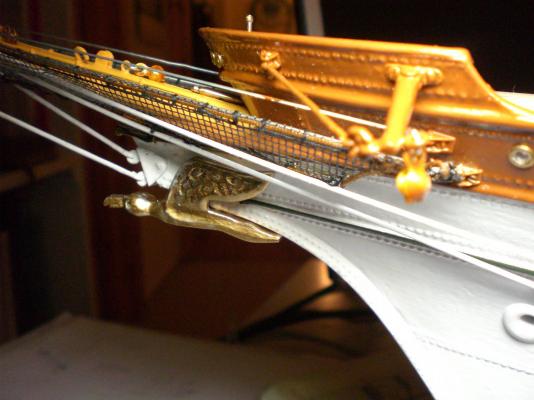

build log part 21 variety of Yards in different completion stages view skywards jib boom rigging done without figurehead Albatros at its place side hull bumpkins for bracing tackle bulwark bolts to be cut and nuts and washers to be painted white Build log part 22 to follow..... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

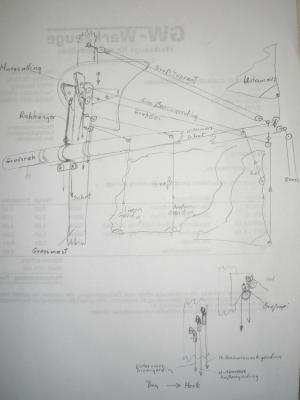

Build log part 20 scetch for Yard / block tackle at mast preparing for soldering jackstays to the lower yard on the next model I would`nt do the footrope (horses) holders this way, They would touch the yard tangentialy from the Yard aft side, and be attached to the second jackstay row checking the Yard swiviling capability the geometry of the yardracks must allow a Close as possible Position of the leeward yardend to the shrouds when full braced startig jib boom tackle and safety netting the solid bobstays are from brass wire the Albatros figurehead is attached removable Build log part 21 to follow... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.