-

Posts

7,409 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Mike, I knew that this is going to be a great model, and I am by no means disappointed from what I see at this sequence already... Very well done !! Nils

- 175 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

- 222 replies

-

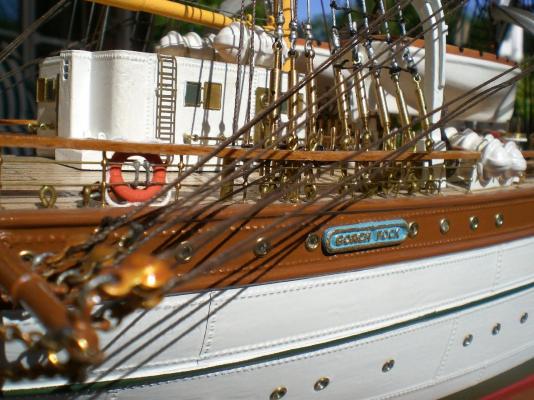

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Hi Nigel, I see you have a nice new member Icon, is that Little pal a Jack russel you have ? I have a 7 year old Fox Terrier. I had so many ideas as to what Details could be added some became realism and some went to the bin, but not being a kit, the mind was free to adopt many Details from all the gathered photos I had saved on my PC. Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Danke Karl, nice comment of yours , I`m glad you like this 3 mast barque Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Bob, the objects next to the depth mark numbers are printed dashes. I was not my aim to to resemble the rivets on These pieces as well. I tried before to print on transperent (thin ! ) blanc decale sheet and to have the hullplate rivets pressed through, but that did`nt stick well, also the very thin sheet was tearing every now and then, driving me crazy and so a compromise had to be made..... no feelable rivets there, but good visible markings instead. Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

great lesson Michael, very nice way of getting anchor tube openings flush to the hull, without just sawing them off at a certain angle, Thank you for sharing Nils

- 2,215 replies

-

thanks David, the Picture flow is now slowly moving on to its end, but still 6 more parts to come Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

HMS Bounty by UdoK

Mirabell61 replied to UdoK's topic in - Build logs for subjects built 1751 - 1800

Hi Udo, I think we are all whitnessing a great scratch-build to plan of the famous HMS Bounty after the keellaying is done. Shall follow your superb construction with high interest Thanks for sharing this log... Nils -

Build log part 46 liferaft Containments on poopdeck additional Name on auxilliary rudder device chest nav light Towers equipped wit lanterns and glass covers the sail operating running rigging is coiled up onto the wooden bits at the yards the functional strapping down device for the boats horn / loudspeaker of the mizzen mast pedestal brackets for the nameplate that go to the glass casing later on Build log part 47 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 45 all ready for making sails captains pinnace with Position lanterns and window frames shrouds and backstay spanners in row drydock view on port bow Fitting out the poopdeck done forecastle deck likewise the three masts bear the badges attached to the platform railing : State Hanburg, fed. Rep. of Germany, state Schleswig-Holstein Tackling for lower gaffboom and wire lead (all around) for lower mizzen sail attached, als capstan for poopdeck each a set of oars for the boats Build log part 46 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 44 Now some Pictures in daylight Illumination for better Quality in Color and sharpness.... one boat inside poop area, the starboard boat cleared for lowering over the side Build log part 45 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

I like that Bob, very nice work indeed ! Nils

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

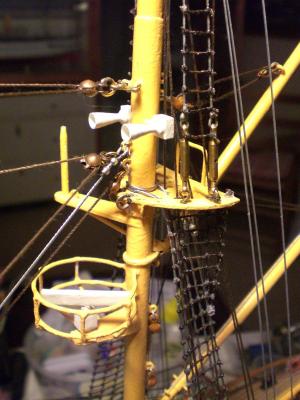

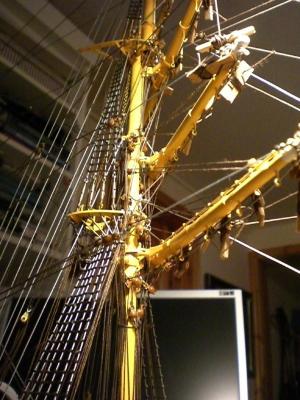

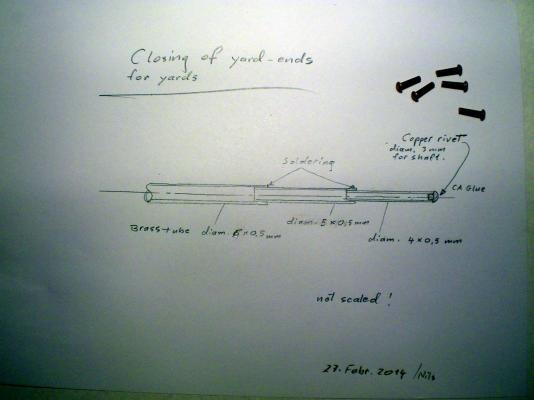

Build log part 43 here the boats are swung to the inside. Shrouds with ratlines at this stage latest the forecastle stairs had to be attached middle hight shrouds the running rigging is also being attached mizzen mast main mast moving towards completion (without sails), White tipped Yard Ends closed Close Yard Ends with semi round rivets THE NEXT 3 SETS OF PICTURES SHALL SHOW THE MODEL IN DAYLIGHT ILLUMINATION PHOTOGRAPHS, BUT STILL WITHOUT THE SAILS Build log part 44 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 41 the shroud wire alignment in relation to the mast belaying Points is pre-checked with ordinary strings after belaying all the running rigging the deck shall look more busy the depth indicator scales are made with my regular Microsoft Excel program on photo print paper portside shrouds and backstays under way, also ratlines in the upper shrouds Build log Part 42 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 40 view on inner port bulwark side with pinrail and shroud- and backstay spanners the yellow boom is just a Yard laying at the wrong place started to rig the bracing ropes the mainmast running bracing ropes are lead over the aft bumpkins starboard foremast backstays Build log part 41 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

Mirabell61 replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

real nice looking ship Tom, also the two boats look very realistic Nils- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

congrats Patrick a proud ship and a proud builder.... well done ! Nils

- 299 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

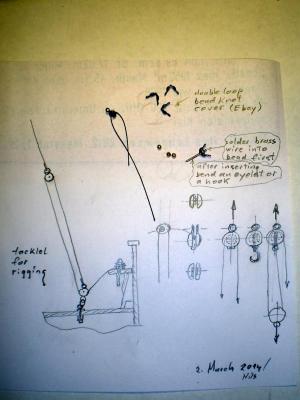

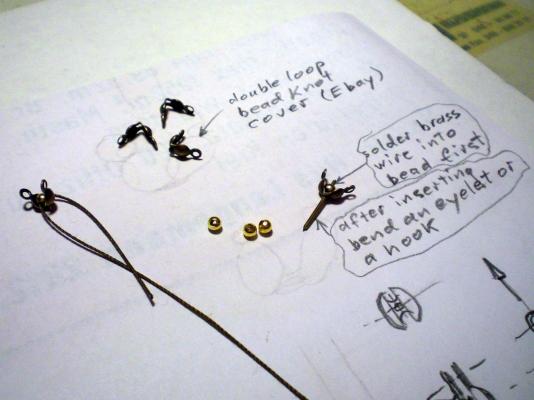

Michael, I was already expecting that question related to the blocks already since the Pamir`s rigging pics had been posted. I once was on search in the web and at Ebay Shops for this type of equipement and finaly found quite a lot of items that with a Little Tuning only would well suit my Needs, an this all at peanuts priceing.... When sighting the articles available at the Ebay sections for Fashion jewelery equipement I discovered Little metal beads of all sorts in diam. and Color. These I use for solderingthe wire chord Ends to the shroud spanners. Criteria is the Little hole through the bead. The beads are very well solderable (clean Ends and sufficiant flux) For the single sheaved blocks I use metal double-Loop capsule type bead knot covers, which are available in different sizes Colors quantities. As rollers I again use metal-beads that resemble rollers also in sizes to suit the bead covers. Shall enclose a scetch for explaination.... I would though not use These for historic wooden shipmodels, here Chuck has the correct ones in his Sortiment. For the mini shackles I use an article from the beadsshop made of brass, nickel galvanized, shall enclose a link cheers Nils http://www.ebay.de/itm/20-Stk-Verbinder-Kettenglied-9mm-nickelfrei-H77-/120407595118?pt=Schmuckgestaltung&hash=item1c08da186e use bead knot cover "blocks" either for hooks, single sheave blocks or blocks with 2 fastening sides

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Nigel, many thanks for sharing that link comprising Jimmy Woods work, you`re right, that is very interesting for me as well, and I`ll take myself more time to study and explore that site more intensively. I love those modelers who build machinery from scratch, modern or historic. I also built a steam river tug with selfmade gas fired Boiler and driven by a self designed and made V-type arrangement 6 cylinder steam engine for RC control. Unfortunately I had a leakage in the Boilers superheater tube coil, and so the model is sitting idle on the shelf for many years already. Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 39 mast top lower top platform here with Counters for upper shroud spanners made several mini shackles for Multi usage Build log part 40 to follow... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Michael, thats a a nice rememberance to your mind. The mainsheet block shall look great when its done Nils

- 2,215 replies

-

Thanks for your nice comment Nigel, I found out that doing models in finer scale than 1:95, max 1:100 is not so well producable for me, too much fiddeling and fagile parts. A Limit of course is the length of an actual ship...., for example I would love to challenge in doing one of those famous 4-stacker Atlantic liners between 1900 and WW1. I have already a beautiful plan for Cunards quadtriple screw "Lusitania" in scale 1:200, that could be magnified, I fell in love with the lines...., but still its a beast in model-length, let alone in scale 1:100, would Need an extra room for that. Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.